Specification Of Auto Engine Cover Injection Mold

——

| Mold Base | LKM Mould Base...etc |

| Mold Material | P20/718/738/NAK80/S136/H13/H13...etc |

| Mold Runner | Hot Tip/Cold Runner...etc |

| SMC/BMC Mould | heating oil or electric |

| Mold Cavity | Single/Multi Cavity |

| Mold Application | Car Engine Motor Cover Mold |

| Design Software | CAD UG |

| Product Material | ABS/PP/PC/PE/PA/POM/NYLON/TPU/PVC/PMMA/PLA...etc |

About Auto Engine Cover Injection Mold

——

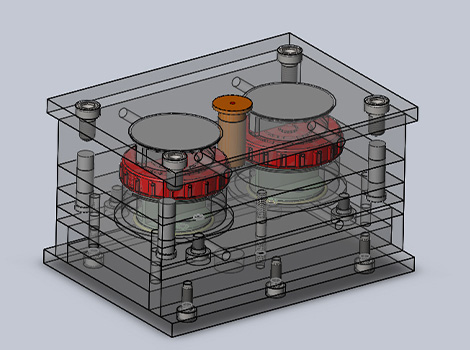

Auto Engine Cover Injection Mold (Auto Engine Cover Injection Mold) is a precision injection molding tool designed for the production of automotive engine covers (Engine Cover), which is used to manufacture lightweight, high-strength and aerodynamic engine cover parts from thermoplastic engineering plastics (e.g., PA+GF, PP-T20, PC/ABS, etc.) through high-pressure injection molding process. The hood is a lightweight, high-strength and aerodynamic part of the automobile.

Automotive hoods are mainly used to cover and protect the core components in the engine compartment (e.g., engine, electric circuit, oil circuit, etc.). The use of carbon fiber raw materials as the production of automotive hood components can improve the lightweight effect, with a strength 5 times higher than steel and 50% lighter in weight. The composite material is molded directly from in-mold injection molding (IMD) to create textured or high-gloss surfaces, reducing the need for painting processes. This for Auto Engine Cover Injection Mold design and production has a high degree of professionalism requirements, KRMOLD Engine Cover Injection Mold made of S136 stainless steel, belongs to the martensitic stainless steel, corrosion resistance, high hardness, deformation resistance, S136 stainless steel service life of up to 500,000 times. The service life of S136 stainless steel can reach 500,000 times or more.

KRMOLD Auto Engine Cover Injection Mold completes the structural molding by reproducing the complex curved shape of the engine cover and assembly interfaces (e.g., clips, heat sinks), and is compatible with a variety of high-temperature (-40℃~150℃), oil-resistant, vibration-resistant special engineering plastics, which helps to produce lightweight automotive engine cover parts.

Manufacturing Process Of Motor Cover Injection Mold

——

KRMOLD uses CAD/CAE software (e.g. UG, Moldflow) to complete the mold structure design according to the functional requirements provided by the customer based on the automotive hood, including the 2D/3D drawings of the product, the material requirements, the production capacity requirements and the production life requirements. Focus on optimizing the parting surface, casting system (e.g. hot runner + needle valve gate) and cooling system (with the shape of the cooling water circuit), to ensure that the melt is filled evenly and the cooling efficiency is high.

Raw material selection for automotive injection molds gives priority to SKD61, H13 and other high-hardness, corrosion-resistant steel, titanium or PVD coating on the surface to extend the life of the mold, compatible with long glass fiber-reinforced PP (PP-LGF30), flame retardant PC/ABS and other materials, need to verify the fluidity (MFI) and heat distortion temperature (HDT ≥ 140 ℃).

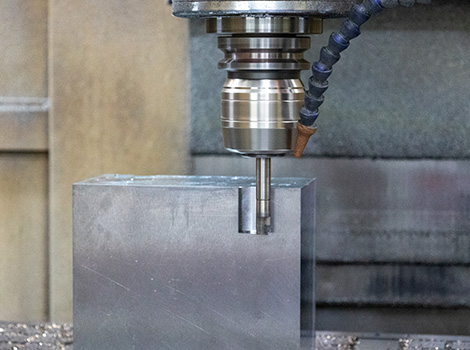

CNC precision machining: using five-axis linkage machining center (Makino) processing injection mold cavity, core, tolerance control in ± 0.02mm.

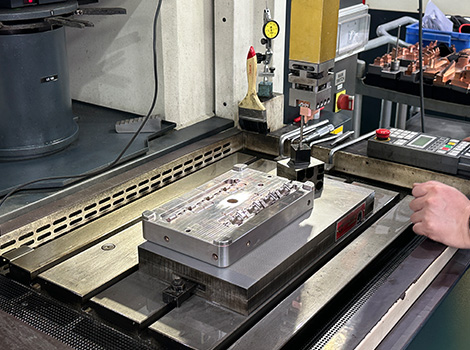

EDM: Using EDGE equipment to process complex curved surfaces and deep groove structures of automobile hood injection molds, with surface roughness Ra≤0.4μm.

