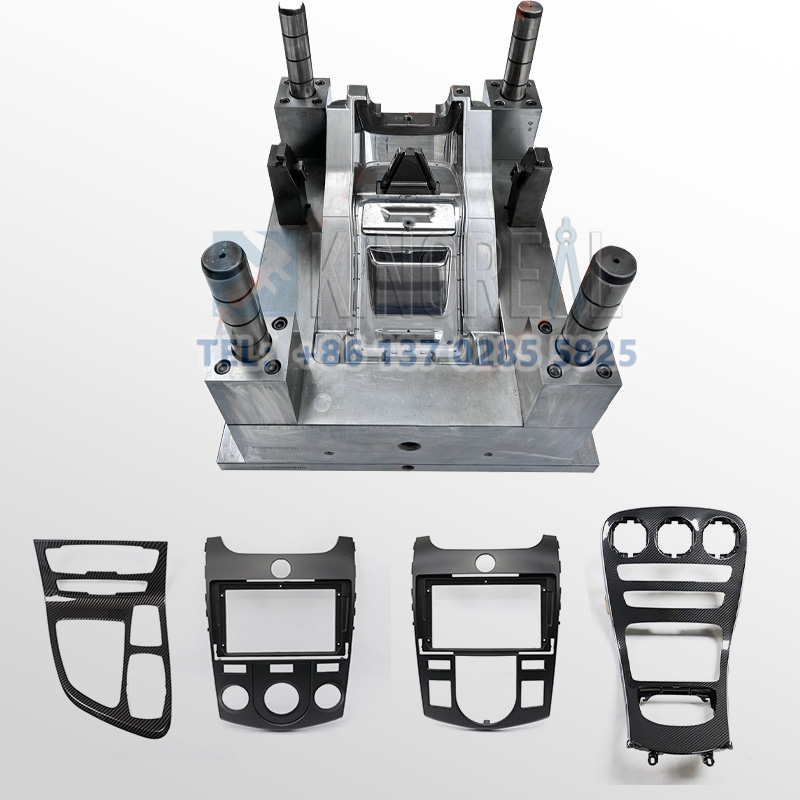

Specification Of Car Center Console Frame Injection Mold

——

| Mould Base | LKM |

| Mold Cavity | Single |

| Mold Material | P20,718,2738,etc. |

| Runner | Hot runner |

| Mold Accessories | Compatible to DME/ HASCO Standard |

| Injection Mold Application | Car Fender Mould |

Description Of Car Center Console Frame Mold

——

The center console mod is one of the types of automotive interior molds. It is a mold system used to manufacture automotive interior decorative parts and is one of the most popular injection molding tools in the automotive industry. It helps major automotive companies complete the mass production of automotive interior plastic parts.

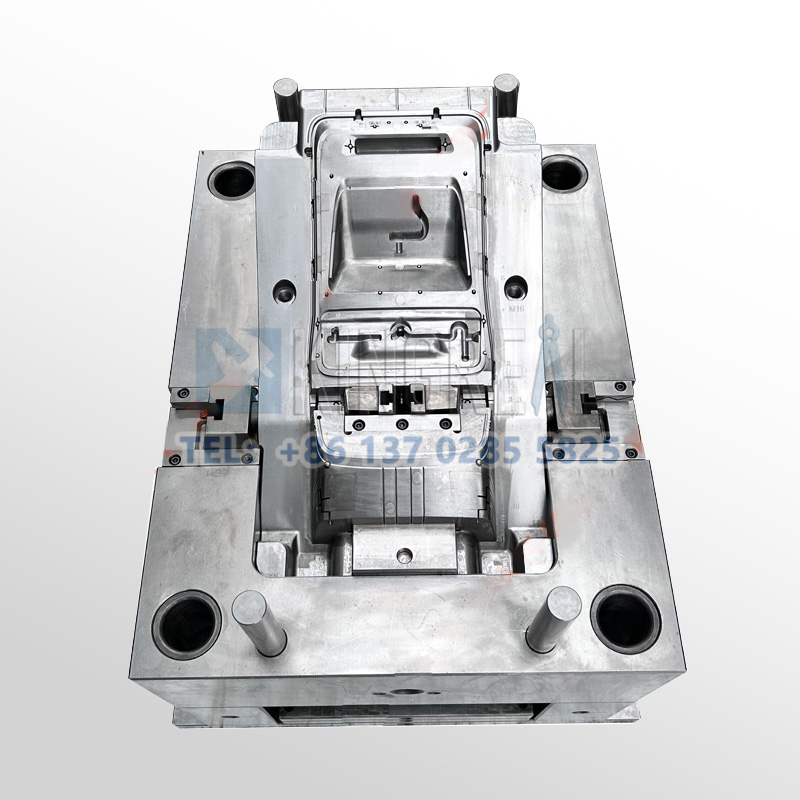

Car Center Console Frame Mold is a special mold system used to manufacture the structure of the car center console. Its core function is to realize the molding, fixing and demoulding of the center console work-piece through the cooperation of the upper and lower molds. The car center console mold frame belongs to the category of injection molds and is mainly used for car center consoles, such as various automotive parts products such as car dashboards, car screen panels and car storage compartments.

