What is Switch Socket Plastic Injection Mold?

——

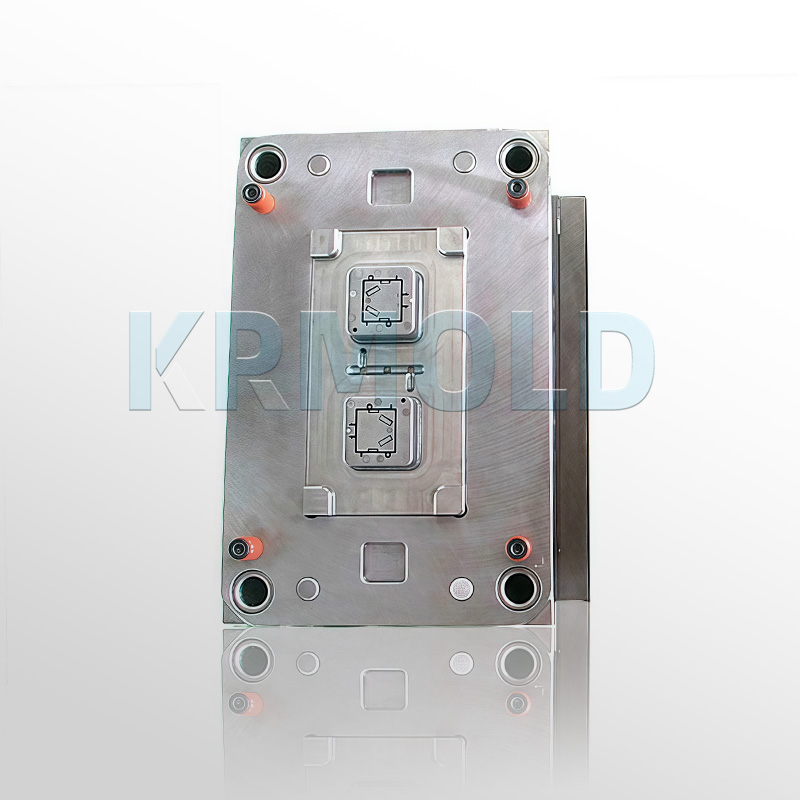

KRMOLD switch socket plastic injection molds are customized to meet specific customer requirements, enabling the production of sockets that comply with various national standards, such as British, South African, and European standards. These products offer diverse shapes and hole placements, meeting the requirements of various markets and maximizing customer satisfaction.

Plastic switch socket injection molds are an essential component of modern electrical equipment. They must not only meet functional and safety requirements but also boast efficient production capacity and excellent surface quality.

KRMOLD specializes in the research, development, and production of switch socket plastic injection molds, ensuring that each plastic switch socket injection mold achieves industry-leading levels of quality, precision, and efficiency. KRMOLD switch socket plastic injection molds feature a well-designed, compact structure, ensuring product precision and surface quality, ensuring superior production quality and meeting customer needs.

Parameters of Plastic Switch Socket Injection Mold

——

| Item# | Item | Description |

| 1 | Product Name | Switch Socket Plastic Injection Mold |

| 2 | Mold base | LKM;HASCO;DME |

| 3 | Mold material | PC, PC/ABS, PMMA, PP, ABS etc |

| 4 | Mold cavity | Single or Multi or up to you.Single or Multi or up to you. |

| 5 | Runner | Hot/Cold |

| 6 | Slider/insert | P20/718H/738/NAK80/2343/S136 |

| 7 | Main process | Milling,grinding,CNC,EDM,wire-electrode cutting, carved, electrospark,lathe,surface treatment |

