KINGREAL UNIVERSAL IND., LTD

Phone

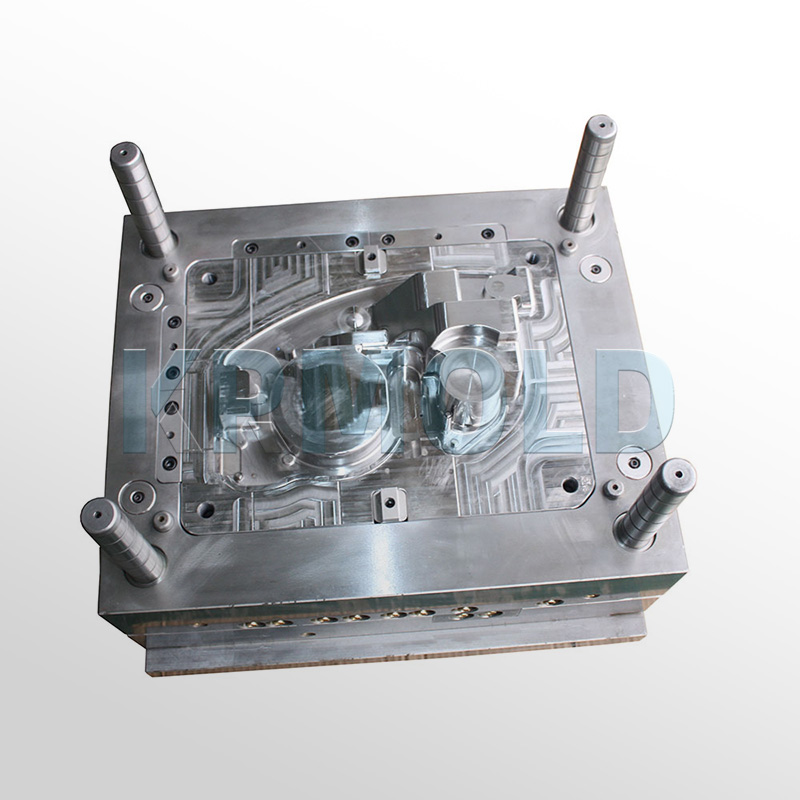

+86-13702855825As plastic injection mold manufacturers, KRMOLD recognizes the significance of ABS injection molding in the plastic manufacturing industry. This article provides a comprehensive overview of various aspects of ABS injection molding to enhance your understanding of this process and enable you to offer superior mold solutions to your customers.

| 1 | What is ABS Plastic Injection Molding? |

| 2 | How ABS Injection Molding Works? |

| 3 | How to Control the ABS Plastic Injection Molding Process? |

| 4 | Common Applications of ABS Injection Molding |

1. What is ABS Plastic Injection Molding?

ABS is a widely utilized thermoplastic polymer, celebrated for its exceptional high-temperature impact resistance and toughness. The unique composition of ABS comprises three monomers:

Acrylonitrile: This component contributes to the chemical resistance and rigidity of the material. Butadiene: It enhances elasticity and impact resistance, making ABS less prone to cracking under stress. Styrene: This monomer provides good processing properties, allowing for easy molding and shaping. These characteristics position ABS plastic injection molding as a preferred choice across various industries, including automotive parts and consumer electronics housings. The versatility and reliability of ABS make it an ideal material for producing high-quality plastic components. |  |

2. How ABS Injection Molding Works?

The ABS plastic injection molding process involves several crucial steps to ensure the efficient production of high-quality plastic parts. Here’s a breakdown of the steps involved:

Drying the ABS Pellets: The first step involves drying the ABS pellets to eliminate any moisture that could affect the quality of the molded parts. Moisture can lead to defects such as bubbles or weak spots.

Heating and Melting: Once dried, the pellets are placed in the hopper of the ABS plastic injection molding machine. The machine heats the pellets until they melt into a viscous liquid, preparing them for injection.

Injection into the Mold: The molten ABS is then injected into the mold cavity through a screw or a plunger at high pressure. This step is critical for filling the mold accurately and ensuring that all details are captured.

Cooling and Solidification: After the ABS injection mold is filled, the material is allowed to cool and solidify. This stage is vital for achieving the desired shape and mechanical properties of the ABS part.

Ejection of the Part: Once cooled, the mold opens, and the newly molded ABS part is ejected. The entire cycle can be repeated to produce a large volume of parts efficiently.

This well-defined process allows manufacturers to produce thousands of consistent, high-quality ABS components in a relatively short time.

3. How to Control the ABS Plastic Injection Molding Process?

1

Optimize Mold Temperature

Controlling the mold temperature is critical for successful ABS plastic injection molding. Typically, the mold temperature should be maintained between 50°C and 85°C (122°F to 185°F). Proper temperature control ensures:

Dimensional Consistency: Maintaining the right temperature helps achieve uniform dimensions across multiple parts.

