KINGREAL UNIVERSAL IND., LTD

Phone

+86-13702855825PC injection molding is a very common process in plastic injection molding, mainly used to produce products made of polycarbonate (PC) materials. PC is widely used due to its excellent mechanical properties, especially in electrical products, electrical instrument housings and electronic product structural parts. The following will introduce the whole process of polycarbonate injection molding in detail, as well as the relevant technical details. |  |

| 1 | Properties of PC materials |

| 2 | Raw material processing |

| 3 | Selection of injection molding machine |

| 4 | Mold and gate design |

| 5 | Melt temperature |

| 6 | Injection speed and pressure |

| 7 | Holding pressure and retention time |

| 8 | Mold temperature control |

| 9 | Screw speed and back pressure |

| 10 | Use of additives |

| 11 | Precautions for polycarbonate injection molding |

1. Properties of PC materials

Polycarbonate (PC) is a material with high mechanical strength, wide operating temperature range, good electrical insulation performance and transparency. Due to its excellent anti-ballistic performance, PC is often called "bullet-proof glue". In addition, there are many types of modified PC products, usually adding glass fiber, mineral fillers, chemical flame retardants, etc. to improve its performance. However, PC has relatively poor fluidity and high processing temperature, so a special plasticizing injection structure is required during the pc injection molding process.

2. Raw material processing

Before pc injection molding, the material must be processed. PC has a high water absorption rate. If it is not dried, the moisture will cause hydrolysis and bond breakage, thereby reducing the molecular and physical strength of PC. To ensure the mechanical strength of the molded product, the moisture content of PC must be strictly controlled below 0.02%. In general, pure PC needs to be dried at 120°C for 4 hours, while modified PC is usually dried at 110°C for more than 4 hours.

The proportion of recycled materials can reach 20%. In some cases, 100% recycled materials can also be used, but it should be noted that different color masterbatches should not be mixed to avoid affecting the properties of the finished product.

3. Selection of injection molding machine

Modern PC products generally use modified materials, especially in electrical products, which need to increase fire resistance. Therefore, when selecting a pc injection molding machine, the requirements of its plasticizing system must be considered to ensure effective mixing and corrosion resistance. Conventional plasticizing screws are difficult to meet these requirements, so they should be clearly stated when purchasing.

