KINGREAL UNIVERSAL IND., LTD

Phone

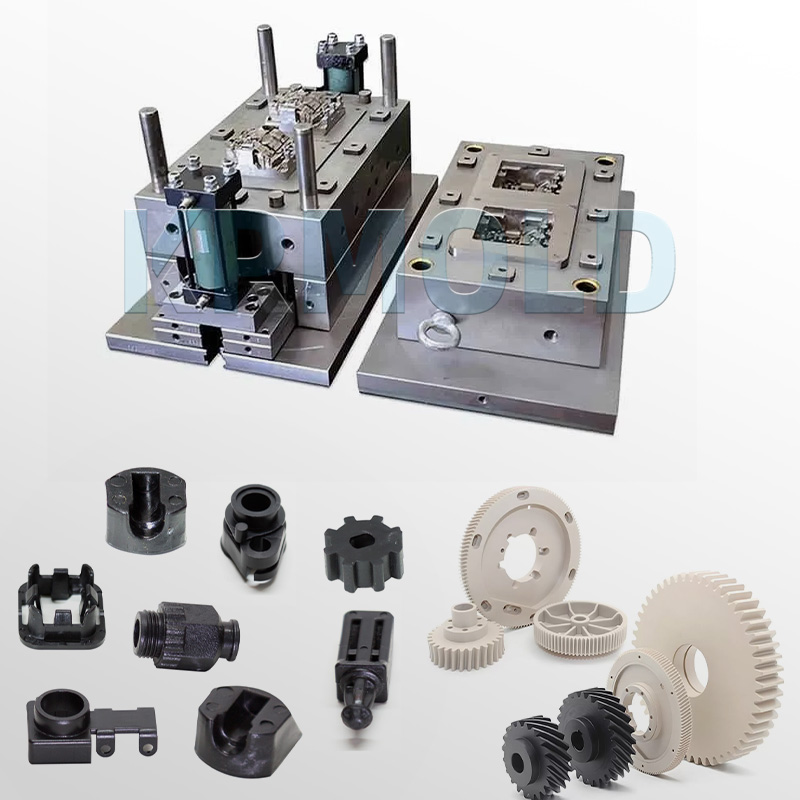

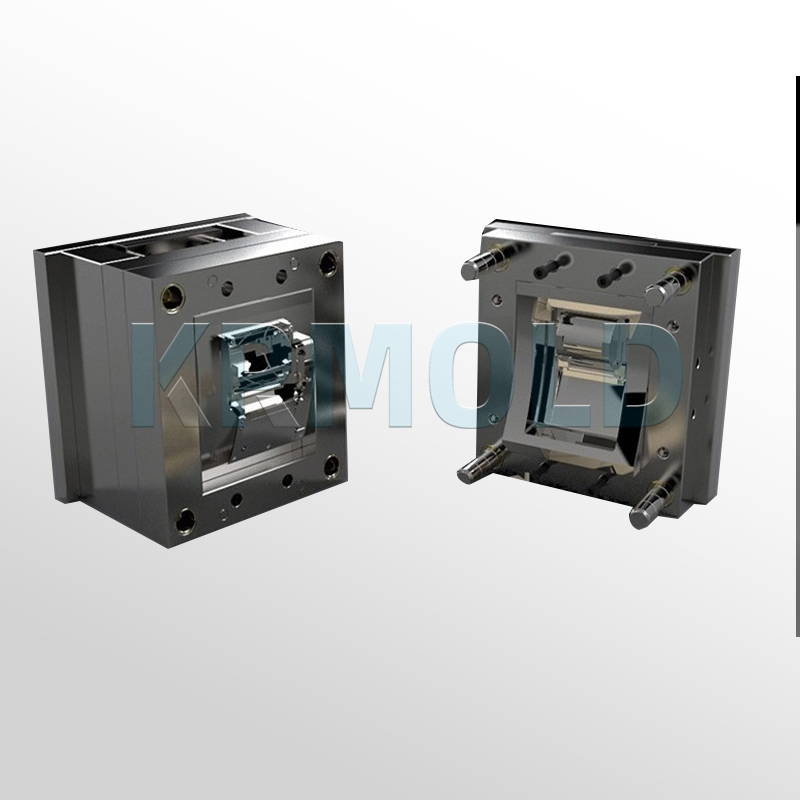

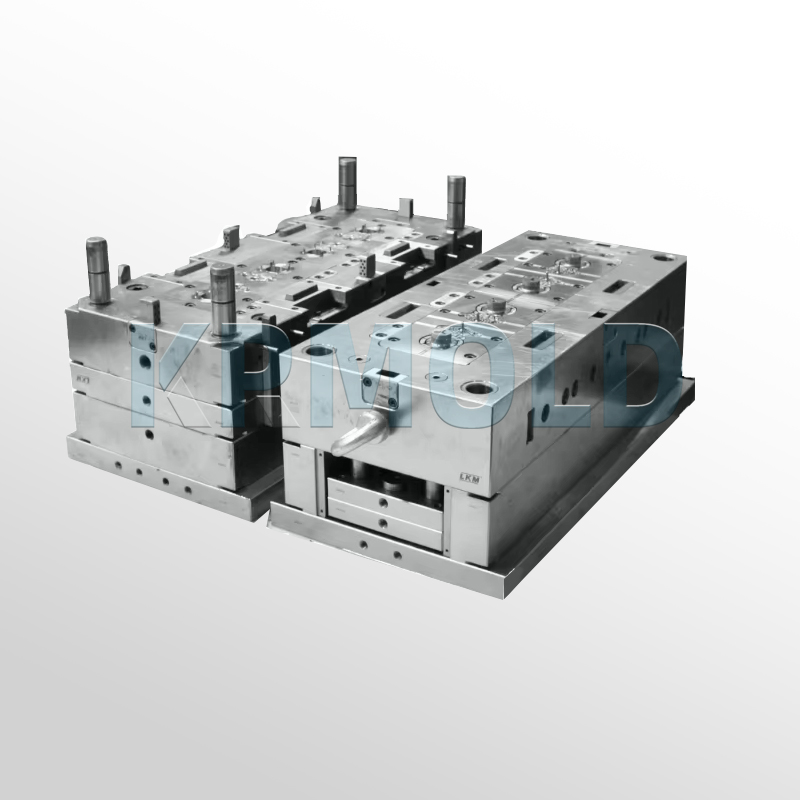

+86-13702855825| PEEK injection molding is the manufacturing of components by injecting its molten form into a mold. The form of the mold is adopted by the finished product after cooling and hardening. PEEK plastic injection molding is employed for high volume part manufacturing, where product consistency is the major problem. Additionally, this manufacturing method works for both thermoplastic and thermosetting polymers. A PEEK plastic injection molding machine, a mold, and plastic materials make up the PEEK injection molding apparatus. To simplify, PEEK injection molding is done in phases. It mostly breaks down into melting phase, injection phase, cooling phase, ejection phase, post-processing. |  |

| 1 | Why Choose PEEK Injection Molding? |

| 2 | Reasons for Great Development of PEEK Injection Molding |

1.Why Choose PEEK Injection Molding?

PEEK injection molding components perform superbly in severe surroundings compared with conventional plastics like PP, ABS, and nylon. Standard polymers are subject to distortion and corrosion and cannot resist high temperatures; PEEK, on the other hand, can run consistently at 260°C. High strength and resistance to concentrated acids characterize PEEK plastic injection molding items as well. PEEK plastic is thus a perfect material for producing accurate wear-resistant parts including medical implants and aircraft engine components.

High temperature resistance: continuous working temperature is 260°C, short-term temperature resistance is up to 300°C.

Mechanical strength: tensile strength 90-100 MPa, wear resistance is 4 times that of polytetrafluoroethylene