| 8 | Design software | UG,PROE,CAD,SOLIDWORK |

| 9 | Plastic Material | PP,PC,PE,ABS,PVC,etc. |

| 10 | Mold life | >500,000 shots |

| 11 | Transportation | By sea, by air or by land as you request |

| 12 | Package | According to clients requirement |

| 13 | Surface treatment | Polishing |

Plastic Switch Socket Injection Mold Materials and Surface Treatment Technology

——

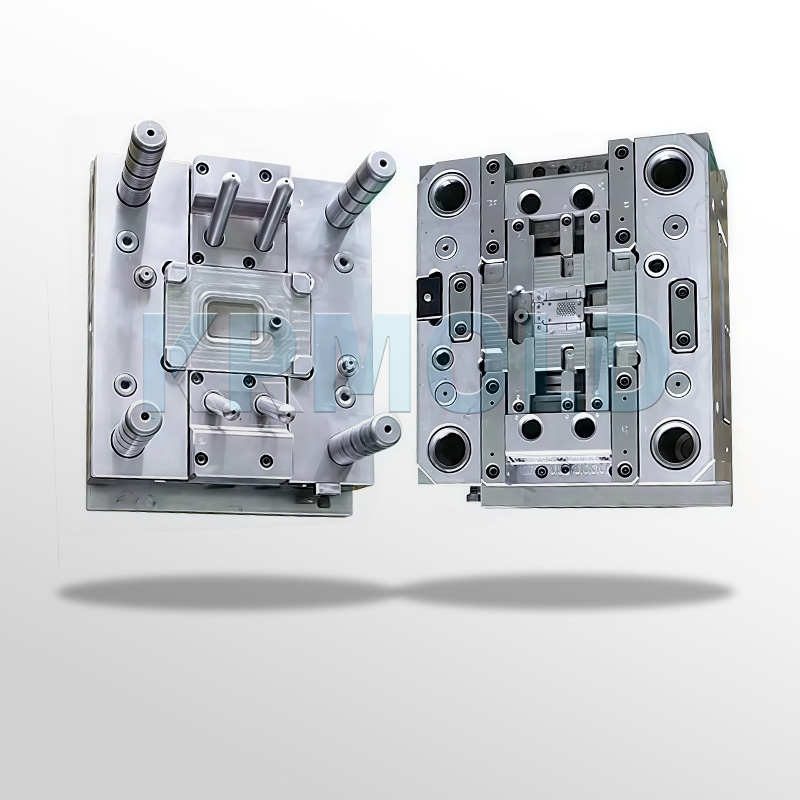

Selecting the appropriate material and surface treatment technology is crucial to switch socket plastic injection mold life and product quality. KRMOLD adheres to stringent standards in this regard:

-Cavity/Core: Made of S136 mirror steel, vacuum-hardened to a hardness of HRC 48-52, and coated with a nano-PVD coating for enhanced wear and corrosion resistance.

-Slide Rail: Made of 8407 hot-work steel, nitrided to a 0.1mm thick nitride layer for enhanced wear resistance.

-Ejector Pin: Made of SKD61, cryogenically treated, and coated with a DLC coating for high strength and wear resistance.

