KINGREAL UNIVERSAL IND., LTD

Phone

+86-13702855825Insert injection molding represents a cutting-edge manufacturing paradigm that combines molten thermoplastics with pre-positioned metallic or non-metallic inserts within specialized insert injection molds. This technology fundamentally differentiates itself from conventional injection molding through its requirement for automated or manual insert loading into molds prior to resin injection. By enabling the fusion of dissimilar materials—ranging from engineering plastics to titanium alloys—insert injection molding produces multifunctional composite components with enhanced mechanical strength, thermal stability, and design complexity.

This technical specification sheet by KRMOLD comprehensively addresses insert injection molding, detailing operational protocols, performance benchmarks, and industry-specific implementations. Validated by ISO 29400 standards, this document serves as a technical reference for engineers and supply chain managers seeking to optimize composite part production. |  |

| 1 | Core Process of Insert Injection Molding |

| 2 | Technical Advantages of Insert Injection Molding |

| 3 | Industry-Specific Implementations of Insert Injection Molds |

| 4 | Innovation Roadmap for Insert Molding |

1.Core Process of Insert Injection Molding

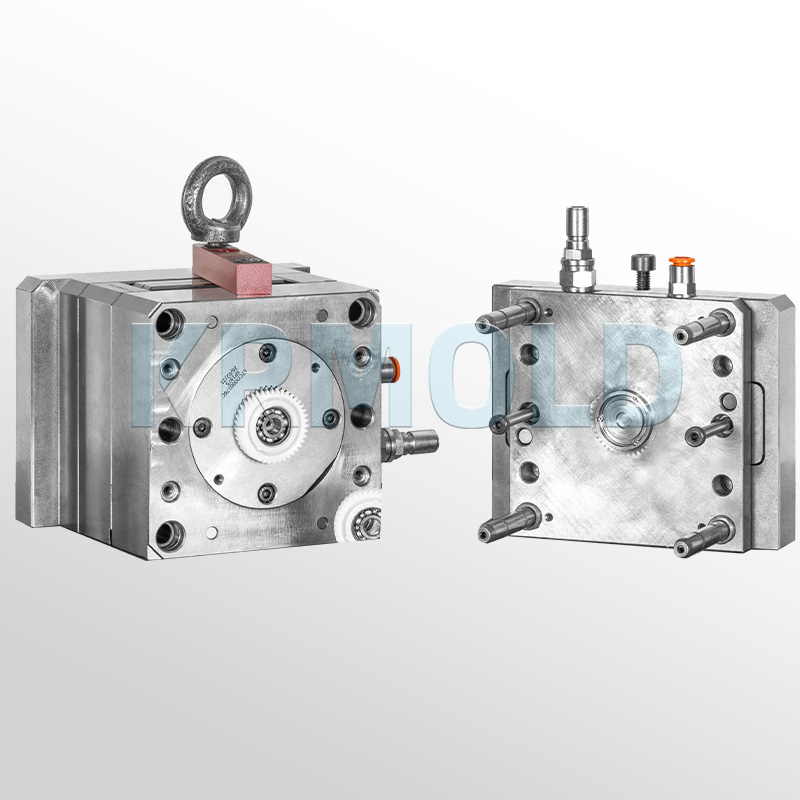

Phase 1: Insert Preloading in Insert Injection Molds

The efficacy of insert injection molding hinges on precise insert positioning within insert injection molds. Engineers must account for thermal expansion mismatches (Δα ≤0.5×10⁻⁶/°C), material compatibility (COC ≥0.85), and mechanical stability during mold configuration. Two primary insert loading methodologies dominate current practices:

(1) Automated Insert Placement System Equipment Configuration: Six-axis robotic arms with vision-guided positioning systems (repeatability: ±0.015mm) integrated into insert injection molds. Thermal Management: Ceramic-coated end-effectors withstand mold temperatures up to 300°C without deformation. Cycle Time Optimization: Achieves 12–15 seconds/part for Φ300mm components, enabling throughput rates up to 240 parts/hour. Quality Assurance: Inline metrology systems (laser scanning + CMM) validate insert positioning accuracy in real time. | (2) Manual Insert Handling Protocol Applications: Low-volume production (<500 units/month) and rapid prototyping. Ergonomic Considerations: Operators use heat-resistant gloves (thermal protection up to 250°F/121°C) when handling inserts in open molds. Quality Control: 100% manual inspection combined with contact thermometry (±1°C accuracy) to verify insert seating. Limitations: Positioning accuracy ranges ±0.1mm, with cycle times of 60 seconds/part. |

