Introduction to Auto Headlight Holder Plastic Mold

——

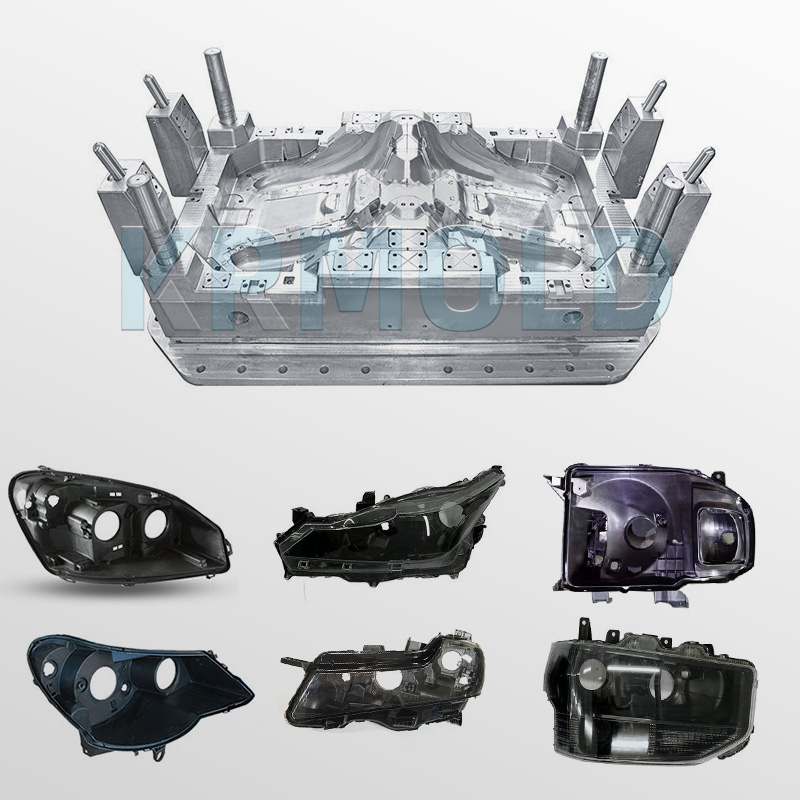

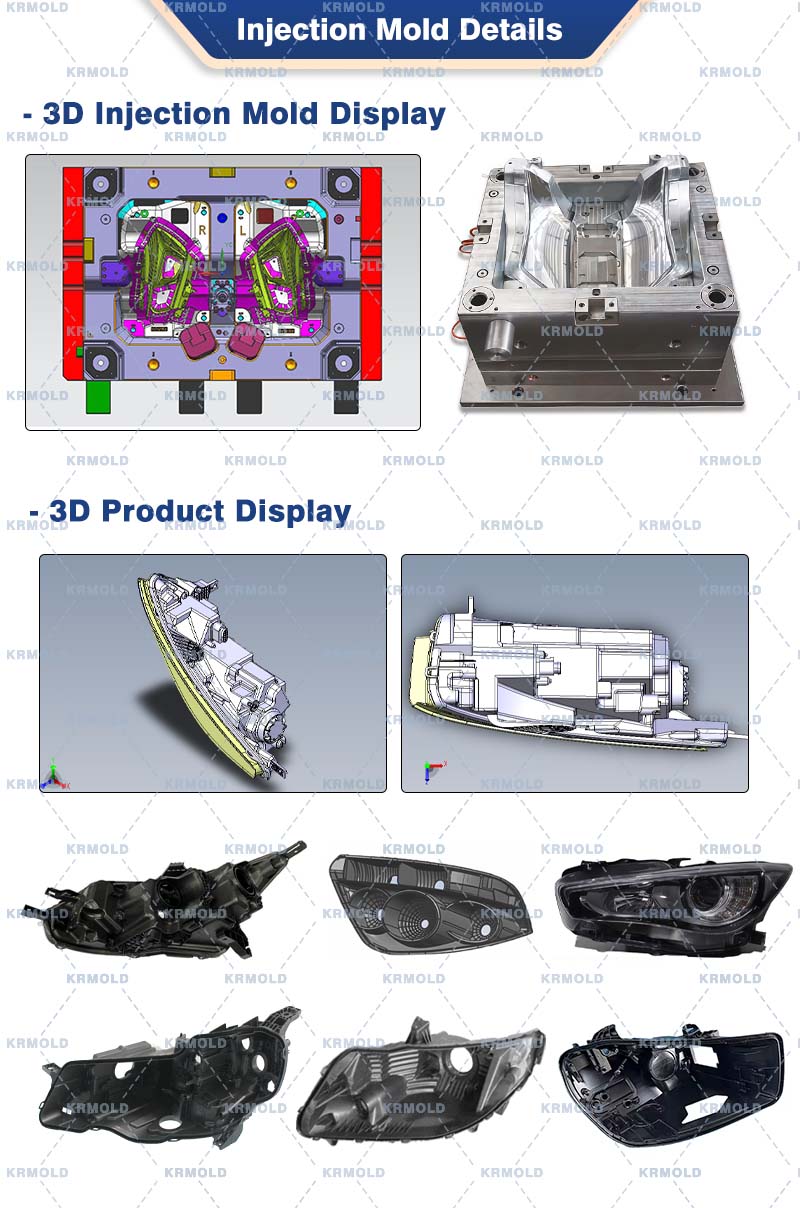

KRMOLD has accumulated extensive experience in the design and manufacture of auto headlight holder plastic molds, committed to providing customers with high-quality headlight auto lamp housing plastic mold solutions. As a crucial support component of the headlight, the auto headlight holder has a profound impact on its safety and reliability.

KRMOLD auto headlight holder plastic mold enables high-precision, high-volume production, helping customers deliver high-quality products in a short time. This headlight auto lamp housing plastic mold is customized according to the customer's specific project requirements, producing auto headlight holders suitable for various sizes and types of automotive installations. Its primary function is to fix and support the headlight, thereby ensuring the headlight's stability and illumination effect.

Furthermore, KRMOLD provides mold flow analysis and DFM reports to help customers optimize designs, reduce production costs, and improve final product quality. KRMOLD professional team will develop the most suitable customized auto headlight holder plastic mold manufacturing solutions for customers to meet diverse market demands.

Parameters of Auto Headlight Holder Plastic Mold

——

| Mold Material | 1.2343 |

| Product Material | PC |

| Number of Cavities | 1 Cavity |

| Runner System | Cold Runner |

| Ejection Method | Ejector Pin |

| Injection Cycle | 48 seconds |

| Injection Life | 500,000 cycles |

| Shrinkage Rate | 1.005% |

| Quality System | IATF16949 & ISO9001 |

Advantages of Auto Headlight Holder Plastic Mold

——

Customized auto headlight holder plastic mold

KRMOLD headlight auto lamp housing plastic mold offers personalized designs. Customers can define their needs for material, shape, and size. KRMOLD engineers and designers will exactly plan and perfect the automotive headlight holder plastic mold to guarantee it satisfies the customer's manufacturing requirements in addition to provides effective production output. Customers can select high-quality tool steels like P20 or H13, for instance, to guarantee great wear resistance and longevity throughout injection molding in terms of materials. These premium components keep the performance and stability of the headlight auto lamp housing plastic mold by withstanding frequent use and tear.

