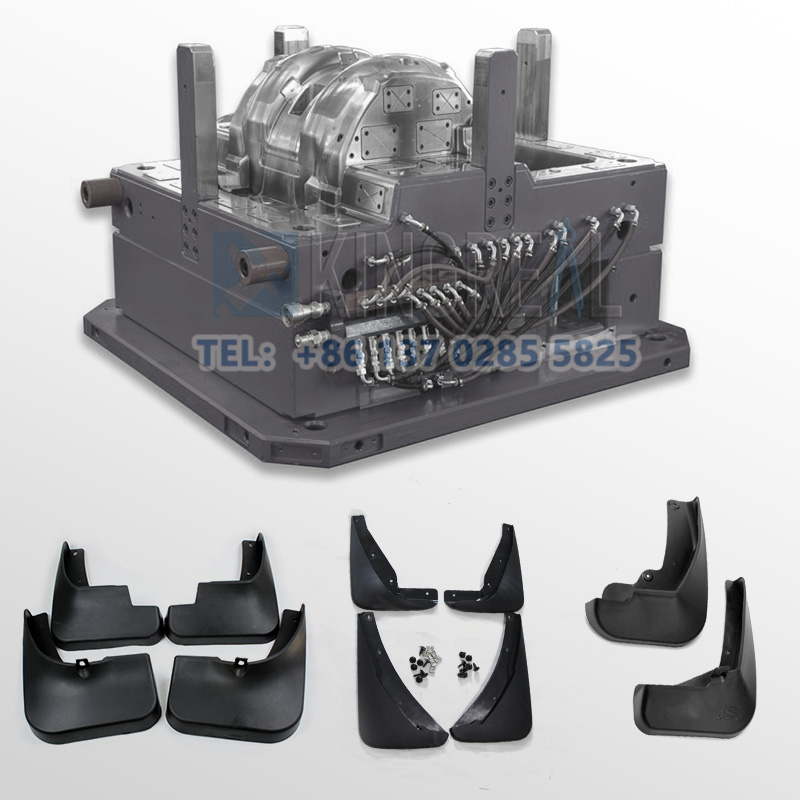

Specification Of Car Fender Injection Mold

——

| Mould Base | LKM,HASCO,DME,etc |

| Mold Cavity/Core Material | P20, H13, 2738,S136,718,etc |

| Mold Cavity | Single |

| Mold Accuracy | ±0.01-0.05mm |

| Mold Type | 1+1 family mold, cold runner |

| Mold Steel | 718H |

| Mold Size | 245×183mm |

| Mold Lifetime | 50K Times |

| Gate | Submarine gate,side/edge gate |

| Car Fender Accuracy | ±0.1~0.5mm |

| Plastic Material | ABS |

Brief Introduction Of Car Fender Injection Mold

——

Injection molds are precision production tools designed for the mass production of plastic products by injecting different types of molten plastic into the mold cavities and then cooling and ejecting the plastic products. The characteristics of mass production, such as high precision and customization, make injection molds one of the most important production tools for automotive interior and exterior plastic parts, and can meet the production needs of injection molding of high-temperature-resistant raw materials, such as automotive dashboard injection molds, automotive door panels, automotive battery shell injection molds and charging interface injection molds and other key parts.

