Description of Plastic Fan Blade Injection Mould

——

Plastic fan blade injection mould are the core of precision manufacturing, determining fan blade performance and quality.

KRMOLD can provide customers with plastic fan blade injection molds. From design key points to manufacturing processes, high-precision plastic fan blade injection mould ensure consistent blade size and efficient airflow.

Customized plastic fan blade injection mould can meet the production needs of different customers for fan blades of varying sizes, shapes, and designs, meeting the specific requirements of different industries.

Parameters of Plastic Fan Blade Injection Mould

——

| Mold Name: | plastic fan blade injection mold |

| Product Size: | 300x300x180mm (Can be customized) |

| Product Description: | Fan Blade |

| Mold Cavity: | 1 cavity |

| Mold Size: | 800x800x680mm (Can be customized) |

| Suitable Machine: | DKM-650Ton |

| Mold Main Material: | S136 |

| Mold Injection System: | Hot Runner |

| Mold Ejection System: | Eject Plate |

| Mold Cycle Time: | 20 Seconds |

| Mold Running Time: | 1 M |

| Mold Features: | Multi-slider movements, high precision, and tested for balance. |

Key Design Considerations for Plastic Fan Blade Injection Molds

——

"When designing plastic fan blade injection mould, the first step is to ensure that the plastic fan blade injection mold can accommodate the specific shape of the blade. This is typically done using CAD software. Key factors that must be considered during the design process include plastic shrinkage, cooling effects, and separation from the mold wall.

The choice of ejection method is also crucial. Common ejection methods for plastic fan blade injection mould include rotary ejection and multiple slider core pulling. This mold design utilizes a three-slide core pulling mechanism with unique design features, including a hydraulic cylinder ejector, a push plate mechanism, a bent pin, and a delayed core pulling mechanism.

This plastic fan blade injection mold, used for the fan blade’s connector, features complex internal functions and six arc-shaped pull-out directions. Conventional sliders are difficult to eject, making the multiple core pulling mechanism a key consideration.

The product's shape is undercut, with a small exterior and a large interior. The slider's three-slide core pulling mechanism ensures sequential ejection of the sliders."

● Mold layout and gating system for plastic fan blade injection mold

This fan blade part is nearly circular, with five blades evenly spaced around the perimeter. Due to size constraints, the mold cavity layout adopts a 1×1 configuration, and the mold base material is FAI 4545 A60 B60 C135.

To meet the required fan blade shape, the mold design utilizes a point-gated injection system. Due to its large size, five gates are used. Each nozzle is located near the edge of the central dome, directly adjacent to each blade.

A balanced gating system ensures even material distribution, which is crucial for consistent size and weight across each blade.

● Mold structure and cooling system for plastic fan blade injection mold

This plastic fan blade injection mould features a simple structure, without complex slides or tilting mechanisms. Its design and manufacturing process are centered around balance. The cooling system is also designed to be balanced, sandwiched between the front and rear plates and featuring large circular cooling channels and seals. Thermocouples are strategically placed on the A and B plates for temperature monitoring and control.

● Precision machining and assembly for plastic fan blade injection mold

Balance is crucial in plastic fan blade injection mould design and manufacturing. High-quality tooling and new blades are used for high-speed machining of the front and rear mold cores to ensure consistent shape and dimensional tolerances for each blade.

After precision machining, three-dimensional coordinate inspection is essential to ensure accurate assembly. Rapid clamping is key to efficient modern plastic fan blade injection molding production. This mold utilizes a mechanical rapid clamping system, with V-grooves on both the fixed and movable platens ensuring tight tolerances on width, angle, and platen thickness.