Surface Smoothness: A well-regulated temperature contributes to a smooth surface finish, enhancing the aesthetic appeal of the final product.

Minimized Internal Stress: Proper cooling reduces the risk of warping or internal stresses that could compromise the part’s integrity.

By adjusting the temperature within this recommended range, manufacturers can ensure stable production of high-quality ABS products.

2

Stable Injection Pressure

Maintaining consistent injection pressure is essential for ensuring the quality and tolerance of ABS injection molding parts. The typical injection pressure should be between 70 and 140 MPa, depending on the complexity of the part and material requirements. Consistent pressure can help:

Reduce Defects: Stable pressure minimizes defects such as sink marks, voids, and incomplete fills, leading to a more reliable product.

Enhance Consistency: By ensuring a uniform injection process, manufacturers can achieve a higher level of consistency across all produced parts.

Implementing real-time monitoring and control systems can help maintain the desired injection pressure, ensuring quality and reliability in production.

3

Optimize Cooling Time

Cooling time plays a significant role in the ABS plastic injection molding process and directly impacts the quality of the final product. Optimizing the cooling process can help avoid issues such as deformation and shrinkage. Key strategies include:

Monitoring Mold Temperature: Keeping a close eye on mold temperature helps ensure effective cooling.

Adjusting Coolant Flow Rate: Proper coolant flow rates can significantly influence cooling efficiency.

Managing Cycle Time: Tailoring the cycle time to match the materials and design requirements can lead to better outcomes.

By focusing on these factors, manufacturers can produce consistent ABS components that meet quality standards.

4. Common Applications of ABS Injection Molding

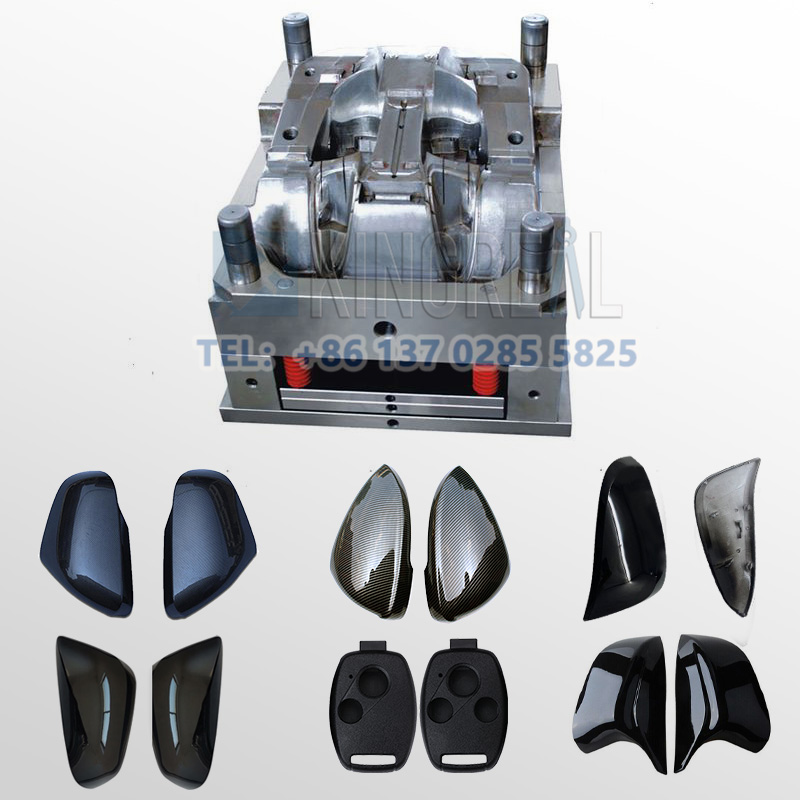

ABS plastic injection molding finds extensive application in the automotive field due to its high strength and impact resistance. Common uses include:

Dashboards and Interior Parts: ABS is ideal for components that require durability and aesthetic appeal.

Exterior Components: Its ability to withstand harsh environmental conditions makes it suitable for various external applications.

The high dimensional stability and smooth surface finish of ABS ensure that automotive parts maintain their appearance and functionality over time.

