Video About Automotive Parts Injection Mold

——

Introduction to Automotive Parts Injection Mold

——

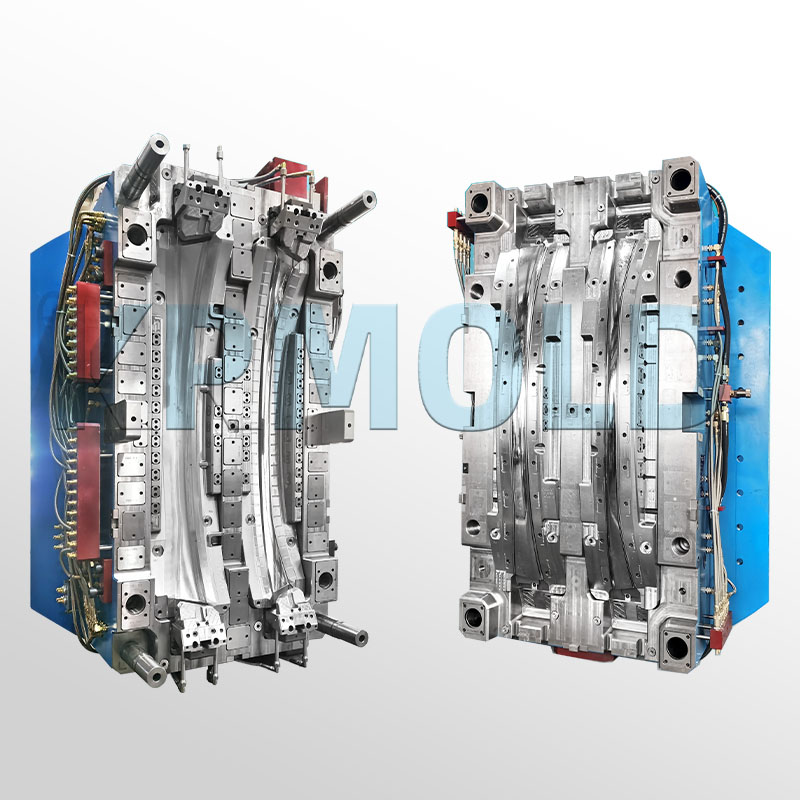

KRMOLD automotive parts injection molds efficiently produce a variety of parts used in automotive manufacturing. These parts include interior instrument panels, side panels, SUV side panels, interior door panels, roofs, front and rear bumpers, and tailgate panels, ultimately forming a complete automotive system. Bringing great ease to consumers in the vehicle sector, KRMOLD car parts injection molds produce plastic items appropriate for vehicles of different sizes and types.

KRMOLD strives to generate value for customers, hence boosting their market competitiveness, in addition to supplying premium automotive components injection molds.KRMOLD is not only committed to providing high-quality automotive parts injection molds, but also to creating value for customers, thereby enhancing their market competitiveness. KRMOLD adhere to high standards and precision in the design and production of car parts injection molds.

Advantages of KRMOLD Car Parts Injection Mold

——

1. Fast production speed for car parts injection mold KRMOLD automotive parts injection molds are renowned for their fast and efficient production capabilities. Utilizing advanced production processes and technologies, KRMOLD car parts injection molds are capable of producing highly consistent plastic products in a short time. By using KRMOLD automotive parts injection molds, customers can not only effectively improve productivity but also significantly reduce production costs.

2. High-quality car parts injection mold High-quality requirements for automotive parts injection molds kept by KRMOLD assure producers achieve outstanding results by maintaining these standards. Precision car parts injection molds create uniformly thick components, thereby removing structural flaws that could otherwise cause later issues. Strict tolerance control also guarantees that components satisfy or go beyond industry standards. This premium guarantee offers repeatable performance for every component, therefore delivering the reliability manufacturers need. |  |

