KINGREAL UNIVERSAL IND., LTD

Phone

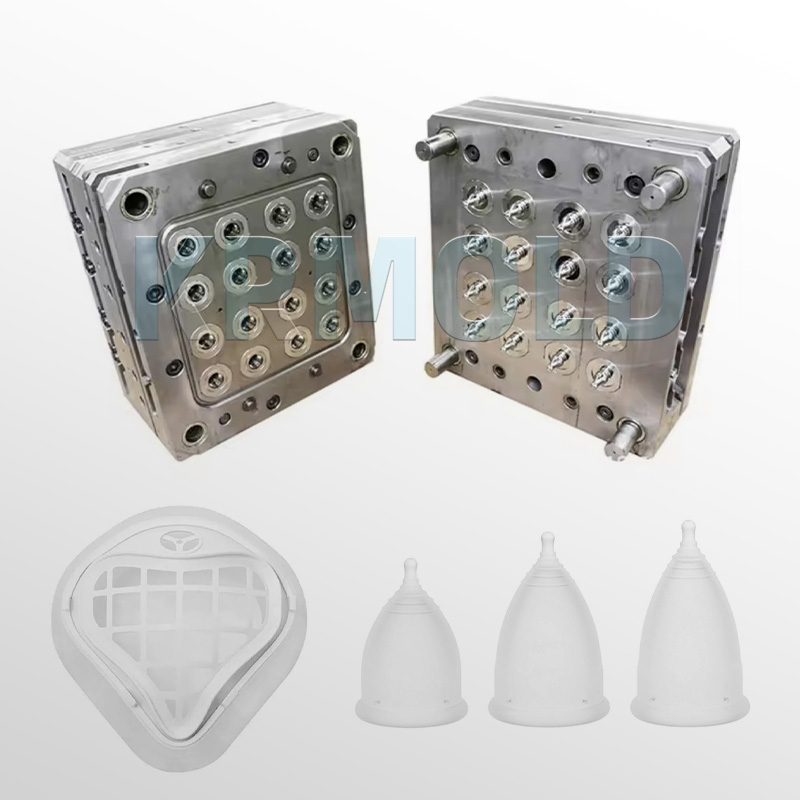

+86-13702855825Silicone rubber injection molding is an advanced manufacturing process that is widely used in many industries to efficiently produce complex silicone parts. This process involves injecting heated silicone material into a mold, cooling and curing it to form the desired shape. In this article, KRMOLD will take a deep dive into the steps and advantages of using silicone rubber injection molds to help you better understand this manufacturing technology.

