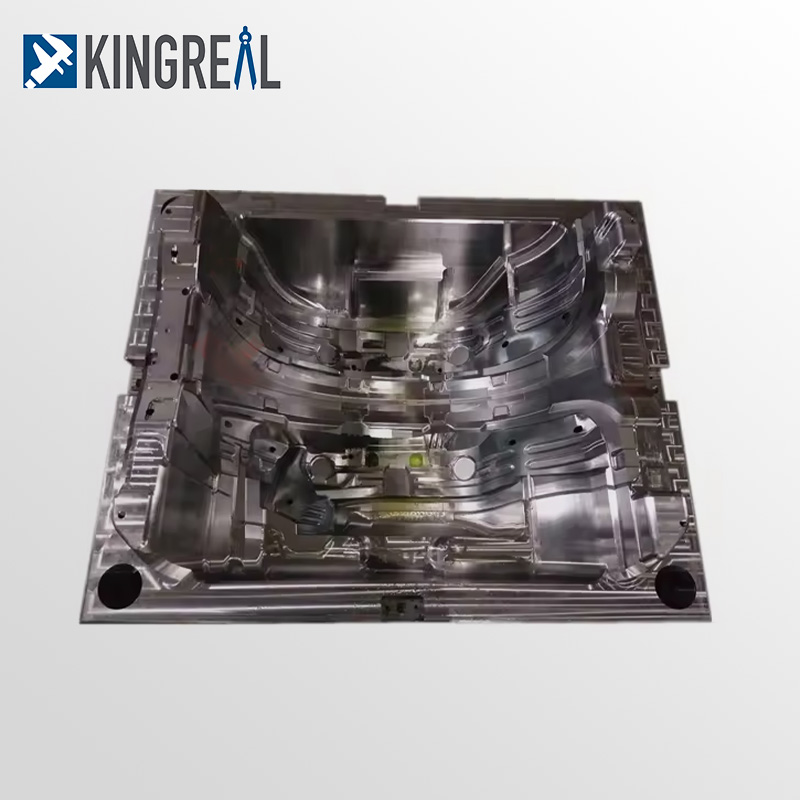

Technical Specification Of Automotive Wheel Arch Liner Mold

——

| Mold Material | P20 |

| Mold Cavity | 1+1 |

| Mold Size | 1580x950x1080mm |

| Mold Weight | 12680T |

| Injection Mold Application | Auto Wheel Arch Liner |

| Product Size | 1100x420x630mm |

| Product Material | PP |

| Main Structure | 2 Sliders On Core Side |

| Surface Of Cavity And Core | Polish |

Description Of Automotive Wheel Arch Liner Mold

——

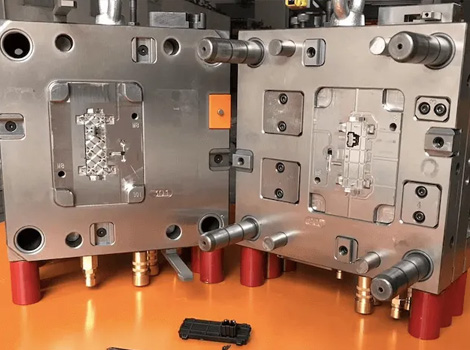

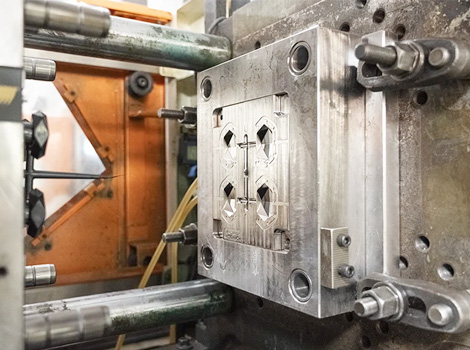

KRMOLD is a professional injection mold manufacturer in China, with professional design and production capacity, the production of injection molds involved in most of the injection molding production processes, including automotive industry injection molds, medical industry injection molds, consumer electronics industry injection molds, home appliances and furniture injection molds, as well as aerospace and marine, KROMOLD will be based on the customer's production requirements for the KROMOLD will carry out the mold modeling design, CNC machining and manufacturing, as well as mold assembly and commissioning process according to the customer's production needs.

