KINGREAL UNIVERSAL IND., LTD

Phone

+86-13702855825| 1 | Production Applications of Plastic Bumper Injection Molding |

| 2 | Auto Bumper Mould Materials for Automotive Parts |

| 3 | Methods to Select the Best Injection Molding Material for Auto Bumper Mould |

1. Production Applications of Plastic Bumper Injection Molding

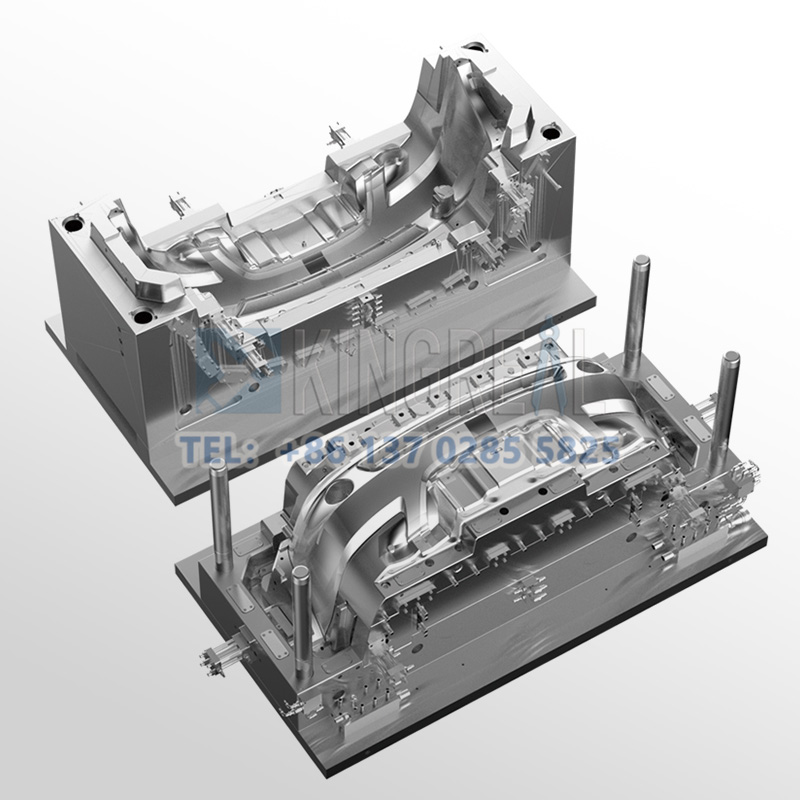

In the automotive world, Multi-Cavity bumper mold design is one of the main methods manufacturers use to form plastic parts. However, it is difficult to list the plastic parts in cars that are produced using plastic bumper injection molding, so we will look at some of the main ones.

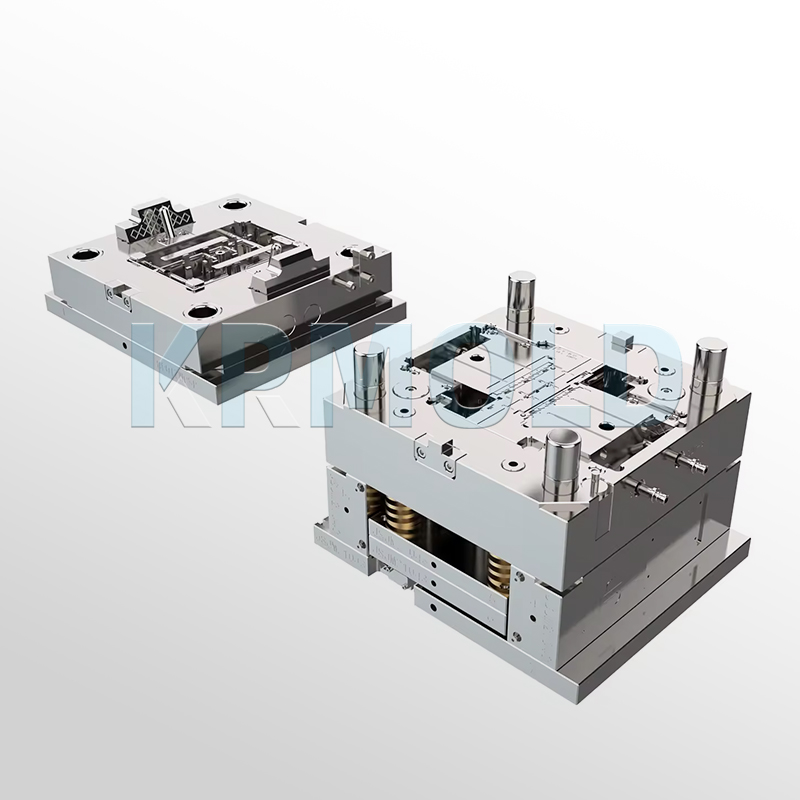

(1) Under the Hood Components

Over the past two decades or so, many manufacturers have switched to plastics for under-the-hood parts that were previously made of metal. For these applications, strong polymers such as ABS, nylon, and PET are common. However, manufacturers now use multi-cavity bumper mold design to make parts such as cylinder head covers and oil pans. This method is lighter in weight and less expensive than metal parts.