Features of Plastic Switch Socket Injection Mold

——

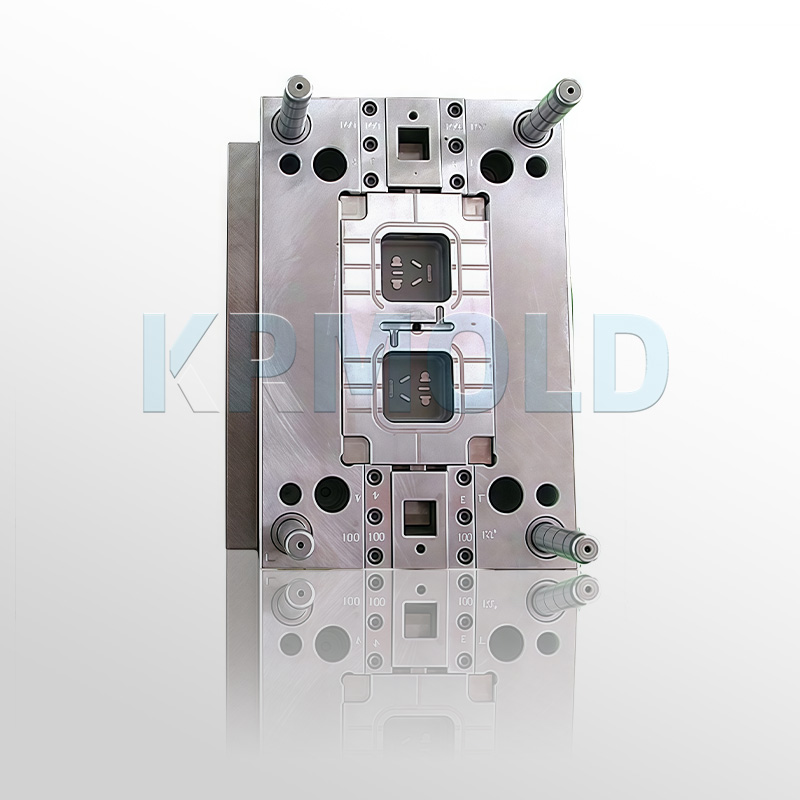

1) High precision switch socket plastic injection mold

KRMOLD plastic switch socket injection molds utilize state-of-the-art design technologies and production equipment during their design and production, ensuring the highest industry standards for molding precision. Switch socket plastic injection mold manufacturing tolerances are strictly controlled, with the socket hole spacing tolerance exceeding ±0.02mm. This ensures that KRMOLD plastic switch socket injection molds achieve a perfect fit between plugs and sockets in production. This high precision not only improves product quality but also significantly reduces material waste, thereby effectively increasing production efficiency.

Furthermore, high-precision switch socket plastic injection mold design provides a guarantee for subsequent production. When plastic switch socket injection mold precision is guaranteed, the resulting switch socket's stability and reliability are enhanced during use.

2) Customizable design for plastic switch socket injection mold

KRMOLD switch socket plastic injection molds are highly customizable, allowing for designs of varying sizes, shapes, and materials to meet specific customer requirements. KRMOLD adaptability allows it to satisfy the particular needs of several customers, therefore guaranteeing that every plastic switch socket plastic injection mold produces a product that matches market demand.

Thoroughly interacting with customers to learn their exact needs—including socket type, number of holes, and design—the KRMOLD design team From this, KRMOLD offers tailored electric switch socket plastic injection molds. For complex plastic switch sockets needing several sockets, for instance, KRMOLD may create effective and accurate switch socket plastic injection molds to guarantee top output quality and efficiency.

Tailored to the particular qualities of several materials, KRMOLD offers plastic switch socket injection mold design solutions. Whether it is polycarbonate (PC), polypropylene (PP), or other plastic materials, KRMOLD may create a switch socket plastic injection mold customized to the particular properties to guarantee flawless molding during manufacture.

3) Fast production cycles for plastic switch socket injection mold

KRMOLD switch socket plastic injection molds are typically designed to last between 800,000 and 1,000,000 injections, with a molding cycle time of less than 20 seconds. This effective production cycle allows clients to swiftly react to market demands and raise general production efficiency.

KRMOLD may shorten molding time while retaining switch socket plastic injection mold strength and accuracy by optimizing plastic switch socket injection mold construction and using sophisticated runner design. This effective production capability helps consumers to rapidly alter production schedules in response to market changes and promptly satisfy needs of consumers.

4) Standard compliance for plastic switch socket injection mold

All KRMOLD switch socket plastic injection molds comply with the GB2099.1 national standard for earthquake-resistant structures. Furthermore, KRMOLD molds are designed to meet the specific standards of the customer's region. KRMOLD plastic switch socket injection molds are highly adaptable and can perfectly meet the diverse needs of global customers, providing them with safe, reliable, and efficient switch socket plastic injection mold solutions.

All KRMOLD plastic switch socket injection molds strictly comply with the GB2099.1 national standard for earthquake-resistant structures, ensuring product safety and reliability during use. Moreover, KRMOLD electric switch socket injection molds are made to satisfy the particular specifications of the customer!s area. KRMOLD knows that electrical product safety rules and standards differ nation to country. Thus, the KRMOLD design team takes all these aspects into account to guarantee that every switch socket plastic injection mold is exactly suited to the needs of several markets.

5) Surface treatment standards for plastic switch socket injection mold

KRMOLD electric switch socket plastic injection molds feature high surface treatment standards. The matte textured surface has an Ra value controlled within the range of 0.8-1.6μm, ensuring a smooth and delicate surface finish for the final product, enhancing both visual appeal and user experience. Surface treatment isn't just for aesthetics; it's also a critical step in improving product wear and corrosion resistance.