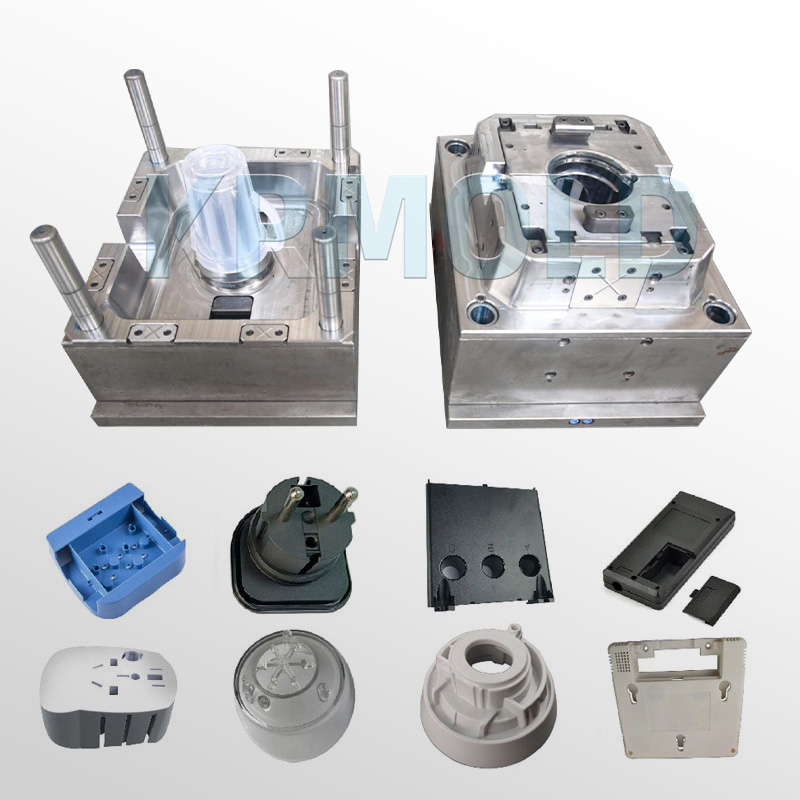

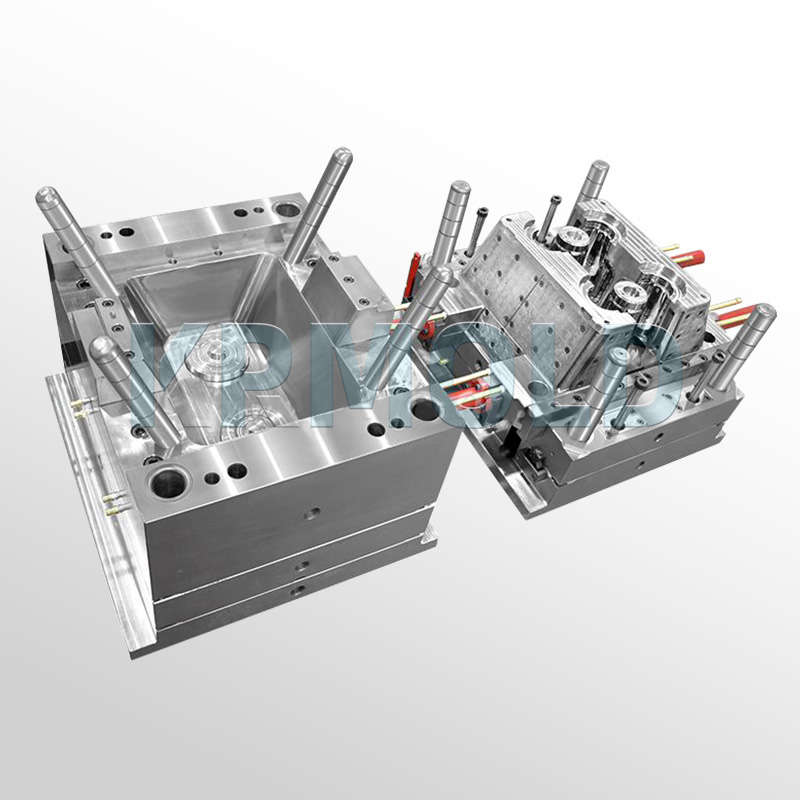

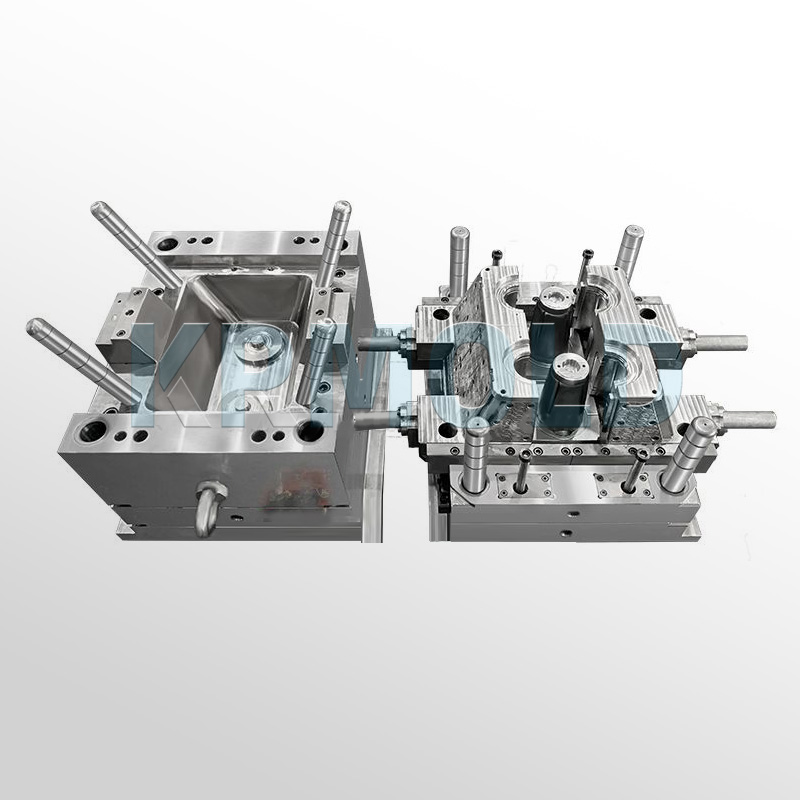

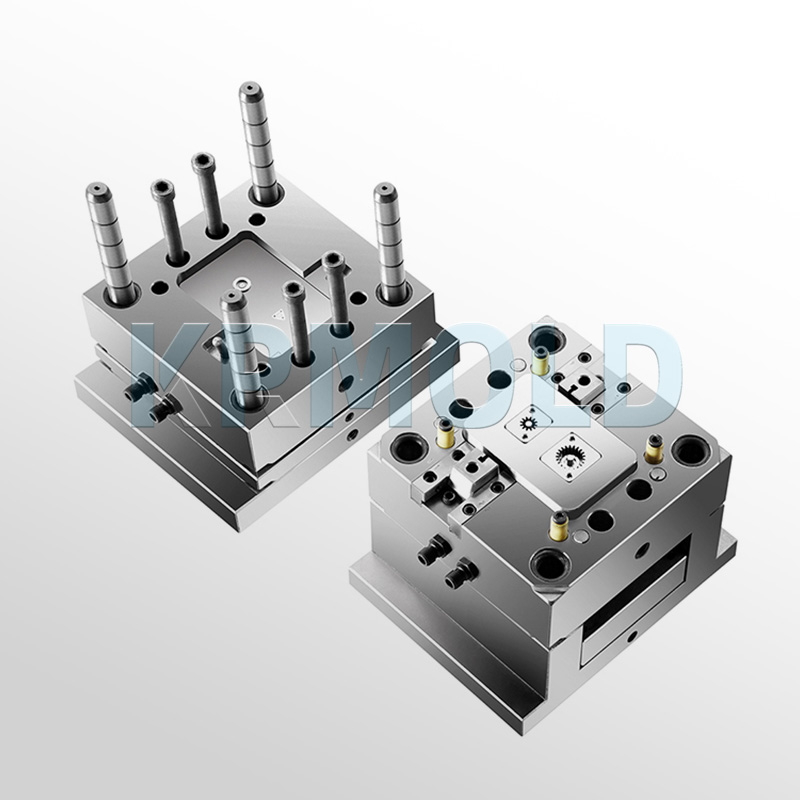

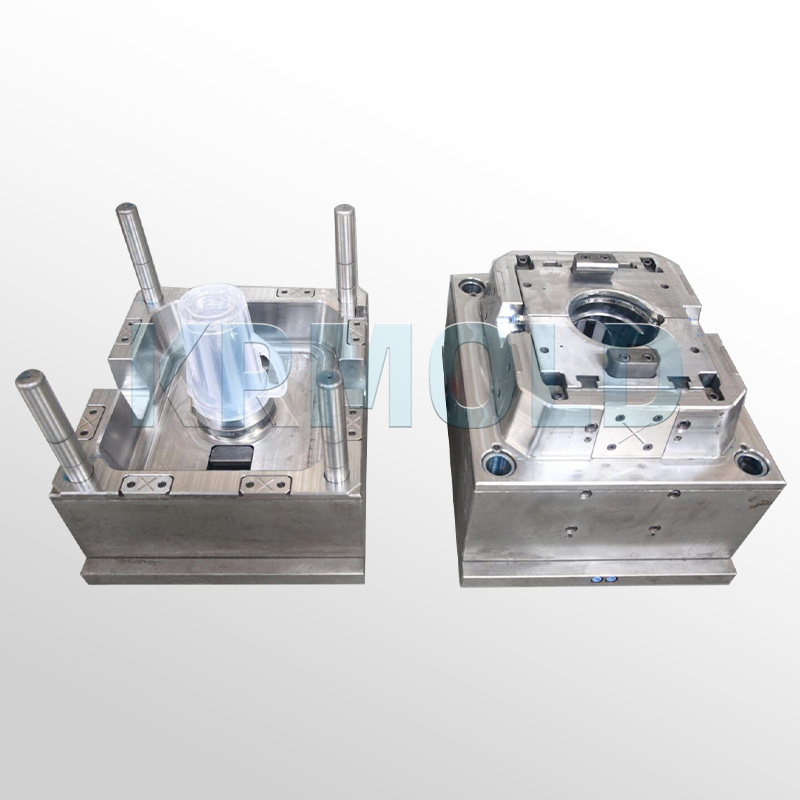

4. Mold and gate design

Mold design is crucial for PC injection molding. The common mold temperature range is 80-100°C, and for PC with glass fiber, it is 100-130°C. Small products can use a pin-shaped gate, and the gate depth should be 70% of the thickest part. The larger the gate, the less defects caused by excessive shearing of the plastic. The depth of the vent should be less than 0.03-0.06mm, the runner should be as short and smooth as possible, and the demolding slope is generally 30′-1°.

5. Melt temperature

The melt temperature of PC is usually between 270-320℃, and some modified or low molecular weight PC is 230-270℃. The choice of melt temperature needs to be adjusted according to the shape, size and mold structure of the product to avoid decomposition and appearance defects caused by excessive temperature.

6. Injection speed and pressure

Polycarbonate injection molding usually uses a faster injection speed, especially when producing electrical switch parts. The injection pressure should be controlled between 80-120MPa, and products with complex shapes or small gates may require higher injection pressures (120-145MPa). The choice of injection speed needs to be combined with the wall thickness and shape of the product, and usually a slow-fast-slow multi-stage injection method is used.

