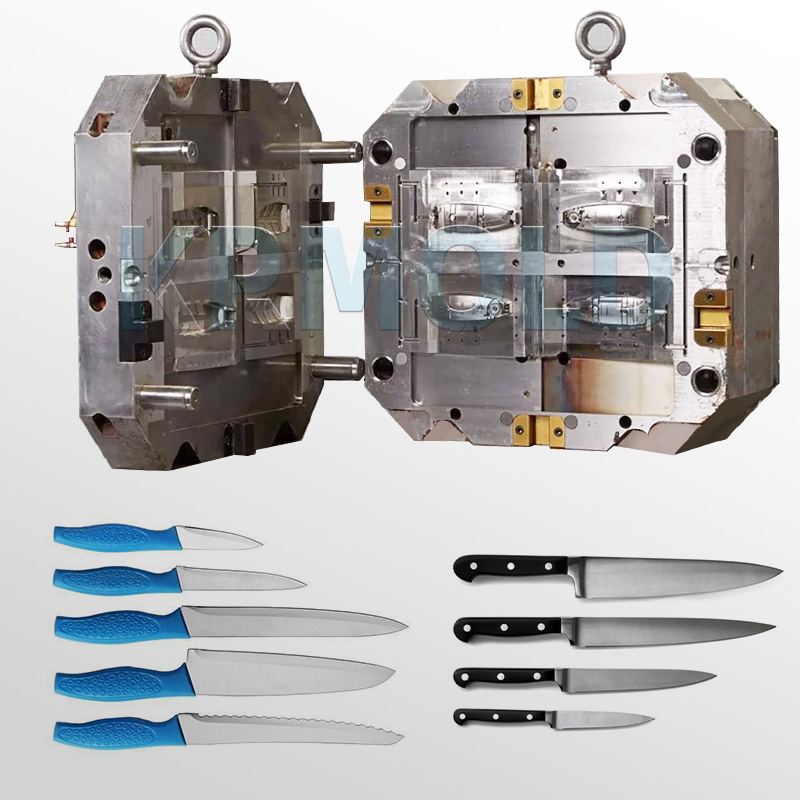

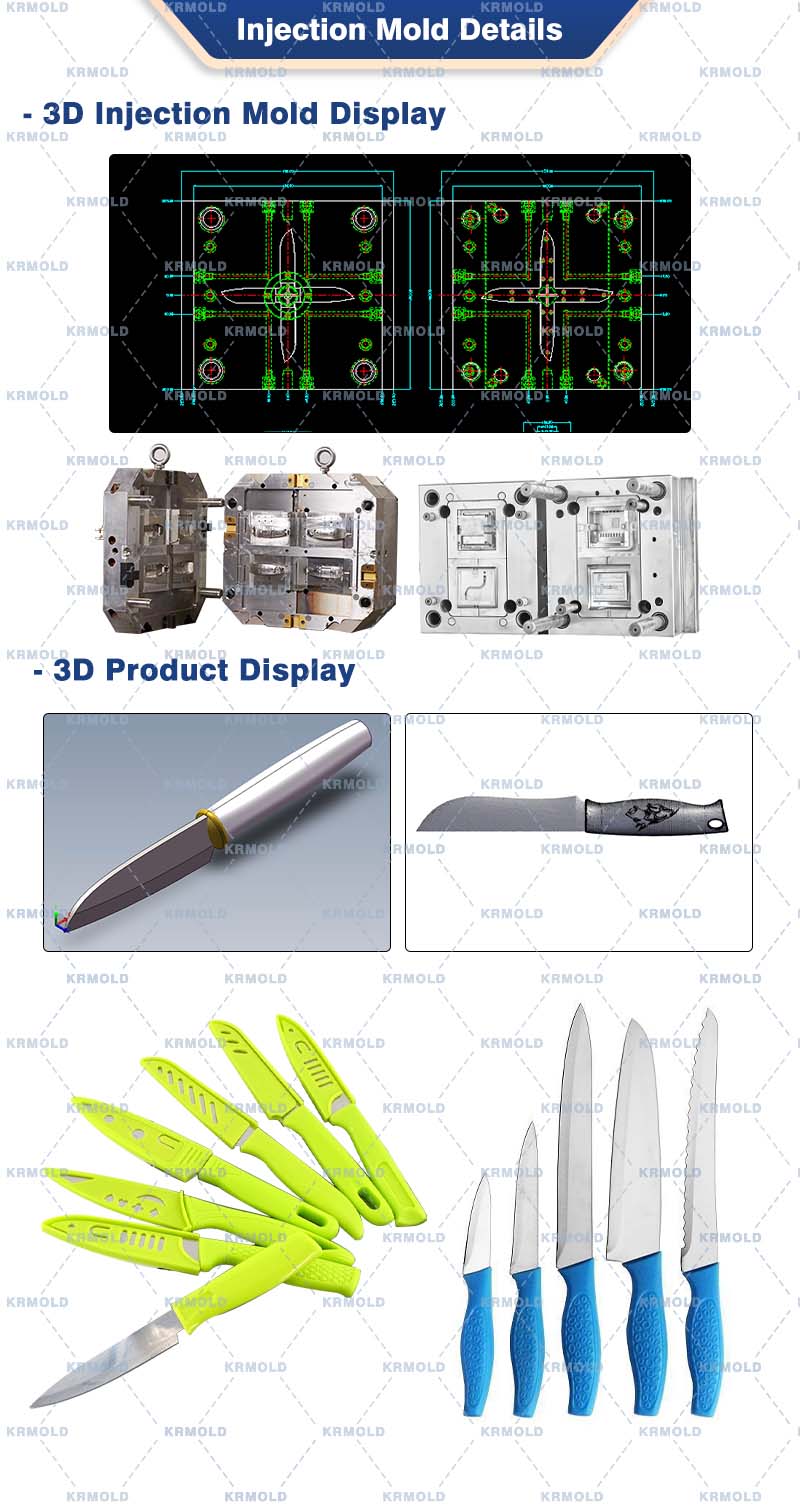

As an indispensable part of knife components, knife handle injection molds are widely used in the mass production of various knife handles, especially fruit knife handles and folding fruit knife handles. KRMOLD, with its extensive experience and advanced technology, is committed to providing high-quality plastic knife handle mould that meet customers' comprehensive needs for precision, functionality, and aesthetics.

Introduction to Knife Handle Injection Mold

——

KRMOLD plastic knife handle mould are meticulously designed, emphasizing lightweight, easy cleaning, ease of use, and cost-effectiveness. KRMOLD uses thermoplastics for injection molding, providing a solid foundation for the complexity and precision of knife handle injection mold shapes.

