KINGREAL UNIVERSAL IND., LTD

Phone

+86-13702855825Plastic injection molding is an important technology widely used in the field of plastic processing, and its processes are various and have their own characteristics. In the big family of injection molding technology, insert injection molding is a very special one.

| 1 | Introduction of Insert Injection Molding |

| 2 | Process Flow of Insert Injection Molding |

| 3 | Advantages of Metal Insert Injection Molds |

| 4 | Application of Metal Insert Injection Molds |

1. Introduction of Insert Injection Molding

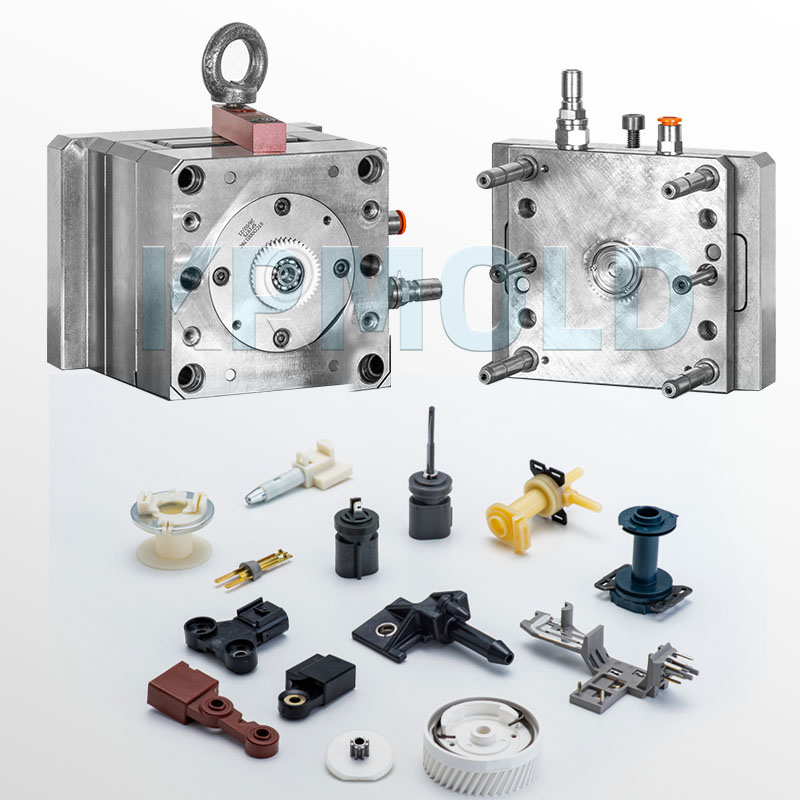

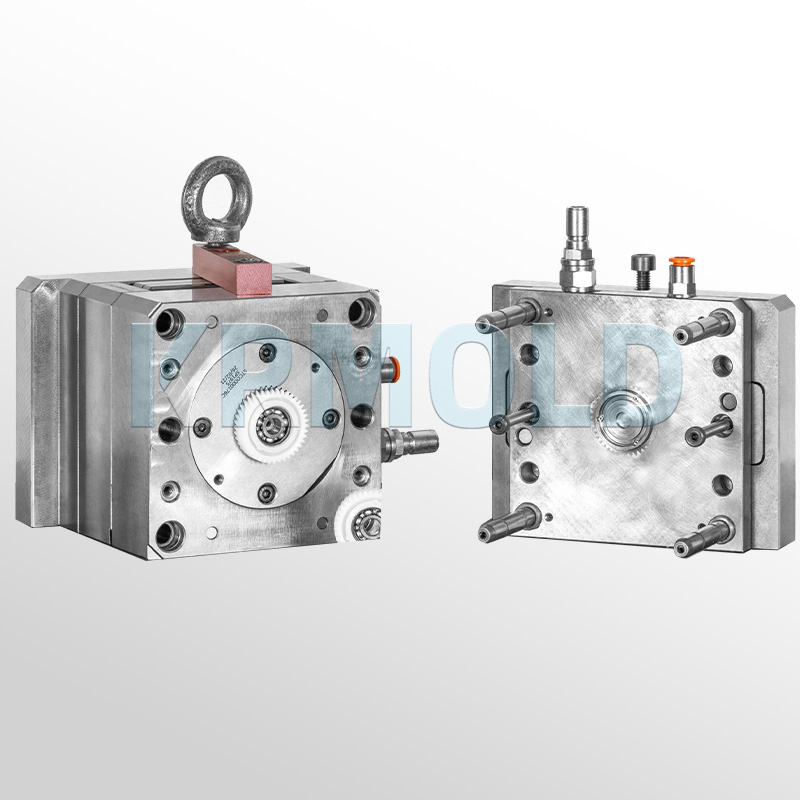

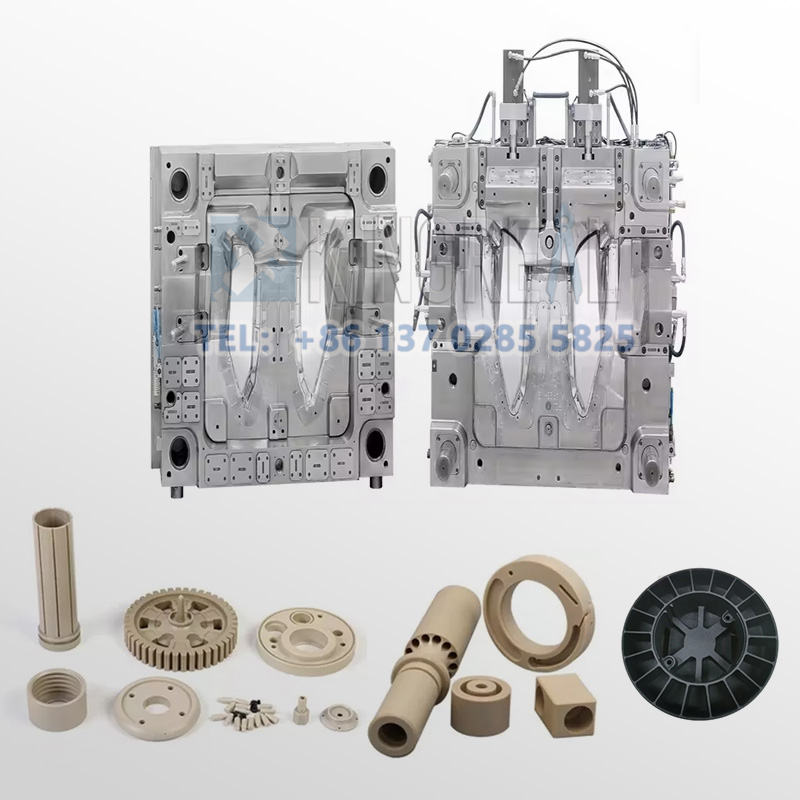

Insert injection molding means that in the process of injection molding, the prepared inserts made of different materials of metal or other materials are put into the metal insert injection molds, and then molten plastic is injected. After the multi-material insert molds are opened, the inserts are wrapped tightly in the plastic, and the plastic and the inserts are firmly combined to form complex and exquisite integrated parts or products with inserts such as threads and electrodes.

Insert injection molding is a complex and exquisite process, which uses the combination of the insulation of plastic resin and the mechanical strength, stiffness and conductivity of metal, and the molded products can meet the basic functions of electrical products and create complex devices that make our lives more convenient. It is a technology that cannot be separated from electronics, automobiles and other industries.