When KRMOLD designs injection molds for customers such as car center console mold frames, it needs to pay attention to ensuring the molding accuracy of the complex curved surfaces and functional structures of the center console through the precise cooperation of the upper and lower molds. At the same time, the new mold frame designed for the car fender mould realizes rapid demoulding through components such as limit mechanisms and side pressure plates, and the side pressure plates dynamically clamp the work-piece to reduce the risk of deformation of the work-piece during demoulding.

How To Choose The Raw For Car Fender Injection Mold

——

First, analyze the actual application and demand of the car center console components. When selecting the raw materials for production, it is necessary to meet the requirements of lightweight, weather resistance, impact resistance and surface decoration to ensure the precision molding and long-term stability of the finished car fender parts. Usually, the raw materials of car fender are ABS, PC, ABS alloy, PP (polypropylene), POM (polyoxymethylene). For example, the center console components of Tesla Model 3 will use PC/ABS + magnesium alloy skeleton, which has the characteristics of combining lightweight and high strength.

To meet the production needs of car center console components, the selection of raw materials for car center console injection mold steel is also crucial. It is necessary to consider multiple factors such as the complexity of the actual product produced by the customer, the demand for mold life and production cost. Usually, 718 steel is a common choice for injection mold raw materials, and H13 raw material steel is used in high temperature scenes. Taking Toyota Corolla as an example, the choice of 718 steel for the injection mold steel of the car center console components has low cost and high toughness, which is suitable for mass production.

Design Feature Of Auto Car Fender Mold

——

Our advantage

The center console mold frame adopts a split design of lower mold, upper mold, guide mechanism, etc., which supports rapid assembly and maintenance. It can flexibly adapt to the needs of different models through pre-reset mechanism, mold foot pad and other components, reducing the overall complexity of the mold. It can shorten the mold debugging cycle by more than 30% and improve the compatibility of the production line.

The sliding connection design of the side pressure plate and the linkage rod is adopted to release the workpiece laterally during demoulding. Compared with the traditional bolt-fixed mold, the demoulding efficiency is improved by 40% and the manual intervention is reduced by 50%. The workpiece is dynamically clamped by the side pressure plate, and the shrinkage and deformation of the material are reduced by combining the workbench temperature control system (such as constant temperature oil circuit)

The mold frame needs to reserve electronic buttons to meet the intelligent trends such as voice control and touch screen interaction, and integrate micro ejectors to avoid damage to the circuit board. The mold frame mirror polishing (Ra≤0.01μm) and chrome plating process can avoid flow marks or orange peel patterns on the surface of the injection molded parts, achieve a spray-free appearance, and reduce post-processing costs by more than 20%.