Chemical stability: resistant to strong acids (except concentrated sulfuric acid) and organic solvents

Dimensional stability: shrinkage rate is 0.1-0.5%, thermal expansion coefficient is similar to that of metal aluminum

Flame retardancy: UL94 V-0 grade, halogen-free flame retardant

2.Reasons for Great Development of PEEK Injection Molding

(1)Market demand for PEEK plastic injection molding is growing:

| Aerospace field: | PEEK material has the characteristics of high strength-to-weight ratio, flame retardancy and resistance to extreme temperatures, and can be used to manufacture structural components, electrical connectors, fasteners, etc. of aircraft and spacecraft. With the development of the aerospace industry, the demand for high-performance materials continues to increase, and PEEK injection molding parts will be more widely used in this field. |

| Automotive industry: | PEEK plastic injection molding can be used to manufacture automotive engine inner covers, bearings, gaskets, seals, clutch rings and other parts. It can maintain good performance under high temperature, high pressure and harsh chemical environments, and provide better durability and reliability. As the automotive industry's demand for lightweight and high-performance parts continues to increase, the market demand for PEEK injection molding parts will also increase accordingly. |

| Medical field: | PEEK has excellent biocompatibility, chemical resistance and radiotransmittance, and is widely used in orthopedic implants, dental instruments, endoscope components and artificial joints. With the aging of the population and people's pursuit of a healthy life, the demand for PEEK plastic injection molding parts in the medical field will continue to grow. |

