KINGREAL UNIVERSAL IND., LTD

Phone

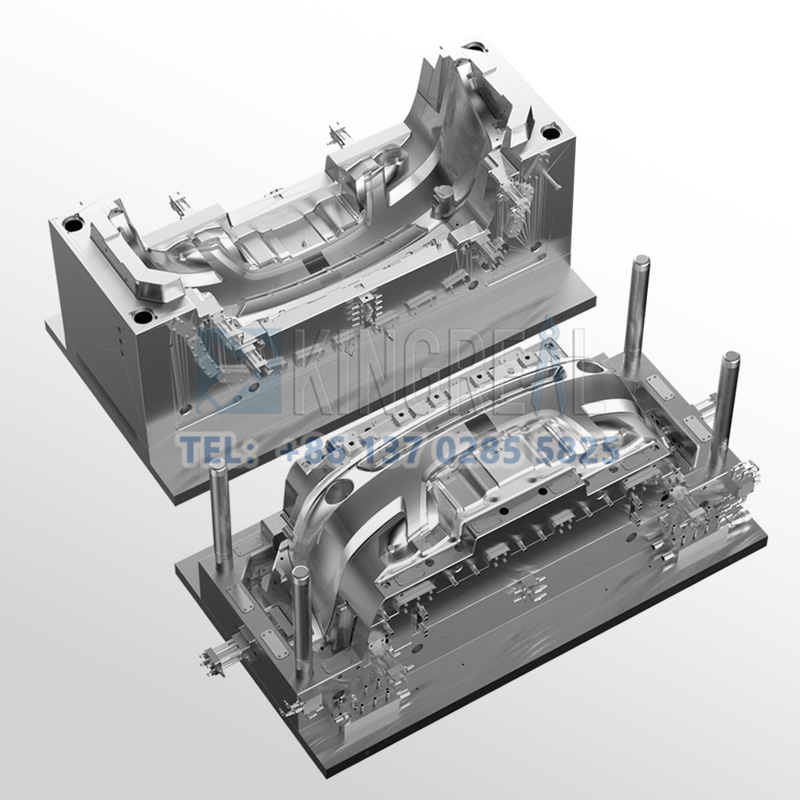

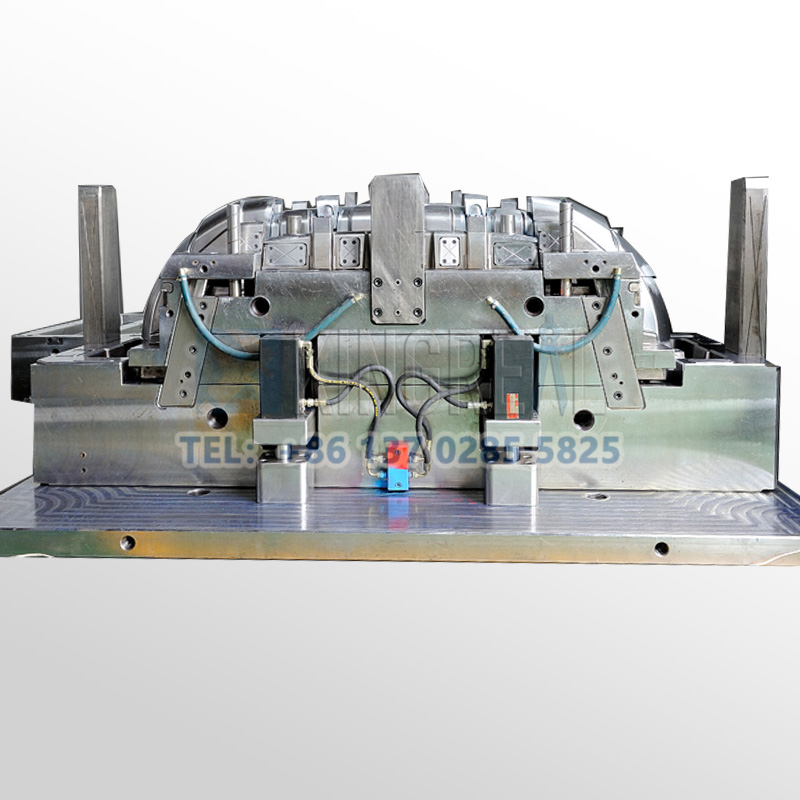

+86-13702855825Plastic injection molding is an important technology widely used in the field of plastic processing. It injects molten plastic into the plastic injection mold through high pressure, and obtains plastic products of the desired shape after cooling and solidification.

