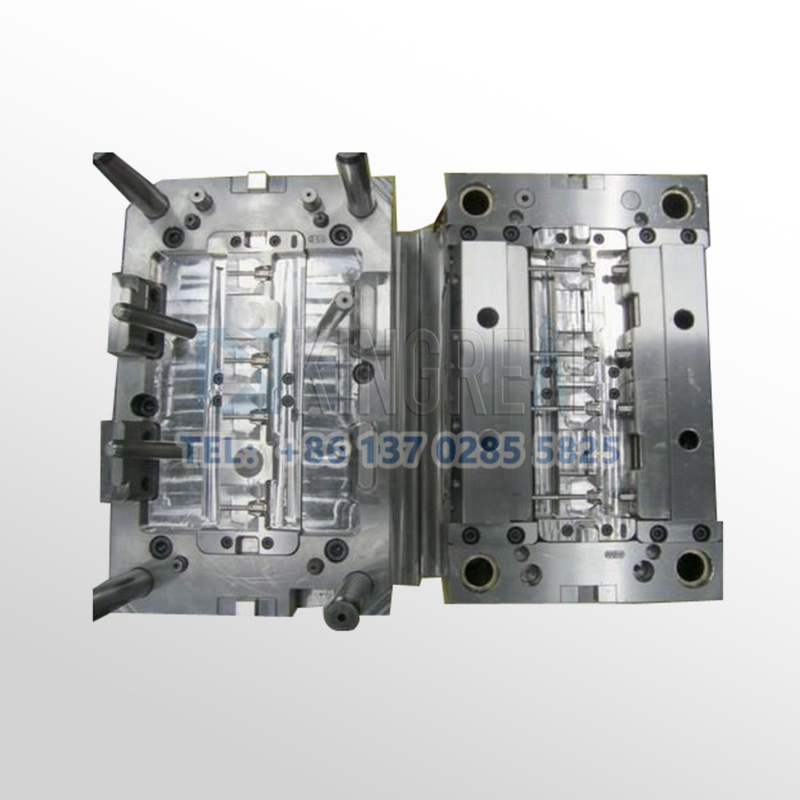

Description Molds Large Home Appliance Injection Molds

——

Molds Large Home Appliance Injection Molds are used for the production of large home appliance plastic parts such as refrigerators, washing machines, air conditioners, and other most common home appliances shells, panels, liners, and other plastic parts, through the high temperature melting of the original plastic injected into the injection mold for the cooling and curing process to achieve the mass production of home appliance plastic. parts of household appliances.

The quality of Molds Large Home Appliance Injection Molds directly affects the appearance, size and fit of the plastic parts of home appliances. Therefore, how to design large home appliance injection molds to meet the production requirements, quality and accuracy is an area that KRMOLD has been constantly researching and improving, helping customers in the home appliance manufacturing industry to produce injection molded tools to improve the accuracy of the customer's products, production efficiency and competitiveness in the market.

KRMOLD Large Home Appliance Injection Mold Manufacturing Services

——

1

Large Appliance Design

KRMOLD can design product models that meet functional and aesthetic requirements based on customer needs and market research. This stage usually uses Computer Aided Design (CAD) software for 3D modeling to ensure manufacturability and performance.

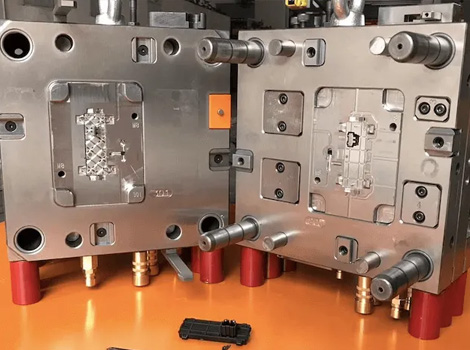

Large home appliance injection mold design: Based on the large home appliance product model to design the corresponding mold structure, including cavities, cores, parting surfaces, pouring system, cooling system and exhaust system. When designing the injection mold, we need to consider the fluidity and shrinkage of the original plastic, as well as the processing and assembly requirements of the mold.

2

Processing of injection molds for large home appliances

Selection of suitable injection mold materials, usually high-strength tool steel or hard alloy, to ensure the durability and precision of the mold. Pretreat the material, such as forging and annealing, to improve its mechanical properties.

Precision machining techniques such as CNC machining (CNC), electric discharge machining (EDM), and wire cutting are used to process the mold material to form the various components of the mold. Dimensional tolerances and surface roughness need to be strictly controlled during processing to ensure the precision and quality of the mold.

3

Large home appliance injection molding heat treatment

heat treatment of processed mold parts, such as quenching and tempering, in order to improve its hardness and abrasion resistance, to extend the service life of the mold. Meanwhile, the surface of the mold cavity is polished and chromium-plated to improve the surface quality of the product and the corrosion resistance of the mold.

4

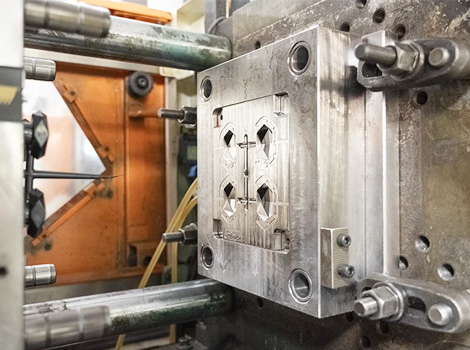

Large home appliance injection molding assembly and debugging

KRMOLD will carry out precision assembly of each mold component in the factory to ensure its matching accuracy. Then we conduct mold trial on the injection molding machine to check the size, appearance and performance of the products, and adjust the mold design or processing parameters in time when problems are found.

