KINGREAL UNIVERSAL IND., LTD

Phone

+86-13702855825| 1 | What is PC Injection Molding? |

| 2 | Benefits of Polycarbonate Injection Molding |

| 3 | Design Tips of PC Injection Mold |

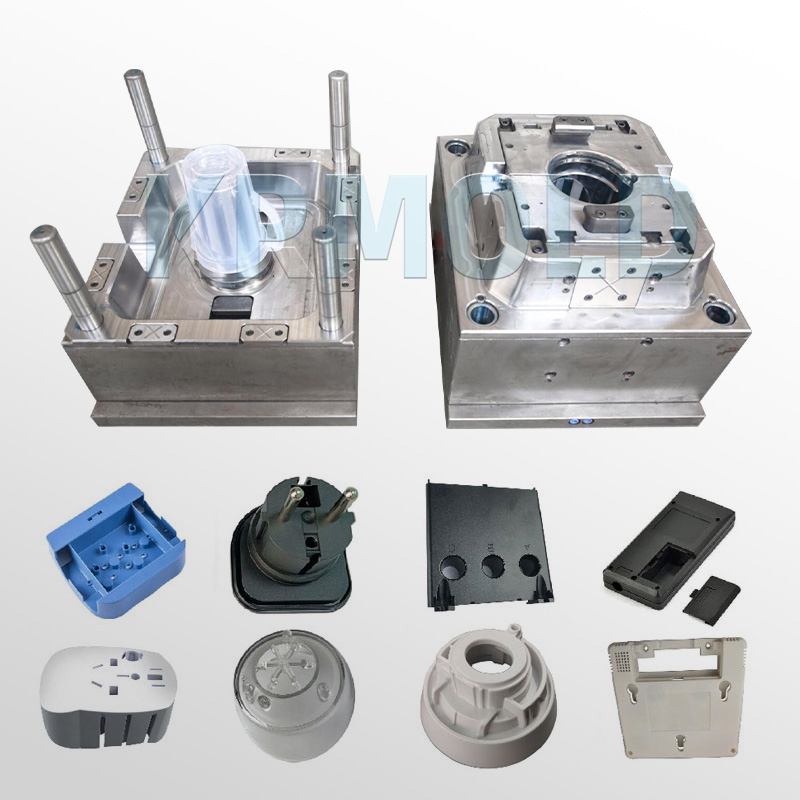

| 4 | Application of PC Injection Molding |

1.What is PC Injection Molding?

