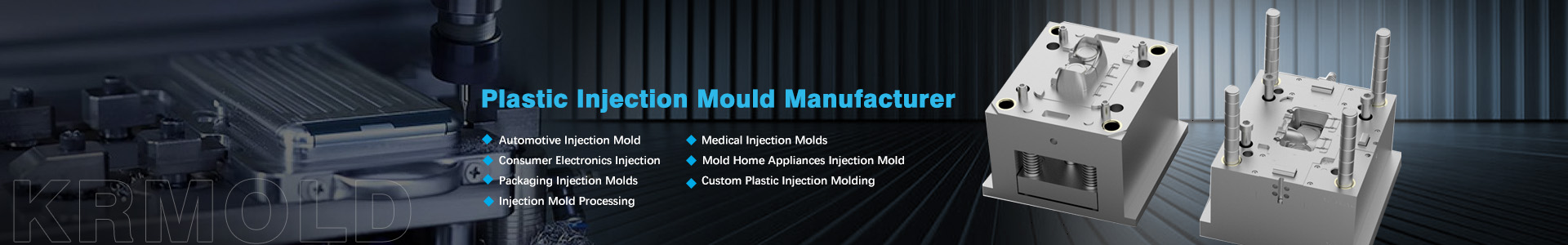

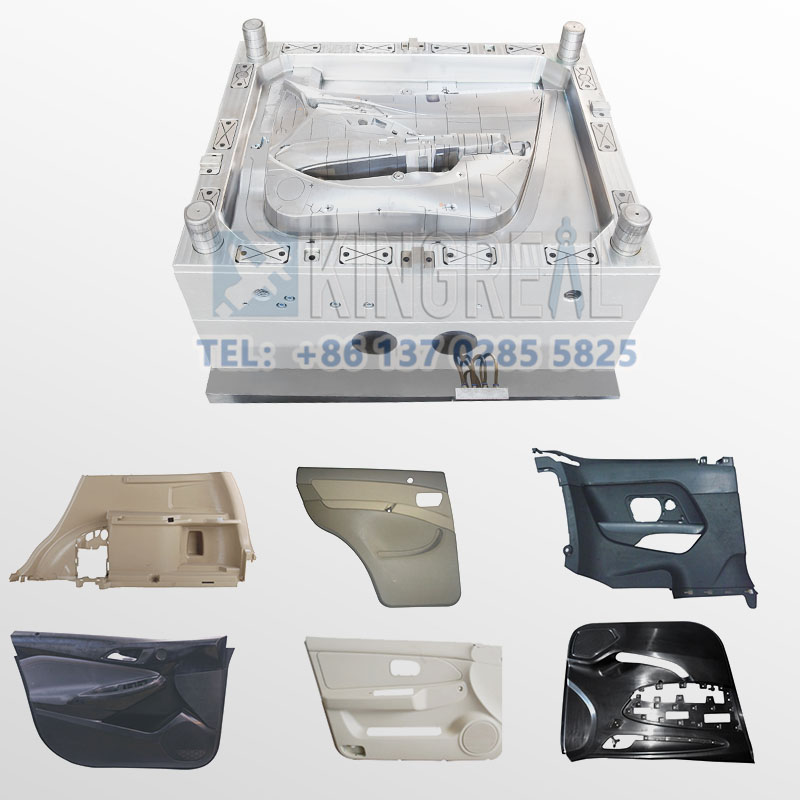

"Automotive injection molds are used to produce a wide range of automotive parts, including interiors, exteriors, engine compartments, air conditioning systems, safety and control systems, and other structural components. KRMOLD provides high-quality plastic battery case injection mold, automotive control panel injection mold, automotive door handle injection mold, etc to customers worldwide. Having more than twenty years of expertise, KRMOLD constantly seeks to raise plastic battery case injection mold accuracy and improves research, development, and production of automotive door handle injection molds. Simplify manufacturing methods so giving consumers more value."

Before starting plastic battery case injection mold design, KRMOLD engineers thoroughly analyze the component provided by the customer. This covers a thorough knowledge of the geometry of the component, planned application, necessary tolerances, and surface finish. KRMOLD engineers therefore choose suitable materials considering the demands of the automobile industry, the customer's production capacity, and cost. KRMOLD thorough front analysis helps it to create plastic battery case injection molds suited to consumer needs. These plastic battery case injection molds satisfy the efficiency and reliability demands of modern car manufacture in addition to exactly matching many different vehicle makes, kinds, and sizes. KRMOLD works closely with its customers to guarantee that every automotive injection mold design and manufacture completely meets their expectations and those of the market.

1/Why Do You Need High-quality Automotive Injection Molds?