(2) Exterior Parts

Plastic bumper injection molding is an established process for many automotive exterior parts, including fenders, grilles, bumpers, door panels, floor rails, light covers, and more. Splash guards are a good example of the durability of auto bumper moulded parts. In addition, parts that protect the car from road debris and minimize splashes are often made of rubber or other durable and flexible materials.

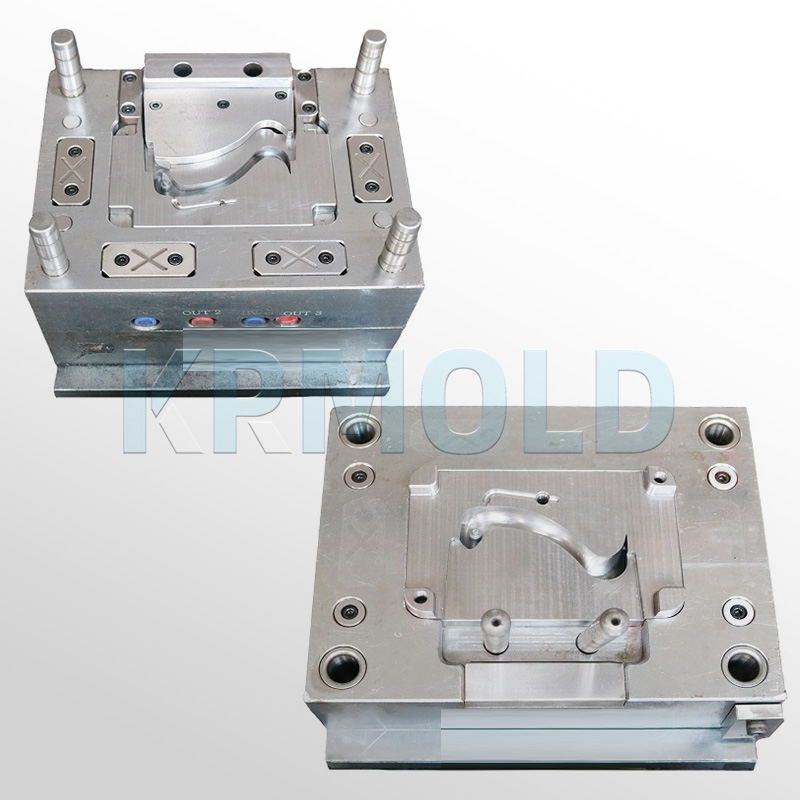

(3) Interior Parts

Manufacturers also use plastic bumper injection molding to produce many automotive interior parts. They include instrument components, interior surfaces, dashboard panels, door handles, glove boxes, air vents, etc. In addition, they also use multi-cavity bumper mold design to produce decorative plastic elements.

