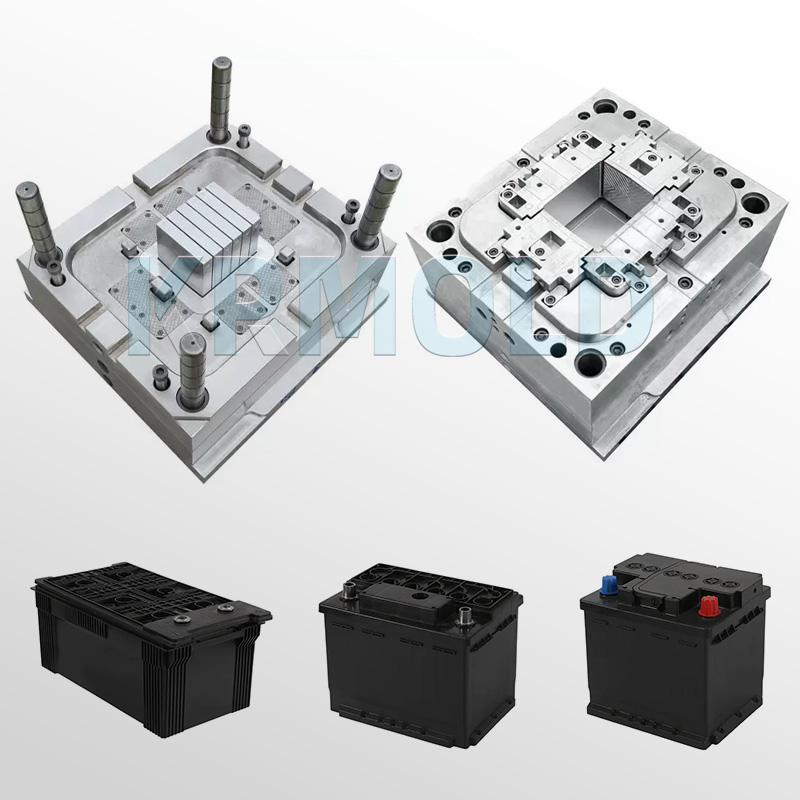

Plastic Battery Case Injection Mould Description

——

Plastic battery case injection mould are a key tool for forming the battery casing, which is then transformed into the actual battery. Battery casings are typically made of highly insulating and high-pressure-resistant polypropylene, ABS, or FR-ABS, using advanced plastic injection molding technology. With the growing demand for batteries across various industries, high-quality battery container injection mould are crucial for a company's competitiveness.

KRMOLD plastic battery case injection mould can be customized to meet specific customer requirements in various specifications and styles. KRMOLD has extensive experience in designing and producing a wide range of battery container injection mould, catering to a wide range of sizes, from small to large. KRMOLD also offers both single-cavity and two-cavity molds to meet diverse customer needs.

