KINGREAL UNIVERSAL IND., LTD

Phone

+86-13702855825"In the production and manufacturing of automotive parts, dashboards are one of the most common automotive parts. Generally speaking, the design of automotive dashboards is also mostly produced by plastic manufacturing. With the development of automobiles in terms of safety and environmental protection, people have higher and higher requirements for the safety and environmental protection of automotive accessories; at the same time, more and more dashboards adopt the appearance design of seamless airbag doors, which puts forward higher and higher requirements for the manufacturing process of dashboards."

1/Dashboard injection molding process

The dried plastic particles are sheared by the screw and melted by the barrel in the injection molding machine, and then injected into the dashboard mold and cooled to obtain the finished product. It is used to manufacture the hard plastic dashboard body, blister and soft dashboard skeleton and most other related parts. Hard plastic dashboard materials mostly use PP, and the dashboard skeleton materials are mainly modified materials such as PC/ABS, PP, PPO (PPE). Other parts choose ABS, PVC, PC, PA and other materials according to different functions, structures and appearance requirements.

Injection molding process can be further divided into: gas-assisted injection molding, insert injection molding, two-color injection molding, secondary injection molding, etc.

1.1 Gas-assisted injection molding

Gas-assisted injection molding is an injection molding process that injects a certain amount of inert gas while injecting molten plastic particles into the mold, and forms a hollow structure in a specific area of the part through the design of the gas path and structure and process control. The hollow structure not only enhances the mechanical properties of the part, but also reduces the wall thickness of the part, improves the appearance of the part, and reduces the material cost and molding cycle.

1.2 Instrument panel insert injection molding

It is more popular in the home appliance industry, and this process is used in the manufacture of various electrical switches in the production of instrument panels. It is to place the metal parts to be embedded in the injection molded parts in the mold before injection molding, and the molten plastic after injection molding will partially cover it to form a part.

1.3 Instrument panel two-shot injection molding

On a two-shot injection molding machine, different colors/types of raw materials are injected into a special injection mold simultaneously/sequentially in the same production cycle, so that the product has different appearance/performance, but due to its huge investment in equipment and molds, it is gradually replaced by secondary injection molding.

1.4 Instrument panel secondary injection molding

Secondary injection molding is insert molding where the injection molded part is an insert. It is mainly used for parts with high mechanical performance and appearance requirements. Material selection is the key to this process.

