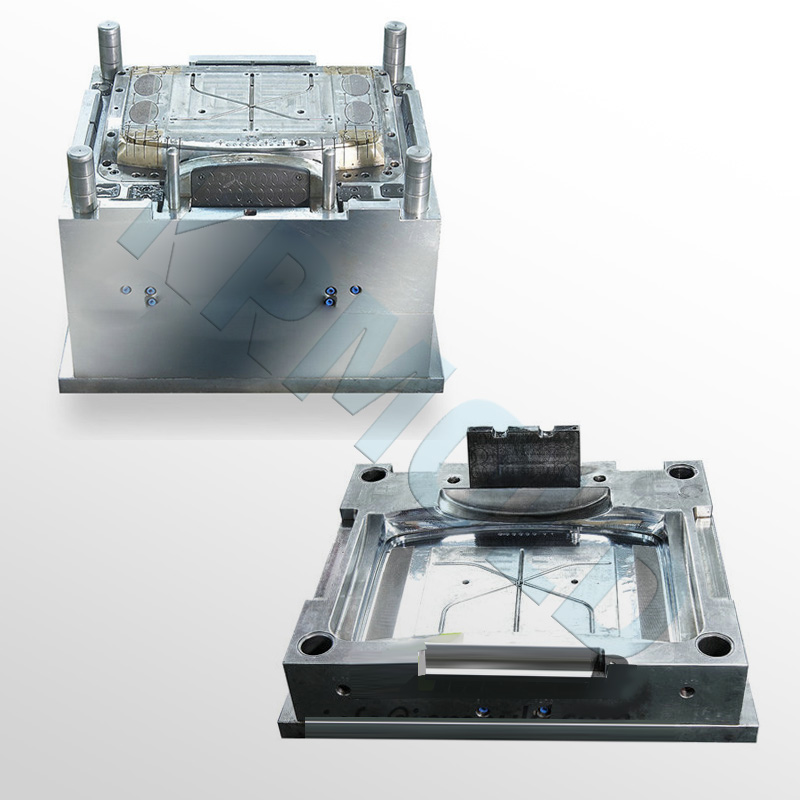

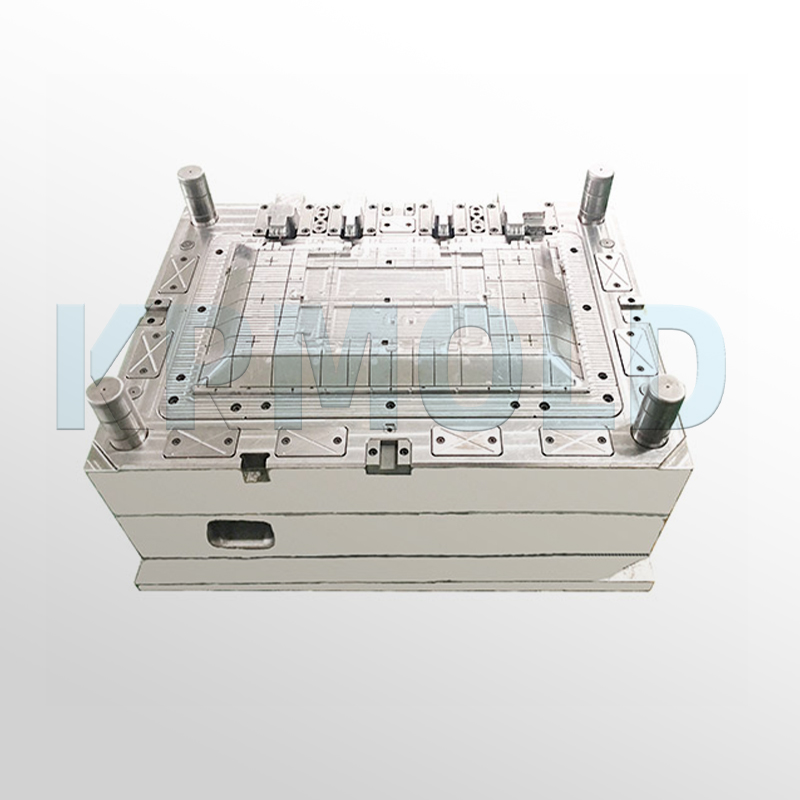

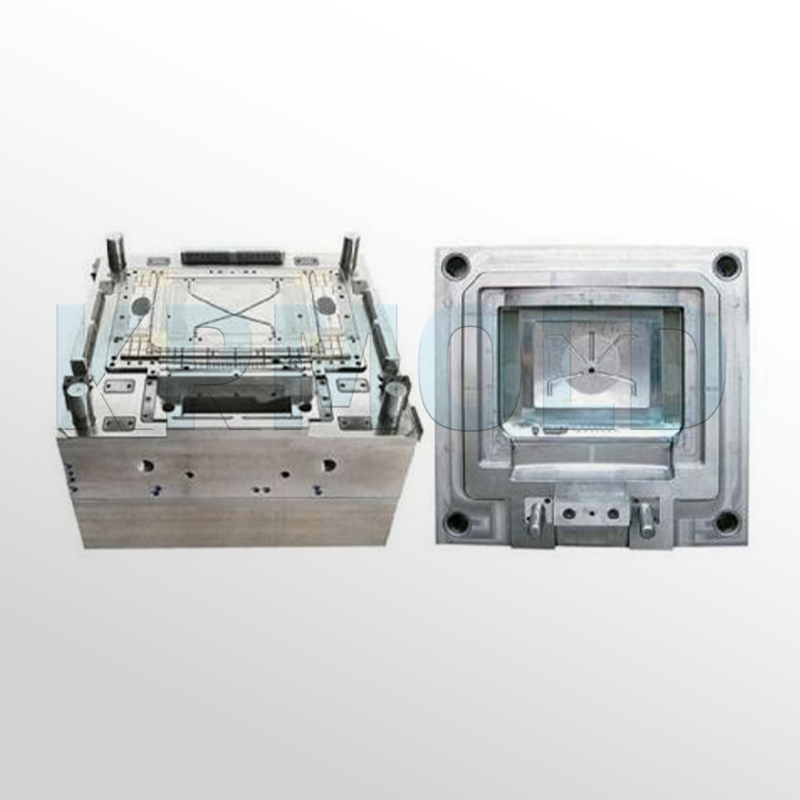

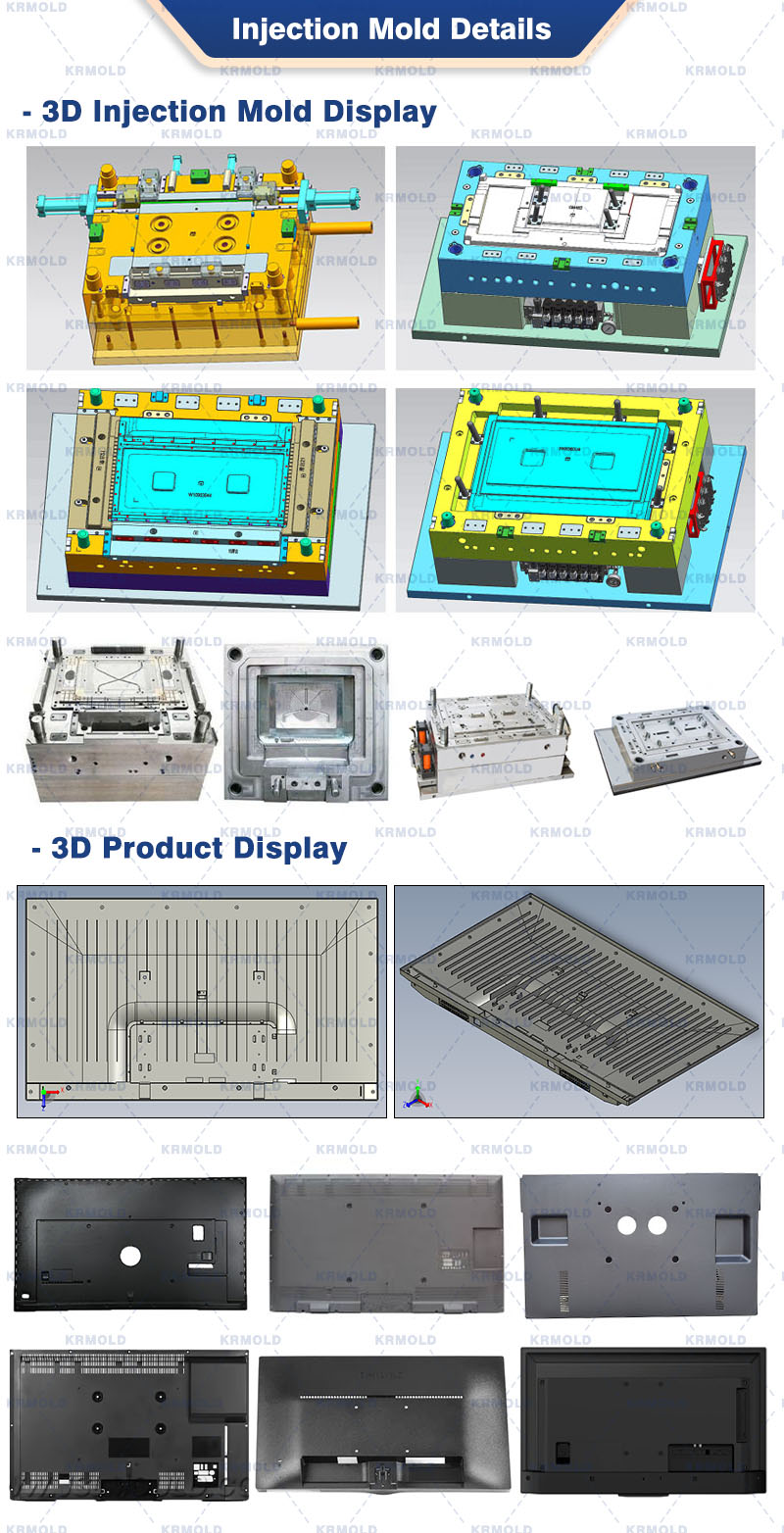

Description of TV Back Cover Injection Mold

——

KRMOLD is dedicated to providing customers with high-quality TV back cover injection molds that meet diverse needs while ensuring excellent product performance and appearance. These TV back cover plastic injection mould play a critical role in modern TV production.

KRMOLD can manufacture TV back cover injection molds of various sizes for CRT, LCD, and LED TVs, tailored to customer needs. KRMOLD team of engineers will use customer-provided TV back cover plastic injection mould designs and advanced software tools to precisely craft exquisite TV back cover injection molds. Once the TV back cover plastic injection mould design is confirmed, KRMOLD uses CNC machining for precision inspection and EDM processes to further ensure TV back cover injection mold quality.

KRMOLD is committed to quickly and efficiently producing high-quality TV back cover plastic injection mould for customers, providing customized solutions. To learn more about KRMOLD plastic injection molding services and how they can meet your TV back cover injection mold needs, please contact KRMOLD today!