| Electronic information field: | PEEK resin is an ideal electrical insulator, which can still maintain good electrical insulation properties under harsh working conditions such as high temperature, high pressure and high humidity. It can be used to manufacture pipes, valves and pumps for transporting ultrapure water, as well as wafer carriers, electronic insulation diaphragms and various connecting devices in the semiconductor industry. With the rapid development of the electronic information industry, the demand for PEEK injection molding parts will continue to expand. |

| Emerging fields: | such as the humanoid robot industry, the lightweight, high strength, and high precision of PEEK materials are highly consistent with the requirements of humanoid robots for materials, and have been used in joints, bearings, gears and other parts. With the rise of the humanoid robot industry, it will bring new market growth points for PEEK plastic injection molding. |

(2)Technology development promotion of PEEK injection molding:

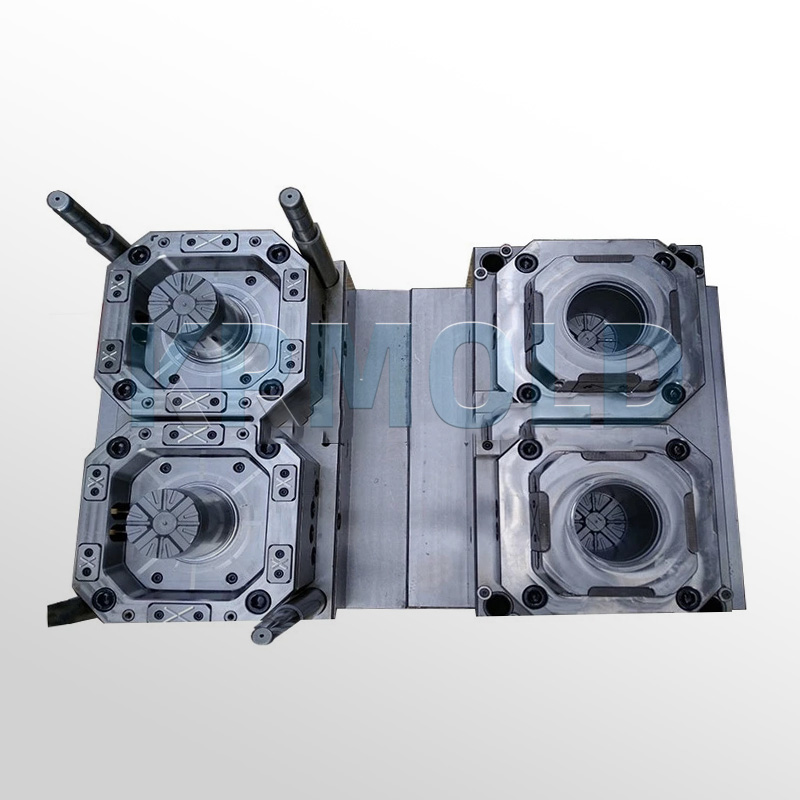

| Process optimization: | With the advancement of technology, PEEK plastic injection molding technology is developing towards high performance, intelligence, and customization. For example, through precise control of process parameters, optimization of mold design, and application of advanced manufacturing technology, production efficiency can be improved, scrap rate can be reduced, and higher quality and more complex injection molded parts can be produced. |

| Modification technology development: | Through filling, blending, cross-linking and other modification technologies, the application scope of PEEK can be further broadened, its performance can be improved, and it can better meet the special needs of different fields, thereby promoting PEEK injection molding to replace traditional metal materials in more industries. |

| Integration of 3D printing technology: | The development of 3D printing technology has brought new processing methods and application prospects for PEEK resin special materials, provided more advantageous solutions for the production of complex structures, and further expanded the application field and market space of PEEK plastic injection molding. |

| Policy support: | The country's support for the new materials industry has been increasing. For example, relevant policies have proposed to build new growth engines such as new materials. PEEK materials, as an important new material, are expected to benefit from policy dividends and obtain more R&D and industrialization support, thereby promoting the development of the PEEK injection molding industry. |

| Rising environmental awareness: | Producers are investigating how bio-based materials and recycled resources can be employed to create PEEK to address sustainability issues. Apart from lowering environmental effects, this improves PEEK plastic injection molding products' market competitiveness and adjusts to developments in environmental protection regulations and customer demand. |

Generally speaking, the PEEK injection molding process is a technology-intensive one needing accurate manipulation and expert knowledge. The possible benefits of PEEK materials may only be completely realized to create high-performance products meeting the needs of certain sectors by profoundly understanding and mastering this process.