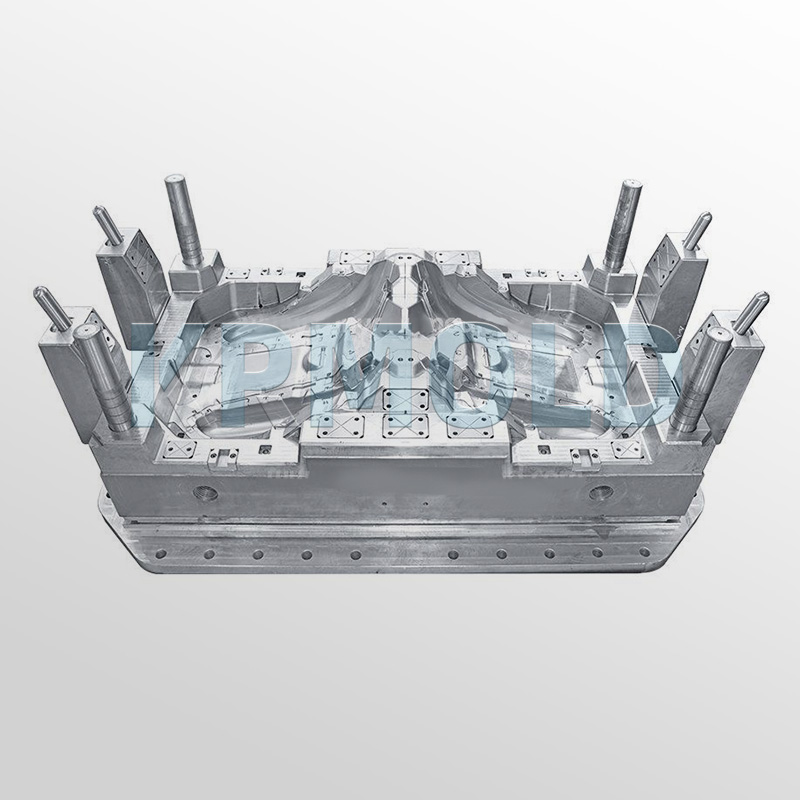

High-volume production auto headlight holder plastic mold

KRMOLD headlight auto lamp housing plastic molds are characterized by high-efficiency production, enabling the production of high-quality automotive headlight holders with simple equipment within a short molding cycle. This not only improves production efficiency but also significantly reduces production costs. Furthermore, finished products produced under the same auto headlight holder plastic mold exhibit high consistency, ensuring that each product meets stringent quality standards.

Durable auto headlight holder plastic mold

KRMOLD headlight auto lamp housing plastic molds are not only superior in design but also outstanding in durability. KRMOLD standard headlight auto lamp housing plastic molds have a lifespan of 300,000 to 1 million cycles, while advanced auto headlight holder plastic molds, with proper maintenance, can have a lifespan extended to 2 million cycles. This means customers can improve profit margins through long-term stable production. Moreover, auto headlight holders produced using KRMOLD headlight auto lamp housing plastic molds maintain high quality and reliability, fully meeting the requirements for installation in automobiles.

Why are Auto Headlight Holder Plastic Molds Important?

——

Auto headlight holders produced by KRMOLD headlight auto lamp housing plastic molds are indispensable components in automotive systems, playing a crucial role in supporting and securing headlights. The stability of headlights directly impacts driving safety, making the quality of these components paramount. High-precision auto headlight holder plastic molds used to produce auto headlight holders ensure the durability and reliability of each light fixture during use, enabling vehicles to perform excellently in various driving environments.

Auto Headlight Holder Plastic Mold Design Considerations

——

1. Mold material selection for auto headlight holder plastic mold

The first step in designing an auto headlight holder plastic mold is selecting the appropriate mold material. The mold material must meet the characteristics of the plastic material and the requirements of the molding process. Generally, hot-work and cold-work mold steels are preferred materials due to their excellent wear resistance, corrosion resistance, and thermal conductivity. These properties not only extend the headlight auto lamp housing plastic mold's lifespan but also improve production efficiency.