7. Holding pressure and retention time

The size and time of holding pressure have a significant impact on the internal stress of PC products. Too small holding pressure may cause shrinkage and bubbles, while too large holding pressure may cause increased internal stress. The holding time should be selected according to the thickness of the product and the mold temperature. Usually, small and thin products do not require too long holding time, while large and thick products require a longer holding time.

8. Mold temperature control

The influence of mold temperature on PC injection moldingcannot be ignored. Usually, the mold temperature should be controlled at 85-120℃. For products with complex shapes or higher requirements, the mold temperature can be increased to 100-120℃. High mold temperature helps to reduce the internal stress of parts.

9. Screw speed and back pressure

Due to the high melt viscosity of PC, the screw speed should be controlled at 30-60 rpm. The back pressure should be controlled between 10-15% of the injection pressure to ensure plasticization and exhaust effects.

10. Use of additives

During the polycarbonate injection molding process, the use of additives should be strictly controlled. The use of release agents should be cautious, and the proportion of recycled materials should not exceed one-third. Generally, the use rate of recycled materials in the PC injection molding process should be maintained at around 20% to ensure the quality of the product.

11. Precautions for polycarbonate injection molding

When performing PC injection molding, there are several key precautions that need special attention:

√ Moisture control: Excessive moisture will cause bubbles or surface defects in the product, so the drying process must be strictly followed.

√ Pressure and temperature: The control of injection pressure and temperature is crucial to the quality of the molded product. Too high temperature may cause material decomposition, while too low pressure may lead to insufficient filling.

√ Mold design: The design of the mold needs to consider fluidity and exhaust to reduce internal stress and defects.

Polycarbonate injection molding is a complex but efficient process that involves fine control of multiple links. From the drying of raw materials to the selection of pc injection molding machines, to mold design and injection process, each link has an important impact on the quality of the final product. Mastering the technical points of polycarbonate injection molding not only helps to improve production efficiency, but also ensures the mechanical properties and appearance quality of the product. With the continuous advancement of technology, PC injection molding will show its unique advantages in more fields.