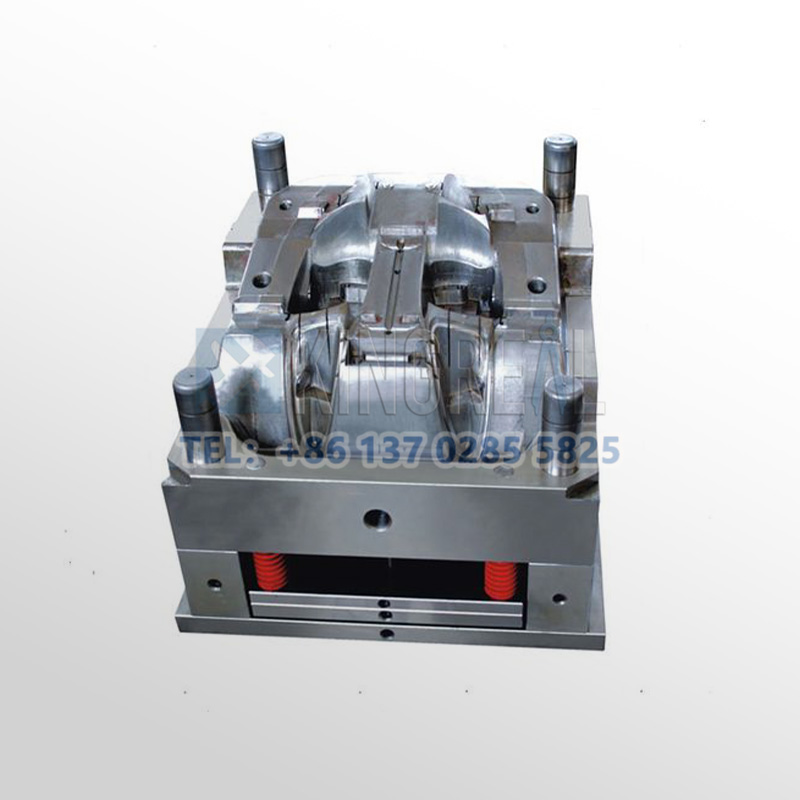

Description of Plastic Car Side Mirror Injection Mould

——

KRMOLD offers a variety of high-precision plastic car side mirror injection mould tailored to meet diverse customer needs, specifically designed for high-volume production of car side mirrors. These plastic car side mirror cover injection mould help to incorporate many functional components, including turn signals, cameras, and heating elements in addition to their great injection molding capabilities.

KRMOLD plastic car side mirror injection mould are designed with streamlined surfaces and aerodynamics in mind, ensuring the plastic car side mirror cover injection moulding process meets modern automotive design standards. These plastic car side mirror injection mould not only finish the fundamental molding of the building but also enable embedded or pre-reserved mounting places for components including turn Elements of heating, cameras, and signals enable integrated design and manufacturing. Additionally, KRMOLD plastic car side mirror cover injection mould can support a range of exterior finishes including electroplating, leather textures, and high gloss to guarantee the finished result strikes the ideal compromise between usefulness and beauty.

Technical Parameters of Plastic Car Side Mirror Injection Mould

——

| Name | Plastic car side mirror cover injection mould |

| Mold Materials | 45#, 50#, 60#, P20 steel. 718, 2083, etc. |

| Mold Life | 500,000 to 1,000,000 cycles |

| Mold Analysis | Detailed mold analysis (including pins, gates, mold base, sliders, etc.) |

| Cavity Type | Single-cavity, Multi-cavity (1*1, 1*2, 1*4, 1+1, 1+1+1, etc.) |

| Mold Runner | Cold runner, hot runner |

| Application Software | Pro/E, UG, Auto-CAD, SolidWorks, CAM |

| Surface Treatment | Logo printing, texturing, polishing, painting, chrome plating |

| Product Materials | Nylon GF, ABS, PP, POM, PC, PE, TPU/TPR, PVC, PPS, HDPE, etc. |

| Processing Trade Type | OEM and ODM |

| Main Processing Equipment | LKM, DME, HASCO |

| Number of Processing Equipment | Over 30 injection molding machines |

| Injection Molding Machines | 80-1600 tons |

Working Process of Plastic Car Side Mirror Injection Mould

——

The melt descends into the mold cavity through the injection molding machine's hot nozzle during the actual injection molding operation. Pressure holding, cooling, and solidification follow the melt to give the component adequate stiffness inside the mold cavity. The injection molding machine's slide then drives the plastic car side mirror cover injection mould' movable mold platen to open the mold from the parting line.

