Description of Refrigerator Plastic Parts Injection Mold

——

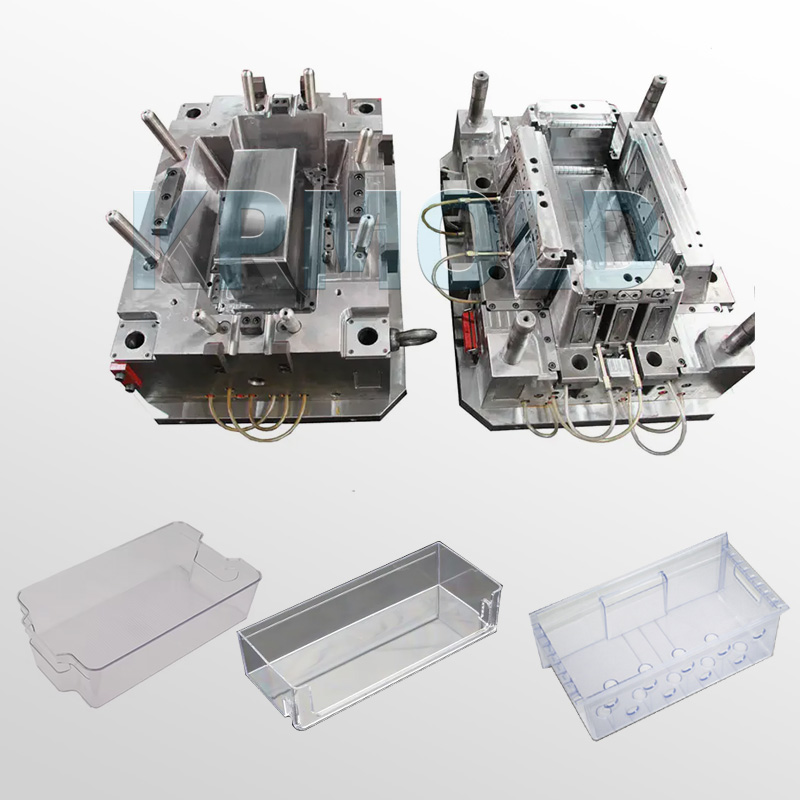

KRMOLD specializes in producing various refrigerator plastic parts injection molds, particularly refrigerator drawer accessories injection mould capable of creating refrigerator drawers. KRMOLD is committed to providing customers with efficient, high-quality solutions. KRMOLD refrigerator plastic parts injection molds are suitable not only for double-door and single-door refrigerators, but also for a wide range of refrigerator types.

KRMOLD refrigerator drawer accessories injection mould utilize advanced plastic injection molding technology to efficiently produce a variety of plastic refrigerator drawer designs. These drawers are designed for freshness preservation and freezing, perfect for storing vegetables, fruits, meat, fish, and other foods. KRMOLD refrigerator plastic parts injection molds keep food clearly organized, prevent odors, and eliminate clutter.

KRMOLD refrigerator drawer accessories injection mould offer customers a simpler and more user-friendly refrigerator food storage solution. This not only improves internal refrigerator space utilization but also enhances the user experience, ensuring convenience and comfort for every family member.

