Automotive Lighting Injection Molds Solution

——

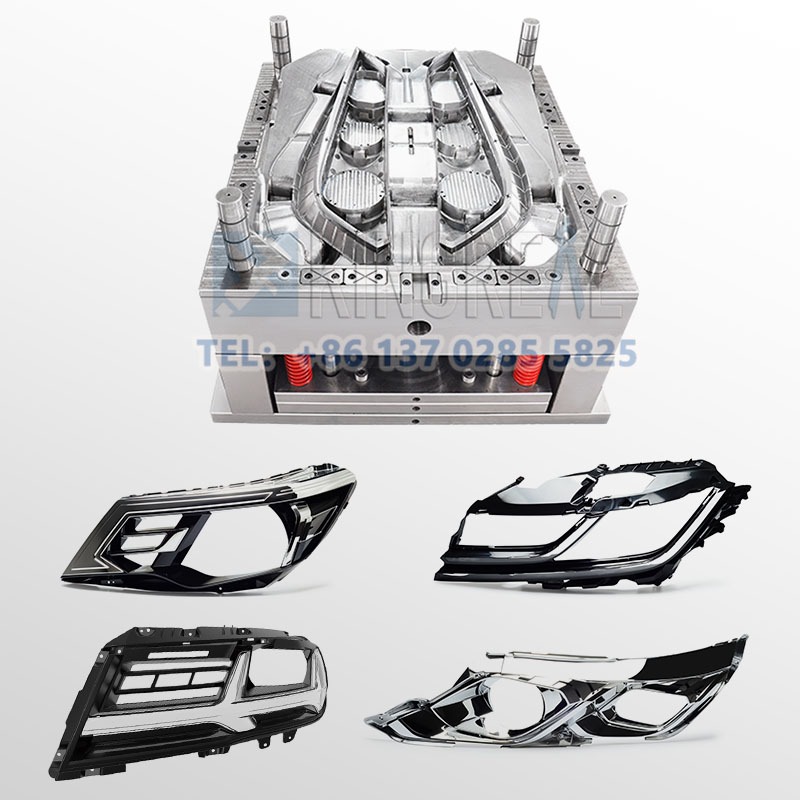

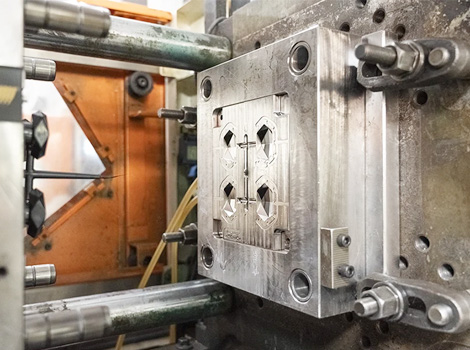

KRMOLD provides customers with complete Automotive Lighting Injection Molds solutions. With complete design and production capabilities, KRMOLD provides automotive lighting companies with high-precision, long-life (up to 30K cycles) injection molds to meet customers' needs for high-volume, high-quality automotive lighting products.

In the field of automotive lighting, Automotive Lighting Injection Molds are used to manufacture plastic parts with complex structures, such as lamp housings, light guide strips, lenses, etc. Since automotive lighting parts require very high optical properties, the injection molds are required to ensure that the product surfaces are smooth and free of bubbles or deformations, and KRMOLD has a professional production and design team to provide customers with KRMOLD has a professional production design team to provide customers with tool design, tool creation and tool iteration standard industry production process, KRMOLD is committed to helping customers to provide a complete production solution, to become a long-term partner!he material shrinkage and cooling rate to avoid light scattering.