Parameters of Plastic Battery Case Injection Mould

——

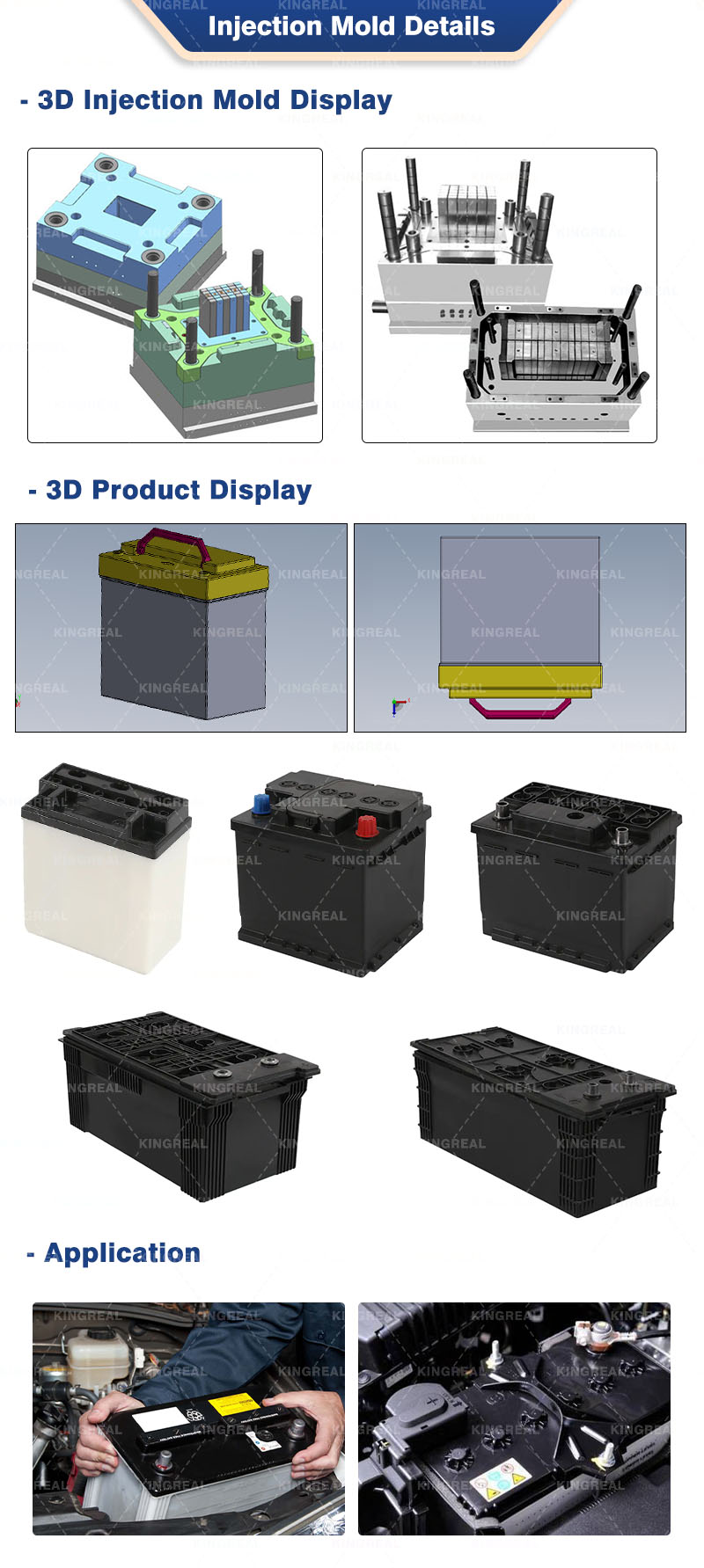

| Mold Name | Battery Container Injection Mould |

| Product Size | 206*175*164mm |

| Product Description | 1L Battery Box |

| Mold Cavity | 1 Cavity |

| Mold Size | 690*640*760mm |

| Suitable Machine | SE-450T |

| Mold Material | H13 |

| Mold Injection System | 7-Point Hot Runner |

| Mold Ejection System | Push Plate |

| Mold Cycle Time | 35S |

| Mold Features | Good Cooling System, Stable Injection Molding. |

| Mold Life | 1 Million |

Advantages of Plastic Battery Case Injection Mold

——

1. Battery container injection mould compliant with national standards

KRMOLD fully considers the standards of the customer's country and region when designing plastic battery case injection mould and makes localized adjustments. This flexibility ensures that KRMOLD battery container injection mould not only meet local regulatory requirements but also effectively reduce KRMOLD customers' compliance risks. KRMOLD manufactures plastic battery case injection mould that meet multiple standards in Japan, Europe, and other regions, including NS40, N40/NS60, N50/NS70, and more. For customers with specific production standards, KRMOLD welcome you to provide relevant drawings and information. KRMOLD will adjust to your needs to ensure accurate and effective battery container injection mould design.

2. Widely applicable plastic battery case injection mould

KRMOLD battery container injection mould are widely used in various industries, particularly the automotive industry, where demand is growing. Whether it's electric cars, e-bikes, or e-scooters, KRMOLD plastic battery case injection mould are a perfect fit for a wide range of vehicles. With the growing global focus on green travel, the popularity of electric vehicles is driving demand for battery cases.