Parameter of TV Back Cover Plastic Injection Mould

——

| Project | Description |

| Product | Injection mold parts |

| Plastic materials | ABS, PP, nylon, PC, or other materials as required |

| Services | OEM, design based on your ideas or mold and production according to your drawings |

| Production dimensions | Based on your drawings or samples |

| Packaging | Standard cartons, pallets, or custom packaging |

| Prototyping | 3D printing, CNC, laser cutting, etc. |

Advantages of TV Back Cover Injection Mold

——

●Customized Design: KRMOLD offers OEM services, customizing TV back cover plastic injection mould based on specific customer needs and design requirements. Whether it's size, shape, or functionality, KRMOLD can meet them.

●Excellent Material Selection: KRMOLD is extremely strict in selecting TV back cover injection mold materials, ensuring they are wear-resistant, tough, and suitable for plastic injection molding, such as ABS, PP, and nylon. These materials not only ensure TV back cover plastic injection mould strength but also optimize the production process.

●Precision Machining: By introducing gas-assisted injection molding technology, KRMOLD effectively eliminates the surface shrinkage problem that can occur with traditional molds, shortening molding cycles and reducing material waste.

●Strict Quality Control: KRMOLD implements stringent quality control measures at every stage of TV back cover injection mold production. From design to production to final product inspection, KRMOLD ensures that every TV back cover plastic injection mould meets industry standards.

KRMOLD Technological Breakthrough in TV Back Cover Injection Mold Manufacturing

——

As television screens continue to grow, the strength requirements for their back covers are also increasing. KRMOLD has improved TV back cover plastic injection mould strength by increasing the thickness of reinforcing ribs and, using gas-assisted injection molding technology, has successfully addressed the issues of surface shrinkage and long molding cycles. This innovation significantly improves the economic efficiency of the TV back cover injection mold, reducing production costs while ensuring quality.

KRMOLD strategically positioned the gate during TV back cover plastic injection mould design, effectively minimizing weld marks and resulting in a smooth, seamless surface finish, significantly enhancing the appearance. This high-quality TV back cover injection mold can produce excellent results on standard injection molding machines, meeting the market's dual demands for aesthetics and durability.