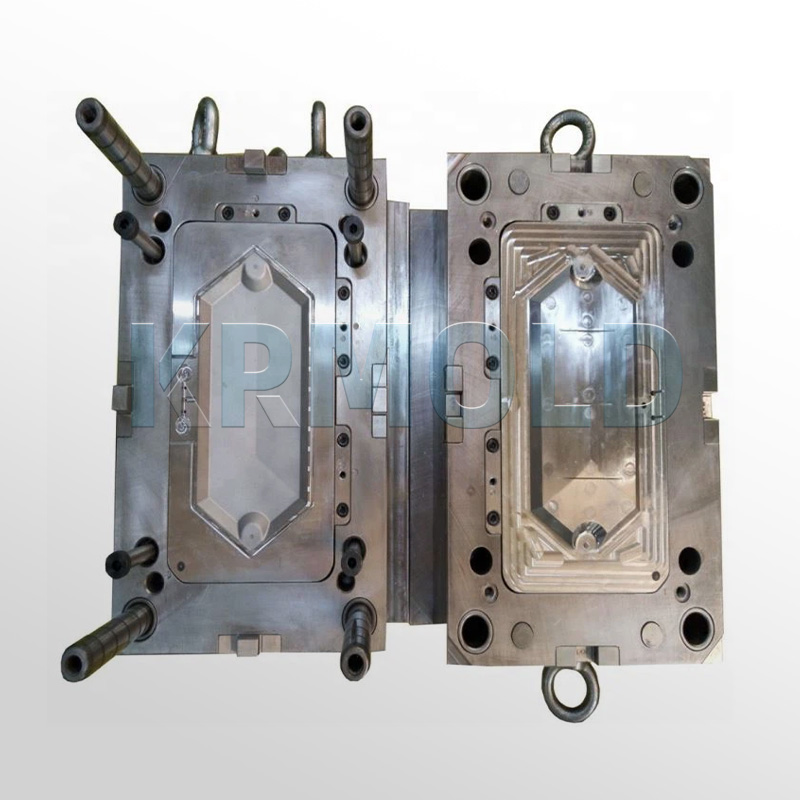

In the design process of plastic knife handle mould, KRMOLD pays special attention to the gating system design. Some knife handle injection molds utilize side gates and core-pulling structures. This design not only contributes to the uniformity of plastic flow but also fully considers the design requirements of core-pulling distance, parting line determination, and venting grooves. Through these meticulous designs, KRMOLD ensures high efficiency and excellent molding quality in the production process of plastic knife handle mould.

KRMOLD plastic knife handle molds not only guarantee the quality and accuracy of the knife handle injection mold but also highlight the fit between the blade and the handle. Some fruit knife handles are made to pivot from 0 to 180 degrees; hence, testing and plastic knife handle mould design are particularly important. KRMOLD performs several exact tests during knife handle injection mold testing to make sure the handle fits the blade exactly and satisfies customer expectations.

Advantages of Plastic Knife Handle Mould

——

1. Widely applicable knife handle injection mold KRMOLD plastic knife handle mould offer significant wide applicability, supporting blades of various sizes, with a maximum width of 2 cm. This characteristic allows KRMOLD knife handle injection molds to produce handles that meet the needs of a wide range of knives on the market, whether for home or commercial use.

2. Ergonomic design for plastic knife handle mould KRMOLD has deeply considered ergonomics in the design of knife handles. The rounded edges and surfaces of the handles produced by the knife handle injection molds are extremely smooth, providing a more comfortable grip. Especially for knives used for extended periods, KRMOLD plastic knife handle mould effectively reduce user fatigue and enhance the user experience. This contrasts sharply with knife handles produced using other methods, which often result in sharp edges and a lack of tactile feel. |  |

3. Superior grip performance for knife handle injection mold Due to the characteristics of the injection molding process, KRMOLD plastic knife handle mould typically produce knife handles with a rougher texture. In addition to improving grip, this harsh surface also slightly enhances safety. The textured grip of the handle lets users firmly hold the knife and move it freely, hence avoiding falls and mishaps brought on by slipping.

4. Unique patterns and colors for knife handle injection mold Another significant advantage of plastic knife handle mould is its ability to achieve unique pattern and color combinations. KRMOLD knife handle injection molds offer virtually unlimited color choices, from practical triangles and X-shaped patterns to more complex honeycomb and dragon scale patterns, allowing each knife to be unique. Furthermore, the plastic knife handle mould support the production of knife handles in various colors to meet different market demands and consumer preferences.

5. Outstanding durability for knife handle injection mold KRMOLD plastic knife handle mould produce plastic knife handles with exceptional durability, maintaining excellent performance even in high-intensity working environments. The impact-resistant properties of these knife handles make them suitable for a variety of cutting tasks, ideal for everyday use, whether in the home or a professional kitchen. |  |

What Can Knife Handle Injection Mold Produce?