3. High-quality materials for battery container injection mould

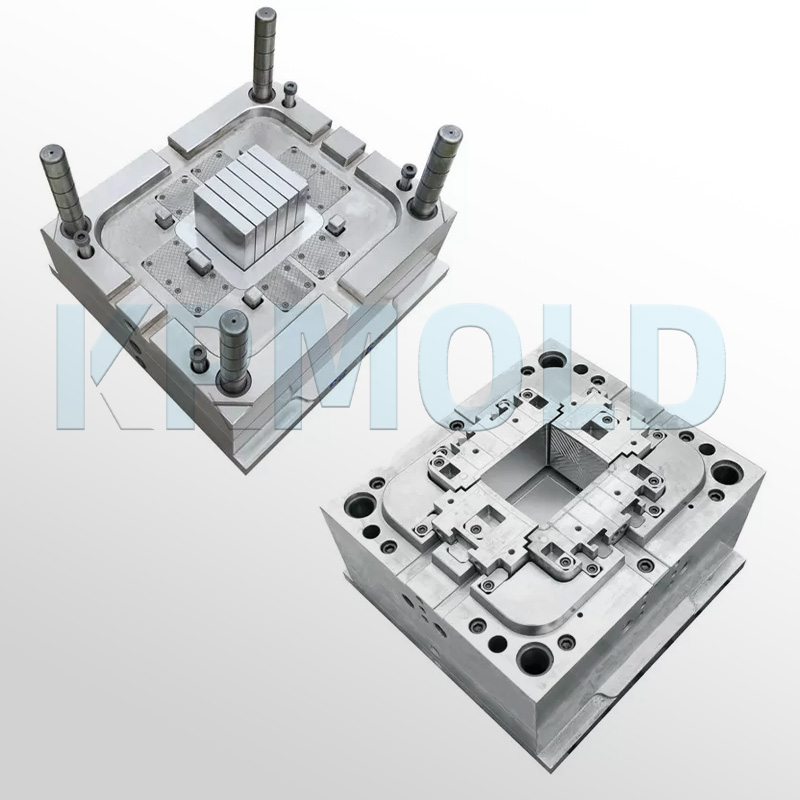

KRMOLD uses plastic battery case materials such as polypropylene (PP) and flame-retardant ABS, which offer excellent insulation and heat stability. These materials effectively resist environmental influences, ensuring battery safety and long-term stability. KRMOLD also maintains strict standards for wall thickness control in plastic battery case injection mould, particularly for core steel materials used for segmented inserts. This design not only enhances Battery container injection mould durability but also ensures overall product quality. KRMOLD employs a comprehensive hot runner design within the plastic battery case injection mould. The strategically positioned hot runner nozzle ensures temperature uniformity during the injection molding process, thus avoiding quality issues caused by temperature variations. This sophisticated design enables KRMOLD battery container injection mould to maintain excellent injection balance during the injection molding process, ensuring the quality of each battery case.

4. Advanced mold flow analysis for battery container injection mould

KRMOLD conducts detailed mold flow analysis to ensure the rationality and effectiveness of the plastic battery case injection mould structure. This analysis allows KRMOLD to identify potential issues and make proactive adjustments to avoid unnecessary production losses. KRMOLD also optimizes the battery container injection mould’ cooling system design. An efficient cooling system can significantly shorten production cycles and improve production efficiency. KRMOLD plastic battery case injection mould design not only focuses on injection molding quality but also considers subsequent production processes to ensure stability and efficiency throughout the entire production chain.

Why Choose KRMOLD for Battery Container Injection Mould?

——

1. Professional Team

KRMOLD specializes in the design and production of plastic battery case injection mould. KRMOLD employ a team of dozens of experienced engineers. These engineers possess extensive academic backgrounds and industry experience in battery container injection mould development, design, and manufacturing, enabling them to quickly respond to market demands and provide optimized solutions.

Whether large-scale projects or small-batch production, KRMOLD provides efficient and stable service to meet our customers' diverse needs.

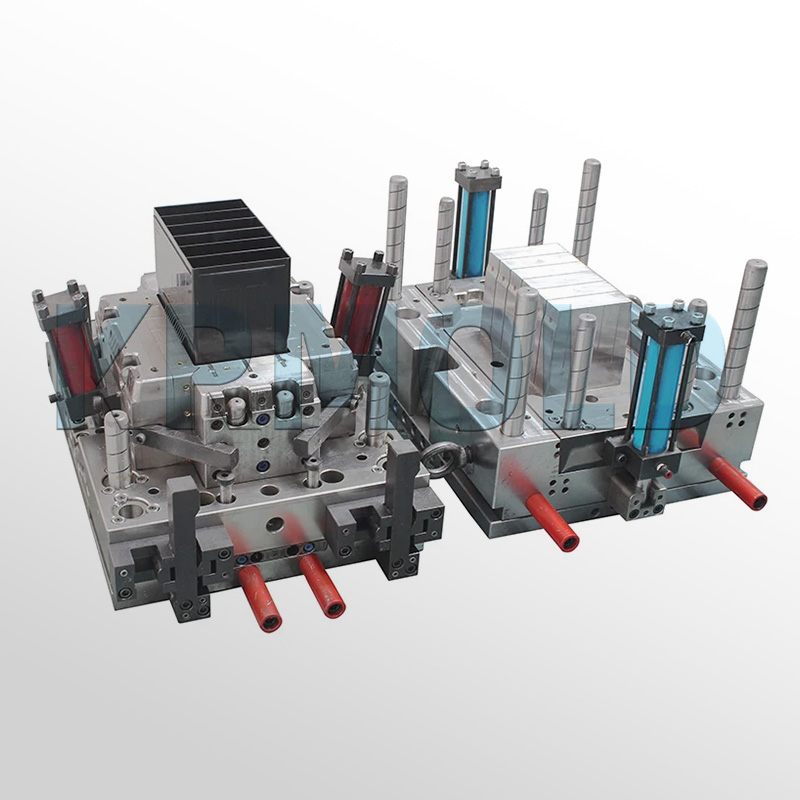

2. Efficient Production Facilities

KRMOLD currently possesses modern production facilities, including prototyping and injection molding workshops, as well as a high-standard quality control laboratory. These facilities enable KRMOLD to operate efficiently across all stages of design, production, and testing. KRMOLD is committed to continuously optimizing its production processes to improve efficiency and reduce costs.

