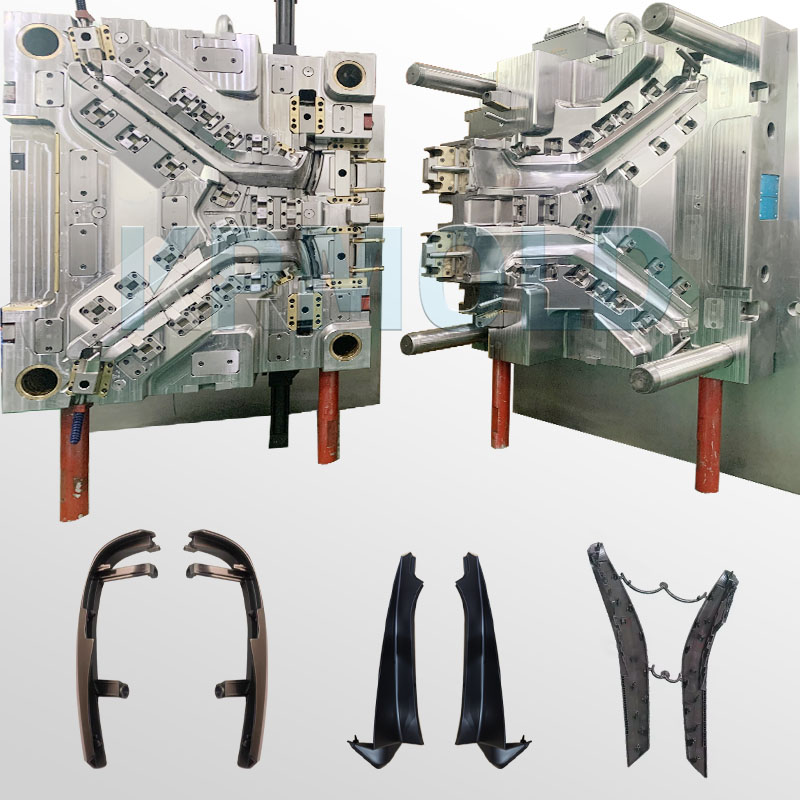

Automotive trim strip injection molds can efficiently produce trim strips of various complex shapes, materials, and designs, widely used in key areas such as doors, dashboards, center consoles, and window frames. By using high-quality car trim strip injection molds, automakers can not only improve the overall aesthetics of their vehicles but also enhance the protective performance of various body components.

Parameters of Automotive Trim Strip Injection Mold

——

| Mould Name | Car trim strip injection mold |

| Core & Cavity Steel | 718H, P20, 738H, H13, 420, NAK80, 2316, 2738, 2344, etc. |

| Mould Steel | NAK80,S136,2316,2738,H13,5CrNiMo,718H,P20,40Cr,60#,50#,45#, SKD61 2738,2344,718,8407,etc.high hardness steel with heat treatment, wear resistance, corrosion resistance. |

| Mold Base Steel | S50C, P20.73H8, 718H, H13, NAK80, S136, LKM,HASCO,DME,etc. or according to customer's request |

| Product Material | PP,PE,PC,PA,PS,PU,PVC,PMMA,ABS,TPU, POM , PBT ,HIPS, TPE , TPR, ,HDPE,PPR, PET, Rubber, Silicone , PPSU, PPS, etc. |

| Mould standard | HASCO, DME, MISUMI, or by requested etc. |

| Design software | UG, PROE, CAD,Solidworks, AutoCAD,Moldflow,ect. |

| Surface treatment | Polishing/smooth,Texture/frosted,Printing,Painting,Plating, or as per customer request |

| Main Technique | Milling, Grinding, Drilling, EDM, Wire-cutting, Engraving, CNC, etc. |

| Cavity No. | Single or multi |

| Runner System | Hot runner, Cold runner, Pin-point gate, Submarine gate, etc |

| Mould life time | 100,000-1,000,000 shot times |

Importance of Automotive Trim Strip Injection Mold

——

Firstly, the primary functions of automotive trim strips are decoration and protection. As accessories for automotive components, trim strips not only enhance the visual appeal of a car's appearance but also protect edges from scratches and wear. For example, trim strips on car doors and dashboards effectively prevent damage from daily use, extending the car's lifespan. Furthermore, a well-designed car trim strip injection mold ensures both durability and aesthetics, providing consumers with a better user experience. KRMOLD understands its customers' needs for automotive trim strip injection molds and is therefore committed to designing high-performance car trim strip injection molds that meet the specific requirements of automotive components based on their actual project needs. KRMOLD team of designers and engineers possesses extensive industry experience and can tailor automotive trim strip injection molds to meet the specific needs of each customer. |  |

