KINGREAL UNIVERSAL IND., LTD

Phone

+86-13702855825In the field of plastic injection molding, gas-assisted injection molding technology, as a highly innovative technology, is bringing new development opportunities to the injection mold industry with its unique advantages. In this paper, KRMOLD will discuss the gas-assisted injection molding process with you, which will help you better understand the close relationship between this process and gas-assisted injection molds forming, and how it can create greater value for enterprises.

| 1 | Introduction to Gas-assisted Injection Molding Process |

| 2 | Advantages of Gas-assisted Molding Injection Process |

| 3 | Application Field of Gas-assisted Injection Molds |

1. Introduction to Gas-assisted Injection Molding Process

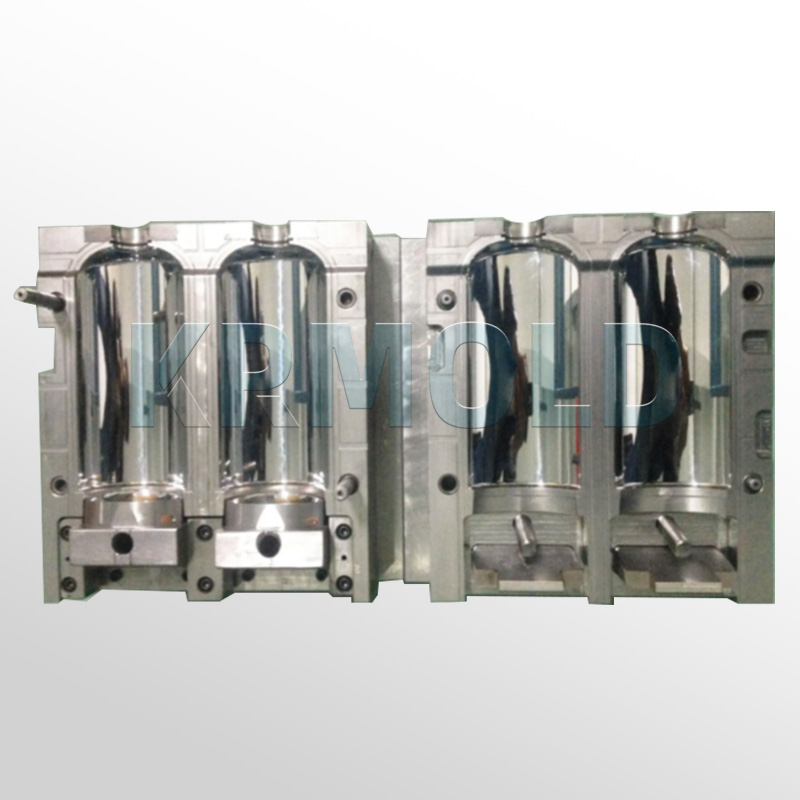

| Gas-assisted injection molding process is a cutting-edge technology in the molding process of injection mold. In the traditional plastic injection molding, plastic material is injected into the mold cavity under the action of injection molding machine, and the whole mold space is filled by the fluidity of plastic itself, and finally the product is cooled and solidified. On this basis, the gas-assisted injection molding process has been innovated, which is a process of pushing plastic materials to the wall of the gas-assisted injection molds by air flow in the gas-assisted injection molding process, thus forming products. |  |

2.Advantages of Gas-assisted Molding Injection Process

(1) Excellent product quality

The gas-assisted injection molding process can produce products with smooth appearance and high precision. In the traditional plastic injection molding, due to the uneven flow of plastic melt in the gas-assisted injection molds, surface defects, such as weld marks and shrinkage marks, are easy to occur, which affects the beauty and performance of products. In the gas-assisted injection molding process, the promotion of high-speed air flow enables plastic materials to fill the gas-assisted injection molds cavity more evenly, thus avoiding these defects. The surface of the product is as smooth as a mirror, which can meet the strict requirements of customers, whether it is for consumer electronic products with high appearance requirements or automobile interior parts with high quality.

In addition, the gas-assisted injection molding process can also achieve higher dimensional accuracy and stability. In the process of injection molding, the injection of high-pressure gas can exert uniform pressure on the plastic melt and reduce the dimensional deviation caused by inconsistent cooling shrinkage. This is especially important for some products that require strict dimensional accuracy, such as medical device parts and precision instrument housings. Stable dimensional accuracy not only improves the qualified rate of products, but also reduces the difficulty of subsequent processing and assembly and reduces the production cost.