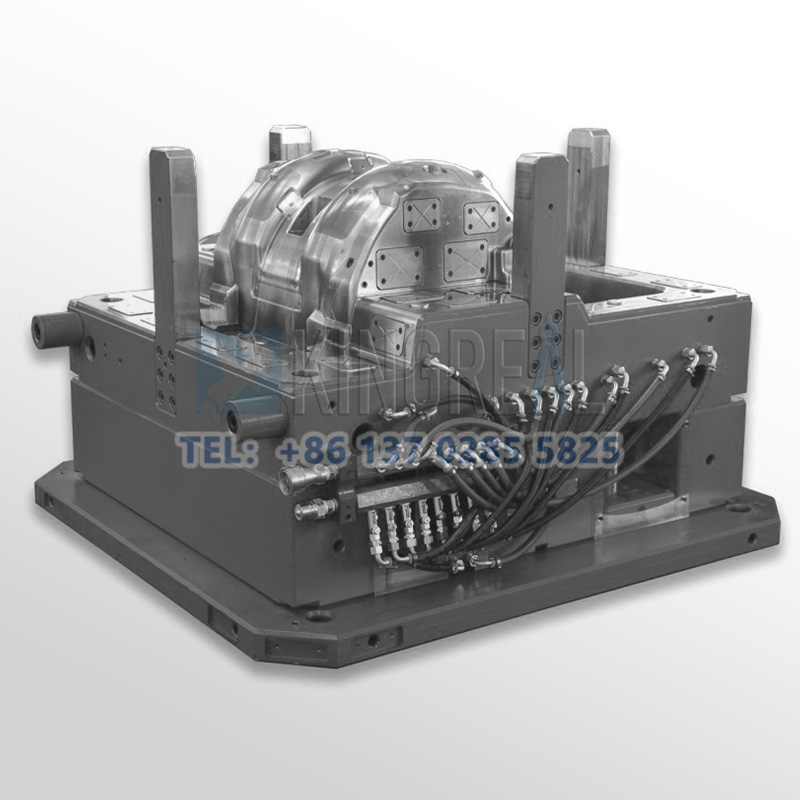

Car fender injection mold consists of two parts, the moving mold(core)and the fixed mold(cavity), which form the cavity and the pouring system when closed, and inject the molten plastic such as ABS or PP by high pressure and cool and solidify to get the plastic car fender finally.The whole car fender injection mold processing involves closing the mold, injecting the glue, and then the molding process, which is very complicated and complicated. The entire car fender injection mold processing involves the stages of clamping, glue injection, pressure holding, cooling, mold opening and picking up, etc. The accuracy of the injection mold cavities directly determines the accuracy and surface precision of the car fender products.

KRMOLD Car Fender Injection Mold cavity adopts differentiated wall thickness design, from the traditional 2MM body thickness down to 1.5MM, and at the same time, the local thickness is thickened to 1.8-2.5MM in order to ensure the strength of injection molding. KRMOLD differentiated design helps Car Fender Injection Mold to produce Car Fender products with a weight reduction of more than 300g, which is in line with the development needs of the automotive industry.

Manufacturing Process Of Car Fender Injection Mold

——

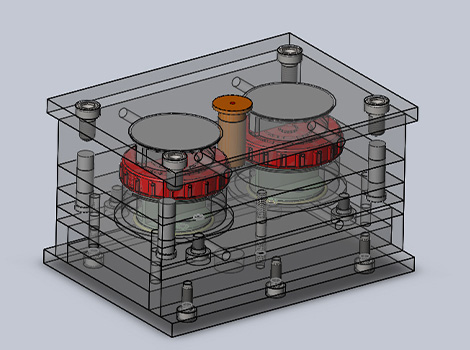

Through 3D scanning the cloud data of Car Fender products that customers need to produce (the accuracy can reach 0.005MM), we carry out mold structure optimization and parting surface planning.

Through mold flow analysis and heat balance design to complete the simulation design of the casting system, and finally complete the design of the ejection and core extraction mechanism.

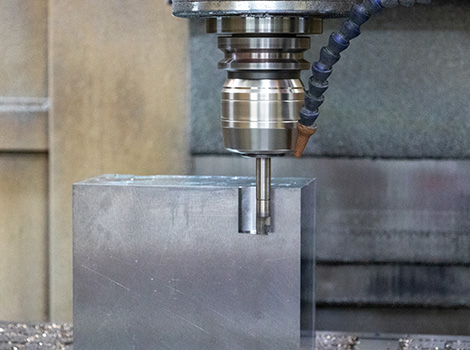

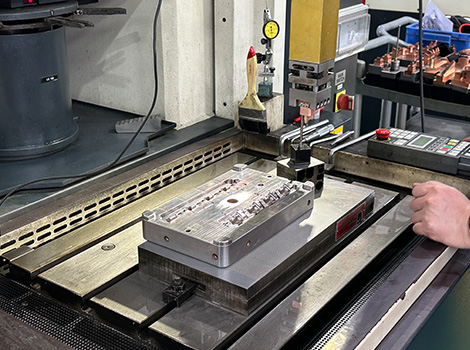

Choose pre-hardened steel P20 or H13 as the raw material for the cavity and core of Car Fender Injection Mold, complete rough machining by gantry milling machine, and complete graphite electrode processing by EDM after precision machining by 5-axis numerical control CNC machining. Finally, the ultrasonic polishing process is completed in the precision area of the injection mold.

KRMOLD has a complete quality control process, with a professional quality inspection team and advanced two-dimensional and three-dimensional quality inspection equipment, for the injection molds produced for customers in the factory to complete the two-dimensional and three-dimensional equipment testing and trial mold modification of the production process.

Injection Mould Technology Design

——

1.Auto Car Fender Mold Casting system: Hot Runner with Valve Gate to reduce runner waste and improve filling balance.

2. Car Plastic Fender Flares Mold Cavity design: Differentiated wall thickness (1.5-2.5 mm) combined with rib layout to achieve a balance between light weight (weight reduction of 300g/piece) and structural strength.

3. Auto Car Fender Mold Melt Flow Index (MFI): 20-25 g/10min for ABS, 30-35 g/10min for PP (230℃/2.16kg test), to ensure the flow-ability and mechanical properties.

4. Car Fender Injection Mold Mold-flow analysis (Mold-flow): simulation of filling rate ≥ 95%, predict the position of the Weld Line (Weld Line) and optimize through the mold structure adjustment.