2. Process Flow of Insert Injection Molding

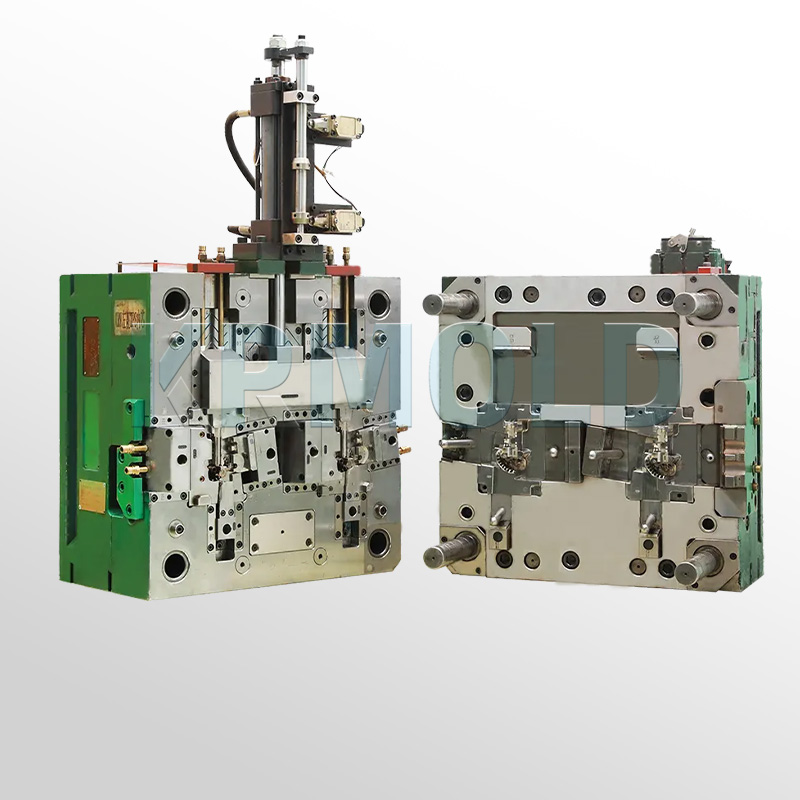

In the insert injection molding process, the injection molding machine is usually only a part of the whole system. Inserts usually need to be oriented first, and a vibrating table can be used to accomplish this task. Then, the insert is put into the metal insert injection molds by the end-of-arm tool (EOAT), usually by means of a pre-positioning device. After the finished product stage, ejection positioning is the most important step, and the repeatability of the multi-material insert molds opening action of injection molding machine is very important here. After the insert is put into the metal insert injection molds, it is fixed in vacuum or by mechanical means (such as using a slider). At the same time as the insert is inserted, the last finished product is ejected.

Inserts can also be placed in the multi-material insert molds manually during insert injection molding, but this will greatly increase the injection molding cycle and reduce the production efficiency of injection products, which is only suitable for small batch production or products with complex structures. Automatic placement is a better choice for mass production, which is conducive to reducing human errors, improving efficiency, shortening insert injection molding cycle and improving product reliability. In this technology, the integrated operation of injection molding machine, multi-material insert molds and automation device plays the most important role. Combined with injection molding machine, manipulator with automatic clamping inserts, insert product arranging device and other equipment, many insert injection processes can realize automatic production, reduce manual error and improve product quality.

3. Advantages of Metal Insert Injection Molds

Improve product strength and functionality: by embedding high-strength materials such as metals, the structural strength and durability of products can be significantly enhanced. And can realize the perfect combination of the respective advantages of different materials, so that the product not only has the advantages of portability, elasticity and easy molding of plastic, but also has the rigidity, strength and durability of metal.

Simplify post-assembly: Metal insert injection molds can make the complicated assembly process be completed at one time in the injection molding process, eliminating secondary processing procedures such as welding and riveting, greatly shortening the assembly time, reducing labor and material costs and improving production efficiency.

Multi-material combination: it can realize the effective combination of multiple materials in one product and solve the cooperative work requirements of various materials in an integrated way. Metal insert injection molds with the combination of plastic insulation and metal conductivity can enhance the functionality of products, for example, in electronic and electrical products, it can achieve better conductivity, magnetic conductivity, heat dissipation and other properties. Inserts are not limited to metals, but also many different types of articles, such as cloth, paper, wires, glass, wood, wires, springs, nuts, electrical parts and so on, which provide unlimited possibilities for product design. KRMOLD designers can create novel shapes and structures according to product requirements.