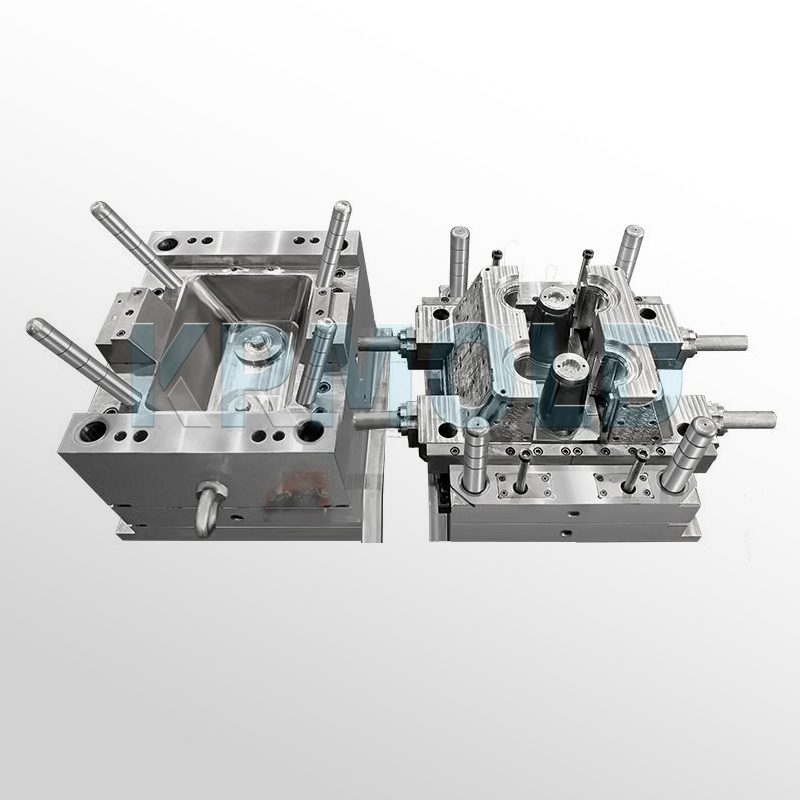

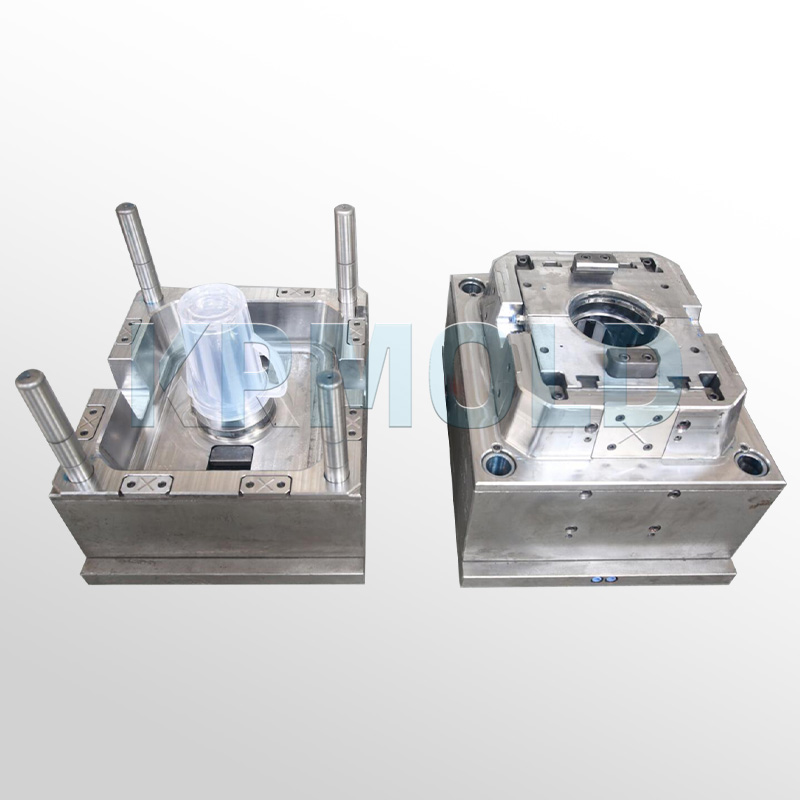

Polycarbonates (transparent thermoplastic elements with carbonate functional groups) are high-strength materials with great impact resistance. During the PC injection molding process, these strong materials are heated and melted to become any possible shape. Every material after Polycarbonate Injection Molding becomes strong and durable, which is beneficial for consumption in most industries. After this PC Injection Molding process, polycarbonate can be used to replace glass, which is why various industries adopt this Polycarbonate Injection Molding process. It also helps manufacturers to achieve low-cost production. PC Injection Molding process requires a proper laboratory as it involves injecting molten polycarbonate into the mold. Proper care and expertise are required to operate the machine. |  |

2.Benefits of Polycarbonate Injection Molding

(1)Durability and Impact Resistance The high impact resistance of PC Injection Molding is suitable for parts that are subject to mechanical stress or potential impact. This feature is very useful in the automotive, electronics and construction industries where parts are frequently used and may be worn. |

|

(2)Transparency and Aesthetic Quality Comparable to glass, PC's transparency is ideal for optical clarity applications, such as eyeglass lenses and medical devices. In addition, Polycarbonate Injection Molding can be colored and customized, providing more aesthetic options for consumer products. |  |