Among them, there are many types of plastic injection moulding processes, each with its own characteristics. In this article, KRMOLD will explain the five main plastic injection molding processes in detail:

| 1 | Conventional Plastic Injection Molding |

| 2 | Two-color Injection Molding |

| 3 | Insert Injection Molding |

| 4 | Micro Injection Molding |

| 5 | IMD Injection Molding |

| 6 | Main Application Areas of IMD Injection Molding |

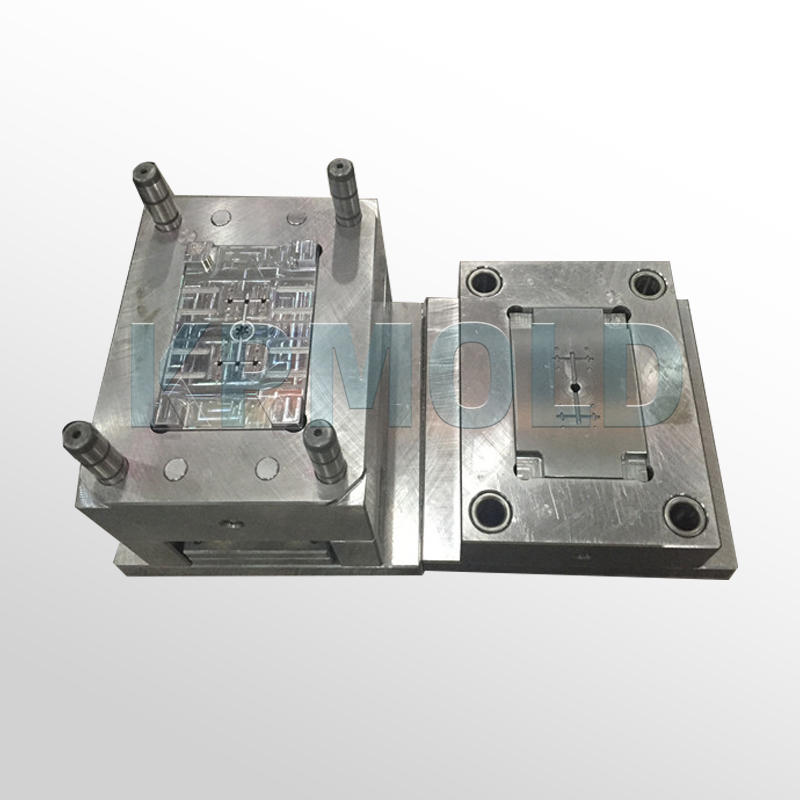

01 Conventional Plastic Injection Molding:

Conventional plastic injection moulding is the most basic plastic injection moulding process, which is suitable for the production of plastic products of various shapes and sizes. This process injects molten plastic into the plastic injection mold cavity through high pressure, and demolds the finished product after cooling and solidification. Conventional plastic injection moulding has the advantages of high production efficiency, strong adaptability, and high molding precision.