KRMOLD Automotive Trim Strip Injection Mold Optimization

——

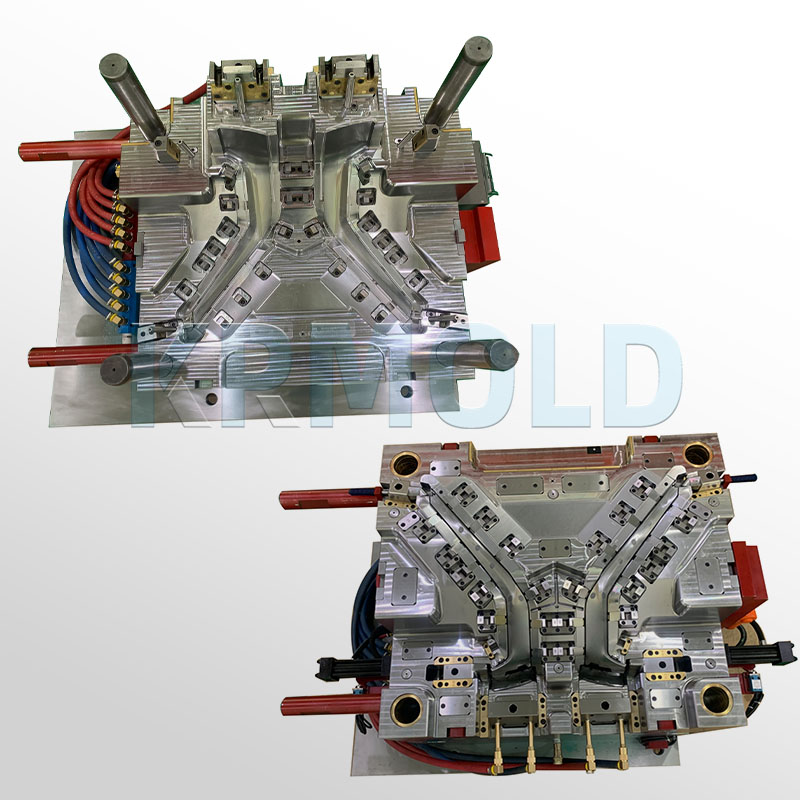

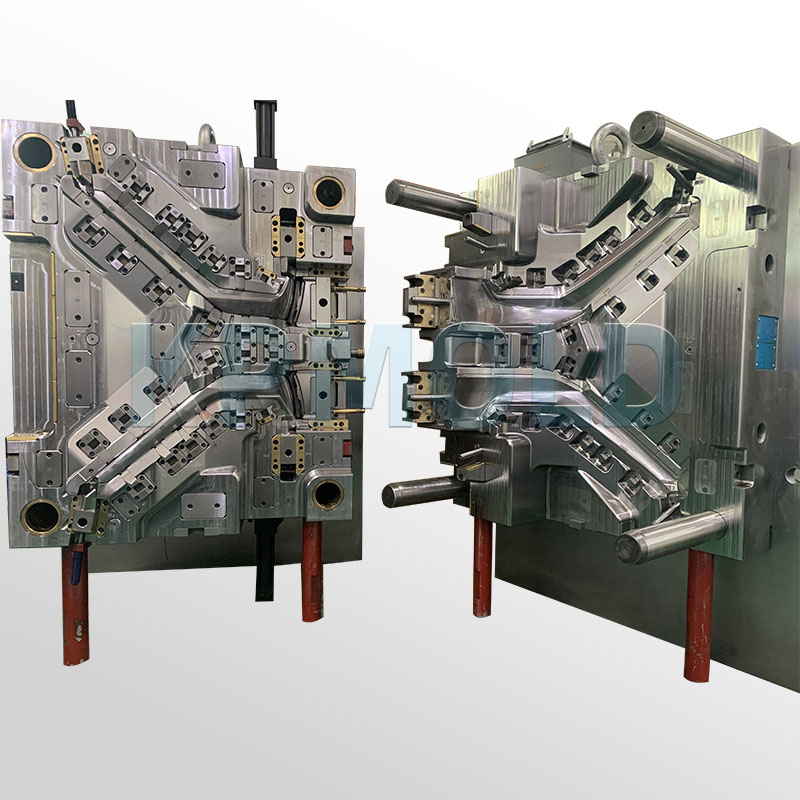

During the car trim strip injection mold design process, KRMOLD strictly adheres to a series of optimization principles and strategies to ensure that every car trim strip injection mold meets or exceeds customer expectations.

| ●Automotive Trim Strip Injection Mold Structure Design Principles - Rationality Principle: KRMOLD car trim strip injection mold structures must meet process requirements, ensuring rational material flow during injection molding, avoiding material stagnation or air bubbles, and ensuring product quality and consistency. - Standardization Principle: KRMOLD automotive trim strip injection mold designs follow industry standards, using universal templates and components. This standardization not only facilitates car trim strip injection mold manufacturing but also streamlines later maintenance and replacement, significantly improving production efficiency. - Modular Design: KRMOLD employs a modular design, breaking down the automotive trim strip injection mold structure into several independent modules. This design facilitates assembly, disassembly, parts replacement, and maintenance, greatly reducing production downtime. - Strength and Stability Considerations: KRMOLD ensures that the car trim strip injection mold possesses sufficient strength and stability during operation to prevent deformation and breakage, which is crucial for improving the precision of injection-molded products. |  |