| 1 | Basic Concepts of Silicone Rubber Injection Molding |

| 2 | Process Steps of Silicone Rubber Injection Molding |

| 3 | Types of Silicone Rubber Injection Molding Materials |

| 4 | Application of Silicone Rubber Injection Molding |

| 5 | Advantages of Using Silicone Rubber Injection Molds |

1.Basic Concepts of Silicone Rubber Injection Molding

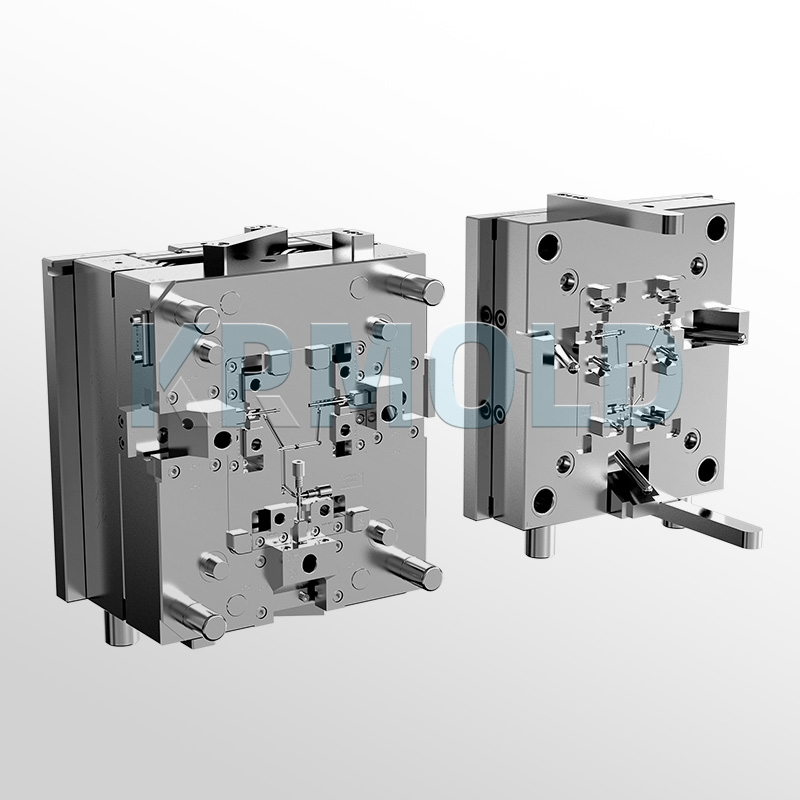

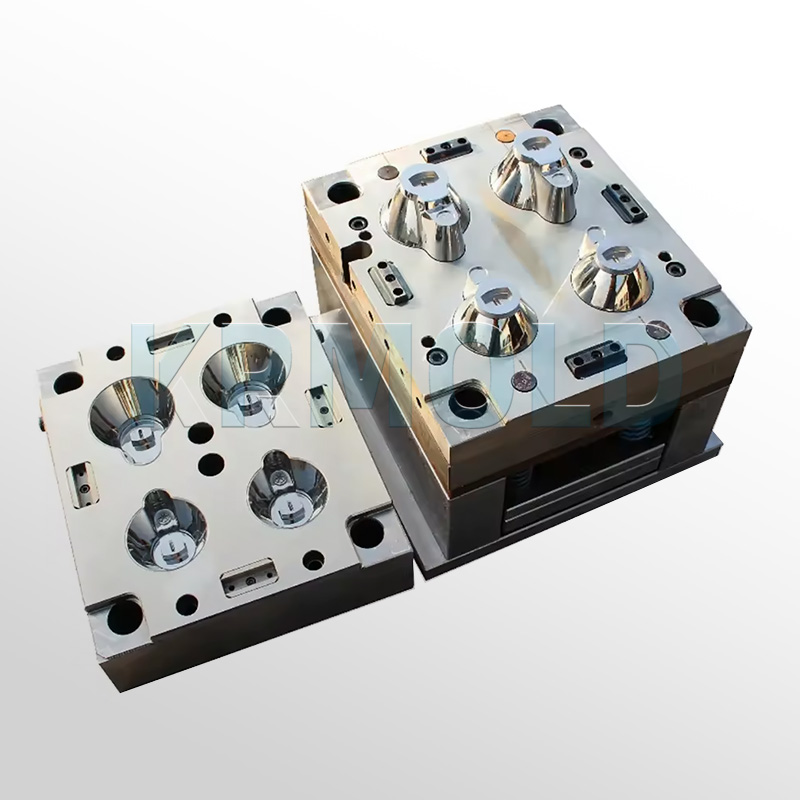

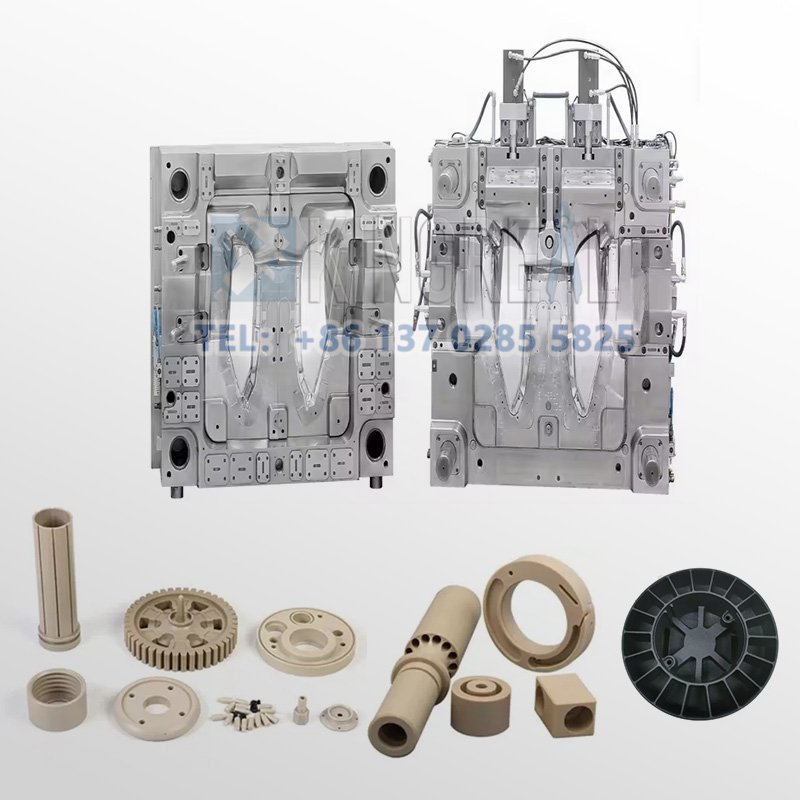

Silicone rubber injection molding involves injecting liquid silicone rubber (LSR) under high pressure into a precision-machined mold. The silicone rubber injection molds are usually made of steel or aluminum and is a key factor in determining the final shape and complexity of the part. After injection, the silicone material cools and cures to form the final product. This process not only reflects advanced technological capabilities, but also has an important impact on the advancement of modern manufacturing.

2.Process Steps of Silicone Rubber Injection Molding

The process of silicone rubber injection molding can be divided into several key steps. Each step requires meticulous attention and precise operation to ensure the quality and performance of the final product.

Step 1: Prepare the silicone material

Before silicone rubber injection molding, the base silicone elastomer needs to be thoroughly mixed with a catalyst (usually a platinum-based compound). This step is critical because the precise preparation of the mixture will directly affect the physical and chemical properties of the final product. During this process, manufacturers usually use advanced mixing and measuring techniques to ensure a uniform and bubble-free mixture.

In addition, pigments can be added during the mixing process to meet product appearance requirements. Ensuring the proportion and uniformity of the mixture is the basis for successful injection molding.

Step 2: Load the injection molding machine

Next, the prepared silicone material will be loaded into the injection molding machine. Injection molding machines are usually equipped with heating barrels and reciprocating screws, where the material is heated to a liquid state. Typically, the temperature needs to be controlled between 250°C and 300°C to ensure good material fluidity. Accurate heating control is essential to prevent material degradation and ensure that the material can be smoothly injected into the silicone rubber injection molds.

Step 3: Molding process

When the silicone material reaches a liquid state, the silicone rubber injection molding process officially begins. The machine injects the silicone into the closed mold under high pressure. This process is essential to molding the silicone into the desired shape. The silicone rubber injection molds usually need to be cooled to accelerate the curing of the silicone and ensure that the material can fully fill every detail of the silicone rubber injection molds.