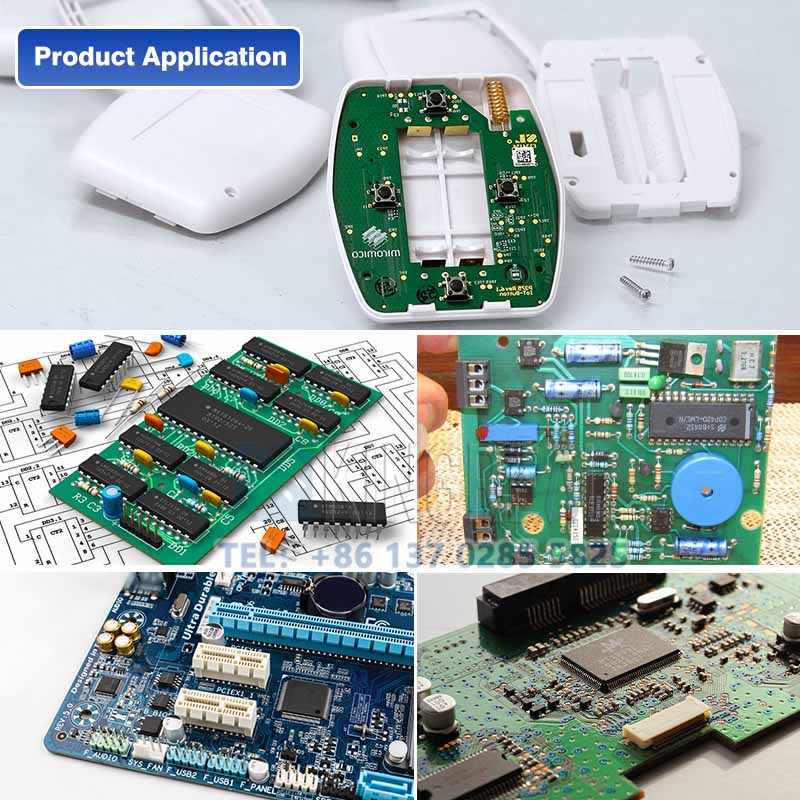

Among industrial products, injection molded products include: kitchen supplies (garbage cans, bowls, buckets, pots, tableware and various containers), housings of electrical equipment (hair dryers, vacuum cleaners, food mixers, etc.), toys and games, various products in the automotive industry, and parts of many other products.