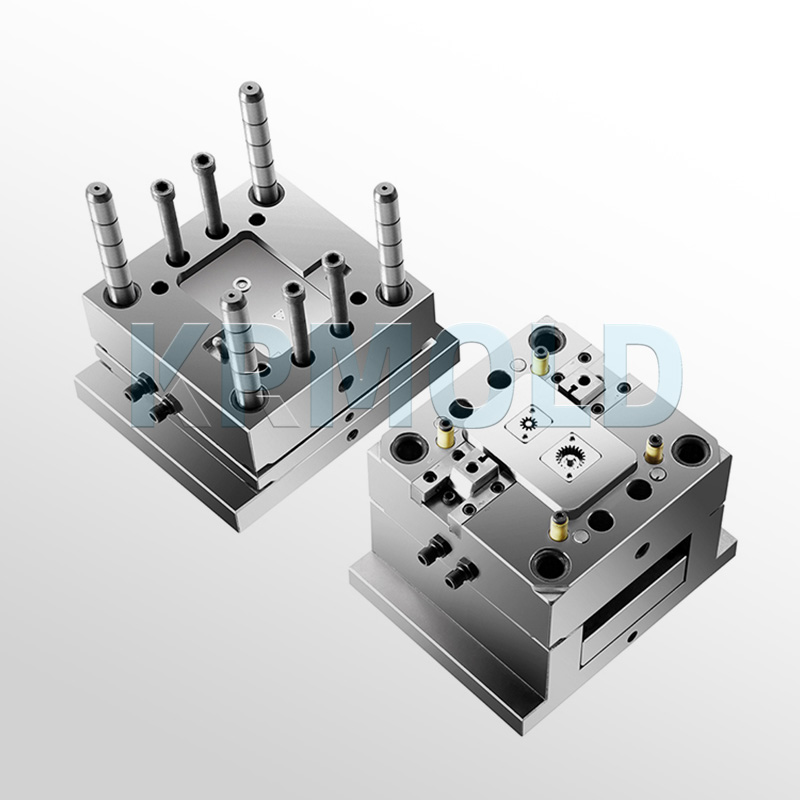

2.Auto Bumper Mould Materials for Automotive Parts

Automotive manufacturers need to manufacture cars to strict safety standards and pass multiple certifications before they can be driven on the road. Therefore, it is very important to choose the right plastic for anymulti-cavity bumper mold design automotive parts.

Here is a non-exhaustive list of common automotive IM plastics and the parts they are used as raw materials:

(1) Acrylonitrile Butadiene Styrene (ABS)

Widely used in plastic bumper injection molding and 3D printing, the durable plastic ABS is fairly weather-resistant. In automobiles, it can be used to make items such as dashboards and housings.

(2) Polyamide (PA)/Nylon

While nylon is not resistant to liquids, it has good wear and chemical resistance. They can be molded into automotive parts such as bushings and bearings.

(3) Methyl methacrylate (PMMA)

The transparency of acrylic makes it an excellent (and shatterproof) alternative to glass. Automotive plastic part manufacturers can use molded PMMA for headlight covers and interior screens (such as for sat-navs or radios).

Automotive parts manufacturers use PP for some of the stronger car parts, including some exterior parts. This is due to its resistance to water, chemicals, and UV rays. PP parts include bumpers, cable insulation, and battery covers.

(5) Polyurethane (PU)

PU is commonly found in spongy, flexible items such as foam seats. This includes car seats, but PU automotive applications also include seals and gaskets, insulation panels, and suspension bushings.

(6) Polyvinyl chloride (PVC)

PVC is the third most popular synthetic plastic polymer in the world, and in the automotive industry it is used for many molded parts that require good chemical resistance. These include interior panels, dashboards, and cable insulation.

(7) Reinforced Composites

Manufacturers can use glass or carbon fiber reinforced plastics, which are much stronger than the common resins used to produce car bodies and bumpers.

3. Methods to Select the Best Injection Molding Material for Auto Bumper Mould

Choosing the best multi-cavity bumper mold design material for any component or product requirement is a detailed and complex process. It requires consideration of several factors, such as mechanical properties, cost, moldability, and application environment. Basically, these factors are criteria for matching the material with the required performance and specifications. In addition, the right material selection is essential for reducing plastic bumper injection molding defects and the safety of the final part as well as the equipment and mold.

The following is a step-by-step explanation designed to guide you in choosing the best material for your auto bumper moulding project.

Step 1: Evaluate Mechanical and Physical Requirements

First, determine the mechanical and physical requirements of the final product or part. It may include evaluating the required strength, toughness, elasticity, thermal properties, UV resistance, chemical resistance, etc.

For example, if the product needs to withstand large loads or impacts, materials with high tensile strength and toughness, such as polycarbonate or ABS, may be suitable.

Step 2: Consider Aesthetics and Functionality

Consider the intended color, transparency, and surface. Then, match which material can meet this requirement. For example, materials such as acrylic have excellent transparency and are ideal for transparent components.

Step 3: Evaluate Cost and Production Efficiency

Cost is another important factor in material selection. It includes multi-cavity bumper mold design raw materials and production costs. Some materials may require longer cycle times or special processing, which affects production efficiency and cost. Also, consider availability and any potential supply chain issues.

Step 4: Regulatory and Compliance Needs

Regulatory compliance is critical, especially for products in the automotive industry. Plastic bumper injection molding materials must meet specific standards and certifications.

Step 5: Leverage Expertise and Material Data

Finally, leverage expertise and data when selecting materials. It can be valuable to consult material experts and engineers or use databases that provide detailed information on various materials.

This step ensures that you make an informed decision that meets technical requirements and production practical aspects. Industry multi-cavity bumper mold designing experts such as Prolin can use their knowledge and experience to help you determine the best match.

Additionally, you can also compare plastic bumper injection molding materials among the available options. Comparing them one by one against a specific list of requirements for the final part can help you filter out the materials.