●Automotive Trim Strip Injection Mold Structure Optimization Strategies In addition to ensuring a rational car trim strip injection mold structure, KRMOLD also employs a series of optimization strategies to improve the overall performance of the automotive trim strip injection mold. - Runner System Optimization: A well-designed gate and runner system ensures uniform plastic distribution within the car trim strip injection mold, preventing defects such as scorching and flow marks on the molded parts. - Improved Cooling System: KRMOLD is committed to optimizing the layout of cooling channels to improve cooling efficiency and ensure uniform automotive trim strip injection mold temperature. This helps reduce deformation and uneven shrinkage of finished products. - Venting System Design: A well-designed venting system perfectly solves the problem of gas trapping, effectively preventing product defects and is a crucial element in improving car trim strip injection mold efficiency. - Mold Material Selection: Appropriate mold materials are selected based on different product materials, injection molding process requirements, and expected service life to ensure automotive trim strip injection mold durability and stability. - CAD and CAM Technology: KRMOLD utilizes modern CAD and CAM technologies to assist in car trim strip injection mold design, thereby improving design accuracy and efficiency, enabling automotive trim strip injection molds to be put into production more quickly. |  |

Advantages of Automotive Trim Strips

——

Automotive trim strips produced by KRMOLD car trim strip injection molds exhibit the following significant advantages due to their unique design and high-quality materials: - Complex and Diverse Shapes: Due to the complexity of automotive components, the required shapes of trim strips are extremely diverse. KRMOLD automotive trim strip injection mold design demonstrates high flexibility and adaptability in this regard, ensuring products meet various design requirements. - Premium Materials: High-quality materials are selected to meet consumers' stringent requirements for automotive interior texture, ensuring the trim strips are both aesthetically pleasing and practical. - High Precision: KRMOLD car trim strip injection mold design enables high-precision production, meaning the produced automotive trim strips possess extremely high accuracy in size and shape, ensuring a perfect fit to the vehicle. |  |

Manufacturing Process of Automotive Trim Strip Injection Mold

——

-Product Design: Customers provide product drawings directly, or KRMOLD design the product based on samples and send it to the customer for confirmation.

-Mold Design: After product drawing confirmation, KRMOLD send the car trim strip injection mold design to the customer for confirmation.

-Mold Manufacturing: After automotive trim strip injection mold design confirmation, the manufacturing process includes material preparation, rough machining, fine machining, and assembly.

-Mold Testing: After car trim strip injection mold assembly, KRMOLD send samples, videos, and trial molding reports to the customer for confirmation.

-Final Process: If the sample is approved by the customer, KRMOLD will perform surface treatment according to customer requirements, such as texturing, nitriding, or chrome plating.

-Mold Testing: The automotive trim strip injection mold is retested, and the final sample and test video are sent to the customer for inspection.

-Mold Packaging: After final sample confirmation, the car trim strip injection mold is packaged in a wooden crate.

-Mold delivery: by sea or air. Customers may specify a freight forwarder.

Specify the type of plastic (e.g. PP, ABS) and post-processing requirements (e.g. spraying, silk-screen printing), and provide 2D or 3D plastic part drawings should be provided. At the same time, provide the production volume, appearance requirements, tolerance standards, etc.

Generally speaking, our engineers will start to prepare the quotation immediately after the customer provides the complete production requirements. Usually it takes about 1-3 days.

The lead time for regular injection molds is usually 30-60 days, and may be longer for complex molds. For example, the typical lead time for liquid silicone molds is around 60 days, covering design, manufacturing, mold testing, etc.

High-precision processing technology: High-precision equipment such as CNC machining centers (CNC) and electric discharge machining (EDM) are used to optimize the design process in combination with CAD/CAM software. Quality control: Inspection of key dimensions of the mold by Coordinate Measuring Machine (CMM) and verification of multiple sample batches during the trial molding stage. Material Selection: Use die steel with high wear resistance (e.g. H13, S136) and surface treatment (e.g. nitriding, chrome plating) for die nuts to extend the life.

After every 50,000 molds, check the guide pillar, ejector pin and other wear parts, and clean up the residual plastic and rust on the mold surface. Use high temperature grease for sliding parts (e.g. tilt top, slider) to reduce friction loss. Ensure that the water circuit is smooth and the temperature difference is ≤5℃ to avoid cracking of the mold due to thermal stress.

Mould cost of materials accounted for about 30-40% (such as 1 ton of P20 steel price of about 20,000 yuan), processing costs accounted for more than 50% (CNC labor hourly rate of about 80-150 yuan / hour). Small batch production can choose aluminum mold or simplify the structural design; more than 100,000 pieces is recommended to use carbide inserts to enhance life!

Mould injection products need to fully meet the design requirements (such as size, appearance), and can be continuous and stable production. Mold marking, inspection reports (such as material hardness test) and engineering drawings should be complete.

Mould steel (such as S136H, NAK80 and other imported materials cost more) and the type of mold embryo (aluminum mold short-term cost is low but short life) directly affect the cost, the use of CAD/CAE/CAM design technology, hot runner system, etc. will increase the upfront investment, but can enhance the long-term benefits (such as reducing the sprues, increase production capacity).