Wire cutting machine: slow-feeding wire cutting technology (such as Japan's Shadick equipment) is particularly critical in the injection mold, used to eliminate fusion lines and enhance the surface finish, through the principle of electric spark discharge, precise control of the electrode wire movement trajectory, to complete the cutting of mold cavities, inserts, and other complex contours, the accuracy of which can be up to ± 0.02 mm.

KRMOLD provides every customer with mold trial and modification services, after the production of automotive hood injection molds, assembly and mold trial inspection process in the factory, KRMOLD has its own injection molding machine for mold trial inspection, the injection mold will be installed into the injection molding machine, the injection molded automotive hood for the dimensions, surface quality, and mechanical properties of the inspection.

At the same time, KRMOLD also uses professional equipment such as secondary and tertiary element to check the precision of the injection mold itself, and finally provides the quality inspection report for the customers.

"Grinding and milling machine: Through grinding and milling machine equipment, remove the low hardness surface layer (white layer) and stress concentration area after wire-cutting, reduce the risk of cracks, improve the durability of the mold, complete the rough milling and semi-finish milling of mold cavities and surfaces, and support the one-time molding of complex geometrical shapes."

Final Product Display

——

About KRMOLD

——

KRMOLD focuses on the field of precision mold design and production, with a manufacturing team of 200+ professional technicians, a technical R&D team of 30+ engineers, and a full-cycle service team covering pre-sales consultation to after-sales maintenance, providing full-process services ranging from mold design, precision processing to injection molding.

KRMOLD Mold is equipped with international first-class equipment such as CNC machining centers, Japan Makino precision spark machine, Japan Shadick wire cutting machine, Japan Toshiba injection molding machine and other domestic and international famous brands of production equipment, to achieve ± 0.002mm processing accuracy, to meet the needs of a variety of high-precision plastic injection molds.

FAQ

—

1.How to get a quote for custom injection molds?

Specify the type of plastic (e.g. PP, ABS) and post-processing requirements (e.g. spraying, silk-screen printing), and provide 2D or 3D plastic part drawings should be provided. At the same time, provide the production volume, appearance requirements, tolerance standards, etc.

2. How long does it take to get a quote for an injection mold?

Generally speaking, our engineers will start to prepare the quotation immediately after the customer provides the complete production requirements. Usually it takes about 1-3 days.

3. What is the lead time for injection molds?

The lead time for regular injection molds is usually 30-60 days, and may be longer for complex molds. For example, the typical lead time for liquid silicone molds is around 60 days, covering design, manufacturing, mold testing, etc.

Specify the type of plastic (e.g. PP, ABS) and post-processing requirements (e.g. spraying, silk-screen printing), and provide 2D or 3D plastic part drawings should be provided. At the same time, provide the production volume, appearance requirements, tolerance standards, etc.

Generally speaking, our engineers will start to prepare the quotation immediately after the customer provides the complete production requirements. Usually it takes about 1-3 days.

The lead time for regular injection molds is usually 30-60 days, and may be longer for complex molds. For example, the typical lead time for liquid silicone molds is around 60 days, covering design, manufacturing, mold testing, etc.

High-precision processing technology: High-precision equipment such as CNC machining centers (CNC) and electric discharge machining (EDM) are used to optimize the design process in combination with CAD/CAM software. Quality control: Inspection of key dimensions of the mold by Coordinate Measuring Machine (CMM) and verification of multiple sample batches during the trial molding stage. Material Selection: Use die steel with high wear resistance (e.g. H13, S136) and surface treatment (e.g. nitriding, chrome plating) for die nuts to extend the life.

After every 50,000 molds, check the guide pillar, ejector pin and other wear parts, and clean up the residual plastic and rust on the mold surface. Use high temperature grease for sliding parts (e.g. tilt top, slider) to reduce friction loss. Ensure that the water circuit is smooth and the temperature difference is ≤5℃ to avoid cracking of the mold due to thermal stress.

Mould cost of materials accounted for about 30-40% (such as 1 ton of P20 steel price of about 20,000 yuan), processing costs accounted for more than 50% (CNC labor hourly rate of about 80-150 yuan / hour). Small batch production can choose aluminum mold or simplify the structural design; more than 100,000 pieces is recommended to use carbide inserts to enhance life!

Mould injection products need to fully meet the design requirements (such as size, appearance), and can be continuous and stable production. Mold marking, inspection reports (such as material hardness test) and engineering drawings should be complete.

Mould steel (such as S136H, NAK80 and other imported materials cost more) and the type of mold embryo (aluminum mold short-term cost is low but short life) directly affect the cost, the use of CAD/CAE/CAM design technology, hot runner system, etc. will increase the upfront investment, but can enhance the long-term benefits (such as reducing the sprues, increase production capacity).