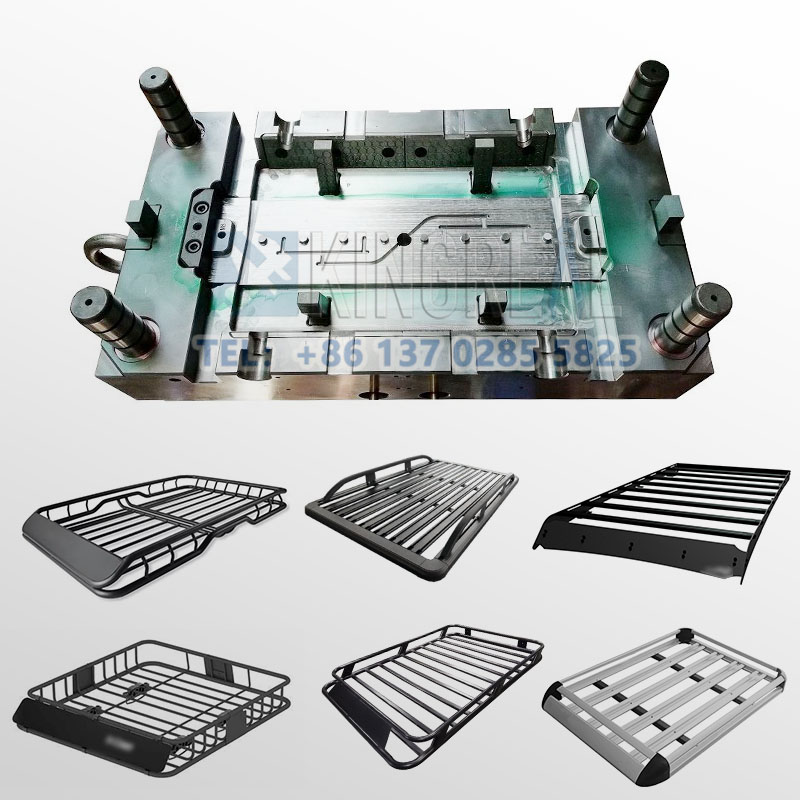

Specification Of Automotive Roof Rack Injection Mold

——

| Injection Mold Name | Automotive Roof Rack Injection Mold |

| Mould Base Standard | Hasco, Dme, Meusburger, Futaba, Lkm, Etc |

| Mould Size | 1630*603*798mm |

| Mold Material | P20 |

| Runner System | Hot runner 3 tip gates |

| Injection Cycle Time | 65 Seconds |

| Grade | P/E-MD20 Impact Mod |

| Grain or Electroplate | fine grain in appearance surface,polish |

| Size Tolerance | +/-0.05mm |

| Fitness | 100% Match |

About Automotive Roof Rack Injection Mold

——

Automotive Roof Rack is a metal or high-strength plastic frame mounted on the roof of a vehicle to extend the vehicle's cargo space.Automotive Roof Rack is designed to be aerodynamically optimized to reduce wind resistance and enhance the vehicle's aesthetics at the same time. In order to meet the needs of the automotive industry, KRMOLD has designed an Automotive Roof Rack Injection Mold for the mass production of automotive roof rack molds.

The Automotive roof rack mold helps to reduce the weight of automotive roof racks by 30-50% (compared to metal) by replicating the complex geometry of the racks and integrating functional components such as locking mechanisms, deflectors, etc., through the use of thin walls (2.0-3.5 mm) and reinforcements. The automotive roof racks are designed with thin walls (2.0-3.5 mm) and reinforcements to help reduce weight by 30-50% (compared to metal) and integrate functional components such as locking mechanisms and deflectors.

Auto Roof Rack Injection Mold Design Points

——

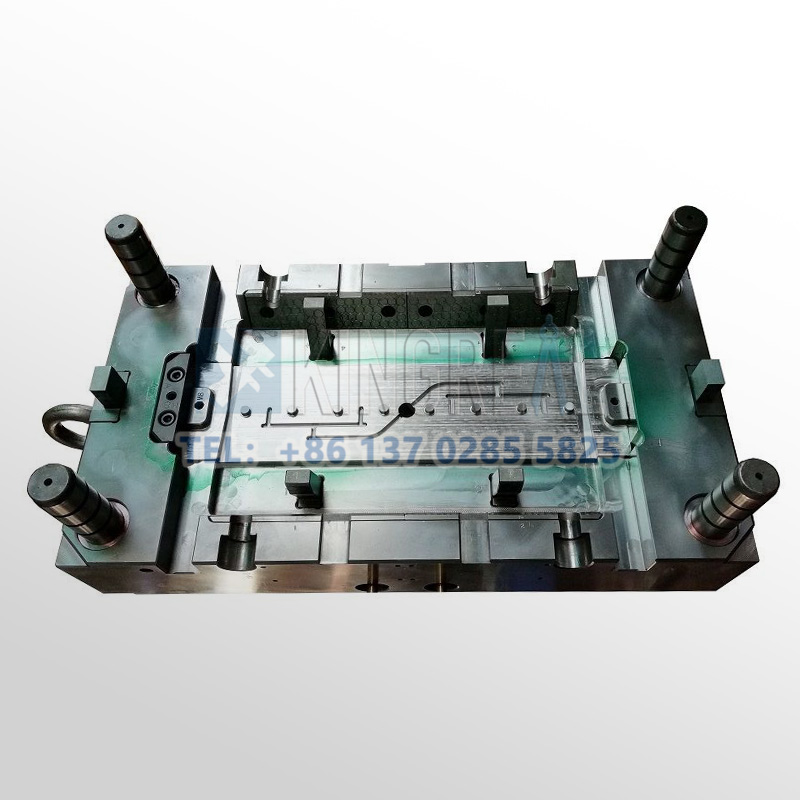

1.Plastic roof rack injection mold is designed with multi-slider and core pulling mechanism for molding the inverted structure of the luggage rack rail (such as slot, mounting holes), the quantity is usually 6-10, the core pulling stroke is 50-120 mm, and the reinforcing rib in the deep cavity is also dealt with for demolding to avoid straining and deformation. The reinforcement in the deep cavity is also processed for demolding to avoid strain and deformation, and the nitrogen spring is used to ensure the stability of ejection.