3. Advanced Processing Equipment

KRMOLD is equipped with a range of advanced processing systems and precision equipment, including coordinate measuring machines (CMMs), CNC machine tools, low-speed wire-cut machines, and EDM machines. These devices significantly enhance mold processing accuracy and production efficiency.

By using advanced processing technology, KRMOLD can shorten production cycles while meeting high quality standards.

Process for Making Battery Container Injection Mould

——

-Design: The battery container is designed using CAD software, taking into account factors such as size, shape, and material thickness.

-Material Selection: Plastic materials with excellent chemical resistance and mechanical properties are selected.

-Mold Design: The mold cavity, core, and runners are designed to ensure the battery container injection mould can properly fill and cool the plastic material.

-Mold Manufacturing: The mold is manufactured using methods such as CNC machining, EDM, or casting.

-Injection Molding: The plastic battery case injection mould is installed in the injection molding machine, and plastic pellets are injected into the mold cavity under high pressure.

-Cooling and Ejection: After the plastic solidifies, the battery container injection mould opens and the newly molded battery case is ejected.

-Trimming and Finishing: The ejected battery case is trimmed to ensure it meets standards.

-Quality Control: The battery case is inspected to ensure it meets specifications.

Tips for Purchasing Plastic Battery Case Injection Mould

——

●Learn about battery container injection mould: Gain a thorough understanding of different plastic battery case injection mould types and their applicable applications.

●Research mold suppliers: Select reputable suppliers to ensure product quality.

●Prioritize battery container injection mould quality: High-quality plastic battery case injection mould improve production efficiency and product quality.

●Compare prices: While ensuring quality, compare prices from different suppliers.

●Consider after-sales support: High-quality after-sales service provides assurance for continued use.

Key Plastic Battery Case Injection Mould Technology Points

——

●Analyze the product molding process, plastic battery case injection mould structure, and manufacturing process to ensure a mold life of over 500,000 cycles. Design a complete mold structure and workpieces, and define assembly and injection molding process requirements.

●Avoid defects in the plastic part's appearance and battery container injection mould structure.

●Ensure the plastic battery case injection mould’ exterior is free of rust, impacts, and other defects.

●Ensure rust prevention and protection during battery container injection mould transportation.

●Provide relevant information on consumable parts to ensure plastic battery case injection mould integrity upon delivery.

Specify the type of plastic (e.g. PP, ABS) and post-processing requirements (e.g. spraying, silk-screen printing), and provide 2D or 3D plastic part drawings should be provided. At the same time, provide the production volume, appearance requirements, tolerance standards, etc.

Generally speaking, our engineers will start to prepare the quotation immediately after the customer provides the complete production requirements. Usually it takes about 1-3 days.

The lead time for regular injection molds is usually 30-60 days, and may be longer for complex molds. For example, the typical lead time for liquid silicone molds is around 60 days, covering design, manufacturing, mold testing, etc.

High-precision processing technology: High-precision equipment such as CNC machining centers (CNC) and electric discharge machining (EDM) are used to optimize the design process in combination with CAD/CAM software. Quality control: Inspection of key dimensions of the mold by Coordinate Measuring Machine (CMM) and verification of multiple sample batches during the trial molding stage. Material Selection: Use die steel with high wear resistance (e.g. H13, S136) and surface treatment (e.g. nitriding, chrome plating) for die nuts to extend the life.

After every 50,000 molds, check the guide pillar, ejector pin and other wear parts, and clean up the residual plastic and rust on the mold surface. Use high temperature grease for sliding parts (e.g. tilt top, slider) to reduce friction loss. Ensure that the water circuit is smooth and the temperature difference is ≤5℃ to avoid cracking of the mold due to thermal stress.

Mould cost of materials accounted for about 30-40% (such as 1 ton of P20 steel price of about 20,000 yuan), processing costs accounted for more than 50% (CNC labor hourly rate of about 80-150 yuan / hour). Small batch production can choose aluminum mold or simplify the structural design; more than 100,000 pieces is recommended to use carbide inserts to enhance life!

Mould injection products need to fully meet the design requirements (such as size, appearance), and can be continuous and stable production. Mold marking, inspection reports (such as material hardness test) and engineering drawings should be complete.

Mould steel (such as S136H, NAK80 and other imported materials cost more) and the type of mold embryo (aluminum mold short-term cost is low but short life) directly affect the cost, the use of CAD/CAE/CAM design technology, hot runner system, etc. will increase the upfront investment, but can enhance the long-term benefits (such as reducing the sprues, increase production capacity).