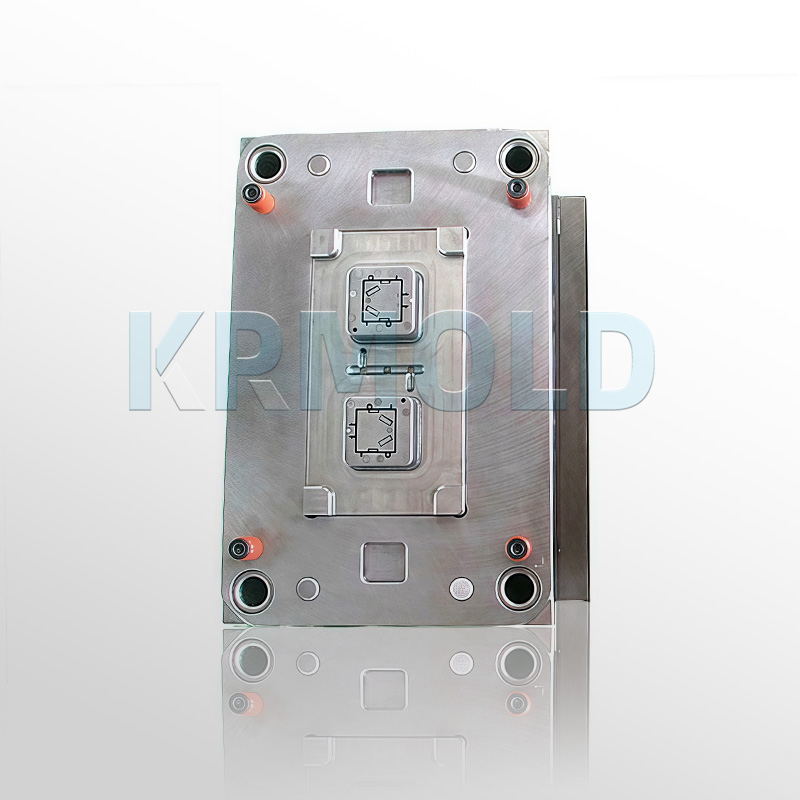

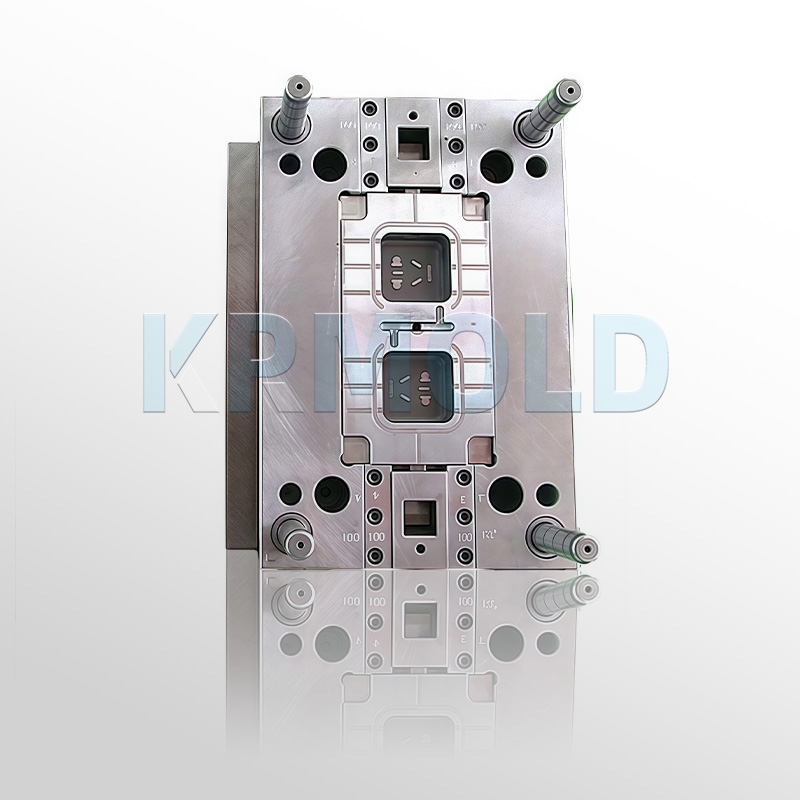

Description of Plastic Plug Socket Injection Mold

——

Customizing plastic plug socket injection molds allows one to create switch socket in a range of forms and sizes. Durable plug sockets meeting safety standards may be made by injecting the proper material into the switch socket injection mold and regulating the mold using pressure, temperature, among others.

