Introduction to Plastic Chair Injection Mold

——

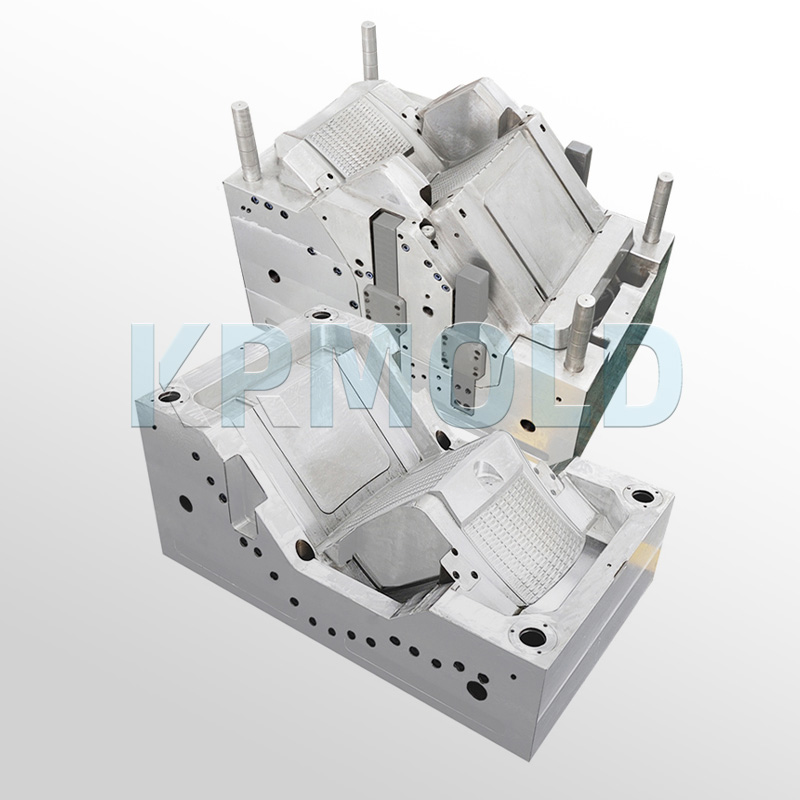

A plastic chair injection mold is a device used to shape molten plastic into a chair. First, the plastic is melted until it becomes a viscous liquid. Then, the new liquid plastic is injected into the plastic chair injection mould. After cooling, the plastic hardens and takes the shape of the chair. This plastic chair injection mold is made of a sturdy metal (usually metal or aluminum). It can be used frequently and is ideal for large-scale production. Plastic chair injection mould can be designed to produce thousands of identical chairs in large factories. KRMOLD plastic chair injection molds can produce traditional and customized chair styles for a wide range of indoor and outdoor applications.

In the manufacturing process of plastic chair injection mould, KRMOLD pays close attention to the cycle time, parting line, wall thickness, and venting. KRMOLD has developed a mature technology and experience in mold design, including parting line smoothness, optimal structure of armrest sliders, ejector pins, and venting, special designs such as gas-assisted injection molding, and interchangeable backrest inserts.

Parameters of Plastic Chair Injection Mold

——

·Mold Type: Plastic Chair Injection Mold

·Mold Steel: P20/S50C

·Mold Cavity: Single/Multi-cavity/Multi-cavity with Interchangeable Inserts

·Heating System: Oil/Electric Rod Heating

·Runner System: Cold or Hot Runner, depending on the product

·Mold Cycle Life: Depending on the mold steel, P20 can produce approximately 300,000 cycles.

Advantages of Plastic Chair Injection Mould

——

(1)Fast Production Speed

Once the plastic chair injection mold is ready, the machine produces chair after chair in seconds. This speed allows the factory to quickly produce hundreds of chairs. This method is very practical for businesses that need to produce large quantities of chairs in a short period of time.

(2)Cost-Effectiveness

Chairs made from plastic chair injection mould can reduce the final price. While the plastic chair injection mold may initially be expensive, it can be reused repeatedly, which helps reduce the cost per chair. Furthermore, since the machine performs most of the work, less labor is required. This saves on wages and other expenses.

(3)Consistent Quality

Every chair made from the same plastic chair injection mould looks and feels identical. This method significantly reduces the chance of errors or damaged parts. Each chair has the same length, shape, and strength. This consistency is crucial for manufacturers who want to deliver the same exceptional product every time. Precision is guaranteed.

(4)Sturdy and Durable Chairs

Chairs made with plastic chair injection molds are exceptionally strong. The plastic used in this technique is strong and durable, ensuring a long lifespan. These chairs can withstand heavy loads without breaking. They are also resistant to water, cold, and most chemicals, making them ideal for both indoor and outdoor use.