Realization Of different Injection Molding Process Requirements

——

Over Molding is an injection molding process that combines two or more different materials together, usually by molding a base material part and then injecting a layer of a different material on its surface to achieve a specific function or aesthetic effect.

Application Example:

Electric toothbrush handle: a soft rubber layer is wrapped around a hard plastic handle to improve grip comfort and non-slip properties.

Remote control housing: Coating flexible material on specific areas of the housing to enhance the feel and prevent slipping.

Insert Molding is a process in which prefabricated metal or other material inserts are placed into a mold, and then plastic is injected so that the inserts are tightly bonded to the plastic parts to form a single unit.

Application Example:

Washing machine knobs: metal bushings are embedded in plastic knobs to enhance wear resistance and connection reliability.

Refrigerator door hinges: metal hinge holders are embedded in the plastic door body to ensure door opening and closing stability and durability.

Commonly used materials for injection molded products for major appliances

——

It has light weight, chemical resistance, good heat resistance, high mechanical strength and excellent fatigue resistance. It is widely used in the manufacture of washing machine inner drum, refrigerator door lining, air conditioner shell and other parts.

●High-density polyethylene (HDPE)

High strength, abrasion resistance, chemical resistance, good resistance to low temperature performance characteristics. Commonly used in the production of refrigerator liners, washing machine drains and other parts.

●Polystyrene (PS)

With good transparency, easy processing, high rigidity, but poor impact resistance characteristics, used in the manufacture of refrigerator drawers, shelves and other parts that require a transparent appearance.

●Acrylonitrile-butadiene-styrene copolymer (ABS)

Excellent overall performance, high strength, good impact resistance and heat resistance, easy processing and surface treatment. Widely used in the manufacture of refrigerator door handles, washing machine control panels, air conditioner vents and other parts.

Large home appliance mold manufacturing case

——

“KRMOLD has a wealth of experience in the manufacture of molds for large home appliances, and is able to complete the design and manufacturing process of injection molds for our customers.”

Washing machine shell: manufactured by injection molding technology, usually using materials such as polypropylene (PP), with durable and lightweight characteristics.

Refrigerator liners: manufactured using materials such as high-density polyethylene (HDPE) through the injection molding process, offering the advantages of corrosion resistance and easy cleaning.

Air conditioner panels: using materials such as acrylonitrile-butadiene-styrene copolymer (ABS), produced through an injection molding process with good surface quality and decorative effects.

Air conditioner radiator shell, internal bracket: injection mold processing and molding of glass fiber reinforced PA or high-temperature resistant PP, to meet the demand for heat dissipation and structural strength

TV shell: the injection mold adopts the design of hot runner system with multiple gates to ensure uniform filling of melt and avoid fusion line affecting appearance

Specify the type of plastic (e.g. PP, ABS) and post-processing requirements (e.g. spraying, silk-screen printing), and provide 2D or 3D plastic part drawings should be provided. At the same time, provide the production volume, appearance requirements, tolerance standards, etc.

Generally speaking, our engineers will start to prepare the quotation immediately after the customer provides the complete production requirements. Usually it takes about 1-3 days.

The lead time for regular injection molds is usually 30-60 days, and may be longer for complex molds. For example, the typical lead time for liquid silicone molds is around 60 days, covering design, manufacturing, mold testing, etc.

High-precision processing technology: High-precision equipment such as CNC machining centers (CNC) and electric discharge machining (EDM) are used to optimize the design process in combination with CAD/CAM software. Quality control: Inspection of key dimensions of the mold by Coordinate Measuring Machine (CMM) and verification of multiple sample batches during the trial molding stage. Material Selection: Use die steel with high wear resistance (e.g. H13, S136) and surface treatment (e.g. nitriding, chrome plating) for die nuts to extend the life.

After every 50,000 molds, check the guide pillar, ejector pin and other wear parts, and clean up the residual plastic and rust on the mold surface. Use high temperature grease for sliding parts (e.g. tilt top, slider) to reduce friction loss. Ensure that the water circuit is smooth and the temperature difference is ≤5℃ to avoid cracking of the mold due to thermal stress.

Mould cost of materials accounted for about 30-40% (such as 1 ton of P20 steel price of about 20,000 yuan), processing costs accounted for more than 50% (CNC labor hourly rate of about 80-150 yuan / hour). Small batch production can choose aluminum mold or simplify the structural design; more than 100,000 pieces is recommended to use carbide inserts to enhance life!

Mould injection products need to fully meet the design requirements (such as size, appearance), and can be continuous and stable production. Mold marking, inspection reports (such as material hardness test) and engineering drawings should be complete.

Mould steel (such as S136H, NAK80 and other imported materials cost more) and the type of mold embryo (aluminum mold short-term cost is low but short life) directly affect the cost, the use of CAD/CAE/CAM design technology, hot runner system, etc. will increase the upfront investment, but can enhance the long-term benefits (such as reducing the sprues, increase production capacity).