After 100mm of mold opening, the slide, driven by inclined guide pins, separates from the part. The injection molding machine's ejector pushes the push platen, ejecting the part. The plastic car side mirror injection mould is reset by the ejector, return spring, and reset lever after the part is eliminated by the robot. Then, the slide of the injection molding machine closes the movable mold platen so enabling the next injection molding cycle to start.

Features of Plastic Car Side Mirror Injection Mold

——

1. High-performance materials for plastic car side mirror injection mould

KRMOLD plastic car side mirror cover injection mould utilize carefully selected high-performance plastic materials, offering excellent scratch and abrasion resistance. The rearview mirror not only looks beautiful but also successfully fights wear and scratches thanks to its carbon fiber texture, smooth borders, and sophisticated surface treatment. This design not only improves the look of the mirror but also lowers upkeep expenses, therefore avoiding the high repainting charges connected with the unremarkable original mirror.

2. Precision plastic car side mirror injection mould

The car side mirror cover must be designed to perfectly match the vehicle's color and lines, and KRMOLs plastic car side mirror injection mould ensure this. The plastic car side mirror cover injection mould’ structural design also guarantees flawless folding of the mirror, therefore preserving the function of the original vehicle. With a range of styles to fit various customer demands, this item mixes functionality with aesthetics.

3. Durable plastic car side mirror injection mould

KRMOLD plastic car side mirror cover injection mould have a lifespan of 20,000 to 30,000 cycles. Constructed with premium materials and cutting-edge technology, they guarantee long-term strength. This great durability improves output efficiency and lowers mold change frequency.

Plastic Car Side Mirror injection Mould Processing Services

——

KRMOLD not only provides high-quality plastic car side mirror cover injection mould design and manufacturing services, but also integrates the following aspects to ensure that customer needs are fully met:

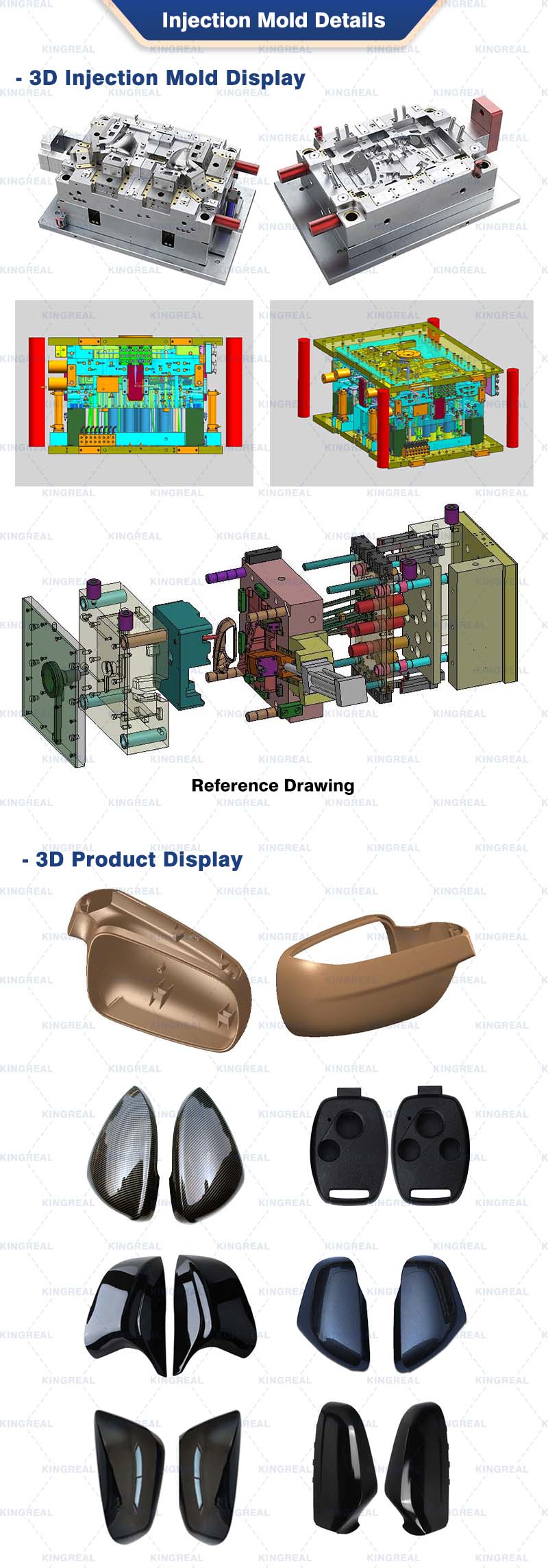

1. Plastic car side mirror injection mould design

Using 3D modeling and CAD drawings, the design team conducts detailed design based on the rearview mirror's dimensions, material properties (such as ABS or ASA), and functional requirements. This ensures a proper demolding direction and minimizes the impact of the flip-chip structure on the plastic car side mirror cover injection mould.