In the automotive injection molding industry, KRMOLD has successfully helped more than 20 international famous automobile companies including Ford, Mercedes-Benz, BMW Tesla, Jaguar, Kia and Land Rover to complete the design and production of automotive interior and exterior injection molds. Among them, Automotive Wheel Arch Liner Mold is an indispensable special tool in automobile manufacturing, which is used to produce wheel arch liners to help automobiles avoid mechanical parts corrosion and paint damage.

KRMOLD Automotive Wheel Arch Liner Mold has the precise geometry to fit the curvature of the wheel arch surface and stable material properties to help mass produce complex structures of Automotive Wheel Arch Liner plastic parts. Typically, the Automotive Wheel Arch Liner Mold requires a multi-cavity design to match the large tonnage of the injection molding machine, and ±0.02mm accuracy through 5-axis CNC machining and EDM to ensure that the parting surfaces are perfectly matched to the wheel arch.

How To Choose Raw Material For Car Wheel Arch Liner Mold?

——

Car Wheel Arch Liner Material

Automotive wheel arch liner materials need to take into account the strength and lightweight product requirements, usually choose polypropylene (PP), glass fiber reinforced PP (PP + GF30), polyethylene (PE), PP and microfoam materials to meet the needs of automotive weight reduction, while supporting the use of recycled plastics (30% of the recycled PP), PE low-temperature, PP + GF impact resistance to meet the needs of different climatic and road conditions, TPE The composite structure of TPE and PP can optimize NVH (noise, vibration and harshness) performance.

Car Wheel Arch Liner Mold Raw Material

Car Wheel Arch Liner Mold needs to withstand long-term high-pressure injection molding process, the use of high hardness materials can extend the life to more than 500,000 times, usually the Car Wheel Arch Liner Mold will use molybdenum-chromium cast iron, alloy tool steel and high hardness cast iron, etc., which is used for the core parts of the large-scale wheel arch liner mold cavities, template base and other core parts, as well as the crimping ring, stretching convex molds and other molds that are subject to high pressure, and so on. In general, Car Wheel Arch Liner Molds are made of molybdenum-chromium cast iron, alloy tool steel and high hardness cast iron.

Both final product and the injection mold raw material can be customized according to the customer's production needs.

Injection Molding Production Process Selection

——

Gas Assisted Injection Molding (GAIM)

Automotive Wheel Arch Liner Mold adopts gas assisted injection molding process to inject high pressure gas (10-30MPa) when the melt is 80%-90% filled to form a hollow cavity and reduce the amount of material, the gas channel needs to be distributed along the reinforcing bar or thick wall area to avoid gas penetration through the thin-walled area resulting in broken holes. At the same time, the holding pressure stage of gas assisted injection molding is combined with gas pressure to compensate for shrinkage and reduce surface depression.

Gas assisted injection molding can form a hollow structure, which helps Wheel Arch Moulding to reduce weight and improve flexural rigidity at the same time, which is suitable for SUV and other high-strength demand scenarios.

Auto Car Wheel Arch Liner adopts over-molding injection process, which combines soft TPE and hard PP to improve sealing, vibration damping and fitment. Generally speaking, PP or PP+GF30 provides structural support and shrinkage needs to be compensated by mold design, while TPE or TPU is co-injected to cover the edges or mounting areas to reduce vibration transmission. over-molding Injection enables the injection of hard materials to form a skeleton, and then injects soft materials to cover the critical areas to avoid interfacial delamination, and integrates TPE sealing strips at the edge of the automotive wheel arch liner to improve waterproof and anti-vibration properties. TPE sealing strip to improve water and dust resistance.