(3)Thermal stability Since PC Injection Molding has high thermal stability, it can withstand long-term exposure to high temperatures without bending or losing strength. This makes them suitable for parts exposed to high temperatures, such as lighting equipment and electronic housings. |  |

(4)Design versatility Polycarbonate Injection Molding can produce products with complex shapes, including thin-walled parts, which are difficult to manufacture with other materials. This flexibility makes polycarbonate a first choice for designers and engineers looking for lightweight, versatile solutions. |  |

(5)Electrical insulation performance PC's insulating properties make it ideal for electrical components, protecting sensitive electronic devices from environmental factors and ensuring user safety. |  |

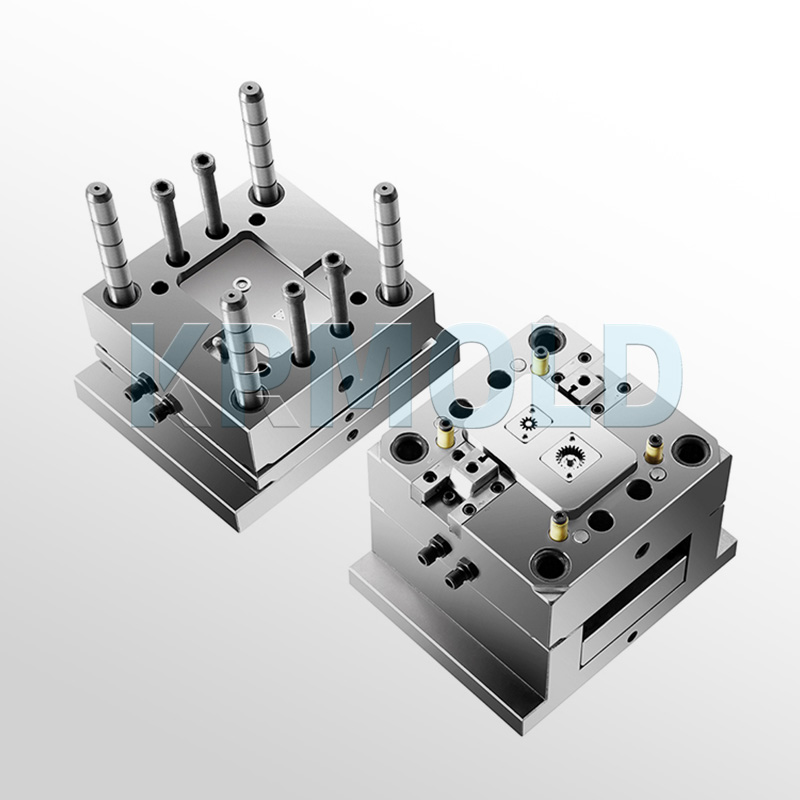

3.Design Tips of PC Injection Mold

(1) Reasonable design of flow channels and inlets PC has poor fluidity, and it is recommended to use "S-shaped side inlet" or "fan-shaped inlet" styles when designing the inlet. The inlet should be as thick as possible to avoid excessive shear stress of the material causing bubbles or silver streaks. Avoid point inlet or diving inlet to ensure smooth material flow.

(2) Control the shrinkage rate of long strip products For long strip products, the shrinkage rate in the length direction needs to be specially controlled. Reserve 0.2~0.4mm shrinkage space on one side in the length direction to prevent the mold from being scrapped due to uneven shrinkage. Because PC transparent mold cores are not allowed to be welded, this method can effectively reduce the risk.

(3) Design of appearance parts ejection When ejecting appearance parts, it is recommended to use a circumferential ejector block design or add an overflow bag to assist ejection. This can reduce the damage to the product surface during the ejection process and maintain the surface finish.