2. Plastic car side mirror injection mould manufacturing

During the plastic car side mirror cover injection mould manufacturing process, commonly used mold steels include NAK800 (high wear resistance) and 2344 (pre-hardened). The hardness of the movable and fixed molds must be differentiated to extend the mold life. Processes such as CNC machining (CNC), electrical discharge machining (EDM), and wire cutting are used to precisely machine complex structures and ensure the precision of each mating area.

3. Plastic car side mirror injection mould testing and calibration

Plastic car side mirror cover injection mould trials verify the mold's dimensional accuracy and the fit of the core puller. Coordinate measuring machines (CMMs) are used to inspect key components. To address potential issues such as warpage and weld marks, cooling system layout adjustments or optimized holding pressure parameters are promptly made to ensure final plastic car side mirror injection mould quality.

4. Plastic car side mirror cover injection mould shipping

Each mold is packed in seaworthy wooden crates prior to delivery to ensure damage during transportation. The specific process is as follows:

Grease the plastic car side mirror injection mould;

Wrap the plastic car side mirror injection mould in plastic film;

Place the plastic car side mirror cover injection mould in the crate.

Molds are typically shipped by sea, but air shipment is available for urgent needs.

Design Features of Plastic Car Side Mirror Injection Mold

——

1. Smooth appearance for plastic car side mirror cover injection mould

A smooth appearance is crucial for automotive parts. No gaps are allowed between all assembled components, so plastic car side mirror injection mould design must strictly control shrinkage.

2. Precise slider processing for plastic car side mirror injection mould

Sliders should be machined using automated machining to ensure precise dimensions. The slider's movement should be stable to avoid flash or scratches.

3. Ejection angle control for plastic car side mirror cover injection mould

To prevent scratching of the texture, the ejection angle should be set greater than 5 degrees to ensure that the plastic car side mirror cover injection mould does not damage the finished product during operation.

4. Runner design for plastic car side mirror injection mould

The structure of the injection molding runner significantly influences the flow of the plastic material, as well as the molding cycle and material consumption. A sound runner design can effectively improve production efficiency.

Specify the type of plastic (e.g. PP, ABS) and post-processing requirements (e.g. spraying, silk-screen printing), and provide 2D or 3D plastic part drawings should be provided. At the same time, provide the production volume, appearance requirements, tolerance standards, etc.

Generally speaking, our engineers will start to prepare the quotation immediately after the customer provides the complete production requirements. Usually it takes about 1-3 days.

The lead time for regular injection molds is usually 30-60 days, and may be longer for complex molds. For example, the typical lead time for liquid silicone molds is around 60 days, covering design, manufacturing, mold testing, etc.

High-precision processing technology: High-precision equipment such as CNC machining centers (CNC) and electric discharge machining (EDM) are used to optimize the design process in combination with CAD/CAM software. Quality control: Inspection of key dimensions of the mold by Coordinate Measuring Machine (CMM) and verification of multiple sample batches during the trial molding stage. Material Selection: Use die steel with high wear resistance (e.g. H13, S136) and surface treatment (e.g. nitriding, chrome plating) for die nuts to extend the life.

After every 50,000 molds, check the guide pillar, ejector pin and other wear parts, and clean up the residual plastic and rust on the mold surface. Use high temperature grease for sliding parts (e.g. tilt top, slider) to reduce friction loss. Ensure that the water circuit is smooth and the temperature difference is ≤5℃ to avoid cracking of the mold due to thermal stress.

Mould cost of materials accounted for about 30-40% (such as 1 ton of P20 steel price of about 20,000 yuan), processing costs accounted for more than 50% (CNC labor hourly rate of about 80-150 yuan / hour). Small batch production can choose aluminum mold or simplify the structural design; more than 100,000 pieces is recommended to use carbide inserts to enhance life!

Mould injection products need to fully meet the design requirements (such as size, appearance), and can be continuous and stable production. Mold marking, inspection reports (such as material hardness test) and engineering drawings should be complete.

Mould steel (such as S136H, NAK80 and other imported materials cost more) and the type of mold embryo (aluminum mold short-term cost is low but short life) directly affect the cost, the use of CAD/CAE/CAM design technology, hot runner system, etc. will increase the upfront investment, but can enhance the long-term benefits (such as reducing the sprues, increase production capacity).