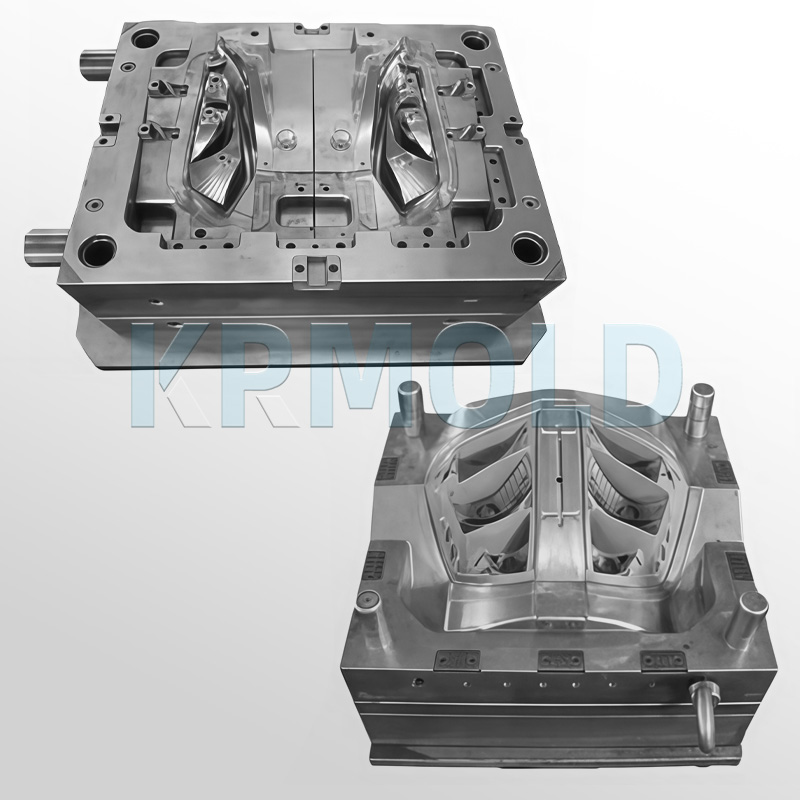

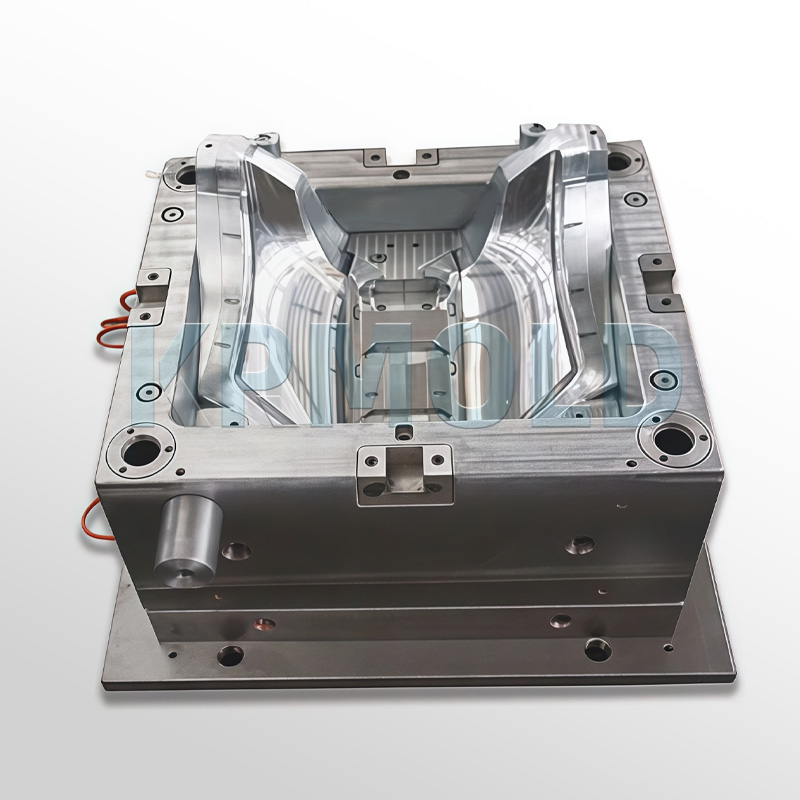

2. Auto headlight holder plastic mold structure design

The structural design of headlight auto lamp housing plastic molds is crucial for the molding process and the quality of the final product. A typical auto headlight holder plastic mold includes a molding section, gating system, venting system, cooling system, and ejection system. During the design process, comprehensively considering the headlight auto lamp housing plastic mold's opening and closing mechanism, parting surface, and cooling channel layout is key to ensuring efficient auto headlight holder plastic mold operation and the production of high-quality parts.