FAQ

—

1.How to get a quote for custom injection molds?

Specify the type of plastic (e.g. PP, ABS) and post-processing requirements (e.g. spraying, silk-screen printing), and provide 2D or 3D plastic part drawings should be provided. At the same time, provide the production volume, appearance requirements, tolerance standards, etc.

2. How long does it take to get a quote for an injection mold?

Generally speaking, our engineers will start to prepare the quotation immediately after the customer provides the complete production requirements. Usually it takes about 1-3 days.

3. What is the lead time for injection molds?

The lead time for regular injection molds is usually 30-60 days, and may be longer for complex molds. For example, the typical lead time for liquid silicone molds is around 60 days, covering design, manufacturing, mold testing, etc.

4. How to ensure the dimensional accuracy of the mold and product consistency?

High-precision processing technology: High-precision equipment such as CNC machining centers (CNC) and electric discharge machining (EDM) are used to optimize the design process in combination with CAD/CAM software.

Quality control: Inspection of key dimensions of the mold by Coordinate Measuring Machine (CMM) and verification of multiple sample batches during the trial molding stage.

Material Selection: Use die steel with high wear resistance (e.g. H13, S136) and surface treatment (e.g. nitriding, chrome plating) for die nuts to extend the life.

5. Molds are easy to wear or short life, how to improve?

After every 50,000 molds, check the guide pillar, ejector pin and other wear parts, and clean up the residual plastic and rust on the mold surface. Use high temperature grease for sliding parts (e.g. tilt top, slider) to reduce friction loss. Ensure that the water circuit is smooth and the temperature difference is ≤5℃ to avoid cracking of the mold due to thermal stress.

Specify the type of plastic (e.g. PP, ABS) and post-processing requirements (e.g. spraying, silk-screen printing), and provide 2D or 3D plastic part drawings should be provided. At the same time, provide the production volume, appearance requirements, tolerance standards, etc.

Generally speaking, our engineers will start to prepare the quotation immediately after the customer provides the complete production requirements. Usually it takes about 1-3 days.

The lead time for regular injection molds is usually 30-60 days, and may be longer for complex molds. For example, the typical lead time for liquid silicone molds is around 60 days, covering design, manufacturing, mold testing, etc.

High-precision processing technology: High-precision equipment such as CNC machining centers (CNC) and electric discharge machining (EDM) are used to optimize the design process in combination with CAD/CAM software. Quality control: Inspection of key dimensions of the mold by Coordinate Measuring Machine (CMM) and verification of multiple sample batches during the trial molding stage. Material Selection: Use die steel with high wear resistance (e.g. H13, S136) and surface treatment (e.g. nitriding, chrome plating) for die nuts to extend the life.

After every 50,000 molds, check the guide pillar, ejector pin and other wear parts, and clean up the residual plastic and rust on the mold surface. Use high temperature grease for sliding parts (e.g. tilt top, slider) to reduce friction loss. Ensure that the water circuit is smooth and the temperature difference is ≤5℃ to avoid cracking of the mold due to thermal stress.

Mould cost of materials accounted for about 30-40% (such as 1 ton of P20 steel price of about 20,000 yuan), processing costs accounted for more than 50% (CNC labor hourly rate of about 80-150 yuan / hour). Small batch production can choose aluminum mold or simplify the structural design; more than 100,000 pieces is recommended to use carbide inserts to enhance life!

Mould injection products need to fully meet the design requirements (such as size, appearance), and can be continuous and stable production. Mold marking, inspection reports (such as material hardness test) and engineering drawings should be complete.

Mould steel (such as S136H, NAK80 and other imported materials cost more) and the type of mold embryo (aluminum mold short-term cost is low but short life) directly affect the cost, the use of CAD/CAE/CAM design technology, hot runner system, etc. will increase the upfront investment, but can enhance the long-term benefits (such as reducing the sprues, increase production capacity).