More Information About Refrigerator Plastic Parts Injection Mold

——

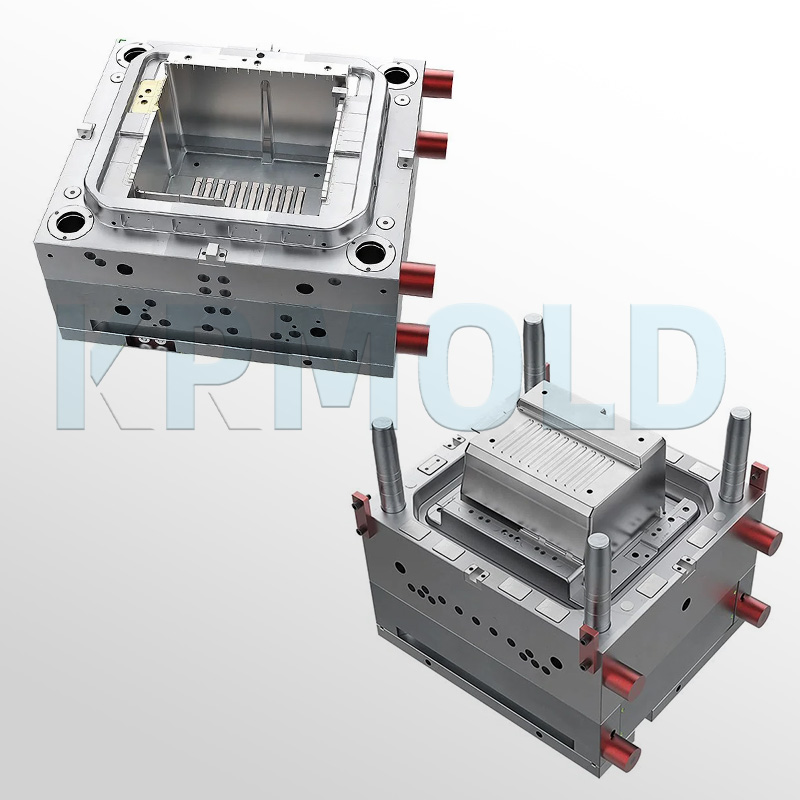

●Manufacturing process of refrigerator plastic parts injection mold: The manufacturing process for refrigerator plastic components primarily relies on injection molding machines, plastic raw materials, and refrigerator drawer accessories injection mould. First, the plastic raw material is heated to a molten state in an injection molding machine and then injected into the plastic refrigerator parts injection mold. As the temperature drops, the molten plastic cools and solidifies in the mold, ultimately forming the desired refrigerator component.

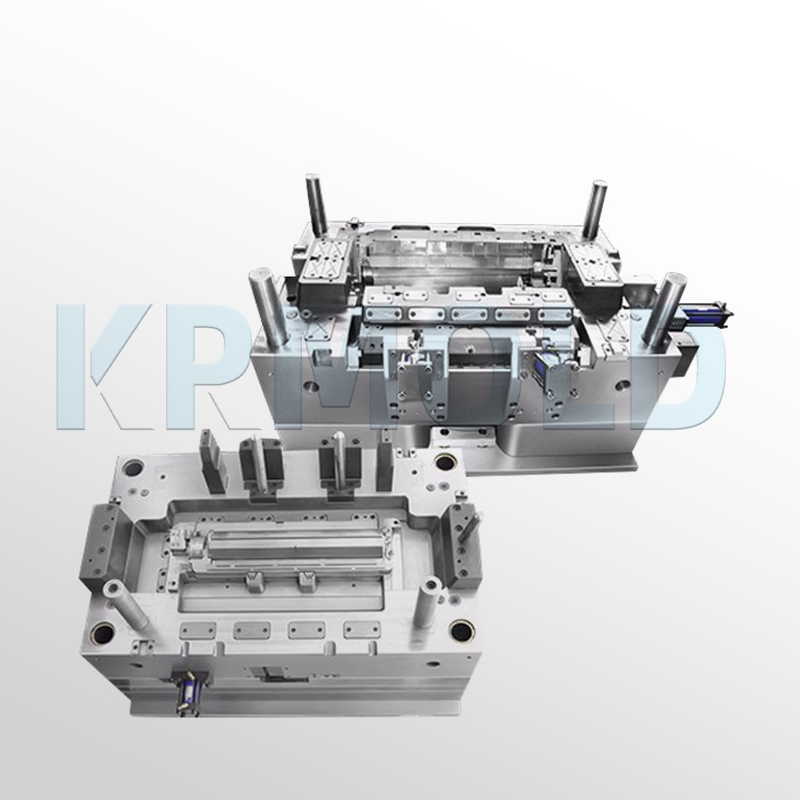

●Refrigerator drawer accessories injection mould design: KRMOLD designers, based on the customer's design drawings, conduct a detailed molding process analysis, select appropriate equipment, calculate refrigerator drawer accessories injection mould dimensions, and verify key parameters. This includes designing the number and distribution of cavities, parting surfaces, and core cavities, as well as rationally designing the gating system, cooling system, ejector mechanism, reset mechanism, draft angle, venting system, and side core pull mechanism.

●Refrigerator plastic parts injection mold technological innovation: KRMOLD also designed a dual-slant slide demolding mechanism, successfully resolving the technical challenge of demolding the ear portion of the plastic part. This innovative design not only improves production efficiency but also significantly reduces the defective product rate during the production process.

●Refrigerator plastic parts injection mold customization: KRMOLD supports custom inserts and plastic refrigerator parts injection mold engraving to further meet personalized needs. KRMOLD also offers polishing services to enhance the product's surface gloss and aesthetics. Through nitriding, KRMOLD can effectively reduce refrigerator drawer accessories injection mould deformation, improve surface hardness and wear resistance, and extend the refrigerator plastic parts injection mold's lifespan.

●Refrigerator plastic parts injection mold material selection: KRMOLD is meticulous in its mold material selection. Standard products utilize high-quality Shanghai Baosteel P20 (hardness 28-32 HRC) and 718 (hardness 32-38 HRC), among others. KRMOLD also uses high-quality S45C mold plates, custom mold bases, or LKM standard mold bases. For products requiring high precision and high requirements, KRMOLD selects imported German steels such as 2738, 2344, 2083, 8407, and NAK80. These materials ensure mold durability and stability, ensuring the long-term, efficient operation of refrigerator drawer accessories injection mould.