Manufacturing Process Of Car Center Console Frame Mold

——

Our advantage

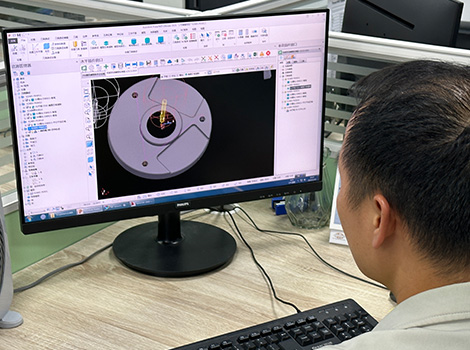

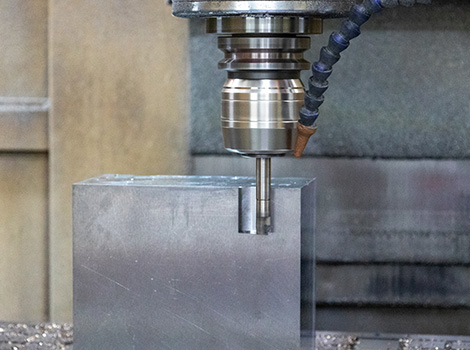

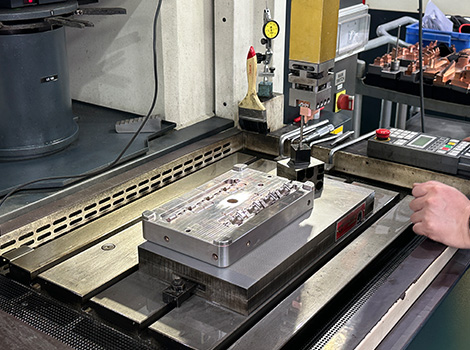

The automobile center control injection mold will be rough-machined with a CNC milling reserve of 0.2-0.5mm (moving model cavity) at the KRMOLD factory, and then the complex curved surface (such as storage compartment undercut) will be machined with an EDM electrode, and the precision machining will be completed with an accuracy of 0.01mm.

Finally, the guide column and bushing of the automobile center control injection mold adopt the H7/g6 matching tolerance, and the matching surface is ground to Ra0.4μm

After completing the machining process, the automobile center control injection mold will be heat-treated with H13 steel after quenching (1020-1050℃) and two temperings (550-600℃), with a hardness of 48-52HRC. Finally, the fixed mold slider will be hard chrome plated (thickness 0.003-0.005mm) to improve wear resistance, and the movable mold inclined top block will be nitrided (depth 0.1-0.2mm) to complete the surface treatment process.

After completing the design and manufacture of the injection mold, KRMOLD will debug and test the mold in the factory, and has a complete quality monitoring system. The actual mold test process in the factory is completed by modular assembly and dynamic balancing debugging of the automobile central control mold, and the mold itself will be tested for cavity size deviation using a three-coordinate measuring instrument.

FAQ

—

1.How to get a quote for custom injection molds?

Specify the type of plastic (e.g. PP, ABS) and post-processing requirements (e.g. spraying, silk-screen printing), and provide 2D or 3D plastic part drawings should be provided. At the same time, provide the production volume, appearance requirements, tolerance standards, etc.

2. How long does it take to get a quote for an injection mold?

Generally speaking, our engineers will start to prepare the quotation immediately after the customer provides the complete production requirements. Usually it takes about 1-3 days.

3. What is the lead time for injection molds?

The lead time for regular injection molds is usually 30-60 days, and may be longer for complex molds. For example, the typical lead time for liquid silicone molds is around 60 days, covering design, manufacturing, mold testing, etc.

Specify the type of plastic (e.g. PP, ABS) and post-processing requirements (e.g. spraying, silk-screen printing), and provide 2D or 3D plastic part drawings should be provided. At the same time, provide the production volume, appearance requirements, tolerance standards, etc.

Generally speaking, our engineers will start to prepare the quotation immediately after the customer provides the complete production requirements. Usually it takes about 1-3 days.

The lead time for regular injection molds is usually 30-60 days, and may be longer for complex molds. For example, the typical lead time for liquid silicone molds is around 60 days, covering design, manufacturing, mold testing, etc.

High-precision processing technology: High-precision equipment such as CNC machining centers (CNC) and electric discharge machining (EDM) are used to optimize the design process in combination with CAD/CAM software. Quality control: Inspection of key dimensions of the mold by Coordinate Measuring Machine (CMM) and verification of multiple sample batches during the trial molding stage. Material Selection: Use die steel with high wear resistance (e.g. H13, S136) and surface treatment (e.g. nitriding, chrome plating) for die nuts to extend the life.

After every 50,000 molds, check the guide pillar, ejector pin and other wear parts, and clean up the residual plastic and rust on the mold surface. Use high temperature grease for sliding parts (e.g. tilt top, slider) to reduce friction loss. Ensure that the water circuit is smooth and the temperature difference is ≤5℃ to avoid cracking of the mold due to thermal stress.

Mould cost of materials accounted for about 30-40% (such as 1 ton of P20 steel price of about 20,000 yuan), processing costs accounted for more than 50% (CNC labor hourly rate of about 80-150 yuan / hour). Small batch production can choose aluminum mold or simplify the structural design; more than 100,000 pieces is recommended to use carbide inserts to enhance life!

Mould injection products need to fully meet the design requirements (such as size, appearance), and can be continuous and stable production. Mold marking, inspection reports (such as material hardness test) and engineering drawings should be complete.

Mould steel (such as S136H, NAK80 and other imported materials cost more) and the type of mold embryo (aluminum mold short-term cost is low but short life) directly affect the cost, the use of CAD/CAE/CAM design technology, hot runner system, etc. will increase the upfront investment, but can enhance the long-term benefits (such as reducing the sprues, increase production capacity).