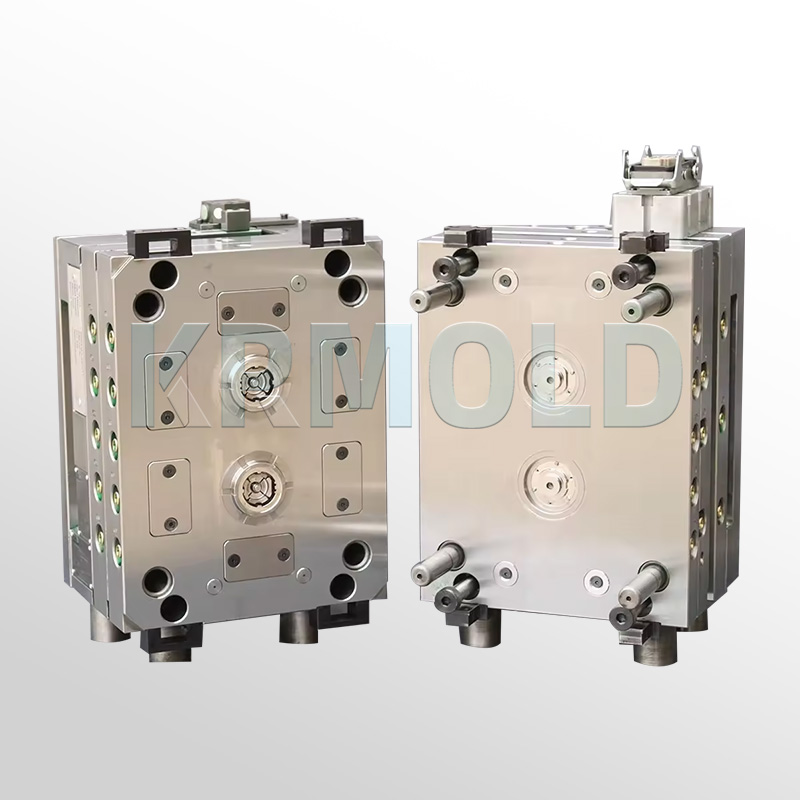

02 Two-color Injection Molding:

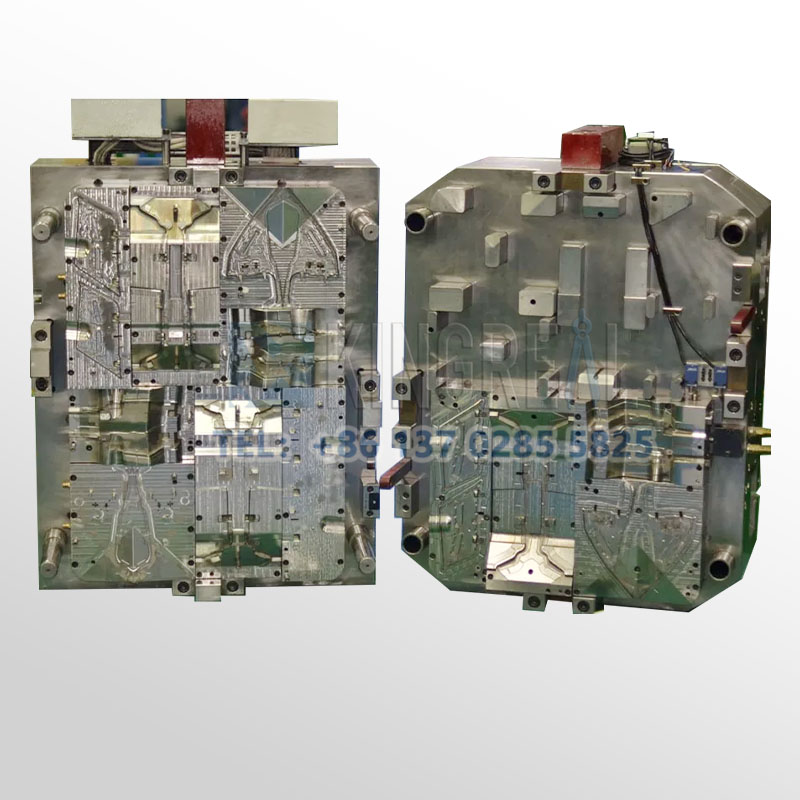

Two-color injection molding is an plastic injection moulding process that achieves multiplecolors or material combinations through multiple injections or transfer molding in the same mold. This is a plastic injection moulding process for multiple materials, which can have multiple combinations, such as plastic + plastic; plastic + silicone; plastic + cloth, etc., which can not only achieve multiple color combinations, but also can achieve multifunctional integration by implanting corresponding hardware, electronic chips and other internal components, greatly reducing assembly processes and saving product production costs. It truly realizes the characteristics of miniaturization, intelligence, multi-function and personalization, and has unique advantages in the field of precision plastic injection moulding products with small regional functions.

