Description of Air Conditioning Panel Injection Mold

——

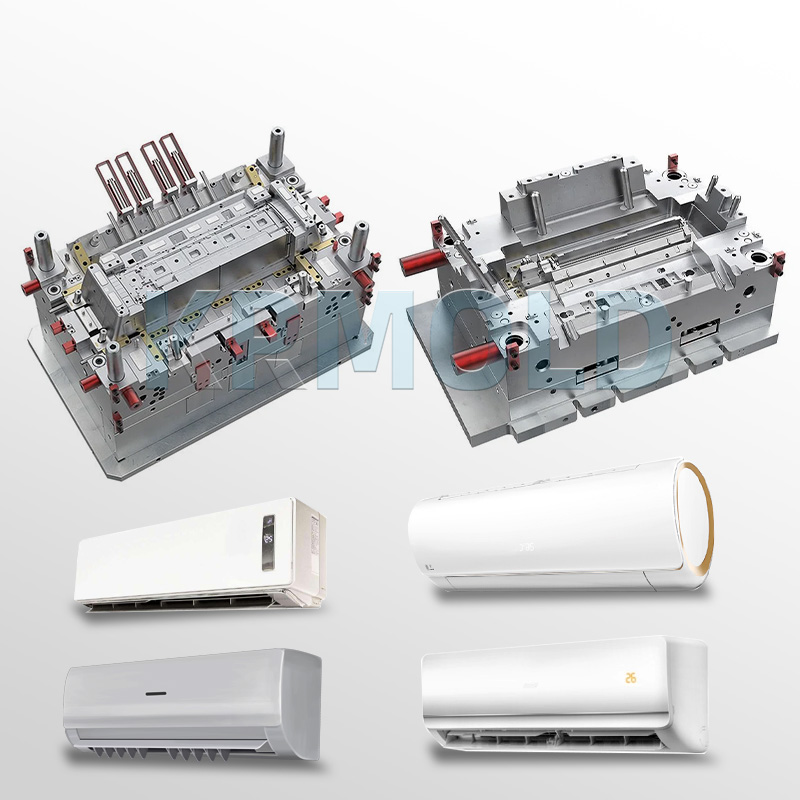

Air conditioning panel injection molds not only offer efficient production capacity and stable product quality, but also enable large-scale production to meet diverse market demands. Along with highlighting the design and technological appeal of the product, air conditioner panels made using this plastic air conditioner shell mould protect the internal structure of the air conditioner.

KRMOLD is dedicated to providing consumers with creative, customized, smart air conditioning panel injection mold solutions as technology advances continually and consumer demands grow more varied. Whether it's a floor-standing or wall-mounted air conditioner, KRMOLD plastic air conditioner shell mould can produce them. These air conditioning panel injection molds, when assembled with other air conditioner components, form a complete air conditioning system, significantly contributing to regulating indoor temperature and providing fresh air.