4. Application of Metal Insert Injection Molds

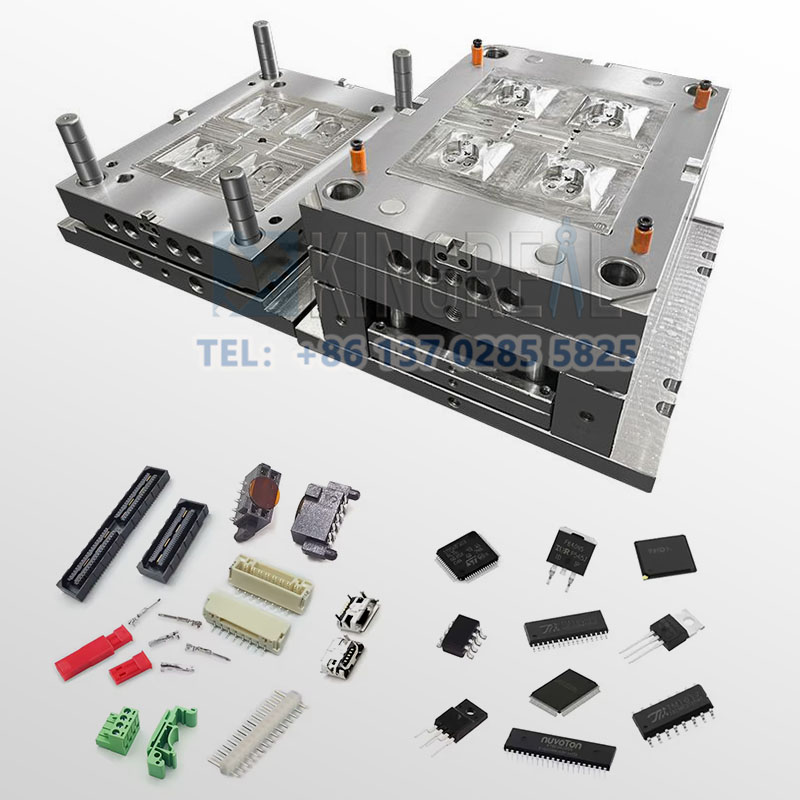

Multi-material insert moldsuses the insulation of plastic resin and the conductivity of metal, and the molded products can meet the basic functions of electronic and electrical products. With the increasing complexity of electronic components, automobiles, medical care and other industries, multi-material insert molds are shining in these fields.

With the seamless integration of metal and plastic, multi-material insert molds has brought an efficient solution to the new energy automobile industry and has been widely used in the new energy automobile industry. This multi-material insert molds not only significantly promotes the integration and simplification of auto parts, helps enterprises to cope with the cost pressure in the increasingly competitive market, but also becomes the key driving force to promote the technological progress and market demand expansion of the entire auto industry.

Due to the limitation of the space at the bottom of the car, it is difficult to keep the safe distance between components, and the bumping and collision of the car in bad road conditions increase the risk of component displacement. Insert injection molding technology has played its unique advantages in this field. It uses insulating multi-material insert molds' materials to closely integrate electronic components made of metal materials, effectively isolating the possibility of short circuit, improving the high-voltage safety protection performance of the automobile, shortening the distance between components and optimizing the overall layout.

(2) Consumer electronics industry

Metal insert injection molds are widely used to meet the requirements of miniaturization, integration and high performance of electronic products. For example, the mobile phone antenna is a perfect example of the application of multi-material insert molds in this industry, which makes the mobile phone antenna thinner and stronger. Other examples include connectors, switches, sensors, etc.

From simple medical equipment to complex and sensitive medical equipment such as suture and implant, we can see the shadow of multi-material insert molds. In addition, metal insert injection molds can also be used to produce some electronic equipment used in the medical industry, such as pipes, medical equipment parts and dental instruments. Other applications include medical knobs, blades, surgical instruments and medical housings, and so on.

Multi-material insert molds are mainly used for airplane seats, luggage latches, bathrooms, handles and user interface switches. In addition, sensors, valves, etc. are often manufactured by insert injection molding process. This process can ensure the accuracy and reliability of components and meet the requirements of high performance and precision in aerospace field.