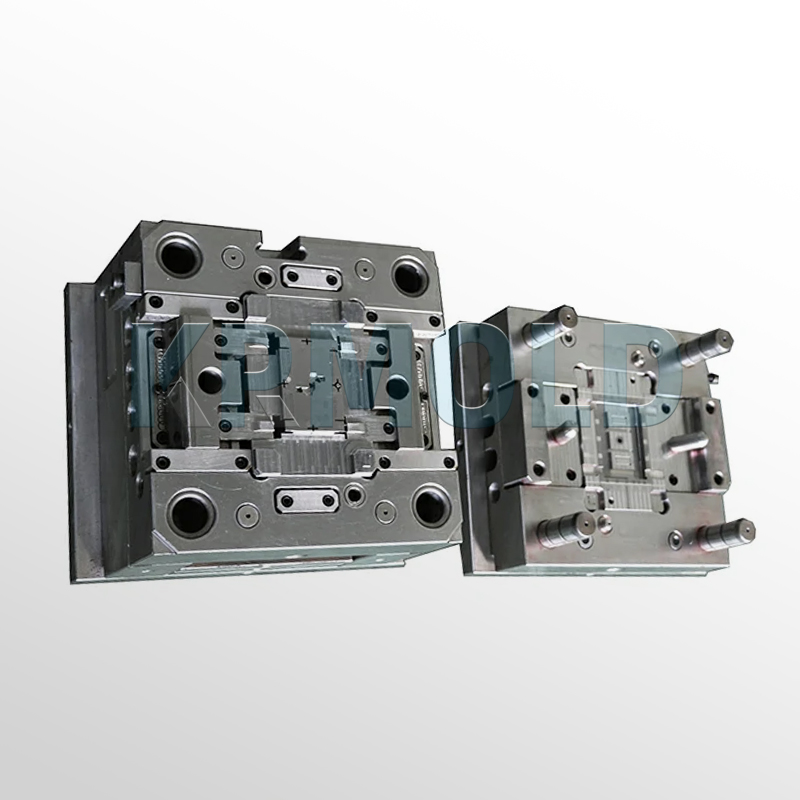

03 Insert Injection Molding:

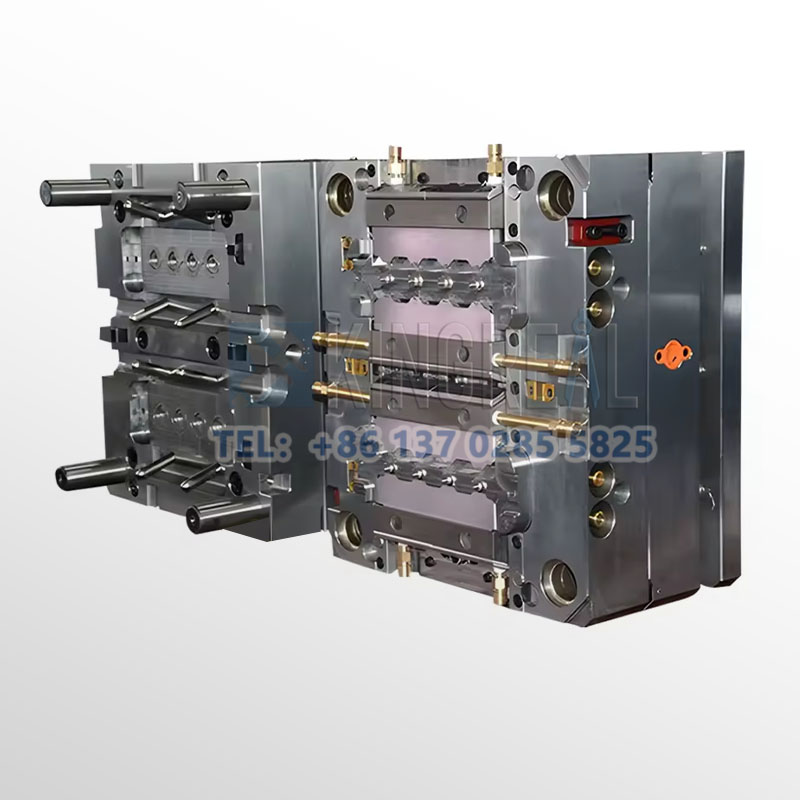

Insert injection molding is a process in which inserts of metal, plastic or other materials are placed in the plastic injection mold during the injection molding process and injection molded together with the plastic. The general process of insert injection molding includes: insert mold → vacuum fixation → injection molding. It is widely used in home appliances, consumer electronics, toys and other fields. The advantages are that plasticity and rigidity are perfectly combined according to design requirements, the composite reliability of inserts and main parts is high, and it has automated mass production.

This process can achieve a close combination of plastics and metals or other materials, and improve the strength and durability of the product. Insert injection molding is widely used in home appliances, automobiles, electronics and other fields.