Parameters of Plastic Air Conditioner Shell Mould

——

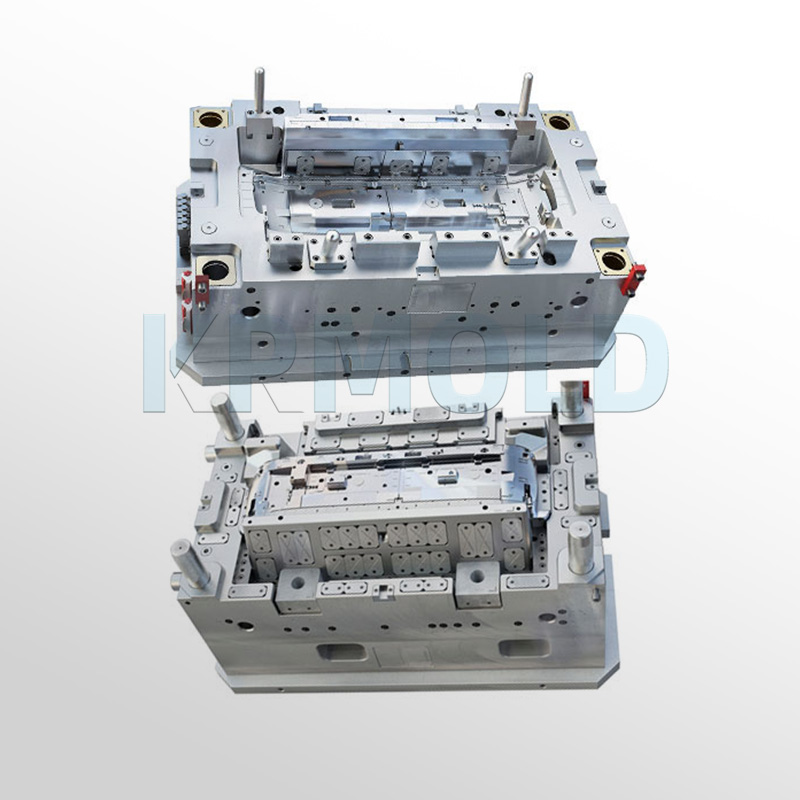

| Mold Materials | P20, 718, 718H, 2738, 2316, S136, etc. |

| Mold Frame | 45# pre-hardened material, hardness greater than 30 HRC |

| Cooling System | Optimized design enables circulating water |

| Mid-Term Processing | Mold tempering and heat treatment to increase hardness. Post-treatment: Nitriding (mold surface hardness greater than HV850, wear resistance) |

| Mold Life | P20 molds can withstand at least 500,000 cycles under normal use |

| Shipping | Molds are fitted with mold locks before shipment to prevent movement, and are securely packaged and rust-proof |

Advantages of Air Conditioning Panel Injection Mold

——

(1) Efficient production capacity of plastic air conditioner shell mould

The efficient production capacity of air conditioning panel injection molds is one of their greatest advantages. Automatic and continuous production made possible by injection molding technology greatly increases production efficiency. This increases the market competitiveness of consumers by allowing them to create more goods in less time.

(2) Precise control capacity of plastic air conditioner shell mould

Advanced control systems and complex plastic air conditioner shell mould design guarantee the dimensional precision and uniformity of air conditioner casings. Guaranteeing that every product satisfies demanding quality standards, plastic panels made with KRMOLD air conditioning panel injection molds are free of flaws including black spots, bumps, missing material, and sink marks.

(3) Diverse designs for plastic air conditioner shell mould

Consumer buying decisions are frequently shaped by the design of air conditioner panels. KRMOLD air conditioning panel injection molds may readily produce intricate shapes and a range of color schemes to satisfy the visual preferences of a broad spectrum of customers. This flexibility enables consumers to innovate and adapt quickly depending on market need.

(4) Environmental protection and energy saving

Compared to traditional manufacturing processes, plastic air conditioner shell mould processing technology is more environmentally friendly and energy-efficient. This enables businesses to create a good image of social responsibility, lowers resource waste and environmental contamination, and fits with modern green manufacturing ideas.

(5) Excellent surface quality for plastic air conditioner shell mould

Air conditioner panels produced with KRMOLD air conditioning panel injection molds are burr-free and free of conductive impurities. Made of reinforced polypropylene, they guarantee product safety and toughness. Ensuring perfection in every detail, KRMOLD engineers create plastic air conditioner shell mould depending totally on consumer drawings and exact needs.

Impact of Plastic Air Conditioner Shell Mould Temperature on Product Quality

——

Mold Temperature/℃ | Check Corner | ||

| 20° | 60° | 85° | |

| 73 | 96.7 | 99.4 | 98.1 |

| 65 | 96.4 | 98.2 | 98.3 |

| 52 | 89.2 | 95.8 | 98.2 |

| 36 | 79.5 | 91.7 | 98 |

The temperatures listed in this table refer to the heating temperatures used during air conditioning panel injection mold manufacturing. Specifically, this temperature plays a crucial role in the injection molding process, directly affecting the plastic's fluidity, curing speed, and the surface gloss of the final product.

During the injection molding process, plastic air conditioner shell mould temperature is crucial to the plastic's processing properties. High or low mold temperatures can significantly impact the quality of the finished product. Therefore, understanding gloss data at different mold temperatures is crucial for manufacturers. This not only helps ensure that the final product's appearance meets standards, but also improves production efficiency, reduces defective products, and ensures that product quality meets customer expectations.

Key Steps in Air Conditioning Panel Injection Molding

——

(1) Material selection for plastic air conditioner shell mould High-quality raw materials are essential for ensuring the quality of air conditioner shells. KRMOLD typically uses plastic materials with excellent heat resistance, weather resistance, and impact resistance, such as ABS and PC. These materials meet the requirements of air conditioners in diverse operating conditions.