(2) Significant improvement in production efficiency

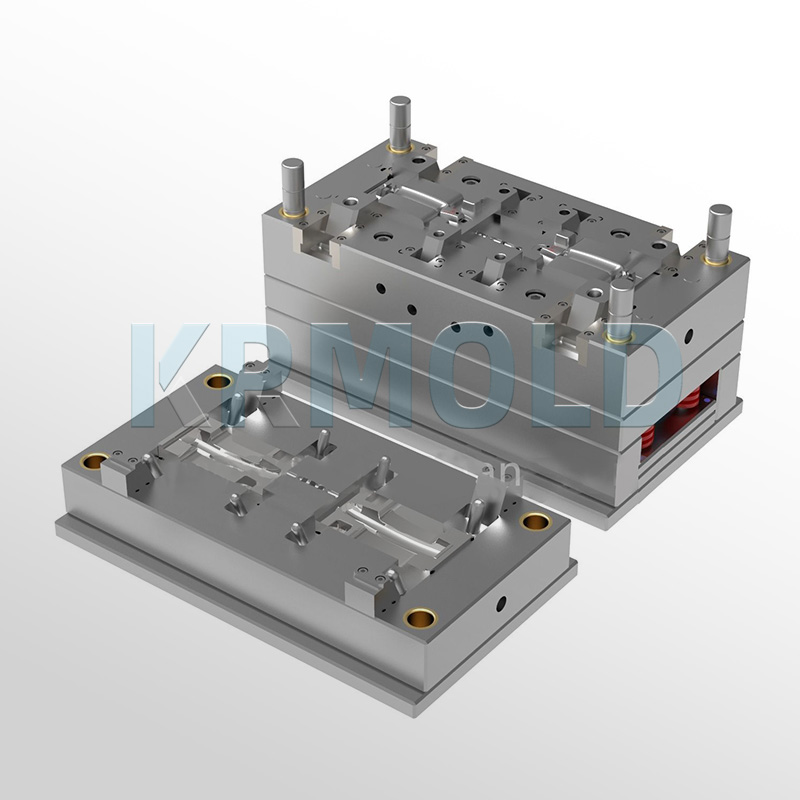

The gas-assisted injection molding process can effectively shorten the injection cycle and improve the production efficiency. In the traditional injection molding, in order to ensure that the plastic melt can completely fill the mold cavity, it often takes a long holding time. In the gas-assisted injection molding process, the injection of high-pressure gas can quickly push the plastic material to fill the cavity and reduce the holding time. At the same time, because the internal structure of gas-assisted injection molding products is more reasonable and the cooling speed is faster, the whole injection cycle is further shortened. According to the statistics of actual production data, the production efficiency can be improved by 20%-30% compared with the traditional injection molding process by using gas-assisted injection molding technology, which greatly increases the productivity of enterprises.

(3) considerable cost reduction

Gas-assisted injection molding technology also has significant advantages in reducing production costs. On the one hand, due to the improvement of production efficiency, the output per unit time increases, and the cost of equipment depreciation and labor allocated to each product decreases. On the other hand, the gas-assisted injection molding process can reduce the use of plastic materials. In the traditional injection molding process, in order to ensure the strength and rigidity of products, it is often necessary to increase the wall thickness of products. The gas-assisted injection molding process can realize the hollow structure of the product and reduce the amount of materials under the premise of ensuring the performance of the product through the assistance of gas. Taking the automobile dashboard as an example, the amount of materials can be reduced by 15%-20% after gas-assisted injection molding process, which greatly reduces the cost of raw materials. In addition, the surface quality of gas-assisted injection molding products is good, which reduces the secondary processing procedures such as subsequent polishing and painting, and further reduces the production cost.

