KINGREAL UNIVERSAL IND., LTD

Phone

+86-13702855825In the world of plastics manufacturing, the demand for precise and complex plastic parts continues to grow. To meet this demand, many product designers and engineers are turning to a revolutionary manufacturing technology - micro injection molding. Compared with traditional plastic injection molding methods, micro injection moulding is able to produce small plastic parts with a diameter of only a few millimeters, meeting the demand for small, precise components.

| 1 | What is Micro Injection Molding? |

| 2 | Principles of Micro Injection Moulding |

| 3 | Differences Between Micro Injection Molding and Traditional Injection Molding |

| 4 | Benefits of Micro Injection Moulding |

| 5 | Applications of Micro Injection Moulding |

1.What is Micro Injection Molding?

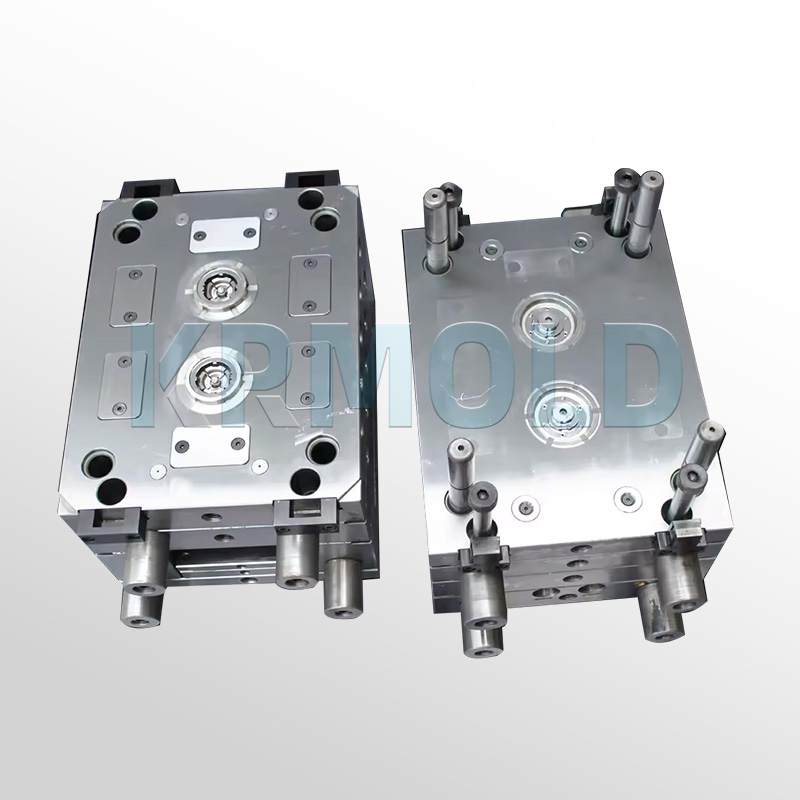

| Micro injection moulding is a highly specialized production technology that focuses on creating extremely small components. The process involves creating a cavity that matches the desired shape of the part. Micro-structured steel or aluminum molds are precision machined (such as CNC machining and EDM) with tolerances in the micron or even sub-micron range. This method is able to produce components weighing less than a gram and with dimensions in the range of a few millimeters. |

2.Principles of Micro Injection Moulding

When starting the micro injection molding process, manufacturers prepare a mold or tool that contains a small cavity according to the shape of the desired component. In the liquid injection molding (LIM) process, liquid silicone rubber (LSR) is quickly injected into the heated cavity. Here, it undergoes vulcanization and forms the final part. Micro injection moulding also includes runner design, which is a channel that guides material into the cavity, which can effectively reduce material waste.

In micro injection moulding, there are three key aspects to consider:

"Micro": refers to the size of the part, emphasizing small-scale manufacturing.

"Micro features": involves small components within larger components.

"Micro tolerance": refers to the precision and accuracy required for part measurement, usually as small as one thousandth of an inch.

Successful micro injection molding parts rely on factors such as tooling, mold design and manufacturing. Industry-leading processing capabilities and experienced professionals with sub-micron processing accuracy are essential. In addition, advanced meteorology is also used to verify the functionality of molded parts.

3.Differences Between Micro Injection Molding and Traditional Injection Molding

Although similar to traditional plastic injection molding, micro injection moulding is significantly different. Micro injection molding requires the integration of special injection units to accommodate small-sized components. In addition, micro injection moulding often uses high-performance polymers such as liquid crystal polymers, which are known for their high temperature resistance and excellent mechanical properties. Traditional plastic injection molding, on the other hand, covers a wider range of materials, including elastomer, thermoplastics, and thermometers.