High-Precision Finished Products

High-precision automotive control panel injection molds are key to producing high-quality auto parts. KRMOLD automotive injection molds guarantee the constant quality of vehicle components by means of sophisticated technology. Every automotive door handle injection mold passes several demanding inspections during the manufacturing procedure, including visual examination, dimensional inspection, mold structure inspection, injection molding performance inspection, material inspection. Heat treatment examination as well as cooling and heating system inspection are both included. Only automotive control panel injection molds meeting these checks are sent to customer factories, hence guaranteeing the accuracy and dependability of the finished product.

Large-Scale Production Capability

KRMOLD plastic battery case injection molds offer extremely high production efficiency, capable of producing parts in seconds. Usually lasting from a few seconds to a few minutes, the exact production cycle depends on the intricateness and size of the element. This high production capability enables vehicle makers to swiftly fulfill the growing demand for vehicles while still maintaining cost-effectiveness and efficient operations.

Durable Finished Products

Automotive parts produced using KRMOLD automotive door handle injection molds are meticulously designed to withstand the rigors of daily use, providing consumers with reliable and durable automotive products. Automotive control panel injection molds enhance the overall quality of vehicle parts from structural integrity to functional performance. Not only does the durability of automotive components influence the life of the car, but also straightly affects customer safety and satisfaction.

2/Which Automotive Parts Require Automotive Injection Molds?

Plastic battery case injection molds can produce a wide range of automotive parts, which can be primarily categorized as follows:

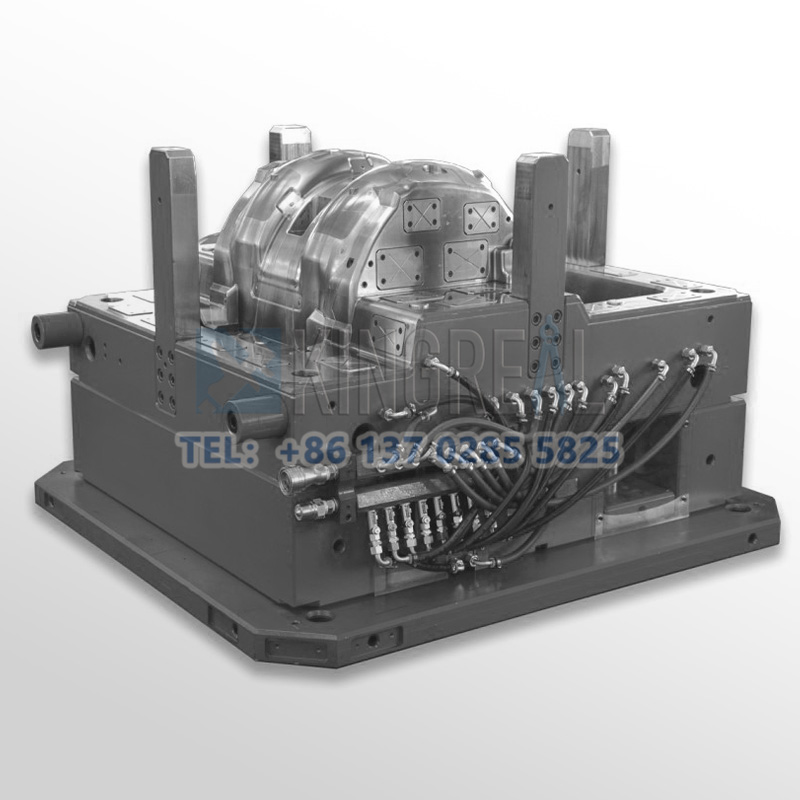

Automotive injection mold for interior parts

KRMOLD automotive injection molds are used to produce a variety of interior components, such as instrument panel assemblies, console components, door handles, and seat components. These components not only require stringent functional requirements but also excellent aesthetics. The design and manufacture of interior components are crucial to enhancing the comfort and luxury of the vehicle.

