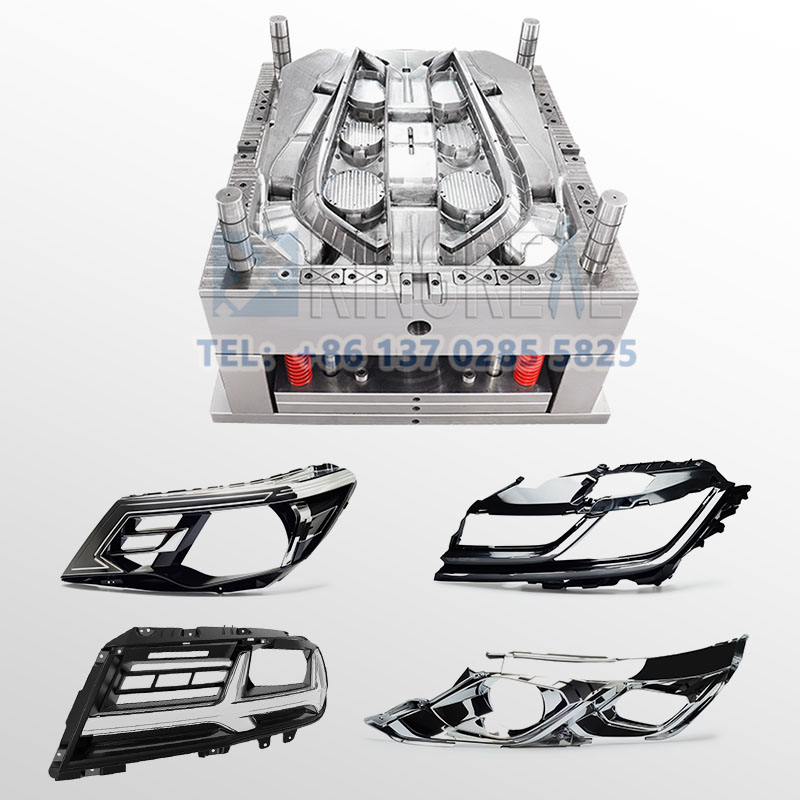

Automotive Injection Mold is one of the most important injection mold industry segments of KRMOLD, which helps dozens of international famous car manufacturers, including GAC Legend, BMW, Mercedes-Benz, Jaguar, Kia, Tesla and Land Rover, to complete the design, innovation, mold manufacturing and modification of automotive plastic parts injection mold services. With the need for environmental protection and energy saving, automobile lightweight has become one of the main trends in the development of world automobile design, automobile injection molds through the plastic raw materials melt injection molding into the automobile assembly required for automobile interior, exterior and functional parts and other components products, with lightweight, easy to mold, corrosion resistance, elasticity deformation, etc., to help the automobile manufacturing industry to reduce the cost of the entire vehicle and its weight, increase the vehicle payload. It helps the automobile manufacturing industry to reduce the cost and weight of the vehicle and increase the effective load of the vehicle.

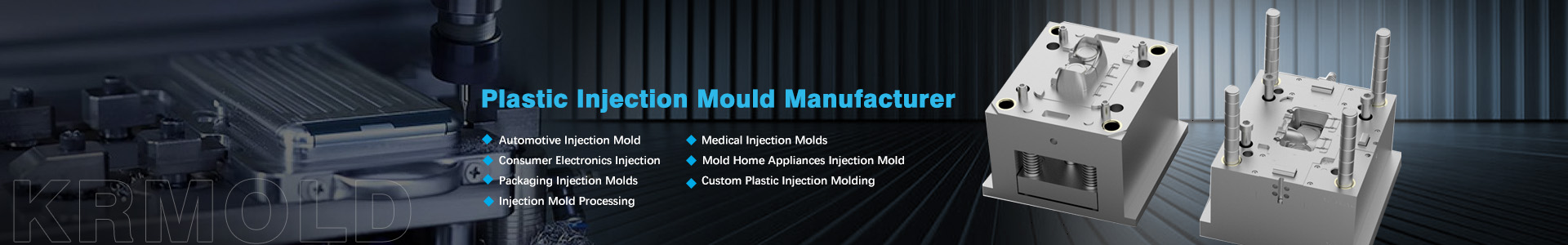

Automotive injection molds are the key production tools for molding automotive parts and achieving mass production of automobiles. In automobile production more than 95% of the parts rely on mold molding, manufacturing an ordinary car needs more than 300 sets of plastic mold. Common injection mold cases include:

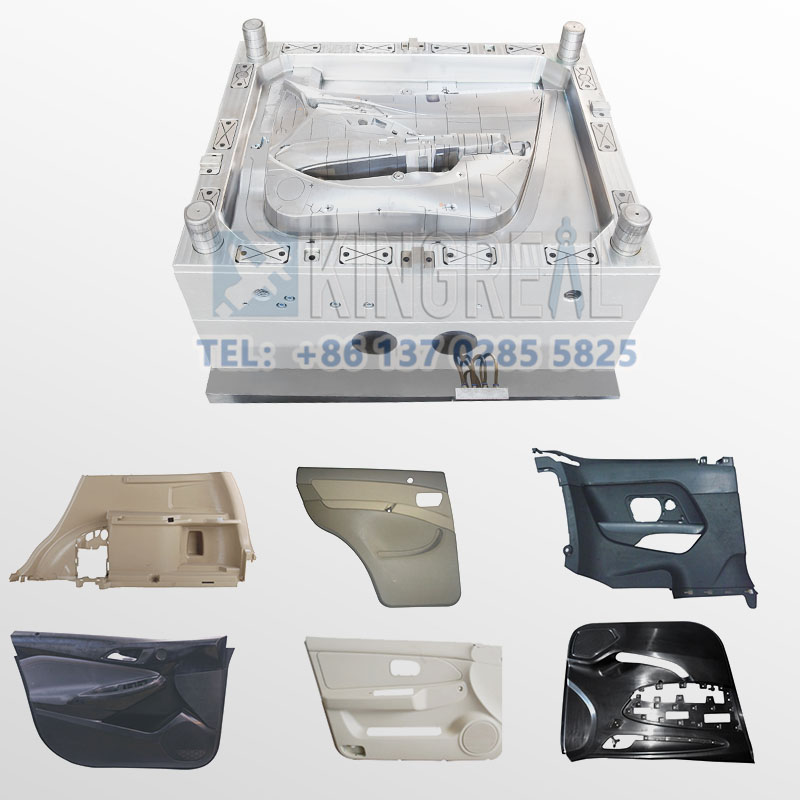

Interior and exterior parts injection molds: including instrument panel injection molds, door panel injection molds and center control panel injection molds, etc. The injection molded products need to be both aesthetically pleasing and functional.

1. Functional parts injection molds: including engine peripheral components (intake manifold, radiator fan), electronic equipment shell (sensors, connectors), etc.,

2. injection molded products need to meet the performance of high temperature and corrosion resistance.

3. Lightweight structural parts injection molds: through the insert injection molding process to combine metal and plastic, such as nut inserts, brackets, etc., to enhance the strength and reduce weight.

The good or bad of automotive plastic mold directly affects the appearance and performance of the car, which is increasing the professional requirements for injection mold manufacturers.KRMOLD has professional injection mold production workshop and manufacturing team, rich experience in automotive injection mold project cases, welcome to contact us.