3. Mold cooling system design for auto headlight holder plastic mold

The headlight auto lamp housing plastic mold's cooling system directly impacts product quality and production efficiency. Uniform mold temperature is guaranteed by a well-designed cooling system, which also reduces the molding cycle and stops the thermal degradation of the plastic material caused by excessive temperatures. Thus, in the design stage, great thought has to be given to the placement and design of cooling channels in order to maximize general production efficiency and enable fast molding.

4. Gating system design for auto headlight holder plastic mold

The gating system is one of the core components of an headlight auto lamp housing plastic mold, consisting of the main runner, branch runners, and gate. A good gating mechanism guarantees that the plastic material swiftly and uniformly fills the mold cavity, therefore producing the required component. Material flowability, filling time, and holding time have to be taken in the design to guarantee product quality.

5. Venting system design for auto headlight holder plastic mold

During injection molding, air within the mold cavity needs to be promptly vented to prevent bubble formation or interference with plastic flow. An effective venting system design includes planning the location and size of venting channels to ensure smooth gas discharge while maintaining headlight auto lamp housing plastic mold strength and rigidity.

Specify the type of plastic (e.g. PP, ABS) and post-processing requirements (e.g. spraying, silk-screen printing), and provide 2D or 3D plastic part drawings should be provided. At the same time, provide the production volume, appearance requirements, tolerance standards, etc.

Generally speaking, our engineers will start to prepare the quotation immediately after the customer provides the complete production requirements. Usually it takes about 1-3 days.

The lead time for regular injection molds is usually 30-60 days, and may be longer for complex molds. For example, the typical lead time for liquid silicone molds is around 60 days, covering design, manufacturing, mold testing, etc.

High-precision processing technology: High-precision equipment such as CNC machining centers (CNC) and electric discharge machining (EDM) are used to optimize the design process in combination with CAD/CAM software. Quality control: Inspection of key dimensions of the mold by Coordinate Measuring Machine (CMM) and verification of multiple sample batches during the trial molding stage. Material Selection: Use die steel with high wear resistance (e.g. H13, S136) and surface treatment (e.g. nitriding, chrome plating) for die nuts to extend the life.

After every 50,000 molds, check the guide pillar, ejector pin and other wear parts, and clean up the residual plastic and rust on the mold surface. Use high temperature grease for sliding parts (e.g. tilt top, slider) to reduce friction loss. Ensure that the water circuit is smooth and the temperature difference is ≤5℃ to avoid cracking of the mold due to thermal stress.

Mould cost of materials accounted for about 30-40% (such as 1 ton of P20 steel price of about 20,000 yuan), processing costs accounted for more than 50% (CNC labor hourly rate of about 80-150 yuan / hour). Small batch production can choose aluminum mold or simplify the structural design; more than 100,000 pieces is recommended to use carbide inserts to enhance life!

Mould injection products need to fully meet the design requirements (such as size, appearance), and can be continuous and stable production. Mold marking, inspection reports (such as material hardness test) and engineering drawings should be complete.

Mould steel (such as S136H, NAK80 and other imported materials cost more) and the type of mold embryo (aluminum mold short-term cost is low but short life) directly affect the cost, the use of CAD/CAE/CAM design technology, hot runner system, etc. will increase the upfront investment, but can enhance the long-term benefits (such as reducing the sprues, increase production capacity).