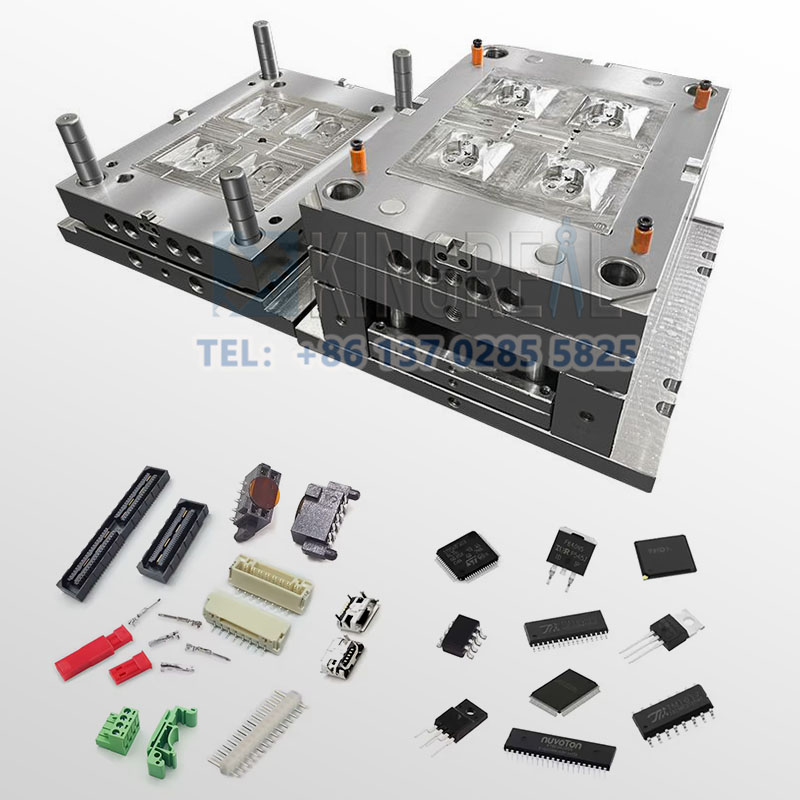

In the consumer electronics industry, ABS injection molding is prevalent for manufacturing casings and internal components of devices such as:

Mobile Phones: ABS provides the necessary protection for sensitive electronic circuits, ensuring long-term reliability.

Laptops and Game Consoles: The toughness of ABS helps safeguard against accidental drops and impacts, enhancing product longevity.

Approximately 40% of global ABS production is utilized in consumer electronics, reflecting its popularity due to ease of processing and aesthetic versatility.

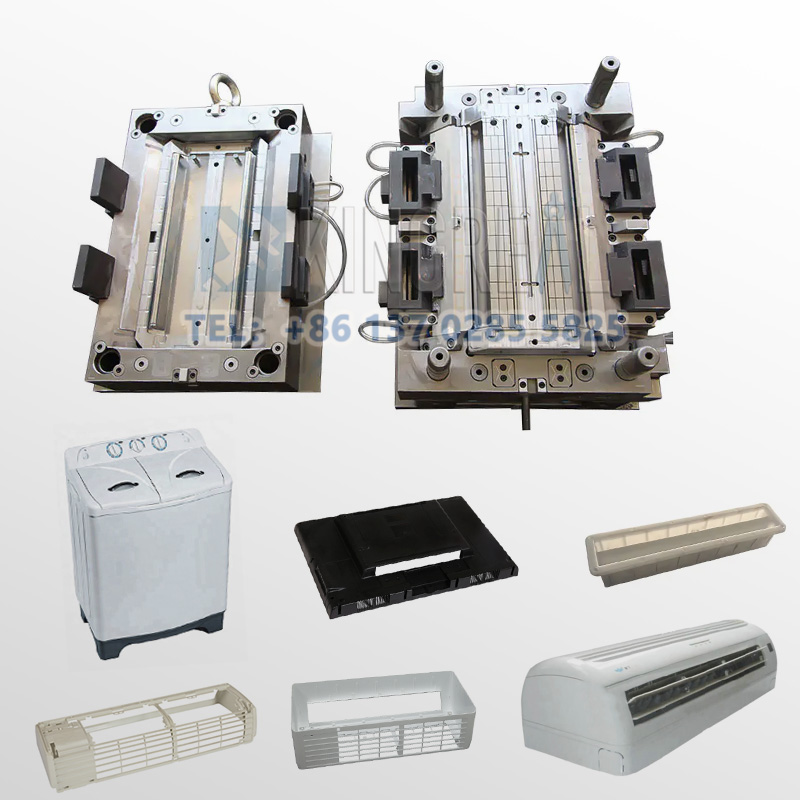

ABS plastic injection molding is also widely applied in the production of household appliances. Its strong structure and durability make it suitable for:

Vacuum Cleaners and Refrigerators: ABS's resilience and ability to withstand repeated use make it a preferred material for these products.

Kitchen Appliances: Its thermal stability and chemical resistance are critical for appliances exposed to high temperatures and cleaning agents.

Manufacturers appreciate the ability to mold complex shapes with ABS, allowing for ergonomic designs and aesthetically pleasing products.

ABS injection molding is a crucial technology that has become an indispensable part of modern manufacturing due to its excellent performance and wide range of applications. As a dedicated mold manufacturer, KRMOLD is committed to providing high-quality ABS injection molding solutions, ensuring that our customers can produce superior products efficiently. We hope this article has provided valuable insights into ABS injection molding, empowering you to succeed in your manufacturing endeavors. If you have any questions or need further assistance, please do not hesitate to reach out to us.