These comprise UL certification in North America, CE certification in Europe, and several country criteria in Asia. KRMOLD plug socket plastic injection molds not only satisfy these requirements but also go through thorough testing to guarantee their safety and dependability in real-world use.

Parameters of Switch Socket Injection Mold

——

Item# | Item | Description |

| 1 | Mold standard | DME or HASCO |

| 2 | Mold Base | LKM,DME, HASCO, FUTABA |

| 3 | Cavity/Core steel | H13,S-7,S136,SS420,NAK80,P20 |

| 4 | Hot Runner | MOULD MASTER, MASTER TIP, HUSKY, HASCO, DME, YUDO, INCOE, THERMOPLAY, SYNVENTIVE. |

| 5 | Hydraulic cylinder | PARKER, TAIYO, STAUBLI, JUFAN |

| 6 | Mold components | DME, Progressive, PCS, Punch, Royal, etc |

| 7 | Steel Treatment | Heat Treatment, Nitriding, Chrome Plating |

| 8 | Surface finish | SPI standard, VDI EDM, Texture, etc |

| 9 | Plastic Material | PP, PC, ABS, PE, HDPE, PET, POM, PMMA, PA(GF), PBT(GF), PVC, PPS, PEI, PEEK, LCP, PSU |

| 10 | Design software | CAD,UG, ProE, Solidworks |

Advantages of Plastic Plug Socket Injection Mold

——

1)Flexible plastic plug socket injection mold

Companies looking for specialized plastic plug socket solutions would find ideal use for KRMOLD switch socket injection molds since they allow production of plug sockets in many different forms and sizes. KRMOLD plastic plug socket injection molds offer adaptable options for specialized outlets, industrial machinery, or general household electrical appliances.The flexibility of switch socket injection molds enables them to constantly broaden their product range and better satisfy a range of consumer expectations.

2)Durable switch socket injection mold

Made of premium materials, KRMOLD forms can resist regular use and wear. Capable of enduring high-intensity manufacturing settings, KRMOLD employs mold steels like as H13 and S136, which provide great wear resistance and strength.

Furthermore, KRMOLD pays great care to detail in plastic plug socket injection mold construction to guarantee that every part of the switch socket injection mold is exactly computed to prolong its lifetime. High-quality products and a long lifespan of its switch sockets are the objectives of KRMOLD.

3)High precision plastic plug socket injection mold

To guarantee constant quality and precision for every switch socket, KRMOLD switch socket injection mold design centers on exact specifications. KRMOLD uses high-precision measuring tools like coordinate measuring machines to ensure the dimensional and positional accuracy of every plastic plug socket injection mold component.High-precision molds help customers not only increase manufacturing efficiency but also minimize waste of raw materials. Every product is carefully inspected to guarantee customers receive only premium switch socket.

4)Efficient-production switch socket injection mold

KRMOLD plastic plug socket injection molds help to increase manufacturing efficiency, hence lowering output costs and time. KRMOLD allows for fast product iterations and production by means of enhanced switch socket injection mold design and processing.

Using an effective hot runner system, for instance, might lower the flow resistance of the plastic melt in the plug socket plastic injection mold and thus speed molding. Moreover, a well-designed cooling system reduces cooling time dramatically, therefore enhancing general production efficiency.

Switch Socket Injection Mold Design Considerations

——

1)Product Structure

KRMOLD designers created a thorough mold cavity arrangement dependent on the demands of the consumer for the switch socket. This procedure guarantees strength and performance after molding in addition to paying attention to the look of the product. Using simulation analysis software, KRMOLD can predict potential defects during the design phase and make proactive adjustments.