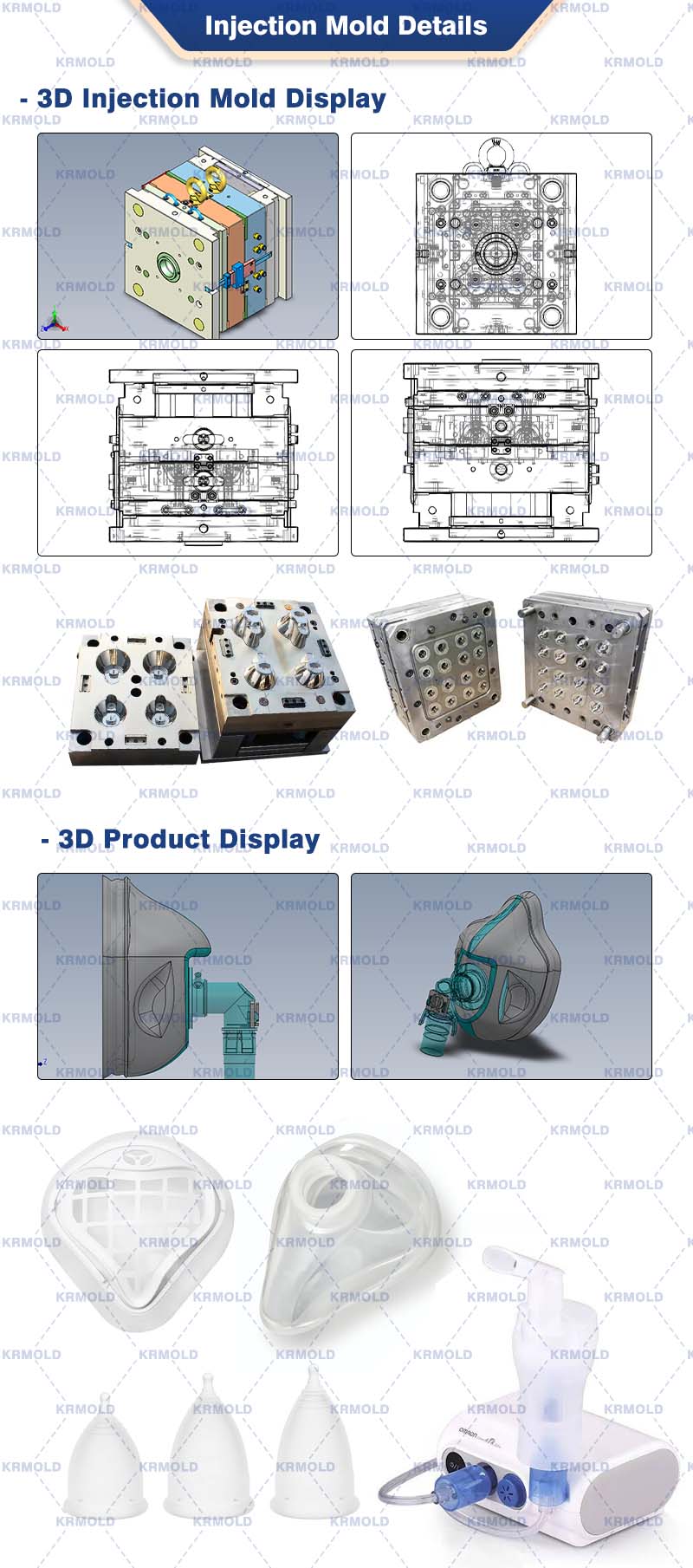

The complexity of the mold design is particularly important at this stage. The cavity size, injection gate location and cooling system of the silicone rubber injection molds must be reasonably arranged to obtain the best injection molding effect.

Step 4: Cooling and Ejection

The silicone injected into the silicone rubber injection molds needs to go through a certain cooling time to ensure that it solidifies and reaches the final performance and strength. The silicone rubber injection molds design needs to ensure that the material can be cooled evenly to prevent deformation and inconsistency. After cooling is completed, the silicone part will be removed from the silicone rubber injection molds by the ejector or ejector mechanism.

Step 5: Post-processing of molded parts

Molded parts usually need to be post-processed to ensure that they meet the design requirements. Post-processing may include trimming excess material, additional curing to enhance physical properties, surface treatment, and quality inspection. These steps ensure that each part meets the standards in terms of function and appearance.

3.Types of Silicone Rubber Injection Molding Materials

| In silicone rubber injection molding, there are many types of silicone materials used, each with its own characteristics to meet the needs of different applications. Mainly include:

High consistency rubber (HCR): suitable for high-strength applications such as automotive parts and industrial seals. Liquid silicone rubber (LSR): widely used in medical devices and consumer products due to its easy processing and fast curing characteristics. Fluorosilicone rubber (FSR): excellent performance in harsh environments, suitable for automotive fuel systems. Room temperature vulcanizing (RTV) silicone: suitable for small-scale applications and prototyping, easy to use and cures at room temperature. |

4.Application of Silicone Rubber Injection Molding

Silicone rubber injection molding is a very flexible manufacturing method that is suitable for a variety of industries and products. Its unique properties, such as flexibility, heat resistance, chemical stability and biocompatibility, make it an ideal manufacturing material. Here are some typical applications:

Medical devices: including catheters, implants and surgical instruments, are favored for their biocompatibility and durability. |  |

Automotive industry: such as seals, hoses and electrical insulation materials, are widely used due to their heat resistance and chemical resistance. |  |

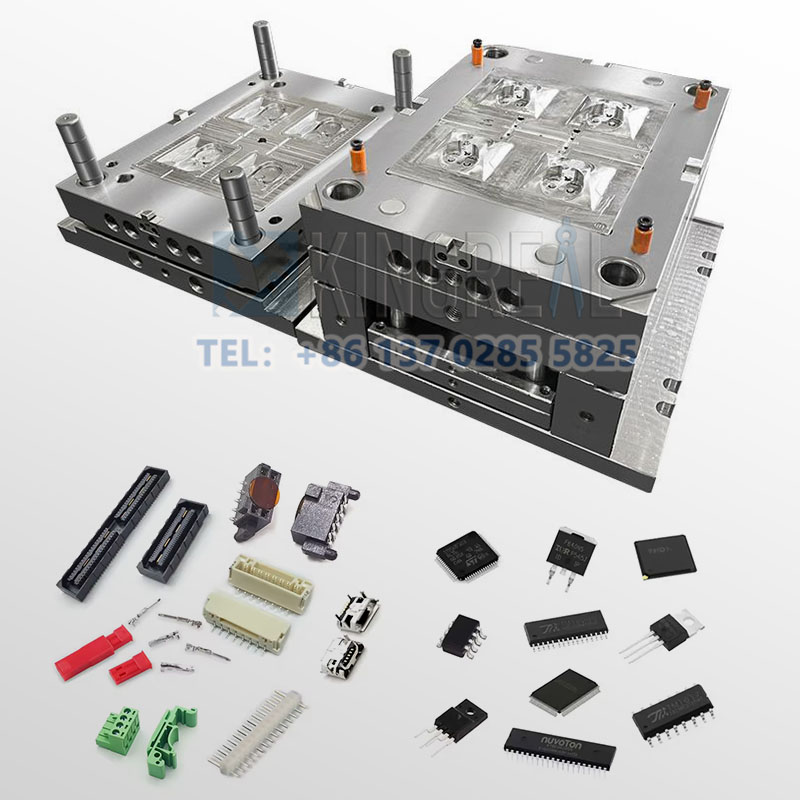

Consumer electronics:such as protective cases and keyboards, the flexibility and shock absorption properties of silicone materials make them an ideal choice. |  |

Aerospace: Silicone’s thermal and chemical stability make it reliable in extreme conditions in seals and insulation materials. |  |

5.Advantages of Using Silicone Rubber Injection Molds

(1) High precision and consistency

Silicone rubber injection molding is able to produce parts with high precision and consistency. The process is extremely precise, allowing manufacturers to produce complex shapes and details under tight tolerances. For industries such as medical and aerospace, any slight deviation can lead to serious consequences, so this high-precision manufacturing is essential.

(2) Compatible with complex designs

Silicone rubber injection molding is compatible with complex designs and can manufacture parts with complex geometries that are difficult to achieve with other manufacturing methods. This compatibility opens up more design possibilities and enables the production of highly specialized and customized silicone parts.

(3) Efficiency and speed

Modern injection molding machines offer fast cycle times, enabling high-volume production in a shorter time. This efficiency not only helps meet market demands, but also reduces total production time and costs.

(4) Flexibility in materials and colors

Silicone rubber injection molding offers flexibility in material and color selection. Manufacturers can customize silicone with different properties according to product requirements and achieve a variety of color options by adding pigments.

(5) Enhanced Strength and Durability

The process ensures that the material properties are evenly distributed, and the molded silicone parts are strong and durable, able to withstand a variety of environmental stresses. This enhanced strength makes the product more reliable during use.

(6) Minimal Waste Generation

Silicone rubber injection molding is very efficient in material use and generates minimal waste. Excess materials can often be recycled and reused, contributing to sustainable manufacturing practices.