What Is Automotive Dashboard Injection Mold?

——

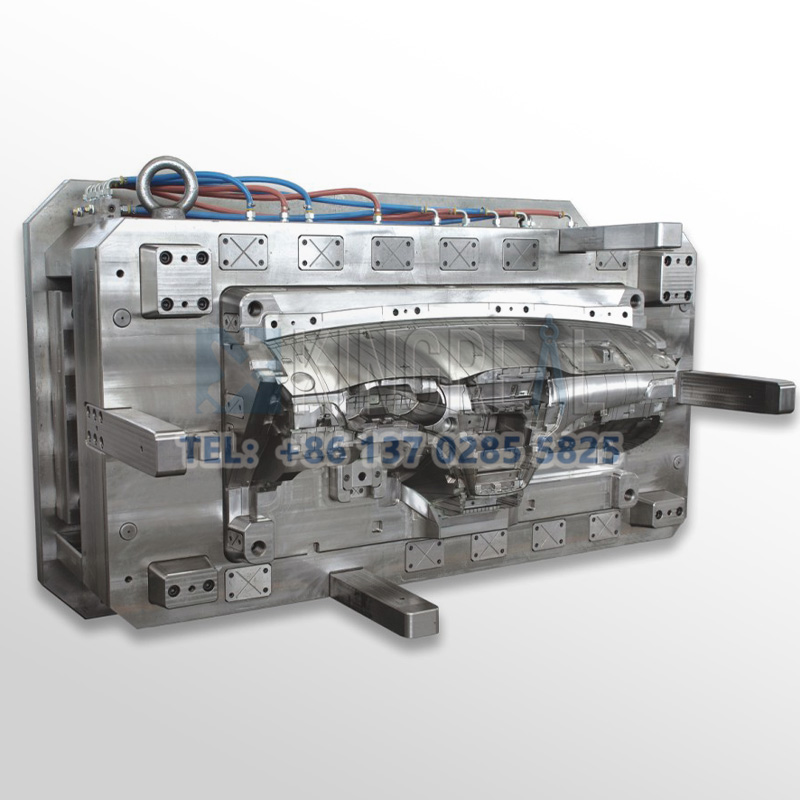

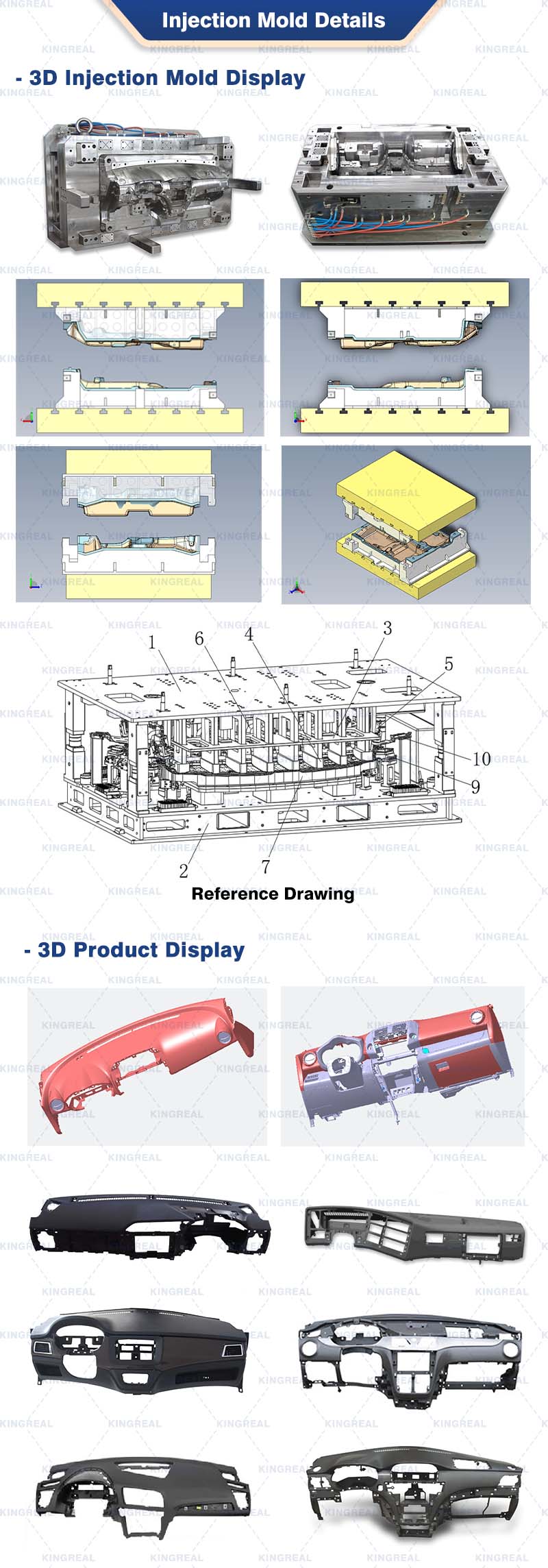

KRMOLD Automotive Dashboard Injection Mold is designed for the production of automotive dashboard products, injection mold, the molten plastic material (such as ABS, polypropylene, etc.) into the mold cavity, after cooling and curing to form the dashboard components to meet the design requirements.