3. Application Field of Gas-assisted Injection Molds

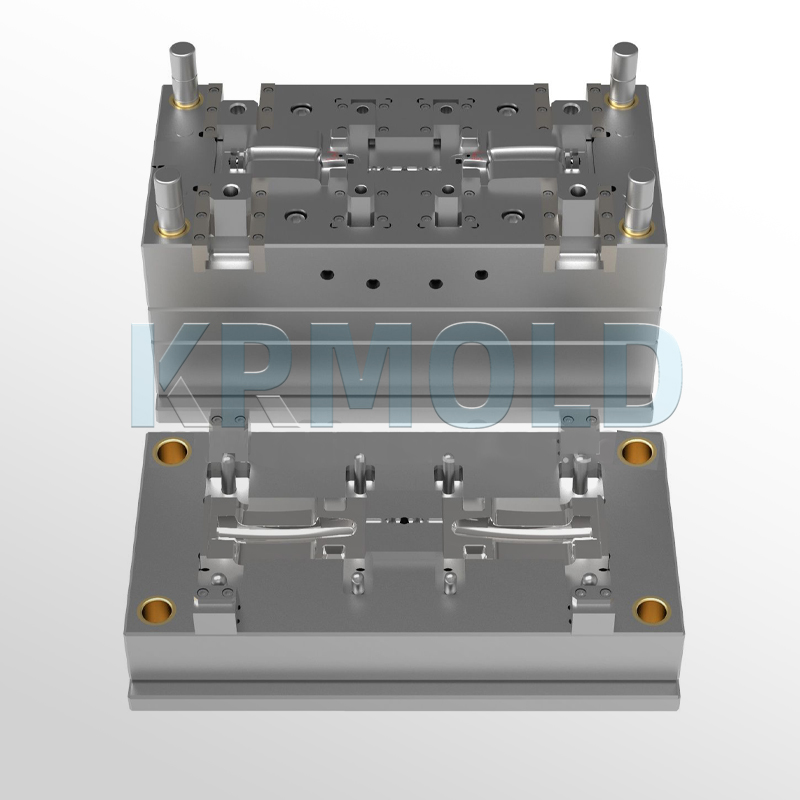

With its unique advantages, gas-assisted injection molds have been widely used in many fields, especially in industries that require high product appearance and accuracy.

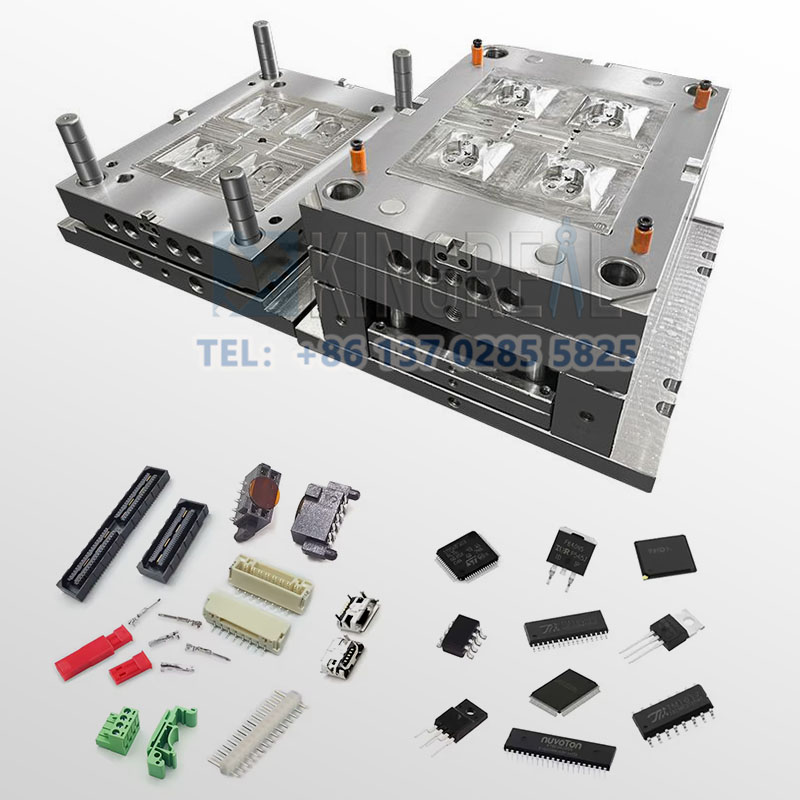

(1) The field of electronics and electrical appliances In the electronic and electrical industries, with the continuous improvement of consumers' requirements for product appearance and quality, gas-assisted injection molds have been widely used. The shells of mobile devices such as mobile phones and tablet computers need not only good feel and appearance, but also sufficient strength and anti-fall performance. Gas-assisted injection molds can manufacture thin-walled and high-strength shells, and at the same time ensure smooth and flawless surface, which meets the dual needs of consumers for product appearance and quality. In addition, the shell and internal parts of large household appliances, such as televisions and refrigerators, also adopt gas-assisted injection molds to improve product quality and production efficiency and reduce costs. |  |

Automobile industry is one of the important application fields of gas-assisted injection molds. Automobile interior parts, such as instrument panel, door panel, center console, etc., require extremely high appearance and comfort. Gas-assisted injection molds can manufacture interior trim with beautiful appearance, realize lightweight design of products, reduce the overall weight of automobiles and improve fuel economy. Gas-assisted injection molds also play an important role in automobile exterior parts, such as bumpers and spoilers. It can manufacture parts with complex shapes while ensuring the strength and rigidity of products. In addition, some parts in automobile engine compartment, such as intake manifold, not only reduce the weight, but also improve the performance and reliability of the parts after adopting gas-assisted injection molds. |  |

(3) The field of medical devices Medical devices have strict requirements on the accuracy, quality and safety of products. Gas-assisted injection molds can produce high-precision and high-quality medical device parts, such as syringe casing, infusion set parts, medical catheter and so on. These parts not only need to meet strict dimensional accuracy requirements, but also need to have good biocompatibility and chemical stability. Gas-assisted injection molds can ensure the surface quality of products, reduce the risk of bacterial growth, improve production efficiency and meet the needs of mass production in medical device industry. |  |