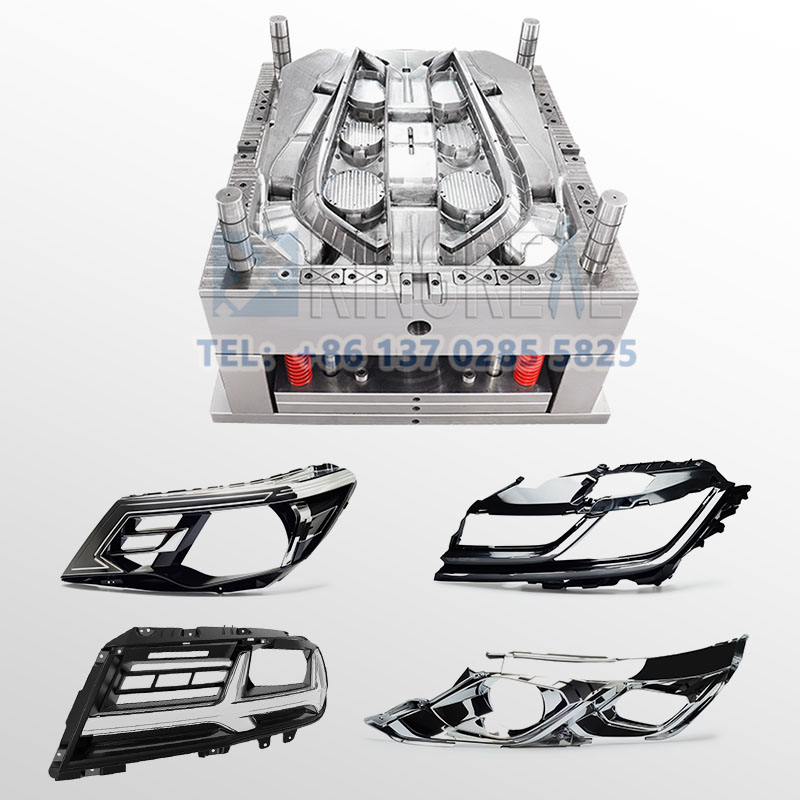

Automotive injection mold for exterior parts

KRMOLD automotive injection molds are expert at making exterior automotive parts including grilles, bumpers, and body panels. Impact-resistant and weather-resistant, these exterior elements must also be aesthetically pleasing to go with the general car design in order to resist different environmental challenges. The quality of exterior components directly impacts a vehicle's appearance and market competitiveness.

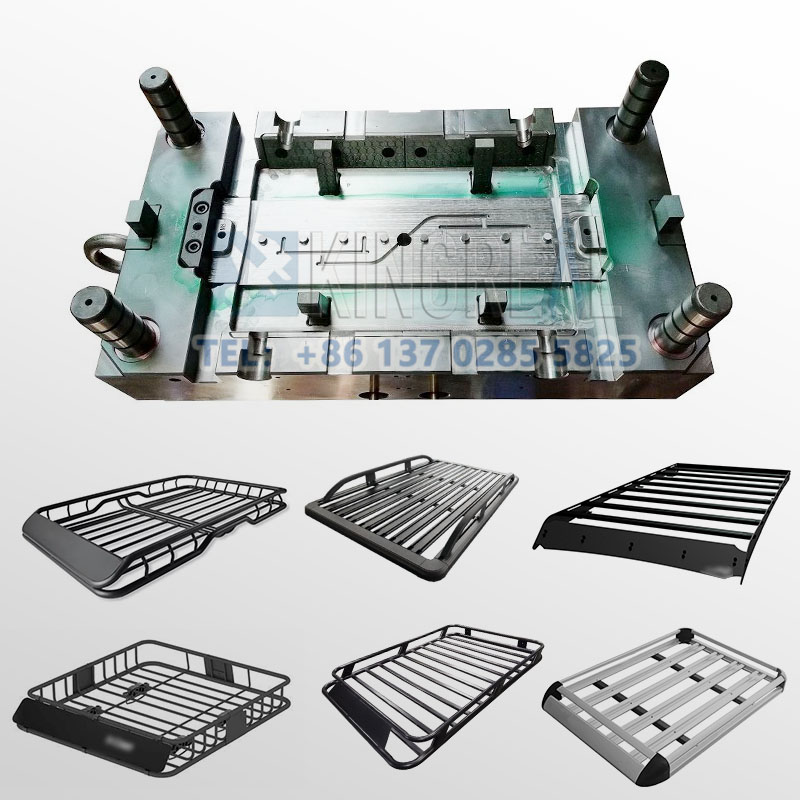

Automotive injection mold for under-the-hood components

KRMOLD automotive injection mold manufactures engine hoods, air intakes, and various housings that are rugged and heat-resistant, perfectly suited to automotive operation. Under-the-hood components must withstand high temperatures, vibration, and chemical attack, making their design and material selection crucial. The quality of these components often determines the performance and lifespan of the entire vehicle.

3/Advantages of Automotive Injection Molds

Versatility for plastic battery case injection mold

KRMOLD automotive control panel injection molds provide flexibility to fit a great variety of material choices and design ideas. This provides customers with the opportunity to explore innovative automotive component designs, experiment with advanced polymers and environmentally friendly materials, pushing the boundaries of creativity while meeting evolving industry and sustainability standards.

High customization for automotive door handle injection mold

KRMOLD engineers can build bespoke plastic battery case injection molds based on customer requirements, therefore facilitating the manufacture of final items having sophisticated features and challenging forms. KRMOLD automotive control panel injection molds, for instance, can be made with different wall thicknesses, reinforcing ribs, and integrated fasteners or snap-fit connections. This high level of customization reduces additional assembly steps for customers and improves production efficiency.

Improved cost-efficiency for automotive door handle injection mold

KRMOLD automotive control panel injection molds help customers obtain a fast return on investment by generating huge quantities of components, therefore greatly increasing manufacturing cost efficiency. Good plastic battery case injection molds not only raise output efficiency but also lower unit costs, therefore giving automakers a market edge.

To learn more about automotive injection molds, watch KRMOLD video or contact us today!