Automotive Dashboard Injection Mold is designed to help manufacturers produce complex, high-tolerance automotive dashboard components in high volume, ensuring consistency and quality during the mass production process. It is especially suitable for automotive interiors, which are not only sleek and stylish, but also durable and easy to maintain.

In the automotive manufacturing industry, injection molds are the key injection tools for achieving mass production of instrument panels. For example, the body of the instrument panel, decorative panels, storage compartments and other components are all manufactured by such molds. As automobiles require high levels of safety and aesthetics, the molds need to ensure that the products are free of shrink marks and burrs and are dimensionally stable.

At the same time, automotive instrument panels often contain curved surfaces, button holes, vents and other delicate structures, so the molds need to be designed with a high degree of precision.

Injection Mold Specification

——

Injection Mold Type | Automotive Injection Mold |

Mold Steel Typ | P20 |

Mould Base | S50c |

Mold Cavity | 1 Cavity |

Injection Mold Size | 2710x1890x1700mm |

Injection Mold Weight | 34.5T |

Mold Surface Treatment | Polish. Etched. Texture, Etc |

Plastic Product Wall Thickness | 2.5mm |

Mold Shrinkag | 0.42% |

Molding Tolerance | ±0.02MM |

Mould processing material | PP/ABS/PC+ABS multi-material molds |

Mold Lif | 500,000+ times life. |

Injection Mold Communication

——

1. Core

2. Cavity

3. Sliders

4. Ejector Pins

5. Cooling Channel

6. Mold Materials: P20、H13

Automotive Injection Mold Design And Manufacturing

——

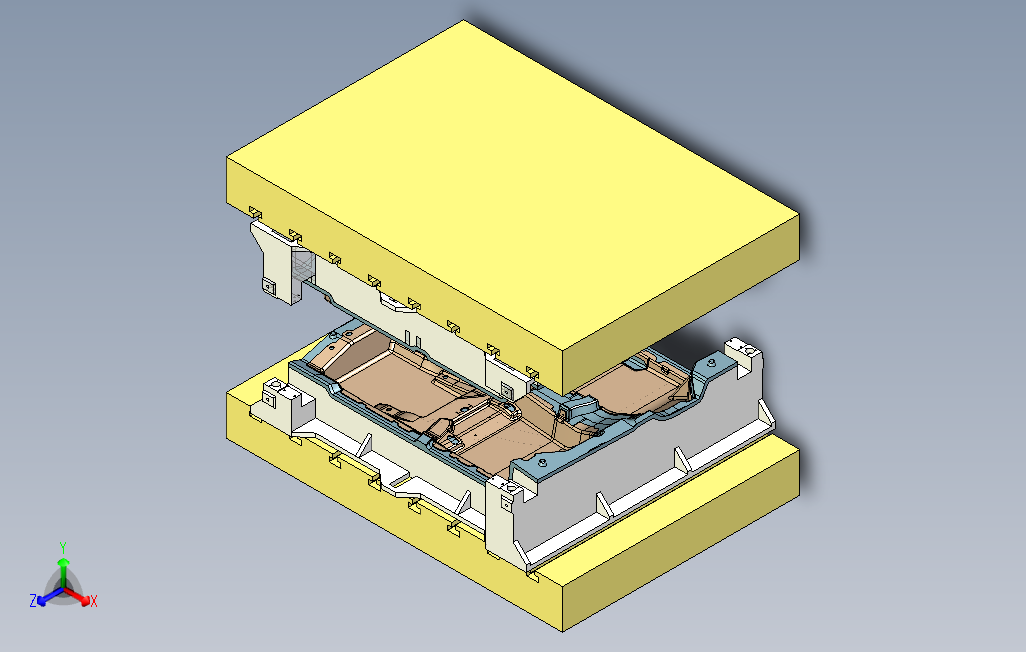

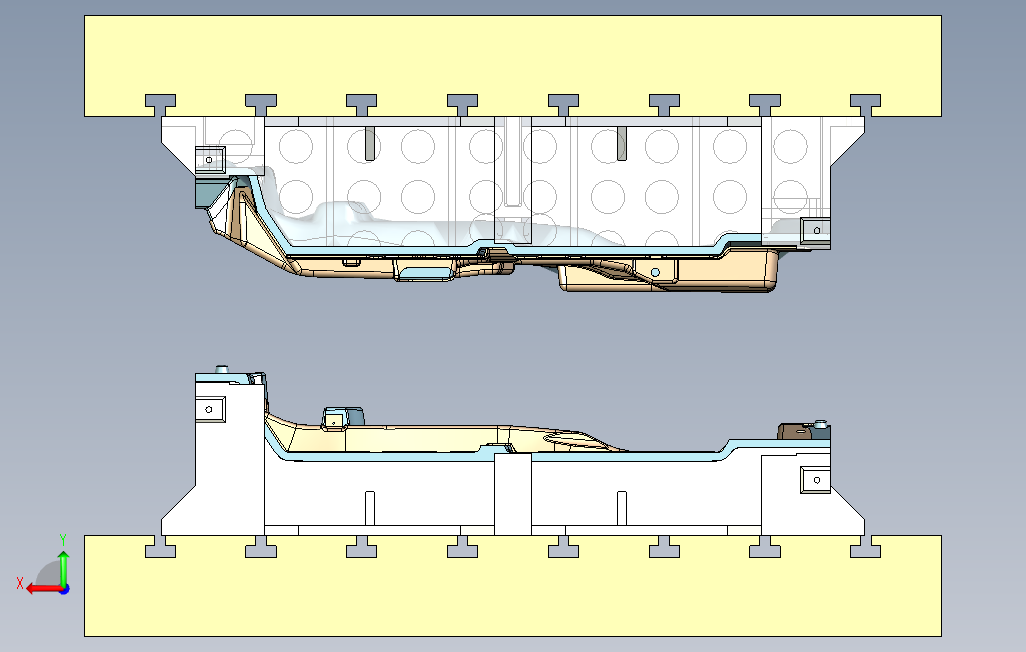

Automotive instrument panel molds often involve irregular parting surfaces, multiple sliders and top block design, which need to be optimized by simulation according to material properties (such as shrinkage, elastic deformation coefficient) and molding temperature. It also ensures that the cooling water layout of the injection mold is reasonable, taking into account the rapid molding and temperature uniformity, and avoiding the deformation or failure of the mold due to thermal stress.

KRMOLD adopts precision machining technology (e.g. CNC, EDM) to ensure the tolerance of key components, and at the same time, the surface strengthening treatment (e.g. nitriding, plating) is carried out on the core components to enhance the wear resistance and service life. Steel materials (e.g. pre-hardened steel or corrosion-resistant steel) are selected to match the life of the mold, and customized material selection is made based on the characteristics of the injection molding material (e.g. ABS, PC/ABS).