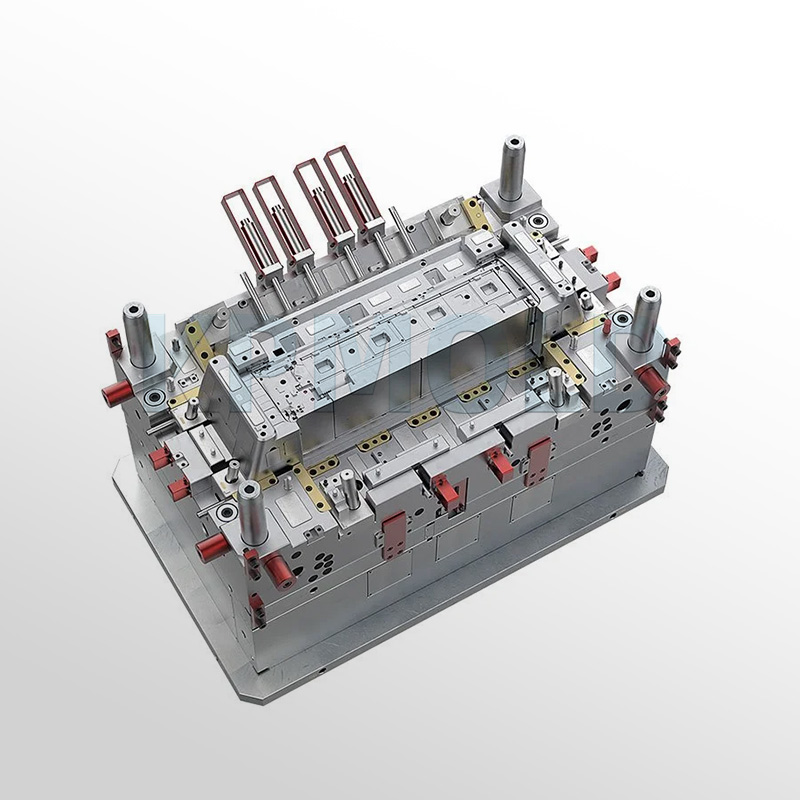

(2) Air conditioning panel injection mold design and manufacturing Central to the injection molding process is the plastic air conditioner shell mould, its design significantly influences the dimensional correctness and look of the product. Ensuring that every plastic air conditioner shell mold meets great manufacturing standards, KRMOLD professional air conditioning panel injection mold design team painstakingly creates and produces it to fit the shape, size, and functional needs of the air conditioner housing.

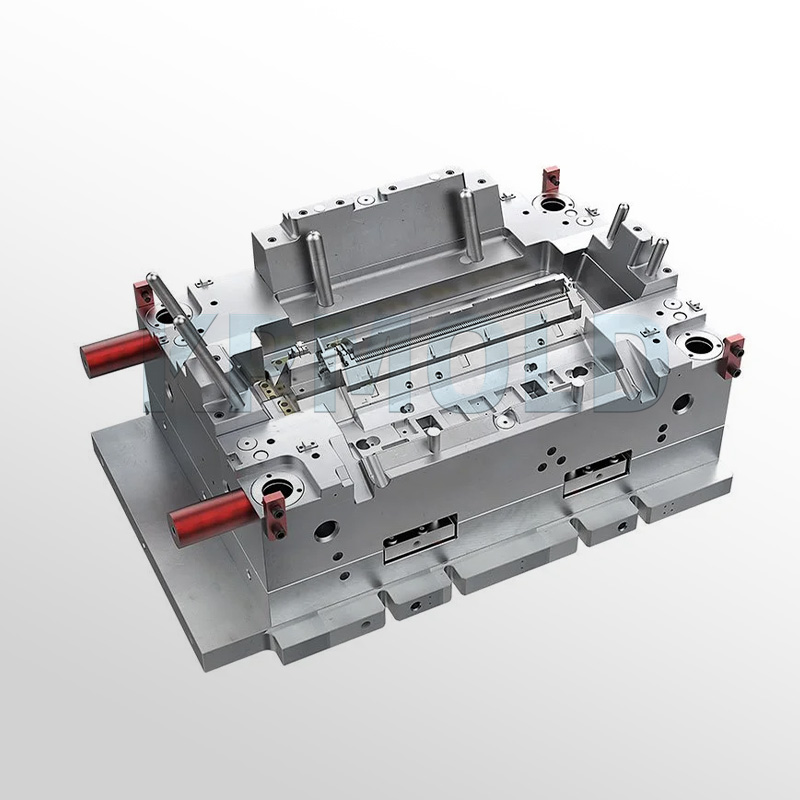

(3) Injection molding During the injection molding process, heated and molten plastic pellets are injected into the plastic air conditioner shell mould. The first form of the air conditioner shell is created following cooling and pressure maintenance. Strict temperature and pressure control is needed during this process to guarantee the plastic's flowability and molding quality.