(5)Reduced Waste

High-Pressure Plastic Molding produces virtually no waste. The machine only injects the correct amount of plastic into the plastic chair injection mould. The remaining plastic can often be melted down and reused. This benefits the environment and saves money. Making chairs with less waste is a smart move for the planet.

(6)Easily Add Color and Style

Plastic chair injection molds allow you to create chairs in a variety of colors and patterns. You can add color to the plastic before it goes into the plastic chair injection mould. This way, the color stays on the chair throughout its use, rather than just on the floor. It also resists fading. You can also create interesting shapes, patterns, and even your organization's logo on the chair.

(7)Safe and Ergonomic Design

Plastic chair injection molds smoothly create comfortable and safe chairs. You can design curves, armrests, and backrests to perfectly shape the body. These designs help people sit comfortably for extended periods. Furthermore, the chair's edges are clean, reducing the risk of damage.

Entire Plastic Chair Injection Mold Manufacturing Process

——

(1)Scan the original sample to measure points;

(2)Use a computer to create a 3D design of the chair;

(3)The actual design of the plastic chair injection mold begins. The plastic chair injection mould design will be sent to the customer for confirmation, and then mold processing will begin. KRMOLD will also provide weekly plastic chair injection mould progress reports to ensure the customer has a clear understanding of the plastic chair injection mold manufacturing process.

(4)Three plastic chair injection trials.

(4.1)T0 is for KRMOLD to inspect the plastic chair injection mould itself. If any issues arise, we will make corrections ourselves.

(4.2) T1 is for the customer. If you don't have time to inspect it directly, don't worry; KRMOLD will provide you with a plastic chair injection mold test video and report. KRMOLD will modify the mold based on customer feedback, which usually takes 10 days. KRMOLD will then send samples for customer confirmation. Once KRMOLD receives the customer's approval, KRMOLD will prepare the plastic chair injection mould for shipment.

(4.3) A final plastic chair injection mold trial allows KRMOLD to inspect and confirm that the mold functions properly at the customer's site.

(5)

Apply anti-rust oil on the plastic chair injection mould surface, wrap it with plastic film, and finally put it in a wooden box for transportation.

Applications of Plastic Chair Injection Mold

——

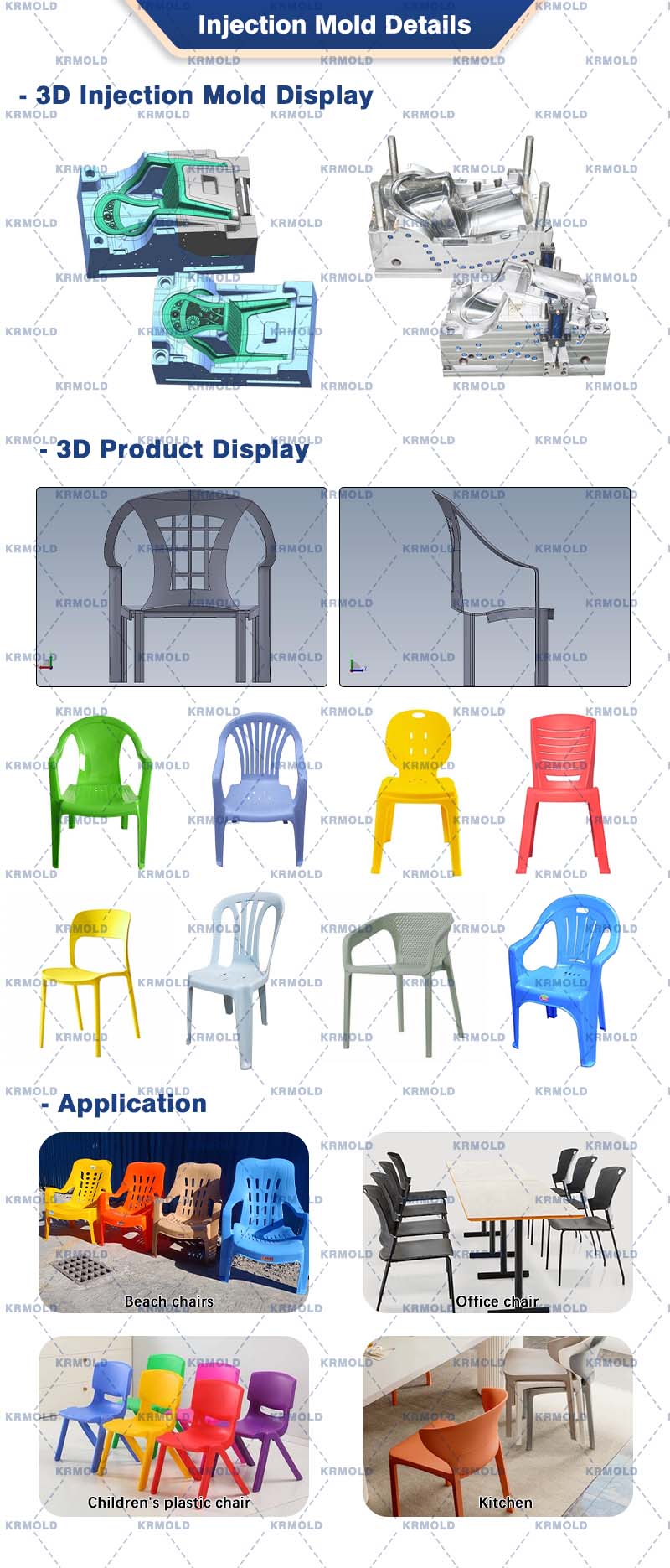

KRMOLD plastic chair injection mould support the production of various chair types.