Parameters of Refrigerator Plastic Parts Injection Mold

——

| Process Type | Refrigerator drawer accessories injection mold |

| Design Software | Moldflow, UG, PROE, AUTOCAD, etc. |

| Plastic Material | PET/PP, etc. |

| Main Processing Equipment | CNC, CNC milling machine, drill press, milling machine, grinder, precision engraving, wire cutting, EDM |

| Number of Cavities | Single/Multi-Cavity |

| Gating | Hot runner, cold runner |

| Mold Life | 45#: 300,000-500,000 cycles / P20: 500,000 cycles |

Refrigerator Drawer Accessories Injection Mould Maintenance

——

-Mold maintenance is crucial to extending its lifespan. KRMOLD recommends the following aspects of plastic refrigerator parts injection mold maintenance:

-Daily Maintenance: This includes lubricating various moving parts, such as ejector pins, guide pins, guide bushings, maintaining a clean refrigerator drawer accessories injection mold surface, and draining the mold regularly.

-Regular Maintenance: Regularly clean the exhaust slots, add exhaust gas to burnt areas, and promptly repair damaged and worn parts.

-Appearance Maintenance: Paint the plastic refrigerator parts injection mold exterior to prevent rust. When lowering the refrigerator drawer accessories injection mold, apply anti-rust oil to the fixed and movable molds and keep the mold tightly closed to prevent dust from entering the cavity.

KRMOLD After-Sales Service

——

KRMOLD prioritizes not only plastic refrigerator parts injection mold quality but also after-sales service. KRMOLD promises:

-Timely Response: KRMOLD will respond quickly to customer questions and needs, ensuring smooth communication.

-Comprehensive Quality Control System: Strict quality control is implemented at every stage of production to ensure the high standards of each plastic refrigerator parts injection mold.

-Competitive Pricing: KRMOLD offers cost-effective refrigerator drawer accessories injection mold, ensuring an excellent balance of quality and price.

-Project Tracking System: KRMOLD advanced project tracking system ensures on-time delivery, providing peace of mind for our customers.

-Extensive Mold Export Experience: KRMOLD has extensive experience exporting refrigerator drawer accessories injection mold to overseas markets, enabling us to meet the needs of KRMOLD international customers.

Specify the type of plastic (e.g. PP, ABS) and post-processing requirements (e.g. spraying, silk-screen printing), and provide 2D or 3D plastic part drawings should be provided. At the same time, provide the production volume, appearance requirements, tolerance standards, etc.

Generally speaking, our engineers will start to prepare the quotation immediately after the customer provides the complete production requirements. Usually it takes about 1-3 days.

The lead time for regular injection molds is usually 30-60 days, and may be longer for complex molds. For example, the typical lead time for liquid silicone molds is around 60 days, covering design, manufacturing, mold testing, etc.

High-precision processing technology: High-precision equipment such as CNC machining centers (CNC) and electric discharge machining (EDM) are used to optimize the design process in combination with CAD/CAM software. Quality control: Inspection of key dimensions of the mold by Coordinate Measuring Machine (CMM) and verification of multiple sample batches during the trial molding stage. Material Selection: Use die steel with high wear resistance (e.g. H13, S136) and surface treatment (e.g. nitriding, chrome plating) for die nuts to extend the life.

After every 50,000 molds, check the guide pillar, ejector pin and other wear parts, and clean up the residual plastic and rust on the mold surface. Use high temperature grease for sliding parts (e.g. tilt top, slider) to reduce friction loss. Ensure that the water circuit is smooth and the temperature difference is ≤5℃ to avoid cracking of the mold due to thermal stress.

Mould cost of materials accounted for about 30-40% (such as 1 ton of P20 steel price of about 20,000 yuan), processing costs accounted for more than 50% (CNC labor hourly rate of about 80-150 yuan / hour). Small batch production can choose aluminum mold or simplify the structural design; more than 100,000 pieces is recommended to use carbide inserts to enhance life!

Mould injection products need to fully meet the design requirements (such as size, appearance), and can be continuous and stable production. Mold marking, inspection reports (such as material hardness test) and engineering drawings should be complete.

Mould steel (such as S136H, NAK80 and other imported materials cost more) and the type of mold embryo (aluminum mold short-term cost is low but short life) directly affect the cost, the use of CAD/CAE/CAM design technology, hot runner system, etc. will increase the upfront investment, but can enhance the long-term benefits (such as reducing the sprues, increase production capacity).