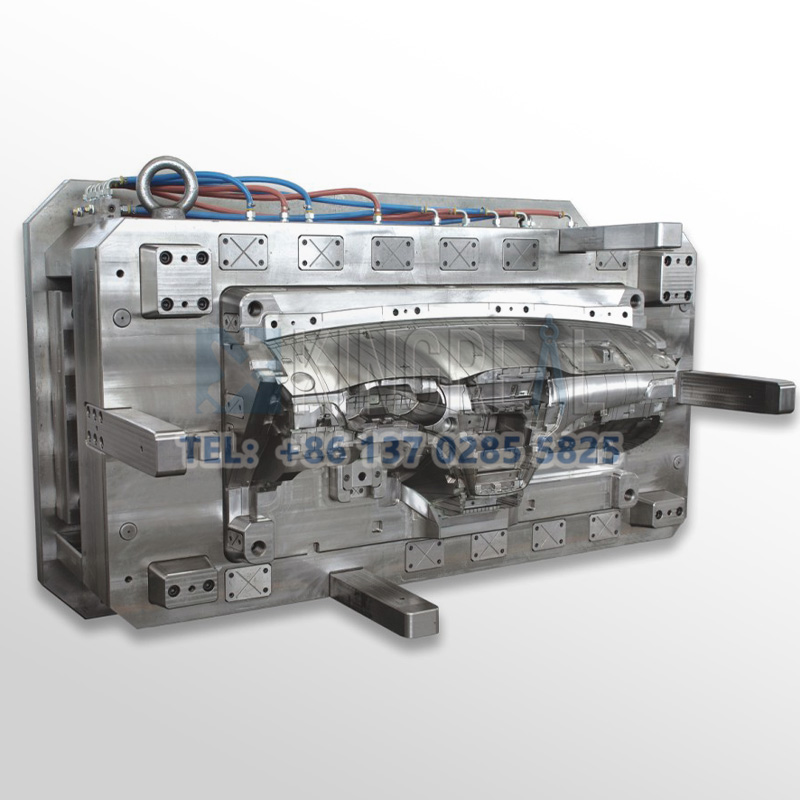

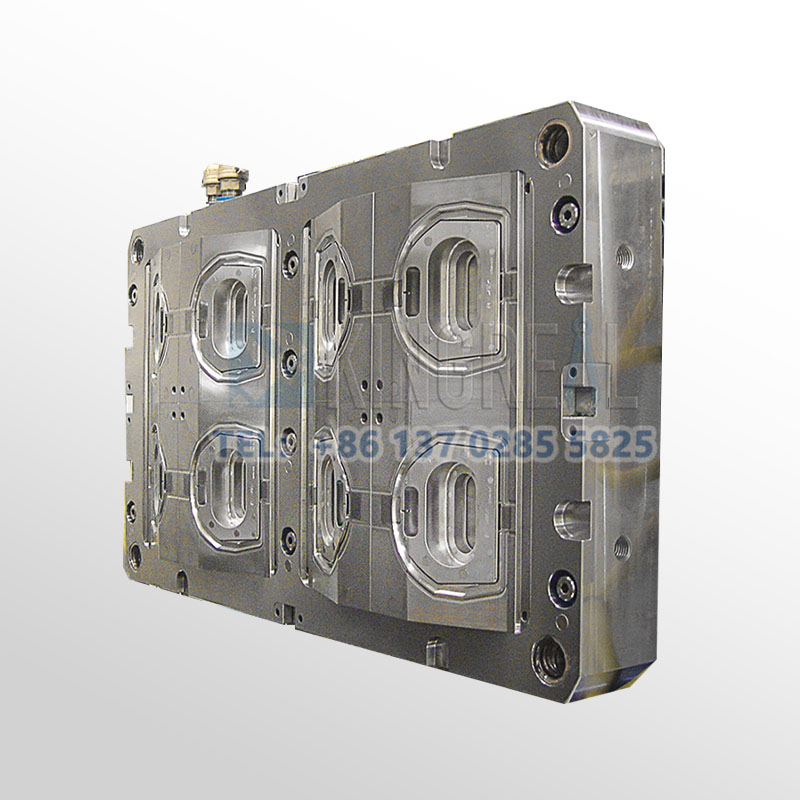

2/Automotive Dashboard Mould Design Feature

The front and rear sides of the punch of the automotive dashboard injection mold are both provided with linear motors, the left side of the punch corresponds to the right side of the die, the front and rear sides of the punch are both provided with limit slots, the front and rear sides of the die are both fixed with limit plates, the inner side of the linear motor mover seat is connected to the end of the support plate, the left side of the support plate is evenly distributed with stripping rods slidably connected to the through holes on the surface of the punch, the rubber head is installed on the left end of the stripping rod, the left side of the punch is provided with an anti-slip unit, and the top surface of the die is provided with a filter unit;

Wherein, it also includes a controller, the controller is provided on the front side of the punch, the input end of the linear motor is electrically connected to the output end of the controller, and the input end of the controller is electrically connected to the output end of the external power supply. The limit plate cooperates with the inside of the limit slot to prevent the problem of misalignment when the punch and the die overlap, the linear motor drives the stripping rod to move the finished product injection molded on the punch to fall off, and the rubber head installed at the end of the stripping rod can prevent the surface from being worn during stripping.

Furthermore, the anti-drop unit includes a placement slot, a motor, a connecting seat, an electric telescopic rod and a gear rod, the placement slots have two and are correspondingly opened at the bottom end of the left side of the punch, the placement slots are internally rotatably connected with a connecting seat, the motor is fixed to the bottom surface of the punch, the output shaft of the motor is connected to the bottom surface of the connecting seat, the electric telescopic rod is fixed inside the connecting seat, the left end of the electric telescopic rod is installed with a gear rod, the input ends of the motor and the electric telescopic rod are electrically connected to the output end of the controller, the motor drives the connecting seat to rotate, and the electric telescopic rod drives the gear rod to extend, thereby preventing the injection molded parts from falling and being damaged during demolding.

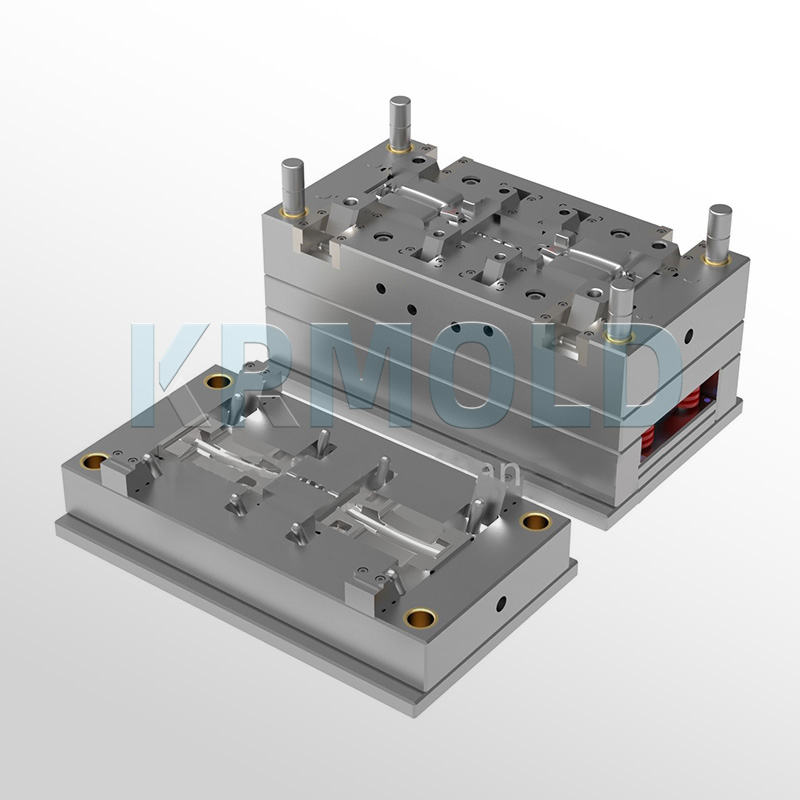

4/About KRMOLD -- Injection Mold Manufacturer

As a professional manufacturer of injection molds, KRMOLD is committed to providing customers with complete production solutions. We provide 3D simulation design and production services for injection molds according to customer needs for various products including car dashboards. Please feel free to contact us.