Specialized Design And Production Capacity For Injection Mold

——

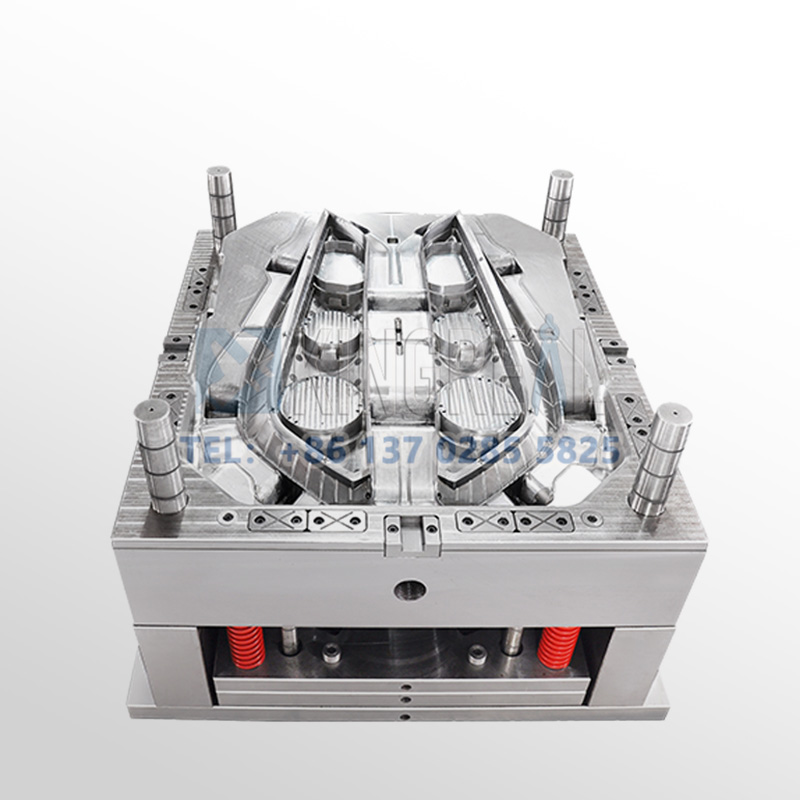

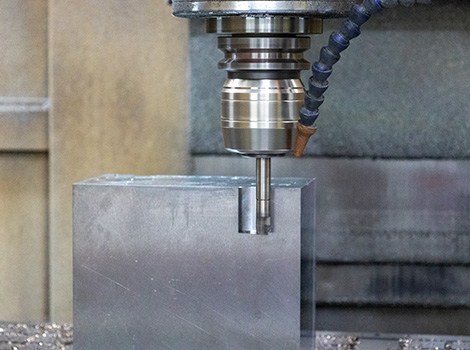

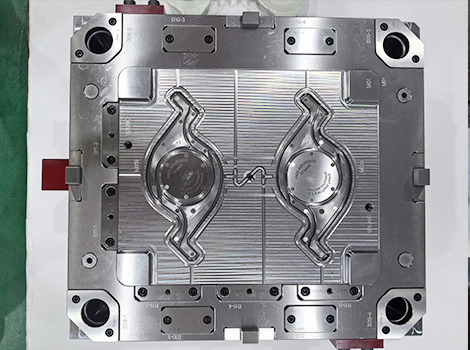

KRMOLD employs Makino V33CNC and EDGE sparking machine in the manufacture of Automotive Lighting Injection Molds, realizing integral machining of the mold core (reducing the number of splices and batch fronts), and the surface roughness of the cavity reaches Ra0.02μm or less. The deep hole drilling technology realizes the cooling channel close to the mold surface, which shortens the molding cycle time by 15%.

KRMOLD also has a perfect manufacturing quality control system for Automotive Lighting Injection Molds, applying three-dimensional measuring system (Hexagon) to check the accuracy of the molds to ensure that the dimensional tolerance is ≤±0.005mm, and at the same time, KRMOLD's injection mold products have passed the ISO 9001 and IATF 16949 quality inspection, and the standardized process documentation from design to delivery has been established. standardized process documentation from design to delivery, and take a collaborative approach with each customer to ensure that each project achieves the desired results.

Automotive Lighting Injection Mold Technical Feature

——

Automotive lighting injection molds produce finished parts with dimensional accuracy of ± 0.3% - ± 0.5%, surface roughness (Ra) can be controlled at 0.8-1.6μm, and the density is close to the theoretical value of more than 95%. This is crucial for precision parts in automotive lighting (such as sensor housings or fixing parts), which can reduce subsequent processing costs and improve reliability.

KRMOLD injection mold manufacturing can be applied to stainless steel, titanium alloys and so on. For example, the lightweight nature of titanium alloys (only 60% of the density of steel) optimizes the weight of a headlight bracket or housing while maintaining high strength. In addition, the high heat resistance of tungsten alloys may be used for lighting components that require high temperature resistance (e.g., LED heat sink modules).

KRMOLD designs automotive lighting injection molds suitable for mass production, with a single mold life of up to 300,000 cycles and a material utilization rate of nearly 100%. In the automotive lighting industry, this can significantly reduce the manufacturing costs of standardized components such as metal clips and fixing bolts.

