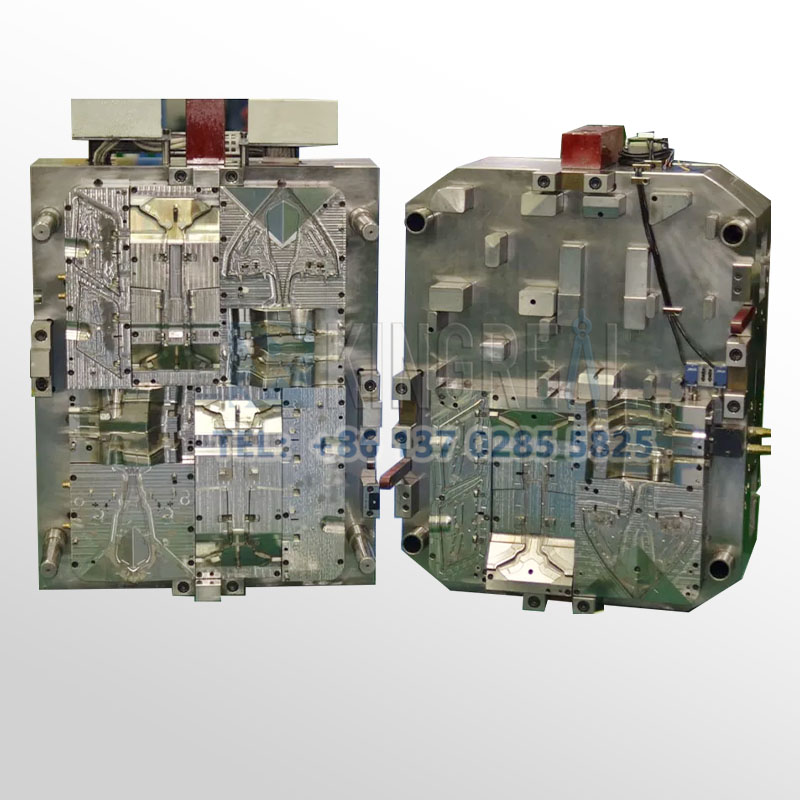

KINGREAL UNIVERSAL IND., LTD

Phone

+86-13702855825Water bottle cap injection molding is also known as injection molding. Plastic bottle cap injection moulding refers to the process of mixing completely molten plastic materials with a screw at a certain temperature, injecting them into the water bottle cap injection mold cavity with high pressure, and obtaining molded injection molded parts after cooling and solidification.

Plastic bottle cap injection mould processing has now become the preferred process for manufacturing various plastic products, and is widely used in many industries such as automobiles, electronics, medical care, packaging, consumer goods, and aerospace. With the continuous advancement of technology, the application scope of water bottle cap injection mold processing is expected to expand further.

| 1 | Process of Bottle Cap Injection Moulding |

| 2 | Advantages of Water Bottle Cap Injection Molding |

| 3 | Diverse Water Bottle Cap Injection Molding Processes |

| 4 | Main Injection Molding Parameters |

Process of Bottle Cap Injection Moulding

Bottle cap injection moulding is suitable for mass production of parts with complex shapes. It is one of the important processing methods. Its processing process mainly includes five stages: mold closing - filling - pressure holding - cooling - demolding.

In order to ensure the smooth and efficient progress of water bottle cap injection molding and the quality standards of the finished injection molded parts, five major factors need to be paid attention to in the plastic bottle cap injection moulding process:

1. Temperature (oil temperature, material temperature, mold temperature);

2. Speed (opening and closing mold speed, ejection speed, injection speed);

3. Pressure (injection pressure, holding pressure, low pressure protection pressure, clamping force);

4. Time (injection time, cooling time, holding time);

5. Position (opening and closing mold position, ejection position, melting position).

Advantages of Water Bottle Cap Injection Molding

High precision

Bottle cap injection moulding can produce parts with extremely tight tolerances and consistent dimensions. The process enables manufacturers to produce complex geometries and complex shapes with extremely high precision, ensuring that each part meets precise specifications.

Complex details

One of the outstanding features of water bottle cap injection molding is the ability to produce parts with complex details and complex features. This includes thin walls, complex patterns, undercuts, threads and other complex details that may be challenging or impossible to achieve through alternative manufacturing methods.

Durability

Plastic bottle cap injection moulded parts are known for their durability and strength. The process ensures that the material is evenly distributed, resulting in parts that exhibit excellent structural integrity and resistance to wear, impact, and environmental factors. This durability makes injection molded parts suitable for a wide range of applications across a variety of industries.

Automation

Water bottle cap injection molding is highly automated, which increases production efficiency and reduces labor costs. Automated bottle cap injection moulding machines can run continuously with minimal human intervention, ensuring consistent part quality and high productivity. This automation also enables fast production cycles, allowing manufacturers to meet tight deadlines and scale up production as needed.