KRMOLD plastic chair injection molds cover traditional styles as well as some customized ones.

Based on different customer groups, KRMOLD plastic chair injection mould include children's chair plastic chair injection molds and adult plastic chair injection mould.

Based on different location environments, KRMOLD plastic chair injection molds include indoor plastic chair injection mould and outdoor plastic chair injection molds.

Based on different customer requirements, KRMOLD offer plastic chair injection mould for chairs with and without armrests, classic styles, and some customized European styles.

If you can't find the type of plastic chair you're looking for on the KRMOLD website, please contact us immediately. KRMOLD professional sales team will respond as soon as possible.

·FAQ About Plastic Chair Injection Molds

1. What is the lifespan of plastic chair injection molds?

The quality of the steel material is a key factor affecting plastic chair injection mould life. Different plastic chair materials require appropriate mold steel.

KRMOLD engineers will provide customers with reasonable suggestions based on actual conditions.

2. Is the parting line of the KRMOLD plastic chair injection mold good? Are there any sharp edges?

The parting line of the KRMOLD plastic chair injection mould is smooth and rounded, without sharp edges. This ensures that the molded chairs will not scratch your hands. Therefore, KRMOLD always monitor injection pressure and ensure CNC milling of the cavities and cores in the plastic chair injection molds.

3. How can I ensure my chair design will fit the plastic chair injection mould?

To ensure your chair design is compatible with the mold-making process, consider factors such as consistent wall thickness, chamfers that avoid possible jams in the molded part, and draft angles that facilitate ejection. Working with an experienced mold-maker can help optimize your design for improved moldability.

4. What are the most common materials used for plastic chair injection mould, considering the final product?

The choice of plastic chair injection mold material not only affects the mold's lifespan but also the quality of the finished chair. Steel is typically used due to its durability and cost-effectiveness.

However, for high-volume production or complex designs, aluminum or even precision-grade materials may be chosen due to their superior surface finish and detail reproduction.

Specify the type of plastic (e.g. PP, ABS) and post-processing requirements (e.g. spraying, silk-screen printing), and provide 2D or 3D plastic part drawings should be provided. At the same time, provide the production volume, appearance requirements, tolerance standards, etc.

Generally speaking, our engineers will start to prepare the quotation immediately after the customer provides the complete production requirements. Usually it takes about 1-3 days.

The lead time for regular injection molds is usually 30-60 days, and may be longer for complex molds. For example, the typical lead time for liquid silicone molds is around 60 days, covering design, manufacturing, mold testing, etc.

High-precision processing technology: High-precision equipment such as CNC machining centers (CNC) and electric discharge machining (EDM) are used to optimize the design process in combination with CAD/CAM software. Quality control: Inspection of key dimensions of the mold by Coordinate Measuring Machine (CMM) and verification of multiple sample batches during the trial molding stage. Material Selection: Use die steel with high wear resistance (e.g. H13, S136) and surface treatment (e.g. nitriding, chrome plating) for die nuts to extend the life.

After every 50,000 molds, check the guide pillar, ejector pin and other wear parts, and clean up the residual plastic and rust on the mold surface. Use high temperature grease for sliding parts (e.g. tilt top, slider) to reduce friction loss. Ensure that the water circuit is smooth and the temperature difference is ≤5℃ to avoid cracking of the mold due to thermal stress.

Mould cost of materials accounted for about 30-40% (such as 1 ton of P20 steel price of about 20,000 yuan), processing costs accounted for more than 50% (CNC labor hourly rate of about 80-150 yuan / hour). Small batch production can choose aluminum mold or simplify the structural design; more than 100,000 pieces is recommended to use carbide inserts to enhance life!

Mould injection products need to fully meet the design requirements (such as size, appearance), and can be continuous and stable production. Mold marking, inspection reports (such as material hardness test) and engineering drawings should be complete.

Mould steel (such as S136H, NAK80 and other imported materials cost more) and the type of mold embryo (aluminum mold short-term cost is low but short life) directly affect the cost, the use of CAD/CAE/CAM design technology, hot runner system, etc. will increase the upfront investment, but can enhance the long-term benefits (such as reducing the sprues, increase production capacity).