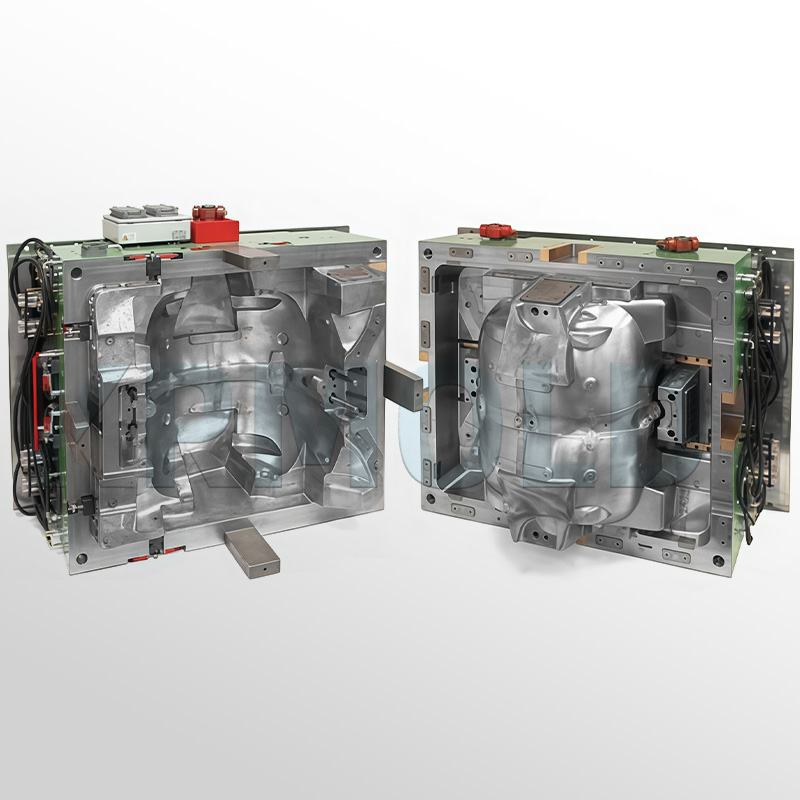

3. Durability for automotive parts injection mold During the injection molding process, KRMOLD engineers thoroughly assess the lifespan of the materials employed in the car parts injection molds. As a result, they create automotive parts injection molds suitable for high-strength polymers like ABS and polypropylene meant to endure extreme situations like those in automotive uses. Strong, resistant to changing temperatures and environmental changes, fracture-resistant, and long service life plastic parts made with KRMOLD automotive parts injection molds are produced.

4. Design flexibility for car parts injection mold KRMOLD prioritizes individual customer needs. Customized automotive parts injection mold designs based on customer drawings can be offered by KRMOLD to guarantee that the produced parts match the specific size and form needed for production. This adaptability guarantees the manufacture of pieces suited for particular uses as well as gives consumers more creative freedom.

5. Versatility for car parts injection mold KRMOLD automotive parts injection molds offer exceptional versatility. KRMOLD car parts injection molds can produce a wide range of automotive parts, including exterior components like grilles, bumper covers, and wheels, while also meeting the demands of interior design systems. Whether for interior or exterior components, KRMOLD automotive parts injection molds efficiently and precisely produce parts that meet customer needs. |  |

KRMOLD New Technologies in Car Parts Injection Mold Manufacturing

——

As the automotive industry's demand for automotive parts injection molds continues to increase, KRMOLD continues to research and introduce advanced technologies to enhance the added value of car parts injection molds, enabling them to better meet customer needs in production.

1. Sequential valve hot runner control technology

Sequential Valve Hot Runner Control Technology (SVG) is an innovative KRMOLD technology. By using hydraulic cylinders to control sequential injection, this technology effectively eliminates the cosmetic defects caused by traditional multi-point simultaneous injection molding, preventing defects such as weld marks and air pockets on automotive interior and exterior trim parts. SVG technology not only reduces flow length and molding pressure but also plays a significant role in the production of automotive interior and exterior trim parts, where appearance requirements are stringent, ensuring product aesthetics and quality.

2. Low-pressure double-layer automotive parts injection mold technology

Low-pressure double-layer car parts injection mold technology is a novel injection molding process that enables parts that would traditionally be hand-wrapped to be molded directly in the automotive parts injection mold in a single step. This technology uses low-pressure injection to allow the plastic to flow over the fabric. When the car parts injection mold is opened, the fabric is attached to the front mold pins. After the automotive parts injection mold is closed, injection molding is completed, resulting in a product with a special soft fabric surface when the part is removed. Products produced using this technology significantly improve decorative properties, feel, and aesthetics. They are widely used in parts such as map pocket frames and ABC pillars in mid- to high-end vehicles.

