KINGREAL UNIVERSAL IND., LTD

Phone

+86-13702855825| 1 | Definition of Two-Shot Injection Molding and Overmolding |

| 2 | Process Flow of Two-Shot Injection Molding and Overmolding |

| 3 | How to Choose Between Two-Shot Injection Molding and Overmolding? |

| 4 | Key Considerations About Two-Shot Injection Molding and Overmolding |

| 5 | KRMOLD Plastic Injection Molding Solutions |

Plastic injection molding is a process suitable for rapidly manufacturing complex, precision parts. It is often employed in aerospace, medical applications, smart home, home appliances, and automotive use among others. Two significant technologies among the several plastic injection molding methods are overmolding and two-shot injection molding. Although these two methods share some features, their applications situations and characteristics differ greatly. Two-shot injection molding and overmolding will be discussed in great detail in this article together with their definitions, process flows, selection techniques, advantages and cons, hence giving industry experts a thorough grasp.

1.Definition of Two-Shot Injection Molding and Overmolding

Two-shot injection molding is a process that uses an injection molding machine to create layers of different materials or colors. In this process, one plastic material is first injected into the mold to form a base material. After the base material solidifies and cools, it is transferred manually, robotically, or by a rotary platform to another cavity in the mold. In this new cavity, the mold opens, and one side of the base material is rotated 180° to mate with the other mold cavity and injection nozzle. A second material is then injected to form a strong bond with the base material. After the second layer of material cools, the final component is ejected.

Overmolding is the process whereby two or more distinct thermoplastic materials are combined to produce one final product. For engineers wanting to design robust, practical, and aesthetically pleasing components, this is a perfect alternative. First injection-molded with a stiffer overmolding material, this procedure starts with a basic component. The base material is then placed in an overmolding mold or an overmolding cavity within the same mold. The molten overmolding material is then injected into, onto, or around the base material, cooling to form a strong bond. The entire overmolding process can typically be completed in less than 30 seconds.

2.Process Flow of Two-Shot Injection Molding and Overmolding

The two-shot injection molding process can be divided into two main stages. Like conventional injection molding, the first stage is injecting a first layer of plastic resin into the mold to create the base material. It is moved to yet another mold cavity for second molding once the basic material cools and solidifies. The adhesion of next materials and the stability of the base substance are guaranteed by this process.

The overmolding process also begins with the formation of the substrate. Usually during this process the substrate is composed of a rather strong material. Following the insertion of the substrate into the overmolding mold, molten overmolding material is injected around the substrate. The overmolding material and substrate mechanically or chemically bond to produce the finished good following cooling. When a product design calls for many overmolding layers, it is imperative to ensure the plastic resins utilized possess thermal or chemical compatibility. to avoid distortion or insufficient adhesion.