Cost-effectiveness for mass production

While the initial tooling costs for bottle cap injection mould can be high, plastic bottle cap injection moulding becomes extremely cost-effective for large-scale production. Once the water bottle cap injection mold is built, the unit manufacturing cost is significantly reduced, making bottle cap injection moulding an economical choice for mass production of identical or similar parts.

Wide range of materials

Bottle cap injection moulding supports a wide range of materials, including thermoplastics, thermosets, elastomers, and composites. This versatility in material selection allows manufacturers to select the most appropriate material for their specific application requirements, whether it is mechanical properties, chemical resistance, or aesthetics.

Reduced post-processing

Water bottle cap injection molded parts generally require minimal post-processing because they typically have smooth surfaces and precise dimensions straight out of the plastic bottle cap injection mould with minimal scrap. This reduces the need for additional machining, grinding or finishing operations, saving time and resources in the manufacturing process. In addition, the consistency and precision of plastic bottle cap injection moulding minimizes the occurrence of defects, further reducing the need for rework or corrections.

Diverse Water Bottle Cap Injection Molding Processes

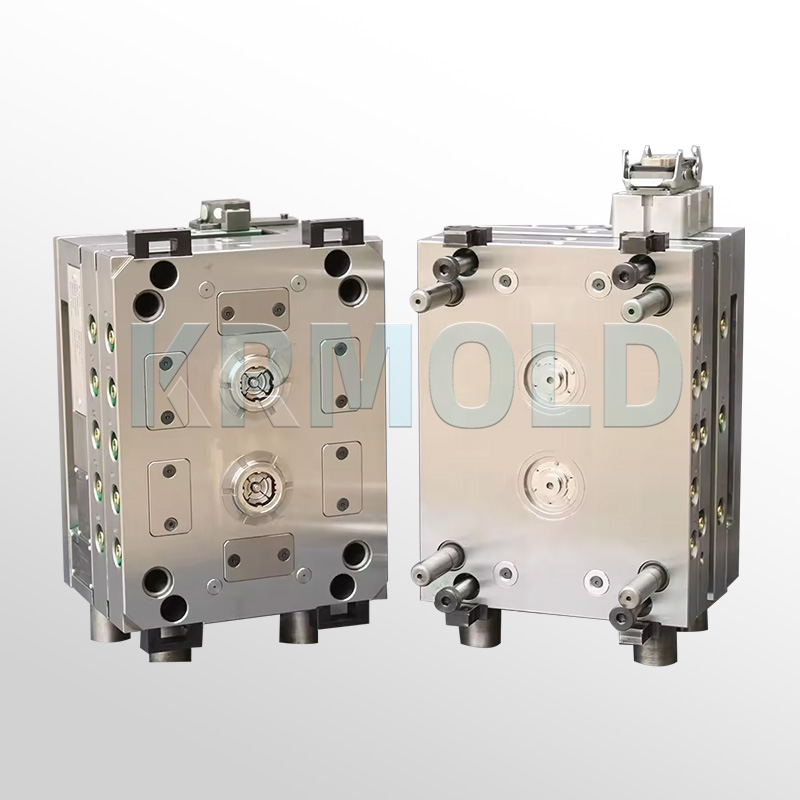

KRMOLD offers a variety of bottle cap injection moulding processes that customers can choose based on the characteristics of the products they need to produce. Among the widely used water bottle cap injection molding processes are:

Conventional injection molding

A standard process in which molten plastic material is injected into the mold cavity, cooled and ejected as a solid part.

Involves placing a pre-molded part (insert) into the cavity before injection to form a single integrated part.

Gas-assisted injection molding

Nitrogen is used to displace the molten plastic material in the cavity to form a hollow profile, thereby reducing material usage and increasing part strength.

Injecting different materials or colors sequentially into the same mold cavity, allowing for the production of multi-material or multi-color parts in one step.

A specialized process for producing extremely small plastic parts with tight tolerances, often used in electronics and medical devices.

Main Injection Molding Parameters

The water bottle cap injection molding cycle consists of many parameters that need to be checked to produce high-quality plastic parts. These parameters include:

Injection pressure: The force applied to inject the molten plastic into the plastic bottle cap injection mould cavity. This is critical to achieving proper mold filling and ensuring part quality.

Mold temperature: This refers to the temperature maintained by the water bottle cap injection mold during the injection molding process. It affects material flow, part cooling, and overall part quality.

Nozzle pressure: The pressure applied to the injection nozzle to force the molten material into the mold. It is part of the total injection pressure, but specifically refers to the pressure at the mold entrance.

Recovery: Refers to how quickly the material rebounds or recovers after being compressed during the injection process.

Shrinkage: This refers to the percentage reduction in size of the molded part from the molten state to the solid state.

Clamping force: The force applied to hold the mold halves together during injection and cooling.

Screw speed: It is the speed of the screw inside the barrel of the injection molding machine. Screw speed determines the rate at which plastic is fed into the bottle cap injection mould cavity and affects filling and cooling times.