TV Back Cover Injection Mold Material Selection

——

Mold material selection is crucial in the manufacturing process of TV back cover injection molds. Key performance indicators include:

-Basic Mold Material Properties: The material used for TV back cover plastic injection mould must possess excellent wear resistance, toughness, hardness, and red hardness (red hardness refers to the mold material's ability to maintain hardness and structural stability at high temperatures). When selecting materials, it's also important to consider performance requirements under actual operating conditions, such as oxidation resistance, compressive strength, tensile strength, flexural strength, and fatigue strength. These properties directly impact the lifespan and production efficiency of the TV back cover injection mold.

-Mold Material Processability: Mold material processability is also a key factor in selection, including machinability, quenching temperature, quenching deformation, hardenability, and hardenability. Furthermore, sensitivity to oxidation and decarburization must be considered to ensure the stability of the TV back cover plastic injection mould during production.

-Mold Material Metallurgical Quality and Other Considerations: The metallurgical quality of the mold material significantly impacts its performance. Only materials with excellent metallurgical quality can fully realize the various properties of the TV back cover injection mold. Common metallurgical quality indicators include smelting quality, forging and rolling processes, heat treatment and finishing results, thermal conductivity, and raw material purity. Furthermore, mold material price and versatility are also important factors that should not be overlooked during the selection process.

-Among many materials, ABS is widely used in the manufacture of TV back cover plastic injection mould. ABS offers excellent comprehensive properties, including high impact toughness, excellent mechanical strength, dimensional stability, good chemical resistance, and electrical properties. Its ease of molding and machining allows for excellent bonding with 372 acrylic glass, supports two-color injection molding, and can be chrome-plated. This makes ABS an ideal material for TV back cover injection molds and is suitable for the production of various mechanical parts, wear-resistant parts, transmission parts, and telecommunications components.

| Item Name | ABS Material |

| Injection Molding Type | General Purpose Type |

| Temperature (°C) | 80-85 |

| Time (h) | 2-3 |

| Material Density (g/cm³) | 1.05-1.15 |

| Melt Flow Rate (g/10min) | 160-180 |

| Impact Strength (kJ/m²) | 15-20 |

| Tensile Strength (MPa) | 20-25 |

| Injection Pressure (MPa) | 80-150 |

| Recommended Screw Speed (r/min) | 30 |

| Suitable Molding Method | Column Molding Allowed |

Specify the type of plastic (e.g. PP, ABS) and post-processing requirements (e.g. spraying, silk-screen printing), and provide 2D or 3D plastic part drawings should be provided. At the same time, provide the production volume, appearance requirements, tolerance standards, etc.

Generally speaking, our engineers will start to prepare the quotation immediately after the customer provides the complete production requirements. Usually it takes about 1-3 days.

The lead time for regular injection molds is usually 30-60 days, and may be longer for complex molds. For example, the typical lead time for liquid silicone molds is around 60 days, covering design, manufacturing, mold testing, etc.

High-precision processing technology: High-precision equipment such as CNC machining centers (CNC) and electric discharge machining (EDM) are used to optimize the design process in combination with CAD/CAM software. Quality control: Inspection of key dimensions of the mold by Coordinate Measuring Machine (CMM) and verification of multiple sample batches during the trial molding stage. Material Selection: Use die steel with high wear resistance (e.g. H13, S136) and surface treatment (e.g. nitriding, chrome plating) for die nuts to extend the life.

After every 50,000 molds, check the guide pillar, ejector pin and other wear parts, and clean up the residual plastic and rust on the mold surface. Use high temperature grease for sliding parts (e.g. tilt top, slider) to reduce friction loss. Ensure that the water circuit is smooth and the temperature difference is ≤5℃ to avoid cracking of the mold due to thermal stress.

Mould cost of materials accounted for about 30-40% (such as 1 ton of P20 steel price of about 20,000 yuan), processing costs accounted for more than 50% (CNC labor hourly rate of about 80-150 yuan / hour). Small batch production can choose aluminum mold or simplify the structural design; more than 100,000 pieces is recommended to use carbide inserts to enhance life!

Mould injection products need to fully meet the design requirements (such as size, appearance), and can be continuous and stable production. Mold marking, inspection reports (such as material hardness test) and engineering drawings should be complete.

Mould steel (such as S136H, NAK80 and other imported materials cost more) and the type of mold embryo (aluminum mold short-term cost is low but short life) directly affect the cost, the use of CAD/CAE/CAM design technology, hot runner system, etc. will increase the upfront investment, but can enhance the long-term benefits (such as reducing the sprues, increase production capacity).