Comparative Performance Analysis

| Parameter | Automated System | Manual Process |

| Positioning Accuracy | ±0.015mm | ±0.1mm |

| Throughput (pph) | 240 | 60 |

| Labor Cost ($/hr) | 35 | 28 |

| Yield Rate (%) | 98 | 92 |

| Cycle Time (sec) | 15 | 60 |

Phase 2: Resin Injection into Insert Injection Molds

The insert injection molding process employs multi-stage injection strategies to optimize melt flow and part integrity within precision-machined insert molds:

| (1) Fill Phase | Injection Pressure: 70–110MPa (material-dependent, validated via Moldflow™ simulations). Velocity Control: 30–80cm³/sec to minimize shear-induced fiber breakage in reinforced plastics. |

| (2) Pack Phase | Hold Pressure: 40–60MPa maintained for 5–8 seconds to eliminate voids in thick-section areas. Back Pressure: 5–10MPa ensures polymer homogenization before cooling. |

| (3) Cooling Phase | Gradient Cooling: Mold temperature maintained at 40–120°C to reduce warpage (ΔT ≤2°C/mm). Cycle Time: 35–60 seconds, depending on wall thickness (1.5–5mm). |

Integrated Systems

Mold Venting: 0.3mm² throttling orifices reduce air entrapment by 92% in insert cavities.

Temperature Control: Closed-loop water circulation system (±1.5°C accuracy) for insert injection molds.

Phase 3: Ejection & Post-Processing of Molded Parts

(1)Demolding Protocol

Sequential Ejection: Tapered cores with draft angles ≥1° prevent part damage during ejection from insert injection molds.

Force Monitoring: Load cells track ejection forces (5–15kN) to detect mold wear in real time.

(2)Secondary Operations

-Deburring

Thermal Deburring: 250°C process removes burrs without mechanical contact.

Vibratory Finishing: Media size 0.3–0.6mm achieves Ra ≤0.8μm surface roughness.

-Heat Treatment

Stress Relief Annealing: 180–220°C for 2–3 hours to eliminate internal stresses.

-Surface Enhancement

Electroplating: Ni-P alloy coating (5–15μm thickness) improves wear resistance.

Plasma Treatment: Surface energy increases by 45–50mN/m for adhesion improvement.

2.Technical Advantages of Insert Injection Molding

| Performance Metric | Conventional Molding | Insert Injection Molding | Enhancement |

