KINGREAL UNIVERSAL IND., LTD

Phone

+86-13702855825| Commonly used in plastic injection molding, double shot injection molding is the application of two injection systems on the injection molding machine to allow for simultaneous or sequential delivery of two materials. Many times, this is used to make composite components with sophisticated functions or performances. However, it is widely known that injection molded parts are readily damaged during double shot injection molding. Many companies on the market with double injection molding specifications are also quite upset.With many years of experience and practice in related industries, the KRMOLD engineering team has proposed a double shot injection mold to overcome the defects of existing technologies. |  |

| 1 | Technical Implementation Ideas of Double Injection Molding |

| 2 | Optimization Details and Implementation Steps |

| 3 | Practical Application and Advantages of Double Injection Molding |

1. Technical Implementation Ideas of Double Injection Molding

(1) Purpose of double injection mold

The main purpose of this technology is to provide a new double shot injection mold that can accurately position the one-color part during the double injection molding process while ensuring the stability and accuracy of the positioning. Through this design, the overall stability of double shot injection molding is improved, thereby ensuring the quality of the product.

(2) Enhanced bonding ability

In addition, another important technical goal is to enhance the bonding ability between the one-color part and the two-color part. By adding a positioning structure, it is ensured that the two parts can be firmly connected after double injection molding to avoid separation.

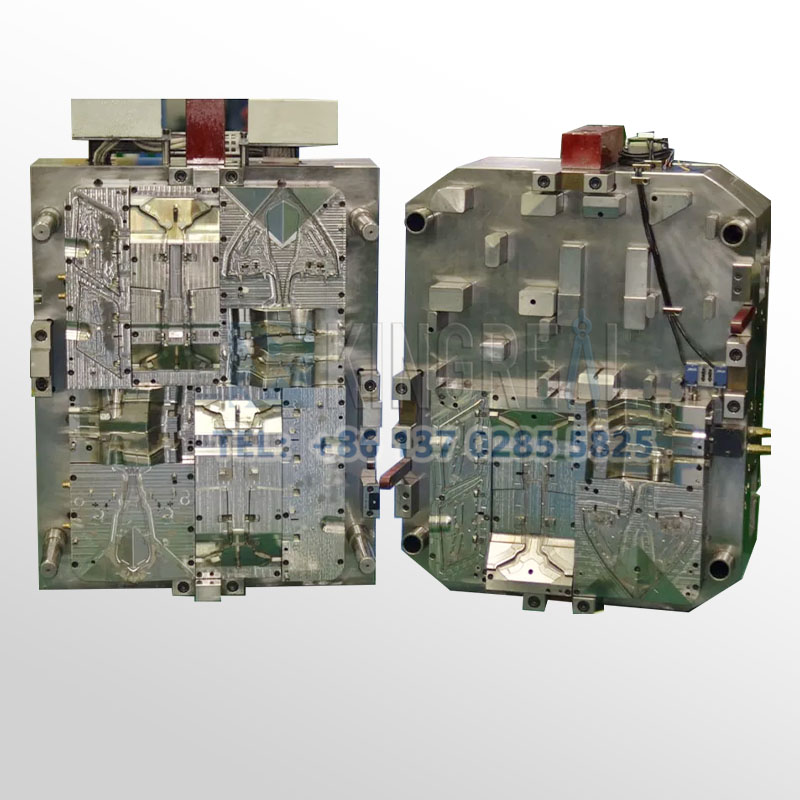

(3) Mold structure design

The double shot injection mold KRMOLD developed has the following main structural features:

First mold: contains at least one double shot injection molding station, which is the core of the double injection molding process.

Second mold: is provided with a single-color molding part and a two-color molding part, which are respectively used to mold parts of different colors or materials.

Positioning module: is arranged around the periphery of the double shot injection molding station to ensure the stability and precise positioning of each part during the double injection molding process.

(4) Formation of injection molding space

The double shot injection molding station, the single-color molding part and the positioning module enclose to form the first injection molding space, which is used to inject the single-color part of the double injection molding product. Subsequently, the double shot injection molding part and the positioning module constitute the second injection molding space, which is used to inject the two-color part on the basis of the single-color part.