2. Through phased control of needle valve gates (8-12) to reduce fusion marks and balance the filling pressure of long parts, complete the automotive roof rack mold timing valve hot runner (SVG) design, and hidden in non-appearance surfaces (e.g., the bottom groove), to avoid gate marks affecting the surface quality.

3.3D printing of shaped cooling channels to shorten the cooling time by 30-40% and ensure uniform cooling, Car roof rack injection tooling parting surface with micro-slots (≤0.03 mm) and push rod gap exhaust to prevent short shot or scorching caused by trapped air.

About Double Shot Molding For Auto Roof Rack Mold

——

The application oftwo-color injection molding process in automotive roof rack (Roof Rack) molds enables the combination of functional integration and aesthetic design through one-shot molding.Auto Roof Rack Mold rotates the moving mold by 180°, and the two sets of fixed molds are alternately injected, which makes the production efficiency twice as high as that of the translating type, and it is suitable for mass production. An example of this is the two-color component of the roof rack's clips and deflectors. Hydraulically driven ram translation, suitable for complex structures (e.g. luggage rack reinforcement combined with soft rubber sealing strip), but the molding cycle time is longer.

Typically PA6-GF30 (30% glass fiber reinforced nylon) or PP-LGF40 (40% long glass fiber polypropylene) are used for the Auto Roof Rack Mold base material to provide high strength and weather resistance, and TPE or TPU (Shore A 50-80 hardness) for anti-slip touch or sealing function as Plastic roof rack injection mold cover material, the Auto Roof Rack two-color injection molding process features material compatibility control and complex mold co-release designs.

Application Of Auto Roof Rack Mold

——

Why Choose KRMOLD?

——

1.One-stop full-process service

We provide full-process service from integrating requirements, mold design and manufacturing to delivery and after-sales service.

The technical team is deeply involved in the customer's product design stage, optimizing the mold structure and designing the mold drawings through the mold flow analysis software (such as Autodesk Moldflow, UGNX). Equipped with imported CNC, Shadick wire cutting machine, mirror discharge equipment and other precision processing equipment to achieve ±0.02mm precision;

We have a large-scale intelligent workshop to support secondary processing such as silk-screen printing, welding, spraying, etc. We strictly implement the quality system of ISO13485 and IATF16949; meanwhile, we provide free transportation, regular mold maintenance and one-year warranty service.

2.Complete quality control system

There is a full chain production workshop, using Makino five-axis machining centers, Haitian injection molding machines and other well-known equipment at home and abroad to avoid delays in outgoing processing. Through the CMM coordinate measuring machine, three-dimensional inspection instrument full inspection of key dimensions, the implementation of PDCA cycle quality management. Meanwhile, we provide complete quality inspection report of injection molds.

3.Accurate delivery control to guarantee the project schedule

Through digital management, production progress monitoring from the beginning of the order, for different orders and delivery date for data monitoring, once there are factors that may be delayed, immediately arrange to speed up the production schedule, to ensure that the customer in the delivery period to complete the manufacturing of plastic injection molds.

Specify the type of plastic (e.g. PP, ABS) and post-processing requirements (e.g. spraying, silk-screen printing), and provide 2D or 3D plastic part drawings should be provided. At the same time, provide the production volume, appearance requirements, tolerance standards, etc.

Generally speaking, our engineers will start to prepare the quotation immediately after the customer provides the complete production requirements. Usually it takes about 1-3 days.

The lead time for regular injection molds is usually 30-60 days, and may be longer for complex molds. For example, the typical lead time for liquid silicone molds is around 60 days, covering design, manufacturing, mold testing, etc.

High-precision processing technology: High-precision equipment such as CNC machining centers (CNC) and electric discharge machining (EDM) are used to optimize the design process in combination with CAD/CAM software. Quality control: Inspection of key dimensions of the mold by Coordinate Measuring Machine (CMM) and verification of multiple sample batches during the trial molding stage. Material Selection: Use die steel with high wear resistance (e.g. H13, S136) and surface treatment (e.g. nitriding, chrome plating) for die nuts to extend the life.

After every 50,000 molds, check the guide pillar, ejector pin and other wear parts, and clean up the residual plastic and rust on the mold surface. Use high temperature grease for sliding parts (e.g. tilt top, slider) to reduce friction loss. Ensure that the water circuit is smooth and the temperature difference is ≤5℃ to avoid cracking of the mold due to thermal stress.

Mould cost of materials accounted for about 30-40% (such as 1 ton of P20 steel price of about 20,000 yuan), processing costs accounted for more than 50% (CNC labor hourly rate of about 80-150 yuan / hour). Small batch production can choose aluminum mold or simplify the structural design; more than 100,000 pieces is recommended to use carbide inserts to enhance life!

Mould injection products need to fully meet the design requirements (such as size, appearance), and can be continuous and stable production. Mold marking, inspection reports (such as material hardness test) and engineering drawings should be complete.

Mould steel (such as S136H, NAK80 and other imported materials cost more) and the type of mold embryo (aluminum mold short-term cost is low but short life) directly affect the cost, the use of CAD/CAE/CAM design technology, hot runner system, etc. will increase the upfront investment, but can enhance the long-term benefits (such as reducing the sprues, increase production capacity).