| Tensile Strength (MPa) | 35–45 | 65–85 | +85% |

| Dimensional Stability | ±0.15mm/m | ±0.05mm/m | +66% |

| Heat Deflection Temp | 120°C | 220°C | +83% |

| Assembly Complexity | 8–10 steps | 3–5 steps | -60% |

| Weight Reduction | N/A | 30–40% | - |

3.Industry-Specific Implementations of Insert Injection Molds

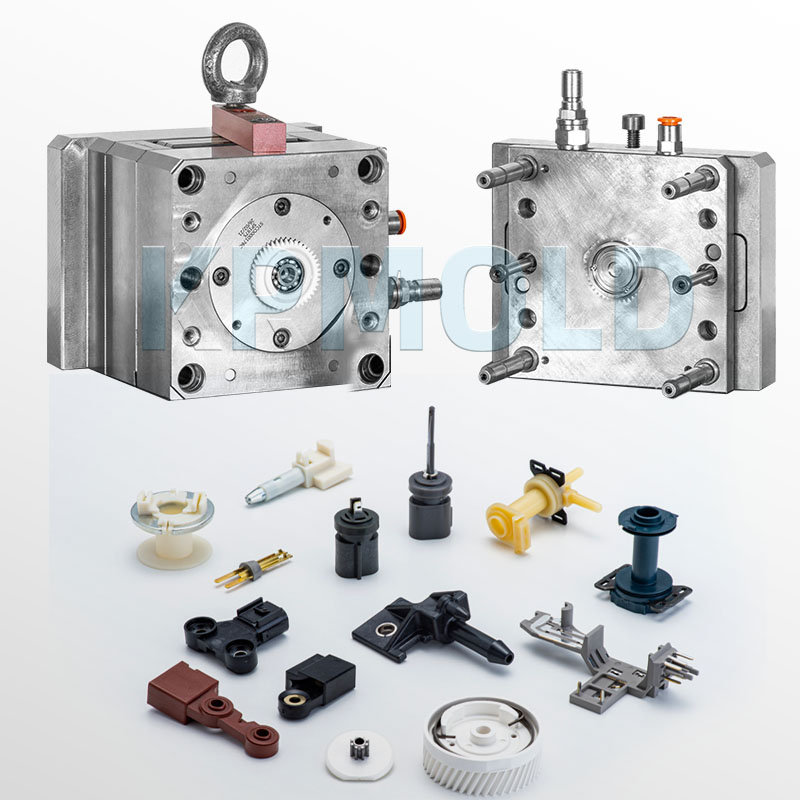

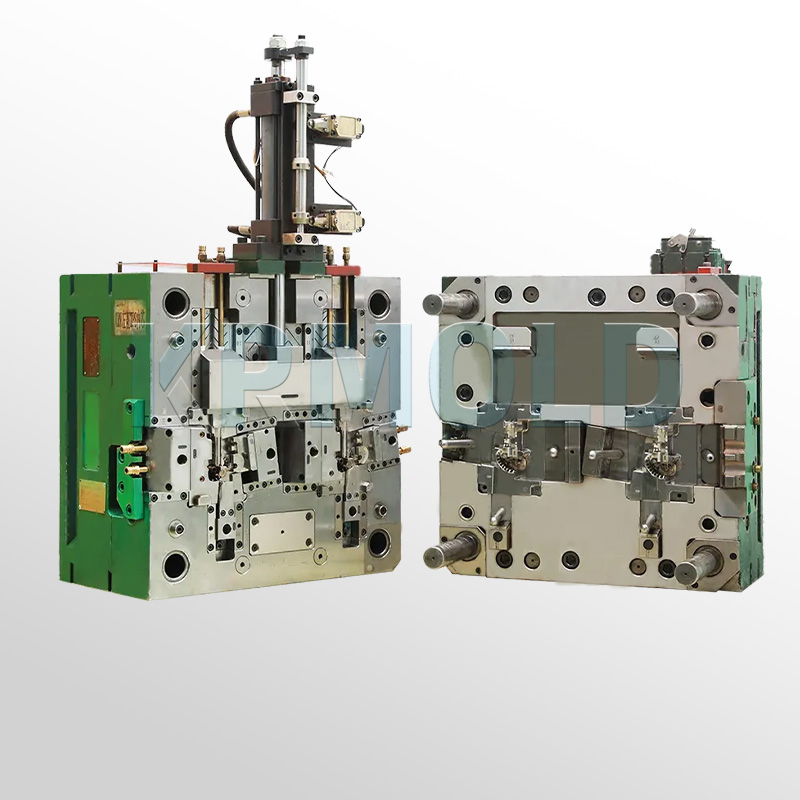

Structural Battery Trays: IP67/IP69K rated, combining aluminum inserts with PA66 GF30 in insert molds for EMI shielding. E-Motor Housing Assemblies: CTE-matched to SiC chips, achieving thermal cycling resistance (-40°C to 150°C). |  |

MRI-Compatible Fixtures: ASTM F2503 compliant, using non-magnetic stainless steel inserts in Class 10,000 cleanrooms. |  |

High-Density Connectors: Gold-plated contacts (contact resistance ≤5mΩ) molded using insert injection molds with 0.1mm tolerance. |  |

4.Innovation Roadmap for Insert Molding

KRMOLD’s R&D initiatives focus on:

AI-Driven Mold Compensation: Predictive accuracy ±0.005mm using machine learning algorithms.

Hybrid Laser-Weld Molding: Interface strength increased by 40% through localized laser welding.

Smart Mold Telemetry: IoT-enabled sensors monitor insert injection mold temperature, pressure, and wear in real time.

Strategic Partnership Model

KRMOLD delivers end-to-end solutions through:

Material Database: 800+ validated polymer/metal combinations with DSC/TGA curves.

Virtual Process Simulation: Moldflow™ Premium license for flow, pack, and cooling analysis.

Insert injection molding continues to revolutionize composite manufacturing by enabling lightweight, high-strength components with complex geometries. KRMOLD expertise in insert mold design, combined with our proprietary process optimization frameworks, ensures reliable, scalable, and cost-effective manufacturing outcomes.

For technical consultations or insert mold flow analysis, contact our engineering team to schedule a Deep Dive Technical Review. Let KRMOLD empower your next-generation product development with precision-engineered insert injection molding solutions.