By applying advanced surface treatment technologies such as electroplating, spraying, and sandblasting, KRMOLD ensures that the switch socket plastic injection mold surface remains in excellent condition over extended use. This is crucial for extending the plastic switch socket injection mold's lifespan and reducing product quality degradation due to surface wear.

In addition, excellent surface treatment enhances the user experience of the outlet panel. A smooth surface is not only easy to clean but also reduces static electricity accumulation, improving safety.

Why Choose KRMOLD Switch Socket Plastic Injection Molds?

——

Manufacturing plastic switch socket injection molds presents several key challenges. Leveraging its professional technical team and extensive industry experience, KRMOLD can effectively address the following:

1) Complex geometry control for electric switch socket plastic injection mold

Modern outlet panels often feature complex geometries and multiple port configurations, such as five-outlet sockets. KRMOLD plastic switch socket injection mold design achieves an accuracy of ±86 mm within a 0.2 x 86 mm area. To achieve this, KRMOLD employs an advanced beveled ejector mechanism with an angle ranging from 15° to 25° to enable damage-free demolding. The parting line design is also optimized to minimize visible seams and enhance product appearance.

2) Synergy of materials and processes

Polycarbonate (PC) is the preferred material for electric switch socket plastic injection molds due to its high strength and flame retardancy. However, its high melt viscosity and low shrinkage place higher demands on thermal control. KRMOLD uses a dual-circuit temperature control system to reduce warpage from 0.744 mm to <0.25 mm, ensuring switch socket plastic injection mold stability during production.

3) Innovative runner design for plastic switch socket injection mold

KRMOLD switch socket plastic injection mold design also incorporates a hybrid hot/cold runner system, utilizing graphene-embedded runner technology to limit melt temperature variation to ±3°C. This innovative design has achieved a 16% increase in yield in a 98.6-cavity mold, significantly improving production efficiency.

Specify the type of plastic (e.g. PP, ABS) and post-processing requirements (e.g. spraying, silk-screen printing), and provide 2D or 3D plastic part drawings should be provided. At the same time, provide the production volume, appearance requirements, tolerance standards, etc.

Generally speaking, our engineers will start to prepare the quotation immediately after the customer provides the complete production requirements. Usually it takes about 1-3 days.

The lead time for regular injection molds is usually 30-60 days, and may be longer for complex molds. For example, the typical lead time for liquid silicone molds is around 60 days, covering design, manufacturing, mold testing, etc.

High-precision processing technology: High-precision equipment such as CNC machining centers (CNC) and electric discharge machining (EDM) are used to optimize the design process in combination with CAD/CAM software. Quality control: Inspection of key dimensions of the mold by Coordinate Measuring Machine (CMM) and verification of multiple sample batches during the trial molding stage. Material Selection: Use die steel with high wear resistance (e.g. H13, S136) and surface treatment (e.g. nitriding, chrome plating) for die nuts to extend the life.

After every 50,000 molds, check the guide pillar, ejector pin and other wear parts, and clean up the residual plastic and rust on the mold surface. Use high temperature grease for sliding parts (e.g. tilt top, slider) to reduce friction loss. Ensure that the water circuit is smooth and the temperature difference is ≤5℃ to avoid cracking of the mold due to thermal stress.

Mould cost of materials accounted for about 30-40% (such as 1 ton of P20 steel price of about 20,000 yuan), processing costs accounted for more than 50% (CNC labor hourly rate of about 80-150 yuan / hour). Small batch production can choose aluminum mold or simplify the structural design; more than 100,000 pieces is recommended to use carbide inserts to enhance life!

Mould injection products need to fully meet the design requirements (such as size, appearance), and can be continuous and stable production. Mold marking, inspection reports (such as material hardness test) and engineering drawings should be complete.

Mould steel (such as S136H, NAK80 and other imported materials cost more) and the type of mold embryo (aluminum mold short-term cost is low but short life) directly affect the cost, the use of CAD/CAE/CAM design technology, hot runner system, etc. will increase the upfront investment, but can enhance the long-term benefits (such as reducing the sprues, increase production capacity).