5. Car Fender Injection Mold War-page control: Adopt ±0.3mm/m cooling tolerance to reduce deformation caused by thermal stress.

6. Car Fender Injection Mold Bubble Elimination: Injection speed is controlled in 3 stages (fast-slow-fast), with vacuum venting tank design, porosity ≤ 0.5%.

Feature Of Car Fender Injection Mold

——

1.Reduce cost-effectiveness through lightweight design

Car Fender Injection Mold can effectively reduce the weight of automotive injection molded parts through Topology Optimization and Glass Fiber Reinforcement Technology, which can help reduce the weight of the whole car by 4-6kg and improve the fuel efficiency by 2-3%.

Automotive injection mold through the design of hot runner system to help reduce the cold runner waste, can be common for automotive mold production annual savings of raw material costs of 15-20 million U.S. dollars.

2.Car Fender Injection Mold Service Life Improvement

Car Fender Injection Mold is manufactured by 5-axis linkage machining center, the final mold CMM testing meets ISO 2768-mK level, the mold cavity tolerance ±0.02mm.

Car Fender Injection Mold adopts SKD61 mold steel (HRC 48-52) with PVD coating, which reduces the wear rate by 60% and helps to increase the life of the mold from 30K times to 120K times.

3.Car Fender Injection Mold High Performance Material Compatibility

Car Fender Injection Mold supports ABS/PC alloy, Long Glass Fiber Reinforced PP (LFT-PP, fiber length 10-25mm), with heat deflection temperature (HDT) up to 140℃ (ISO 75). The injection mold UV stabilizer and antioxidant pre-mixed formulations have also passed the SAE J2527 standard 2000 hours xenon lamp aging test.

About KRMOLD

—

KRMOLD focuses on the field of precision mold design and production, with a manufacturing team of 200+ professional technicians, a technical R&D team of 30+ engineers, and a full-cycle service team covering pre-sales consultation to after-sales maintenance, providing full-process services ranging from mold design, precision processing to injection molding.

KRMOLD Mold is equipped with international first-class equipment such as CNC machining centers, Japan Makino precision spark machine, Japan Shadick wire cutting machine, Japan Toshiba injection molding machine and other domestic and international famous brands of production equipment, to achieve ± 0.002mm processing accuracy, to meet the needs of a variety of high-precision plastic injection molds.

FAQ: How To Get A Quote For Custom Injection Molds?

——

Specify the type of plastic (e.g. PP, ABS) and post-processing requirements (e.g. spraying, silk-screen printing), and provide 2D or 3D plastic part drawings should be provided. At the same time, provide the production volume, appearance requirements, tolerance standards, etc.

Specify the type of plastic (e.g. PP, ABS) and post-processing requirements (e.g. spraying, silk-screen printing), and provide 2D or 3D plastic part drawings should be provided. At the same time, provide the production volume, appearance requirements, tolerance standards, etc.

Generally speaking, our engineers will start to prepare the quotation immediately after the customer provides the complete production requirements. Usually it takes about 1-3 days.

The lead time for regular injection molds is usually 30-60 days, and may be longer for complex molds. For example, the typical lead time for liquid silicone molds is around 60 days, covering design, manufacturing, mold testing, etc.

High-precision processing technology: High-precision equipment such as CNC machining centers (CNC) and electric discharge machining (EDM) are used to optimize the design process in combination with CAD/CAM software. Quality control: Inspection of key dimensions of the mold by Coordinate Measuring Machine (CMM) and verification of multiple sample batches during the trial molding stage. Material Selection: Use die steel with high wear resistance (e.g. H13, S136) and surface treatment (e.g. nitriding, chrome plating) for die nuts to extend the life.

After every 50,000 molds, check the guide pillar, ejector pin and other wear parts, and clean up the residual plastic and rust on the mold surface. Use high temperature grease for sliding parts (e.g. tilt top, slider) to reduce friction loss. Ensure that the water circuit is smooth and the temperature difference is ≤5℃ to avoid cracking of the mold due to thermal stress.

Mould cost of materials accounted for about 30-40% (such as 1 ton of P20 steel price of about 20,000 yuan), processing costs accounted for more than 50% (CNC labor hourly rate of about 80-150 yuan / hour). Small batch production can choose aluminum mold or simplify the structural design; more than 100,000 pieces is recommended to use carbide inserts to enhance life!

Mould injection products need to fully meet the design requirements (such as size, appearance), and can be continuous and stable production. Mold marking, inspection reports (such as material hardness test) and engineering drawings should be complete.

Mould steel (such as S136H, NAK80 and other imported materials cost more) and the type of mold embryo (aluminum mold short-term cost is low but short life) directly affect the cost, the use of CAD/CAE/CAM design technology, hot runner system, etc. will increase the upfront investment, but can enhance the long-term benefits (such as reducing the sprues, increase production capacity).