——

Design Guidelines of Plastic Knife Handle Mould

——

As a manufacturer of knife handle injection molds, KRMOLD follows these key guidelines in plastic knife handle mould design to ensure performance and quality:

1.Material ratio for knife handle injection mold

TPR (thermoplastic rubber) should make up at least 30% of the handle material to guarantee its anti-slip capability. A lower ratio can cause the handle to slip during usage, so influencing user experience and safety. Hence, enhancing the whole performance of the product calls for thought about an ideal material ratio during the design phase.

2.Structural integration for knife handle injection mold

The construction of the handle should guarantee that ABS and TPR fit smoothly, therefore avoiding fractures or separation during use. KRMOLD advises numerous finger-press checks to assess the stability and dependability of the link, therefore guaranteeing it can survive actual usage testing.

3.Size fit for plastic knife handle mould

Handle length is determined by the varied hand sizes of users. For those with tiny hands, it is advised to create a little handle of 8–9 cm; for those with large hands, a long handle may be selected. This will satisfy a range of consumer needs. Make certain the grip size is appropriate so that the user's thumb and index finger can spontaneously locate the ideal grip, therefore increasing comfort and stability.

4. Texture details for knife handle injection mold

The edges need to be smooth and free of burrs during the knife handle injection mold development process to prevent consumer irritation. Using poor materials might also produce a strong scent; hence, tight quality control of ingredients is imperative to guarantee the ultimate product's premium appearance and feel, improving user experience.

5. Compatibility for plastic knife handle mould

Lastly, it's very important to make sure the plastic knife handle mould works with conventional ceramic blades. Generally advised to guarantee a good fit between the handle and the blade and so achieve best performance, a cylindrical handle with a diameter of 3.5mm to 5mm is usually recommended.

Specify the type of plastic (e.g. PP, ABS) and post-processing requirements (e.g. spraying, silk-screen printing), and provide 2D or 3D plastic part drawings should be provided. At the same time, provide the production volume, appearance requirements, tolerance standards, etc.

Generally speaking, our engineers will start to prepare the quotation immediately after the customer provides the complete production requirements. Usually it takes about 1-3 days.

The lead time for regular injection molds is usually 30-60 days, and may be longer for complex molds. For example, the typical lead time for liquid silicone molds is around 60 days, covering design, manufacturing, mold testing, etc.

High-precision processing technology: High-precision equipment such as CNC machining centers (CNC) and electric discharge machining (EDM) are used to optimize the design process in combination with CAD/CAM software. Quality control: Inspection of key dimensions of the mold by Coordinate Measuring Machine (CMM) and verification of multiple sample batches during the trial molding stage. Material Selection: Use die steel with high wear resistance (e.g. H13, S136) and surface treatment (e.g. nitriding, chrome plating) for die nuts to extend the life.

After every 50,000 molds, check the guide pillar, ejector pin and other wear parts, and clean up the residual plastic and rust on the mold surface. Use high temperature grease for sliding parts (e.g. tilt top, slider) to reduce friction loss. Ensure that the water circuit is smooth and the temperature difference is ≤5℃ to avoid cracking of the mold due to thermal stress.

Mould cost of materials accounted for about 30-40% (such as 1 ton of P20 steel price of about 20,000 yuan), processing costs accounted for more than 50% (CNC labor hourly rate of about 80-150 yuan / hour). Small batch production can choose aluminum mold or simplify the structural design; more than 100,000 pieces is recommended to use carbide inserts to enhance life!

Mould injection products need to fully meet the design requirements (such as size, appearance), and can be continuous and stable production. Mold marking, inspection reports (such as material hardness test) and engineering drawings should be complete.

Mould steel (such as S136H, NAK80 and other imported materials cost more) and the type of mold embryo (aluminum mold short-term cost is low but short life) directly affect the cost, the use of CAD/CAE/CAM design technology, hot runner system, etc. will increase the upfront investment, but can enhance the long-term benefits (such as reducing the sprues, increase production capacity).