Specification Of Automotive Lighting Injection Mold

——

| Mould Core | DIN2312,2738,2344,718,S136,8407,NAK80,SKD61,H13 etc. |

| Mold Standard | HASCO,DME,MEUSBURGER,JIS,CHINA LKM Standard |

| Mold Cavity | Single/Multi |

| Maximum Mold Size | 1500*1500 mm |

| Mold Material | H13,2190 VAR,Resin,Plastic |

| Plastic Material | PP, PC, PS, PE, PET, POM, PA,PU, PVC, ABS,PMMA etc. |

| Mold Life | 30K |

| Surface Treatment | Polish,texture,painting,screen printing,turnkey project |

Common Injection Molding Processes

——

“Automotive Lighting Injection Mold involves different types of injection molding processes to meet a variety of customized production needs of customers.”

Rotational or rotary molding to ensure precise alignment of the cavities between the two injections, used for compounding hard structures (PC/ABS) with elastomeric seals (TPE), e.g. for the production of lampshades such as clear and frosted.

Gas-Assisted Injection Molding

The Gas-Assisted Injection Molding process produces hollow structures, such as automotive light housing reinforcements or hidden airway designs, which eliminate shrink marks and improve surface flatness. The process utilizes high-pressure gas to drive the melt to completely fill the cavity and create a hollow structure inside the part, while reducing shrinkage and deformation through gas pressure retention.

Application Of Car Head Light Plastic Injection Mold

——

“Automotive Lighting Injection Molds are used in several key areas of vehicle lighting systems.”

Major Exterior Lamp Assemblies

1. Headlights (headlamps)

Headlamp injection molds are used to manufacture the core components of vehicle headlamps, including lenses, decorative frames, housings and reflectors.

2. Tail light

Tail lamp molds need to take into account both functionality and decoration, such as through 3D printing technology to achieve complex curved surface modeling, to meet the needs of personalization.

Other Exterior Lamps

Fog lamps, turn signals, daytime running lights

The molds for these lamps need to be adapted to the installation space and shape requirements of different models.

Interior Lighting & Function Lamps

Interior ambient lighting, instrument panel back-lighting

Injection molds for manufacturing light guides, lampshades, and other components with uniform light distribution through highly translucent materials (e.g., PMMA) and precise texturing.

FAQ:How to get a quote for custom injection molds?

——

1. Specify the type of plastic (e.g. PP, ABS) and post-processing requirements (e.g. spraying, silk-screen printing)

2. Provide 2D or 3D plastic part drawings should be provided.

3. Provide the production volume, appearance requirements, tolerance standards, etc.

Specify the type of plastic (e.g. PP, ABS) and post-processing requirements (e.g. spraying, silk-screen printing), and provide 2D or 3D plastic part drawings should be provided. At the same time, provide the production volume, appearance requirements, tolerance standards, etc.

Generally speaking, our engineers will start to prepare the quotation immediately after the customer provides the complete production requirements. Usually it takes about 1-3 days.

The lead time for regular injection molds is usually 30-60 days, and may be longer for complex molds. For example, the typical lead time for liquid silicone molds is around 60 days, covering design, manufacturing, mold testing, etc.

High-precision processing technology: High-precision equipment such as CNC machining centers (CNC) and electric discharge machining (EDM) are used to optimize the design process in combination with CAD/CAM software. Quality control: Inspection of key dimensions of the mold by Coordinate Measuring Machine (CMM) and verification of multiple sample batches during the trial molding stage. Material Selection: Use die steel with high wear resistance (e.g. H13, S136) and surface treatment (e.g. nitriding, chrome plating) for die nuts to extend the life.

After every 50,000 molds, check the guide pillar, ejector pin and other wear parts, and clean up the residual plastic and rust on the mold surface. Use high temperature grease for sliding parts (e.g. tilt top, slider) to reduce friction loss. Ensure that the water circuit is smooth and the temperature difference is ≤5℃ to avoid cracking of the mold due to thermal stress.

Mould cost of materials accounted for about 30-40% (such as 1 ton of P20 steel price of about 20,000 yuan), processing costs accounted for more than 50% (CNC labor hourly rate of about 80-150 yuan / hour). Small batch production can choose aluminum mold or simplify the structural design; more than 100,000 pieces is recommended to use carbide inserts to enhance life!

Mould injection products need to fully meet the design requirements (such as size, appearance), and can be continuous and stable production. Mold marking, inspection reports (such as material hardness test) and engineering drawings should be complete.

Mould steel (such as S136H, NAK80 and other imported materials cost more) and the type of mold embryo (aluminum mold short-term cost is low but short life) directly affect the cost, the use of CAD/CAE/CAM design technology, hot runner system, etc. will increase the upfront investment, but can enhance the long-term benefits (such as reducing the sprues, increase production capacity).