2)Plastic plug socket injection mold release

To ensure smooth demolding, KRMOLD meticulously designed the draft angle and ejection system to avoid damage during the demolding process. This design not only improves production efficiency but also reduces switch socket injection mold maintenance costs.

3)Precision control for plastic plug socket injection mold

During switch socket injection mold manufacturing, KRMOLD uses high-precision measuring equipment to ensure the dimensional and positional accuracy of each mold component. Through a rigorous quality control process, KRMOLD ensures that every mold component meets design requirements, thereby improving overall production quality.

4) Material selection for plastic plug socket injection mold

KRMOLD selects high-quality mold steels suitable for plastic molding, such as P20 and NAK80, to ensure mold wear resistance and longevity. These materials offer excellent mechanical and processing properties, meeting the demands of high-intensity production environments.

5)Cooling System for switch socket injection mold

A properly designed cooling channel is crucial for improving plug socket plastic injection mold production efficiency. KRMOLD has designed a scientific cooling system for the switch socket injection mold to ensure uniform cooling during the injection molding process, thereby improving production efficiency and product quality.

Plastic Plug Socket Injection Mold Manufacturing Process

——

1)Switch socket injection mold design phase

First, plug socket plastic injection mold design is performed based on the product drawings and production requirements for the switch socket. Computer-aided design software is used to create a 3D mold model, detailing and optimizing the mold structure, dimensions, parting surfaces, gating system, and cooling system.

Using simulation analysis software such as Moldflow, KRMOLD simulates the flow and cooling of the plastic melt in the mold, predicting potential defects and enabling proactive design adjustments. This meticulous planning phase lays a solid foundation for subsequent processing and production.

2)Switch socket injection mold processing

During the processing phase, KRMOLD uses CNC to mill, drill, and bore mold steel, precisely manufacturing mold components such as cavities, cores, gating systems, and cooling channels. For complex shapes and structures, electrical discharge machining (EDM) may be used.

During the processing, dimensional accuracy and surface finish are strictly controlled to ensure plastic plug socket injection mold quality. Every detail impacts the performance of the final product, so we strive for perfection at every step.

3)Switch socket injection mold heat treatment

Heat treatment of processed mold components is a crucial step in improving plastic plug socket injection mold performance. Through appropriate heat treatment processes, such as quenching and tempering, KRMOLD can enhance the switch socket injection mold's hardness, strength, and wear resistance. This process not only extends the plastic plug socket injection mold's lifespan but also improves its stability during high-intensity production.

4)Switch socket injection mold surface treatment

To enhance corrosion resistance, mold release properties, and surface finish, KRMOLD treats the mold surface. Common surface treatment methods include chrome plating, nickel plating, and nitriding. Chrome plating improves the switch socket injection mold's surface hardness and smoothness, enhancing its corrosion resistance. Nitriding forms a hard, wear-resistant nitride layer on the mold surface, improving its wear resistance and mold release properties.