2.Optimization Details and Implementation Steps

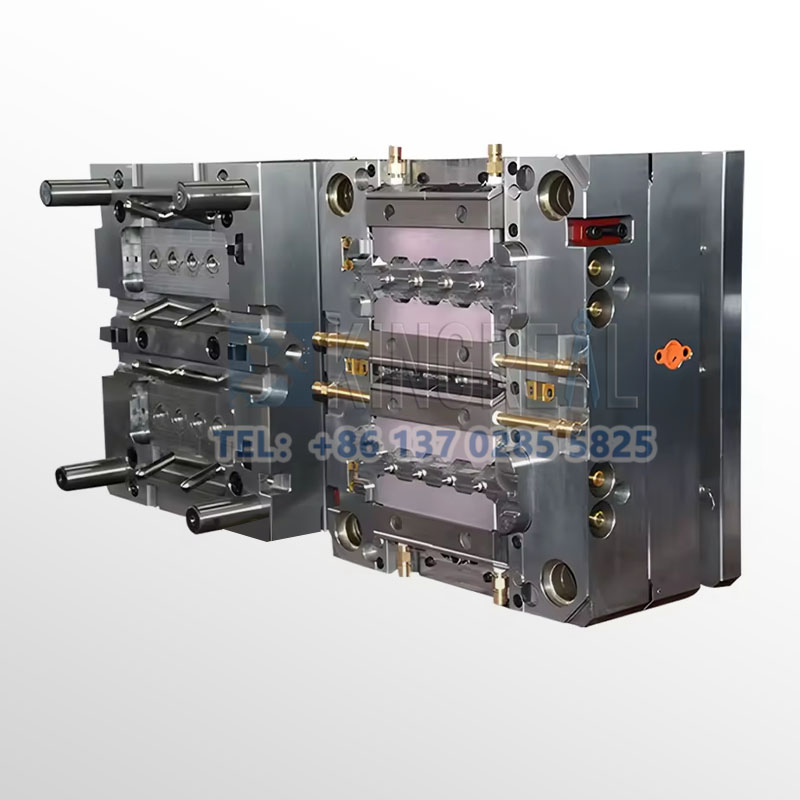

(1) Design of positioning module

In our design, the positioning module includes a plurality of positioning blocks, which are arranged along the circumference of the double injection molding station. Their function is to respectively press the side edges of the single-color part and/or the two-color part to ensure the stability of each part during the double shot injection molding process.

(2) Structure of positioning blocks

These positioning blocks extend in the length direction and can extend from one end of the side edge of the one-color part or the two-color part to the other end. The contact surface of each positioning block is matched with the side edge of the one-color part and the two-color part to ensure a tight combination during the double injection molding process.

(3) Application of concave-convex structure

A concave part or convex part is provided on the one-color molding part so as to form a corresponding convexity or groove on the one-color part. These structures can be connected with the two-color part when the two-color part is injected, thereby improving the bonding ability between the two parts.

(4) Design of the clamping part

At least one first clamping part is provided on the positioning module, which is used to form a second clamping part that is matched with the injection-molded two-color part. This design ensures that the two-color part can be pressed onto the one-color part during the injection molding process, which increases the reliability of the combination.

(5) Relative movement of the mold

The first module can be movably arranged below the second module, and the relative position adjustment of the one-color molding part and the double shot injection molding part can be achieved by moving the device. This flexible design enables the mold to adapt to different production needs.

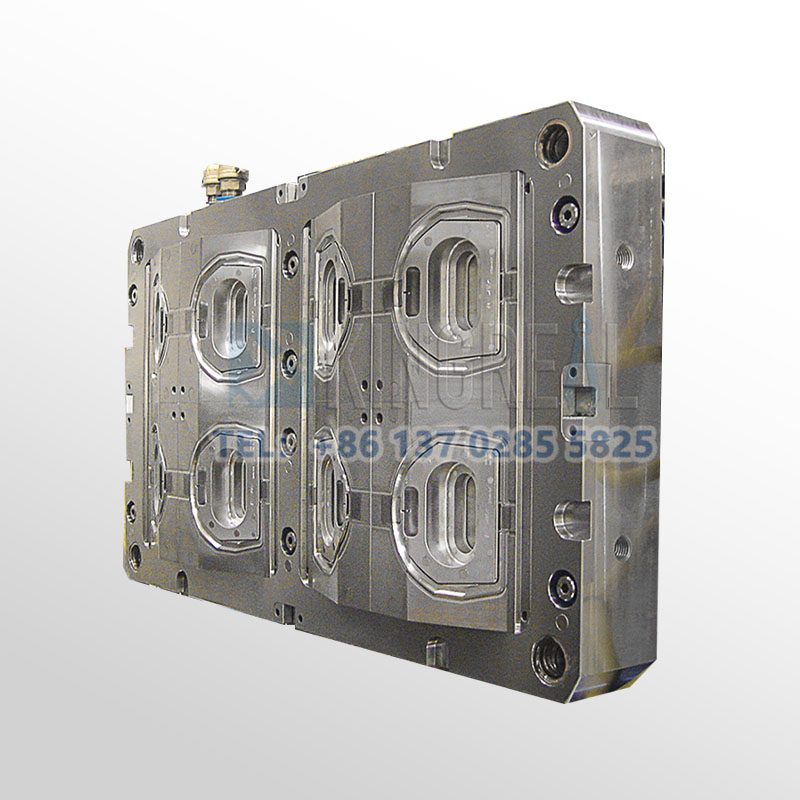

(6) Array layout of double injection molding stations

The injection mold KRMOLD designed has multiple double shot injection molding stations, which are arranged in an array on the first mold, and can perform multiple double injection molding processes at the same time to improve production efficiency.

3.Practical Application and Advantages of Double Injection Molding

Through the above design, KRMOLD double shot injection mold has shown significant advantages in practical applications:

Improve product quality: The stability and accuracy of the mold are greatly improved, ensuring that the quality of the molded product meets the high standards of customers. Reduce production costs: Through optimized design, the losses caused by damaged injection molded parts are reduced, thereby reducing production costs. Flexible adaptation to market demand: The flexibility of mold design enables the production line to be quickly adjusted to meet the needs of different products in the market. |  |

KRMOLD specializes in providing customers with different types of injection molds, striving to provide customers with more efficient, stable and economical production solutions. In addition to double injection molding, gas-assisted injection molding, insert injection molding, multi cavity injection molding, micro injection molding, overmolding, etc. are all available. If you are interested in KRMOLD double shot injection molds or other injection molds, please feel free to contact us. KRMOLD will wholeheartedly provide you with professional services and support.