Adopt high wear-resistant and high-precision components (e.g. HASCO or DME brand) for standard parts to ensure the stability of mold operation. Control injection temperature, pressure and holding time, optimize filling speed and cooling rate to reduce bubbles, shrink marks and other defects. Parameter combinations need to be verified through DOE experiments to ensure molding consistency.

Why Choose Injection Mold For Automotive Dashboard?

——

1. CNC-controlled molding machines ensure that injection molds are made to tight tolerances and high precision, allowing parts to fit perfectly into assemblies.

2. Injection molding is ideally suited for mass production and is the preferred method for producing high volume automotive interior parts.

3. Material flexibility, a wide range of materials, including impact-resistant plastics and composites, can be used for interior components for maximum durability and aesthetics.

4. Customization, injection molding offers design flexibility from texturing to coloring, allowing manufacturers to create unique and functional parts.

5. Reduced labor and lead times. Once the mold is created, the production process is highly automated, reducing labor costs and lead times.

6. Cost effectiveness, mass production and reduced material waste make injection molding a cost-effective solution for automotive interior parts.

Common Automotive Dashboard Injection Mold Production Processes

——

1. Conventional Injection Molding (CIM)

Application Scenario: Production of instrument panel body, skeleton and other basic structures.

Key points of mold design:

Adopt multi-cavity design to improve efficiency, but need to balance the distribution of gates (such as fan gate or latent gate) to avoid fusion line problems.

The cooling system should be optimized for thick-walled areas (e.g. instrument panel mounting pillars) to prevent shrink marks and deformation.

2. Gas-Assisted Injection Molding (GAM)

Function: By injecting nitrogen to form a hollow channel, the amount of material used is reduced and the rigidity of the part is increased. Reduces weight by more than 30% and reduces internal stress, suitable for large instrument panel beams.

Points for mold design:

Need to pre-build gas needles in the mold and design the gas flow path (e.g. distribution along the reinforcement).

