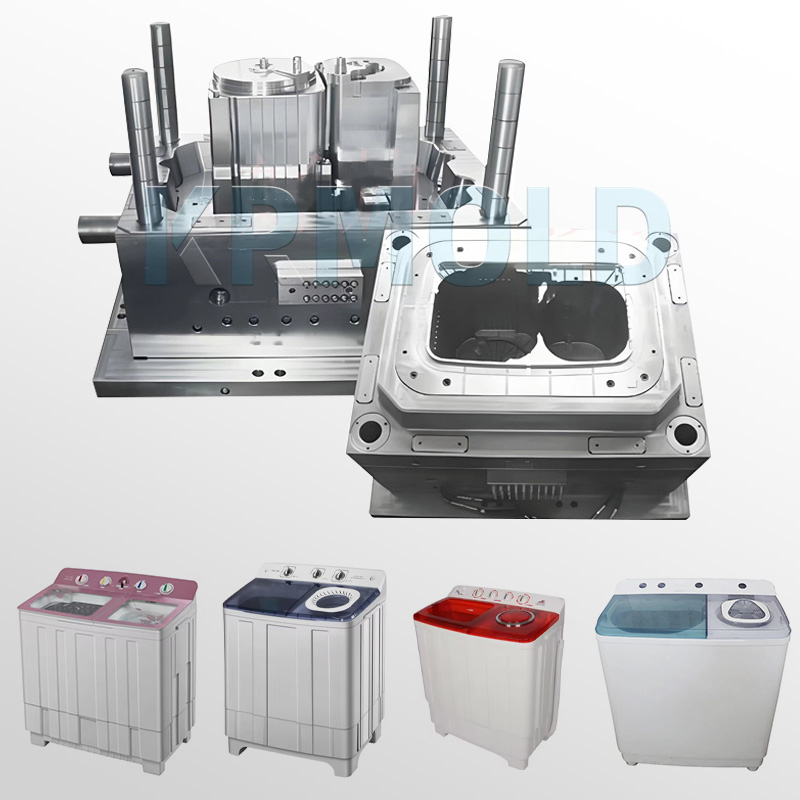

Description of Washing Machine Plastic Mould

——

Washing machine plastic mould are key equipment designed specifically for the production of washing machine. With the continuous development of the home appliance industry, market demand for washing machines is increasing. The precision and quality of washing machine plastic injection mould directly impact the overall performance and appearance of washing machines. KRMOLD is committed to providing washing machine manufacturers with high-precision, customized washing machine plastic mould to meet the specific needs of different customers.

KRMOLD washing machine plastic injection mould are made of high-strength materials, ensuring excellent stability and durability during high-load production processes. By strictly controlling the washing machine plastic mould' dimensional accuracy, surface quality, and structural strength, KRMOLD washing machine plastic injection mould provide customers with excellent product quality.

Parameters of Washing Machine Plastic Mould

——

| Mold Name | Washing machine plastic injection mould |

| Material | ABS, PP |

| Number of Cavities | 1 |

| Core Material | 718/P20H |

| Cavity Material | 718/P20H |

| Slide and Lifter Material | P20H |

| Core Surface Finish | Mirror Polish |

| Cavity Surface Finish | High Gloss |

| Injection Molding System | Cold Runner and Hot Runner |

| Gating Types | Sub-Gate, Direct Gate, and Edge Gate |

| Ejection System | Ejector Pin, Ejector Bushing, and Corner Lifter |

| Injection Life | 500,000 Cycles |

Material for Washing Machine Plastic Injection Mold

——

Material choice for washing machine plastic mould is essential since it immediately affects mould quality and production efficiency. High strength metals and aluminum are often used in the manufacturing of washing machine plastic mould to guarantee the necessary robustness and accuracy for many uses. Steel molds are preferred material for mass manufacture because of their extraordinary endurance and strength. Less strong, aluminum molds are sometimes used for smaller, high-precision manufacture because of their lightweight and excellent performance.

KRMOLD generally employs materials like acrylonitrile butadiene styrene (ABS), polypropylene (PP), polycarbonate (PC), and polyethylene (PE) to handle the plastic additives produced during washing machine plastic injection mould operation.

Features of Washing Machine Plastic Mould

——

1. Highly customizable washing machine plastic injection mould

Usually concentrating on ABS and PP, KRMOLD provides a range of plastic material alternatives for its plastic washing machine injection mould so that it can satisfy the demands of several washing machine models. KRMOLD can create single or multicavity molds depending on the customer's particular needs to increase manufacturing efficiency.

2. Gate selection for washing machine plastic injection mould

KRMOLD supports both hot and cold runner options, depending on customer needs. A rational water channel layout can improve cooling efficiency by 30%, ensuring uniform cooling during the washing machine plastic mold production process, effectively shortening production cycles and extending mold life.