(4) Post-processing and inspection for air conditioning panel injection mold After injection molding, the air conditioner housing requires post-processing such as deburring, polishing, and painting to enhance its surface quality and aesthetics. KRMOLD also conducts rigorous quality inspections to ensure compliance with relevant standards and requirements. This step is crucial to ensuring product quality. |  |

Application of Air Conditioning Panel Injection Mold

——

Why Choose KRMOLD?

——

(1)Top-Notch R&D Team

With 30 years of experience in plastic air conditioner shell mould design, KRMOLD provides customers with optimized solutions for customized products, shortening product development and market launch cycles. KRMOLD R&D team is committed to innovation to meet market changes and customer needs.

(2)Advanced Production Equipment

KRMOLD is equipped with a full range of top-tier precision machining equipment imported from Japan, including Makino CNC and ED equipment. These machines achieve machining accuracies of ±0.01mm, and Mitsubishi WEDM equipment achieves ±0.003mm, ensuring the high precision and quality of every air conditioning panel injection mold.

(3)Perfect Quality Assurance

KRMOLD rigorously controls incoming materials (IQC), in-process quality control (IPQC), finished products (FQC), and mold shipment (OQC), helping customers achieve impeccable quality and ensuring every product meets their high standards.

(4)Ultra-Short Delivery Cycle

KRMOLD implements full-staff delivery management to ensure short delivery times, helping customers reduce product production cycles and shorten time-to-market, ultimately generating greater profits.

(5)Automated Information Management

KRMOLD utilizes advanced information systems such as ERP, OA, PDM, and MES to establish a streamlined, information-based, automated, and intelligent management and production system, thereby improving production efficiency and management levels.

Specify the type of plastic (e.g. PP, ABS) and post-processing requirements (e.g. spraying, silk-screen printing), and provide 2D or 3D plastic part drawings should be provided. At the same time, provide the production volume, appearance requirements, tolerance standards, etc.

Generally speaking, our engineers will start to prepare the quotation immediately after the customer provides the complete production requirements. Usually it takes about 1-3 days.

The lead time for regular injection molds is usually 30-60 days, and may be longer for complex molds. For example, the typical lead time for liquid silicone molds is around 60 days, covering design, manufacturing, mold testing, etc.

High-precision processing technology: High-precision equipment such as CNC machining centers (CNC) and electric discharge machining (EDM) are used to optimize the design process in combination with CAD/CAM software. Quality control: Inspection of key dimensions of the mold by Coordinate Measuring Machine (CMM) and verification of multiple sample batches during the trial molding stage. Material Selection: Use die steel with high wear resistance (e.g. H13, S136) and surface treatment (e.g. nitriding, chrome plating) for die nuts to extend the life.

After every 50,000 molds, check the guide pillar, ejector pin and other wear parts, and clean up the residual plastic and rust on the mold surface. Use high temperature grease for sliding parts (e.g. tilt top, slider) to reduce friction loss. Ensure that the water circuit is smooth and the temperature difference is ≤5℃ to avoid cracking of the mold due to thermal stress.

Mould cost of materials accounted for about 30-40% (such as 1 ton of P20 steel price of about 20,000 yuan), processing costs accounted for more than 50% (CNC labor hourly rate of about 80-150 yuan / hour). Small batch production can choose aluminum mold or simplify the structural design; more than 100,000 pieces is recommended to use carbide inserts to enhance life!

Mould injection products need to fully meet the design requirements (such as size, appearance), and can be continuous and stable production. Mold marking, inspection reports (such as material hardness test) and engineering drawings should be complete.

Mould steel (such as S136H, NAK80 and other imported materials cost more) and the type of mold embryo (aluminum mold short-term cost is low but short life) directly affect the cost, the use of CAD/CAE/CAM design technology, hot runner system, etc. will increase the upfront investment, but can enhance the long-term benefits (such as reducing the sprues, increase production capacity).