3. Internal parting surface technology for car parts injection mold

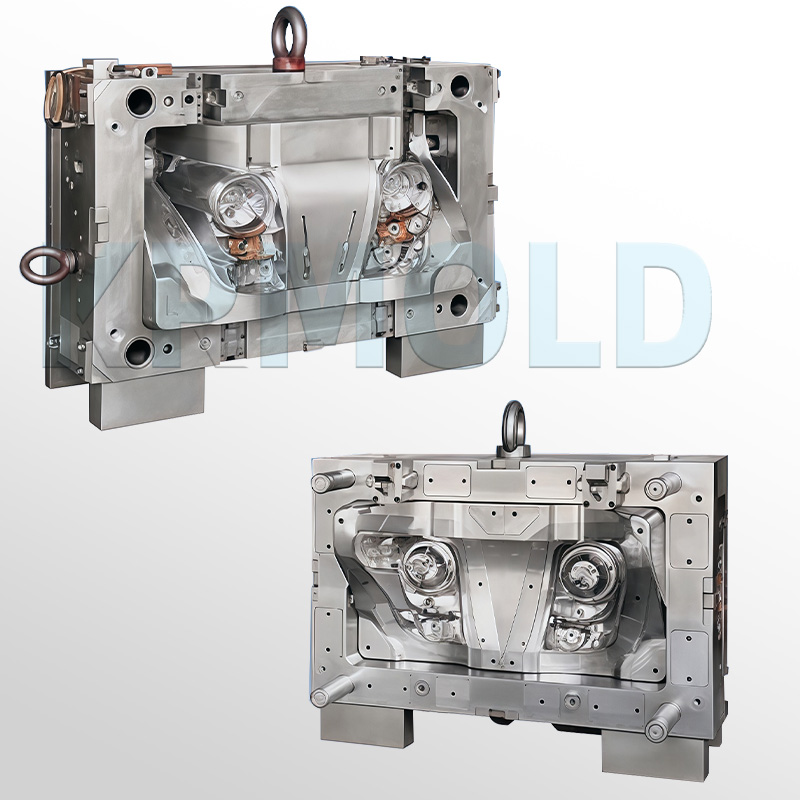

KRMOLD utilizes advanced internal parting surface technology in the design of automotive parts injection molds. This technology has the benefit whereby the parting line is concealed on the non-exterior surface of the bumper, hence not changing the appearance of the item after assembly. In addition to improving the visual appeal of the product, this design increases the general structural stability of the car parts injection mold, hence guaranteeing that the created components have excellent performance and appearance.

Car Parts Injection Mold for Materials and Applications

——

KRMOLD automotive parts injection molds utilize a variety of high-performance materials to meet the needs of diverse parts.

-ABS: Due to its high strength and durability, it is commonly used in dashboards, panels, and exterior body parts.

-Polypropylene: Widely recognized for its superior fatigue resistance, it is ideal for interior trim, battery housings, and bumpers.

-Polycarbonate: Due to its transparency and impact resistance, it is commonly used in headlamp lenses and door handles.

-Polyamide (nylon): Widely recognized for its heat resistance and strength, it is often used in engine hoods and gears.

-Thermoplastic polyurethane (TPU): Widely recognized for its elasticity, it is often used in flexible components such as tubing and seals.

Through the appropriate selection and application of materials, KRMOLD automotive parts injection molds are able to produce high-quality, high-performance automotive parts to meet customers' diverse usage requirements.

Specify the type of plastic (e.g. PP, ABS) and post-processing requirements (e.g. spraying, silk-screen printing), and provide 2D or 3D plastic part drawings should be provided. At the same time, provide the production volume, appearance requirements, tolerance standards, etc.

Generally speaking, our engineers will start to prepare the quotation immediately after the customer provides the complete production requirements. Usually it takes about 1-3 days.

The lead time for regular injection molds is usually 30-60 days, and may be longer for complex molds. For example, the typical lead time for liquid silicone molds is around 60 days, covering design, manufacturing, mold testing, etc.

High-precision processing technology: High-precision equipment such as CNC machining centers (CNC) and electric discharge machining (EDM) are used to optimize the design process in combination with CAD/CAM software. Quality control: Inspection of key dimensions of the mold by Coordinate Measuring Machine (CMM) and verification of multiple sample batches during the trial molding stage. Material Selection: Use die steel with high wear resistance (e.g. H13, S136) and surface treatment (e.g. nitriding, chrome plating) for die nuts to extend the life.

After every 50,000 molds, check the guide pillar, ejector pin and other wear parts, and clean up the residual plastic and rust on the mold surface. Use high temperature grease for sliding parts (e.g. tilt top, slider) to reduce friction loss. Ensure that the water circuit is smooth and the temperature difference is ≤5℃ to avoid cracking of the mold due to thermal stress.

Mould cost of materials accounted for about 30-40% (such as 1 ton of P20 steel price of about 20,000 yuan), processing costs accounted for more than 50% (CNC labor hourly rate of about 80-150 yuan / hour). Small batch production can choose aluminum mold or simplify the structural design; more than 100,000 pieces is recommended to use carbide inserts to enhance life!

Mould injection products need to fully meet the design requirements (such as size, appearance), and can be continuous and stable production. Mold marking, inspection reports (such as material hardness test) and engineering drawings should be complete.

Mould steel (such as S136H, NAK80 and other imported materials cost more) and the type of mold embryo (aluminum mold short-term cost is low but short life) directly affect the cost, the use of CAD/CAE/CAM design technology, hot runner system, etc. will increase the upfront investment, but can enhance the long-term benefits (such as reducing the sprues, increase production capacity).