4.Benefits of Micro Injection Moulding

Micro injection molding technology offers a variety of advantages in terms of precision, processing, and cost. Here are some of the key benefits:

1

Precision and Complexity

Micro injection moulding is capable of achieving high levels of precision and complex geometries. The process can produce extremely small and delicate parts with tight tolerances. Advanced processing technologies such as CNC and EDM can create micro cores, cavities, and features with extremely high precision. This precision is critical for the medical device, electronics, and micro-optics industries.

2

Material Selection and Compatibility

Micro injection molding supports a wide range of material options, including high-performance polymers and engineering thermoplastics. These materials offer excellent mechanical properties, chemical resistance, and thermal stability. The variety of materials ensures that micro-molded parts meet the requirements of specific applications.

3

Cost-effectiveness and Efficiency

Micro injection moulding offers significant cost advantages over traditional plastic injection molding. Cost savings are achieved by smaller and less expensive tooling required. For example, the required clamping force is reduced, allowing for the use of smaller, less expensive machines. Additionally, the process significantly reduces production costs by shortening cycle times.

Micro injection moulding also integrates multiple steps such as assembly or overmolding into one production cycle, increasing efficiency and reducing overall manufacturing time. Optimized micro injection moulding molds and automation capabilities enable faster cycle times, increased productivity and cost-effectiveness.

5.Applications of Micro Injection Moulding

Micro injection molding excels in a variety of applications, especially in industries where size and precision are critical. Here are some of the main application areas:

The medical industry has extremely high precision requirements, and micro injection moulding plays an important role in the manufacture of medical devices, including drug delivery devices, diagnostic systems, catheters, optics and hearing aid components. This technology is particularly suitable for devices used in minimally invasive surgical procedures.

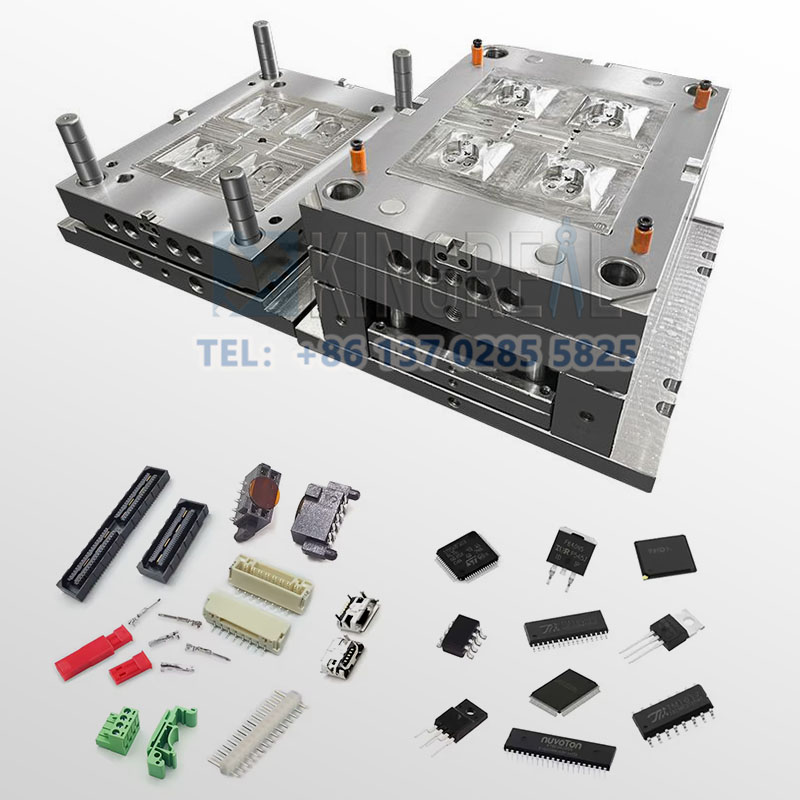

(2)Electronics and Electrical Industry

As electronic devices continue to shrink, micro injection moulding has significant advantages in the manufacture of various electronic components. For example, micro-optics, microelectronic components such as connectors, plugs and switches rely on this technology. Electromagnetically systems also rely on micro injection moulding technology to meet their needs for high precision and miniaturization.

(3)Automotive and Aerospace Industries

Micro injection molding is becoming increasingly important in the manufacture of automotive parts, as automotive parts often require lightweight and compact designs. The technology can be used to produce a variety of automotive parts, including engine components, brakes, and other related parts such as washers and clips.

Micro injection moulding is a revolutionary technology that meets the needs of modern manufacturing for small, precise plastic parts. KRMOLD is committed to providing customers with high-quality micro injection mold solutions to help you stand out in a competitive market. By combining advanced technology, sophisticated material selection, and efficient production processes, micro injection molding is driving innovation and development in various industries.

Whether you are a manufacturer in the medical, electronics, automotive, or other industries, micro injection moulding can provide you with strong support and solutions. Welcome to contact KRMOLD to learn more about the applications and advantages of micro injection moulding, and let us work together to promote the future of manufacturing.