(4) Exhaust design should be in place PC material has poor fluidity, and the front mold core of the Polycarbonate Injection Molding needs to be equipped with a circumferential exhaust groove, and the exhaust depth is controlled at 0.03~0.04mm to prevent defects caused by the inability to discharge gas smoothly.

(5) Drying of materials PC Injection Molding is very sensitive to moisture and must be thoroughly dried before Polycarbonate Injection Molding to reduce the moisture content to below 0.02%. The recommended drying conditions are 100~120℃ for more than 4 hours to avoid quality problems during the PC Injection Molding process.

(6) The barrel temperature should be precisely controlled It is recommended to control the barrel temperature between 270~320℃ and avoid exceeding 340℃, otherwise it will cause material decomposition, darkening, silver threads, bubbles and other problems. In addition, the material should not stay in the barrel for more than 15 minutes to prevent degradation.

(7) Adjust injection pressure and speed PC Injection Molding requires higher injection pressure, but it is also necessary to avoid generating large internal stress. Medium-speed injection is used for thick-walled parts, high-speed injection is used for thin-walled parts, and a slow-fast-slow multi-stage injection method is used to help improve Polycarbonate Injection Molding filling efficiency.

(8) Optimize holding pressure and time Too low holding pressure will cause vacuum bubbles or shrinkage, while too high pressure may cause internal stress problems. Usually, high material temperature and low holding pressure are used. The holding time should be determined by factors such as product thickness and gate size, and can be optimized by testing the gate sealing time.

(9) The influence of mold temperature on quality The PC Injection Molding temperature should be controlled between 85120℃, usually 80100℃. For products with complex shapes or high requirements, the Polycarbonate Injection Molding temperature can be appropriately increased to reduce the difference between mold temperature and material temperature and reduce internal stress.

(10) Special requirements for transparent products PC transparent products have high requirements for surface quality. The PC Injection Molding surface roughness must be less than 0.8, and sufficient exhaust grooves must be set. In the Polycarbonate Injection Molding process, the temperature, pressure and speed must be strictly controlled to avoid internal stress causing product cracking or deformation. In addition, the finished product needs to be post-treated at 110~135℃ to further eliminate internal stress and improve transparency and mechanical properties. |  |

4. Application of PC Injection Molding

In the automotive field, polycarbonate injection molding is used for: ·Headlight cover: PC's transparency and impact resistance are very suitable for use as headlight lenses and lampshades. ·Dashboard: The strength and durability of the material ensure that the panel and housing remain intact and reliable. ·Sunroof and window panels: Polycarbonate sheets are transparent and UV-resistant and are often used as a lighter alternative to glass in sunroofs and windows. |  |

(2)Electronics and Electrical Industry PC Injection Molding is widely used in the following parts of electronic products: ·Switch covers and housings: PC's insulating properties and flame retardancy make it ideal for electrical housings and switch panels. ·Compact discs: Polycarbonate is used in CDs, DVDs, and Blu-ray discs for its excellent optical clarity. ·Connectors and battery cases: PC's high impact resistance and stability make it suitable for battery cases and connector housings in portable electronic devices. |  |

In the medical field, polycarbonate injection molding can create: ·Surgical instruments: PC's bio-compatibility, transparency, and sterilization capabilities make it suitable for surgical tools. ·Diagnostic equipment: Transparent PC parts are used in diagnostic equipment housings, where visibility and durability are critical. ·Drug delivery devices: PC is lightweight and durable, so it is often used in drug delivery devices such as syringes and inhalers. |  |

Polycarbonate Injection Molding is also widely used in consumer products, especially those that require transparency and durability: ·Eyeglass lenses: PC's optical clarity and impact resistance make it a popular choice for eyeglass and sunglass lenses. · Water bottles and food containers: BPA-free polycarbonate grades are used for reusable water bottles and food containers. · Sports equipment: The durability of PC makes it suitable for use as protective gear and equipment for sports and outdoor activities. |  |