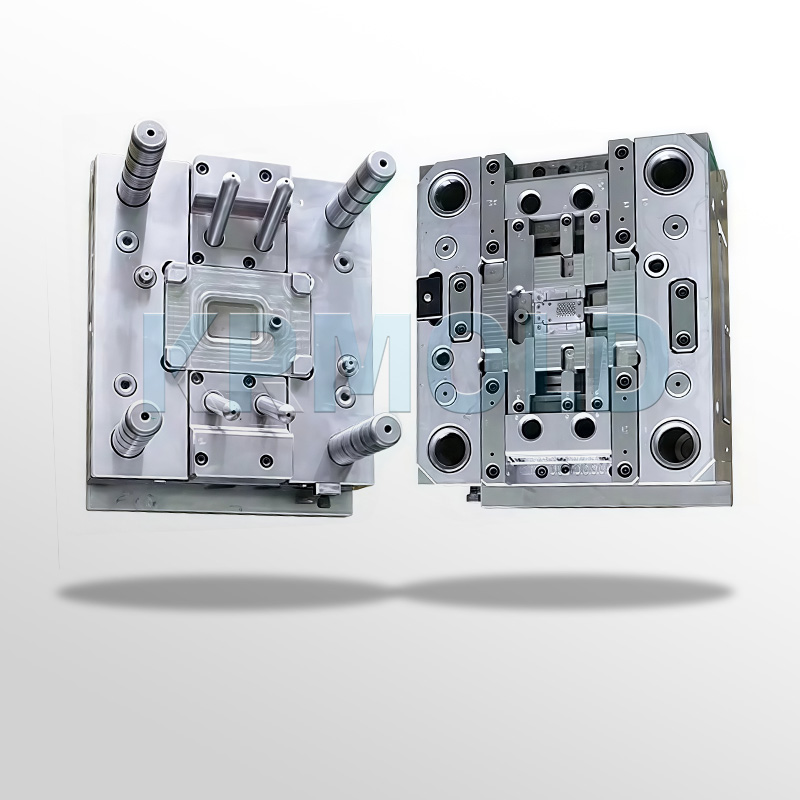

5)Plastic plug socket injection mold assembly phase

The plastic plug socket injection mold components, which have undergone machining, heat treatment, and surface treatment, are assembled. During assembly, installation and commissioning are carried out strictly in accordance with design requirements to ensure precise fit and flexible movement between components. The guide mechanism and ejector mechanism are commissioned to ensure smooth mold opening and closing and proper functioning of the ejector mechanism.

6)Switch socket injection mold trial and debugging phase

After plastic plug socket injection mold assembly is complete, a trial mold is conducted. The switch socket injection mold is installed on the injection molding machine, and plastic melt is injected for trial production. The trial mold is used to check the molding results, such as the dimensional accuracy, appearance quality, and mold release of the plastic product. Based on the trial mold results, the plastic plug socket injection mold is further debugged and optimized until a qualified plastic plug socket is produced.

Specify the type of plastic (e.g. PP, ABS) and post-processing requirements (e.g. spraying, silk-screen printing), and provide 2D or 3D plastic part drawings should be provided. At the same time, provide the production volume, appearance requirements, tolerance standards, etc.

Generally speaking, our engineers will start to prepare the quotation immediately after the customer provides the complete production requirements. Usually it takes about 1-3 days.

The lead time for regular injection molds is usually 30-60 days, and may be longer for complex molds. For example, the typical lead time for liquid silicone molds is around 60 days, covering design, manufacturing, mold testing, etc.

High-precision processing technology: High-precision equipment such as CNC machining centers (CNC) and electric discharge machining (EDM) are used to optimize the design process in combination with CAD/CAM software. Quality control: Inspection of key dimensions of the mold by Coordinate Measuring Machine (CMM) and verification of multiple sample batches during the trial molding stage. Material Selection: Use die steel with high wear resistance (e.g. H13, S136) and surface treatment (e.g. nitriding, chrome plating) for die nuts to extend the life.

After every 50,000 molds, check the guide pillar, ejector pin and other wear parts, and clean up the residual plastic and rust on the mold surface. Use high temperature grease for sliding parts (e.g. tilt top, slider) to reduce friction loss. Ensure that the water circuit is smooth and the temperature difference is ≤5℃ to avoid cracking of the mold due to thermal stress.

Mould cost of materials accounted for about 30-40% (such as 1 ton of P20 steel price of about 20,000 yuan), processing costs accounted for more than 50% (CNC labor hourly rate of about 80-150 yuan / hour). Small batch production can choose aluminum mold or simplify the structural design; more than 100,000 pieces is recommended to use carbide inserts to enhance life!

Mould injection products need to fully meet the design requirements (such as size, appearance), and can be continuous and stable production. Mold marking, inspection reports (such as material hardness test) and engineering drawings should be complete.

Mould steel (such as S136H, NAK80 and other imported materials cost more) and the type of mold embryo (aluminum mold short-term cost is low but short life) directly affect the cost, the use of CAD/CAE/CAM design technology, hot runner system, etc. will increase the upfront investment, but can enhance the long-term benefits (such as reducing the sprues, increase production capacity).