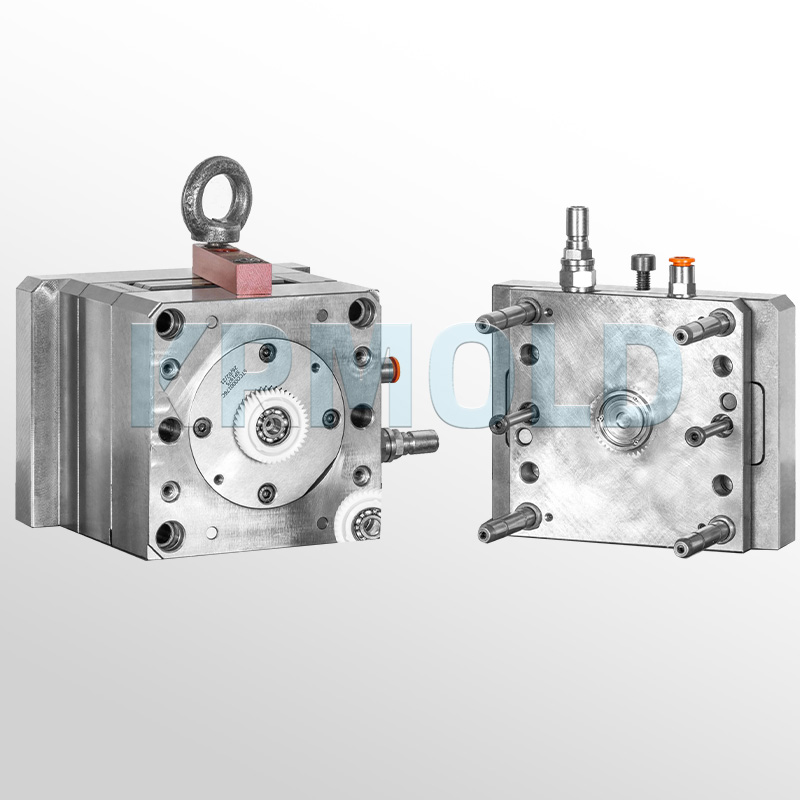

04 Micro Injection Molding:

Micro injection molding is a subcategory of injection molding, which is used to manufacture micro or small plastic parts with extremely precise dimensions. It uses micro injection molds to realize designs that, broadly speaking, cannot be obtained or realized using injection molding alone. It can also be used to produce parts weighing less than one gram or measuring several millimeters. Due to the huge demand for miniaturization of parts in many industries, technology has made great progress to meet this demand.

Micro injection molding has very high requirements for the control accuracy of process parameters due to its small size of plastic parts. This process is mainly used to produce tiny plastic parts in the fields of micro pumps, valves, micro optical devices, micro medical devices and microelectronics. The micro molding process has the advantages of high precision and accuracy, material versatility, and large-scale production cost efficiency.

05 IMD Injection Molding:

IMD injection molding is one of the mainstream decoration technologies currently used in major product fields. In layman's terms, this technology combines the finished product CMF design, film processing and injection molding technology (including mold technology), and the decorated film carrier and the plastic substrate are molded into one piece, directly obtaining a finished product with a certain texture that has been surface treated.

Thermoplastic Injection In-Mold Decoration is a technology that prints decorative patterns and functional patterns on foil films through a high-precision printer, and then uses a high-precision foil feeding device to send the foil into a special molding mold for precise positioning, and then transfers the pattern on the foil film to the surface of the plastic product through the high temperature and high pressure of the injected plastic raw material. This technology can produce plastic products that are bright in color, exquisite and beautiful, and corrosion-resistant, abrasion-resistant and scratch-resistant.

Conceptually, IMD injection molding is a general term, including IML, IMF, IMR, INS, etc. Many domestic industry professionals separate IML from IMD and call IMR IMD process. Since IML and IMF processes are consistent, they are generally classified into two categories: IMD/IMR, IML/IMF/INS/IME.

06 Main Application Areas of IMD Injection Molding:

Home appliance industry: control decorative panels of rice cookers, washing machines, microwave ovens, air conditioners, refrigerators, etc.

Automotive industry: instrument panels, air conditioning panels, interior trims, headlight housings, logos, etc.

Electronics industry: decorative housings and signs for MP3, MP4 machines, computers, VCD, DVD, electronic notepads, cameras, etc.

Computer industry: keyboards, mouse housings.

Communications industry: mobile phone buttons, housings, window lenses.

Other industries: cosmetic boxes, gift boxes, decorative boxes, toys, plastic products, sports and leisure equipment, etc.

KRMOLD has nearly 20 years of rich experience in the field of plastic injection mould manufacturing. It is an plastic injection mold supplier integrating design and production. And it has provided plastic injection mould services to customers in the medical, automotive, home appliance, packaging and other industries. Therefore, KRMOLD engineers will customize the plastic injection molds according to the performance and requirements of the products in various industries. If you are interested in plastic injection moulding, please come to consult!