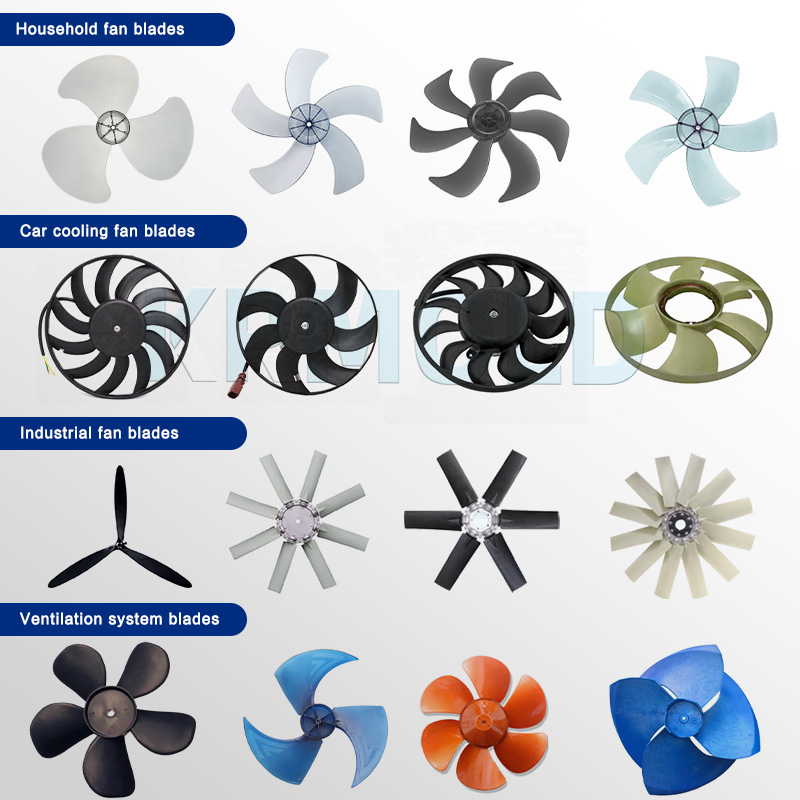

Different Types of Plastic Fan Blade Injection Mould

——

● Axial-Flow Fan Molds

This plastic fan blade injection mould design features multiple curved blades around a central hub, generating airflow parallel to the axis of rotation. Through optimized design, axial-flow fan molds can effectively control air speed and generate a vortex to help cool mechanical systems.

● Centrifugal Fan Molds

Centrifugal fan molds feature curved blades, generating airflow perpendicular to the centrifugal centerline. This enhances airflow pressure, meets aerodynamic requirements, and improves rotational efficiency.

● Cross-Flow Fan Molds

This plastic fan blade injection mold is used to produce cross-flow fans, where airflow is generated through a narrow opening perpendicular to the axis of rotation. Blade design is crucial, influencing the direction, speed, and pressure of the airflow. Adjusting the curvature and angle of the blades can optimize airflow organization and performance.

The above description demonstrates the importance of plastic fan blade injection mould design, layout, structure, and processing, as well as the applicable scenarios for different plastic fan blade injection mold types.

Plastic Fan Blade Injection Molds of Different Materials

——

The material selection for plastic fan blade injection mould is crucial to the performance and service life of the final product. Common materials for plastic fan blade injection molds include ABS and PP, both of which offer excellent fatigue resistance and are suitable for producing high-performance fan blades.

● ABS plastic fan blade injection mold

ABS (acrylonitrile butadiene styrene) is a commonly used plastic material with excellent flowability and processing properties. Compared to other materials, ABS has a higher melt index and better flowability, making it easier to fill complex mold shapes in plastic fan blade injection mould.

However, ABS is relatively weak in aging resistance, and long-term exposure to UV rays or high temperatures may cause performance degradation. Therefore, when designing plastic fan blade injection molds, it is important to consider the operating environment to ensure plastic fan blade injection mould durability and reliability.

● PP plastic fan blade injection mold

PP (polypropylene) is a lightweight plastic with good toughness and chemical stability. PP plastic fan blade injection mould also have excellent fatigue resistance, making them suitable for high-frequency use.

Although PP has average heat resistance of approximately 80°C, it offers better chemical and impact resistance than ABS in certain applications.

● PC + ABS plastic fan blade injection mold

In addition to single-material options, a combination of PC (polycarbonate) and ABS (PC + ABS) has also become a popular choice.

This composite material combines the high heat resistance of PC with the excellent processing properties of ABS, offering comprehensive performance advantages.

PC boasts a heat resistance of up to 130°C, making it suitable for environments requiring high temperatures. Its combination with ABS enhances the overall strength and toughness of the plastic fan blade injection mould, further improving the product's lifespan and stability.