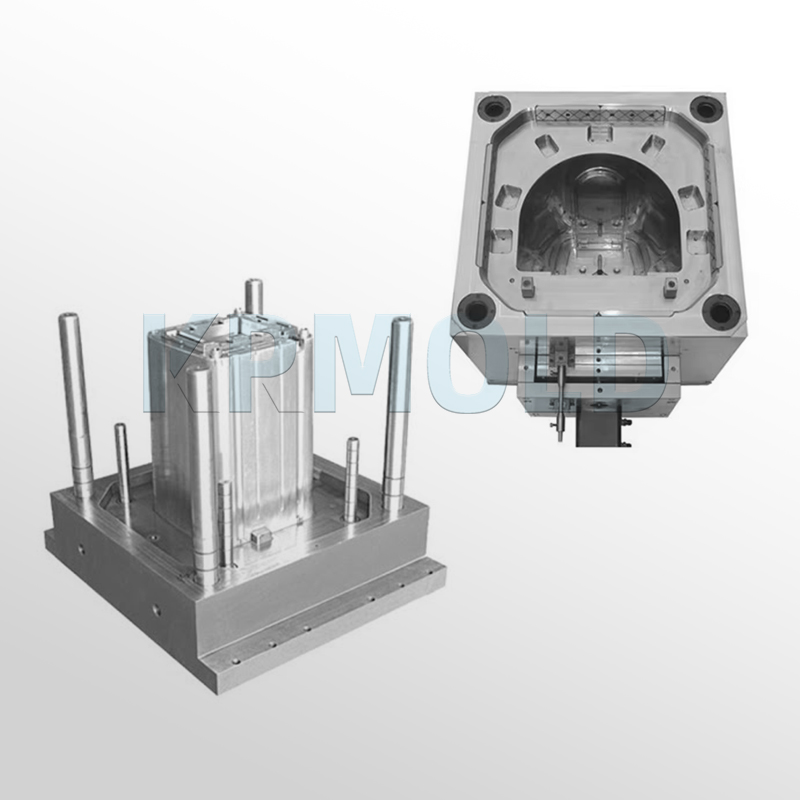

3. Processing precision for washing machine plastic mould

KRMOLD can add inserts or washing machine plastic injection mold lettering to enhance product personalization and aesthetics. Furthermore, KRMOLD offers professional polishing services to enhance the product's surface gloss and make it more attractive.

4. Enhanced durability for washing machine plastic mould

Through nitriding, KRMOLD reduces washing machine plastic injection mould deformation, improves surface hardness and wear resistance, and enhances mold durability, thereby extending its service life.

Design Process of Washing Machine Plastic Mould

——

When designing washing machine plastic injection mold, KRMOLD team of experts works closely with each customer to ensure every detail is carefully considered. KRMOLD design process includes the following key steps:

1. Washing machine dimensions and structure

Before washing machine plastic mould construction, it is essential to clearly understand the precise dimensions and structural characteristics of the desired product. This is because mold cavity design and machining must be tailored to the actual size and structure of the product, and any errors can result in reduced production quality. Larger product sizes increase material and processing costs, while more complex structures increase design and processing complexity.

2. Material selection for washing machine plastic injection mould

Material cost is a crucial component of washing machine plastic mould construction. KRMOLD recommends that customers consider the specific requirements of their production when selecting mold materials. For example, for low-volume, general plastic products, P20 steel is a cost-effective option. For high-volume or high-quality surface finish products, mold steels with improved wear resistance and polishability, such as NAK80 or S136, are more suitable.

3. Process requirements of washing machine plastic injection mould

The process requirements for each washing machine plastic mould are unique, and KRMOLD offers a variety of process options tailored to each customer's needs. For example, the runner can be either cold or hot, and the number of cavities can be adjusted based on the customer's production capacity and product size. Hot runners excel in high-volume production, while cold runners are suitable for small batches.

4. Design for special needs

Customers may have special requirements, such as reinforcing ribs, support surfaces, and rounded corners. These can all be fully considered during the washing machine plastic injection mould design process. KRMOLD design team will optimize the washing machine plastic mould based on the customer's drawings to ensure it meets specific functional requirements.

Specify the type of plastic (e.g. PP, ABS) and post-processing requirements (e.g. spraying, silk-screen printing), and provide 2D or 3D plastic part drawings should be provided. At the same time, provide the production volume, appearance requirements, tolerance standards, etc.

Generally speaking, our engineers will start to prepare the quotation immediately after the customer provides the complete production requirements. Usually it takes about 1-3 days.

The lead time for regular injection molds is usually 30-60 days, and may be longer for complex molds. For example, the typical lead time for liquid silicone molds is around 60 days, covering design, manufacturing, mold testing, etc.

High-precision processing technology: High-precision equipment such as CNC machining centers (CNC) and electric discharge machining (EDM) are used to optimize the design process in combination with CAD/CAM software. Quality control: Inspection of key dimensions of the mold by Coordinate Measuring Machine (CMM) and verification of multiple sample batches during the trial molding stage. Material Selection: Use die steel with high wear resistance (e.g. H13, S136) and surface treatment (e.g. nitriding, chrome plating) for die nuts to extend the life.

After every 50,000 molds, check the guide pillar, ejector pin and other wear parts, and clean up the residual plastic and rust on the mold surface. Use high temperature grease for sliding parts (e.g. tilt top, slider) to reduce friction loss. Ensure that the water circuit is smooth and the temperature difference is ≤5℃ to avoid cracking of the mold due to thermal stress.

Mould cost of materials accounted for about 30-40% (such as 1 ton of P20 steel price of about 20,000 yuan), processing costs accounted for more than 50% (CNC labor hourly rate of about 80-150 yuan / hour). Small batch production can choose aluminum mold or simplify the structural design; more than 100,000 pieces is recommended to use carbide inserts to enhance life!

Mould injection products need to fully meet the design requirements (such as size, appearance), and can be continuous and stable production. Mold marking, inspection reports (such as material hardness test) and engineering drawings should be complete.

Mould steel (such as S136H, NAK80 and other imported materials cost more) and the type of mold embryo (aluminum mold short-term cost is low but short life) directly affect the cost, the use of CAD/CAE/CAM design technology, hot runner system, etc. will increase the upfront investment, but can enhance the long-term benefits (such as reducing the sprues, increase production capacity).