Cavity surface needs to be highly polished to avoid surface defects caused by gas infiltration.

3. Two-shot / Multi-Color Molding (Two-shot / Multi-Color Molding)

Application: Manufacture of parts with integrated hard and soft materials or different colors (e.g. instrument panel trim combined with the substrate). Simultaneous molding of soft-touch areas on the surface of the instrument panel (TPE covering) and the hard substrate (PC/ABS).

Points for mold design:

Adopt rotary mold or cascade mold structure to achieve multi-material sequential injection molding.

Need to accurately control the shrinkage difference of different materials to avoid interface peeling.

About KRMOLD

——

KRMOLD focuses on the field of precision mold design and production, with a manufacturing team of 200+ professional technicians, a technical R&D team of 30+ engineers, and a full-cycle service team covering pre-sales consultation to after-sales maintenance, providing full-process services ranging from mold design, precision processing to injection molding.

KRMOLD is equipped with international first-class equipment such as CNC machining centers, Japan Makino precision spark machine, Japan Shadick wire cutting machine, Japan Toshiba injection molding machine and other domestic and international famous brands of production equipment, to achieve ± 0.002mm processing accuracy, to meet the needs of a variety of high-precision plastic injection molds.

As a long-term mold supplier for Ford, Mercedes-Benz, BMW and other Fortune 500 companies, KRMOLD has delivered more than 500 sets of automotive lighting molds, interior parts molds and other cooperative projects, KRMOLD produces injection molds for the automotive industry, medical industry, furniture industry, consumer electronics industry and so on.

KRMOLD is committed to providing customers with complete production solutions, from design, production to after-sales to complete one-stop service, to help customers solve the production needs, and customers to reach a long-term cooperation and friendly relations.

FAQ

——

1.How to get a quote for custom injection molds?

Specify the type of plastic (e.g. PP, ABS) and post-processing requirements (e.g. spraying, silk-screen printing), and provide 2D or 3D plastic part drawings should be provided. At the same time, provide the production volume, appearance requirements, tolerance standards, etc.

2. How long does it take to get a quote for an injection mold?

Generally speaking, our engineers will start to prepare the quotation immediately after the customer provides the complete production requirements. Usually it takes about 1-3 days.

3. What is the lead time for injection molds?

The lead time for regular injection molds is usually 30-60 days, and may be longer for complex molds. For example, the typical lead time for liquid silicone molds is around 60 days, covering design, manufacturing, mold testing, etc.

Specify the type of plastic (e.g. PP, ABS) and post-processing requirements (e.g. spraying, silk-screen printing), and provide 2D or 3D plastic part drawings should be provided. At the same time, provide the production volume, appearance requirements, tolerance standards, etc.

Generally speaking, our engineers will start to prepare the quotation immediately after the customer provides the complete production requirements. Usually it takes about 1-3 days.

The lead time for regular injection molds is usually 30-60 days, and may be longer for complex molds. For example, the typical lead time for liquid silicone molds is around 60 days, covering design, manufacturing, mold testing, etc.

High-precision processing technology: High-precision equipment such as CNC machining centers (CNC) and electric discharge machining (EDM) are used to optimize the design process in combination with CAD/CAM software. Quality control: Inspection of key dimensions of the mold by Coordinate Measuring Machine (CMM) and verification of multiple sample batches during the trial molding stage. Material Selection: Use die steel with high wear resistance (e.g. H13, S136) and surface treatment (e.g. nitriding, chrome plating) for die nuts to extend the life.

After every 50,000 molds, check the guide pillar, ejector pin and other wear parts, and clean up the residual plastic and rust on the mold surface. Use high temperature grease for sliding parts (e.g. tilt top, slider) to reduce friction loss. Ensure that the water circuit is smooth and the temperature difference is ≤5℃ to avoid cracking of the mold due to thermal stress.

Mould cost of materials accounted for about 30-40% (such as 1 ton of P20 steel price of about 20,000 yuan), processing costs accounted for more than 50% (CNC labor hourly rate of about 80-150 yuan / hour). Small batch production can choose aluminum mold or simplify the structural design; more than 100,000 pieces is recommended to use carbide inserts to enhance life!

Mould injection products need to fully meet the design requirements (such as size, appearance), and can be continuous and stable production. Mold marking, inspection reports (such as material hardness test) and engineering drawings should be complete.

Mould steel (such as S136H, NAK80 and other imported materials cost more) and the type of mold embryo (aluminum mold short-term cost is low but short life) directly affect the cost, the use of CAD/CAE/CAM design technology, hot runner system, etc. will increase the upfront investment, but can enhance the long-term benefits (such as reducing the sprues, increase production capacity).