Applications of Plastic Fan Blade Injection Mold

——

Plastic fan blade injection mould are used in various industries requiring air circulation and ventilation, with the following being common applications:

Home appliances: including refrigerators, air purifiers, air circulators, and exhaust fans.

Electronic cooling: including electronic components in servers, power supplies, and electronic equipment housings.

Automotive cooling: engine cooling fans, HVAC systems, and other vehicle cooling applications.

Industrial ventilation: exhausting harmful gases and promoting air circulation.

HVAC systems: used in the production of fans for HVAC systems.

Related FAQs About Plastic Fan Blade Injection Mold

——

1. What specific work will be carried out after the plastic fan blade injection mold contract is signed?

1) After signing the contract, we will first review the plastic fan blade injection mould with the customer to discuss the specific plastic fan blade injection mold requirements and finalize the design.

2) Material procurement will be carried out simultaneously with plastic fan blade injection mould design.

3) plastic fan blade injection mold production time will vary depending on plastic fan blade injection mould size and complexity.

4) Plastic fan blade injection mould trials and testing.

5) If any issues are found after the T1 trial, the plastic fan blade injection mold will be repaired and then retested in T2. Generally, three trials are required to meet the requirements.

2. How can I get a quote?

To get a detailed quote as quickly as possible and facilitate our work, please provide the following information when inquiring.

1) 3D steps for documents and 2D drawings

2) Material requirements

3) Surface treatment

4) Quantity (per order/month/year)

5) Any special requirements or requests, such as packaging, labeling, delivery, etc.

3. How do you ensure plastic fan blade injection mold quality?

1) KRMOLD have a very comprehensive "Mold Inspection Standard," a complete set of strict mold inspection systems, and an excellent inspection team.

2) KRMOLD can provide inspection reports for all plastic fan blade injection mold materials and proof of purchase.

4.Does your company offer product design services?

1) Absolutely. KRMOLD has helped countless clients from Europe and North America invent new products.

2) Simply provide your requirements, which can be a single image or a few sketches, and our engineers will work with you.

3) KRMOLD will sign a "Confidentiality Agreement" and "Intellectual Property Agreement" with you.

Specify the type of plastic (e.g. PP, ABS) and post-processing requirements (e.g. spraying, silk-screen printing), and provide 2D or 3D plastic part drawings should be provided. At the same time, provide the production volume, appearance requirements, tolerance standards, etc.

Generally speaking, our engineers will start to prepare the quotation immediately after the customer provides the complete production requirements. Usually it takes about 1-3 days.

The lead time for regular injection molds is usually 30-60 days, and may be longer for complex molds. For example, the typical lead time for liquid silicone molds is around 60 days, covering design, manufacturing, mold testing, etc.

High-precision processing technology: High-precision equipment such as CNC machining centers (CNC) and electric discharge machining (EDM) are used to optimize the design process in combination with CAD/CAM software. Quality control: Inspection of key dimensions of the mold by Coordinate Measuring Machine (CMM) and verification of multiple sample batches during the trial molding stage. Material Selection: Use die steel with high wear resistance (e.g. H13, S136) and surface treatment (e.g. nitriding, chrome plating) for die nuts to extend the life.

After every 50,000 molds, check the guide pillar, ejector pin and other wear parts, and clean up the residual plastic and rust on the mold surface. Use high temperature grease for sliding parts (e.g. tilt top, slider) to reduce friction loss. Ensure that the water circuit is smooth and the temperature difference is ≤5℃ to avoid cracking of the mold due to thermal stress.

Mould cost of materials accounted for about 30-40% (such as 1 ton of P20 steel price of about 20,000 yuan), processing costs accounted for more than 50% (CNC labor hourly rate of about 80-150 yuan / hour). Small batch production can choose aluminum mold or simplify the structural design; more than 100,000 pieces is recommended to use carbide inserts to enhance life!

Mould injection products need to fully meet the design requirements (such as size, appearance), and can be continuous and stable production. Mold marking, inspection reports (such as material hardness test) and engineering drawings should be complete.

Mould steel (such as S136H, NAK80 and other imported materials cost more) and the type of mold embryo (aluminum mold short-term cost is low but short life) directly affect the cost, the use of CAD/CAE/CAM design technology, hot runner system, etc. will increase the upfront investment, but can enhance the long-term benefits (such as reducing the sprues, increase production capacity).