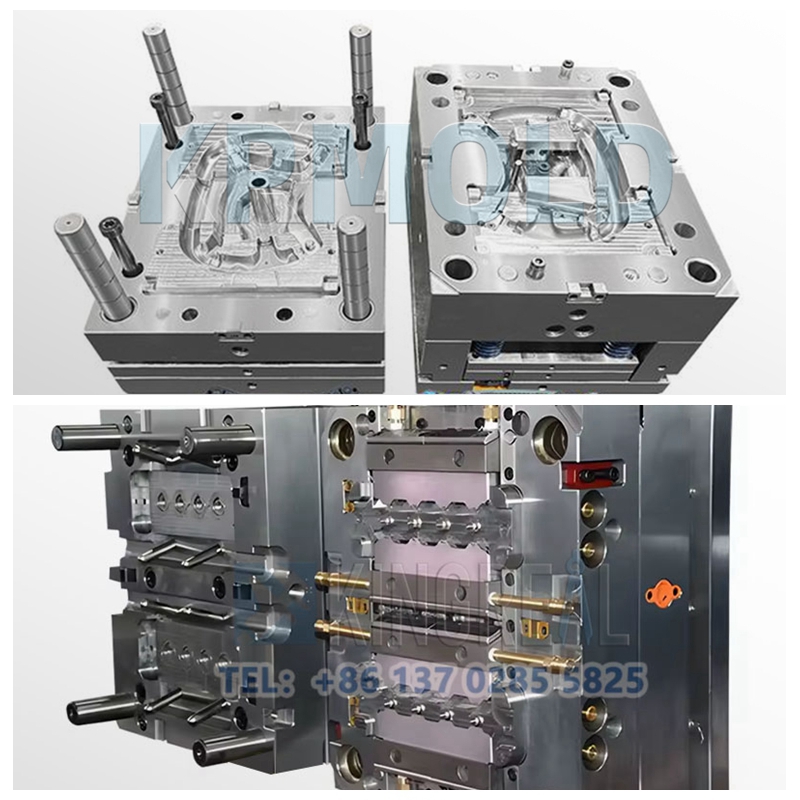

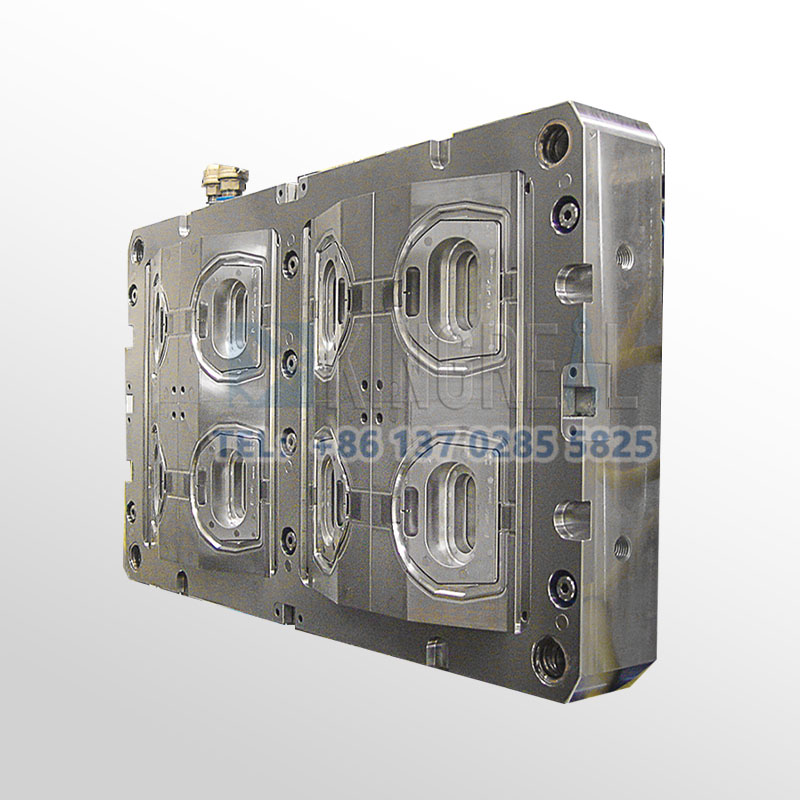

(Photos About Two-shot Injection Molding)

3.How to Choose Between Two-Shot Injection Molding and Overmolding?

Two-shot injection molding or overmolding calls for a thorough assessment of a manufacturer's needs and project features. Every technique has pros and negatives. hence, it fits several manufacturing contexts.

Advantages and disadvantages of two-shot injection molding:

Two-shot injection molding's chief benefit is its capacity for large-scale manufacturing and its effective production method. Two distinct materials can greatly enhance the looks and performance of the item. Two-shot injection molding is especially appropriate for goods demanding great visual and tactile properties since it provides great flexibility, control, and finished product quality. For small-batch manufacture, though, this method has a high initial investment cost and relatively costly mold creation, rendering it probably impractical.

Advantages and disadvantages of overmolding:

Particularly when product tolerances are broad, overmolding is ideal for small-batch manufacture. Its primary advantage is that it may be accomplished on traditional injection molding equipment, therefore obviating the need for new tooling. The overmolding method's adaptability allows manufacturers to quickly satisfy demand and adapt to evolving production situations. Overmolding, nevertheless, demands close consideration of material compatibility and adhesion to prevent future problems with product quality.

4.Key Considerations About Two-Shot Injection Molding and Overmolding

Choosing between two-shot injection molding and overmolding should be based on the following important criteria by KRMOLD engineers and design teams:

Production Scale: If the goal is high-volume production, two-shot injection molding is generally the preferred option. For smaller batches or customized requirements, overmolding may be more appropriate.

Material Compatibility: In overmolding, thermal and chemical compatibility between the materials used is crucial. Ensuring material compatibility effectively avoids poor adhesion.

Cost-Effectiveness: When considering production costs, two-shot injection molding requires a higher initial investment, but its efficient production capacity can offset these costs over the long term. The flexibility of overmolding, on the other hand, allows manufacturers to meet market demands without significant additional investment.

Design Complexity: For products requiring complex structures and multiple material combinations, two-shot injection molding offers greater design freedom. Overmolding, on the other hand, is more suitable for simpler structures and functions.

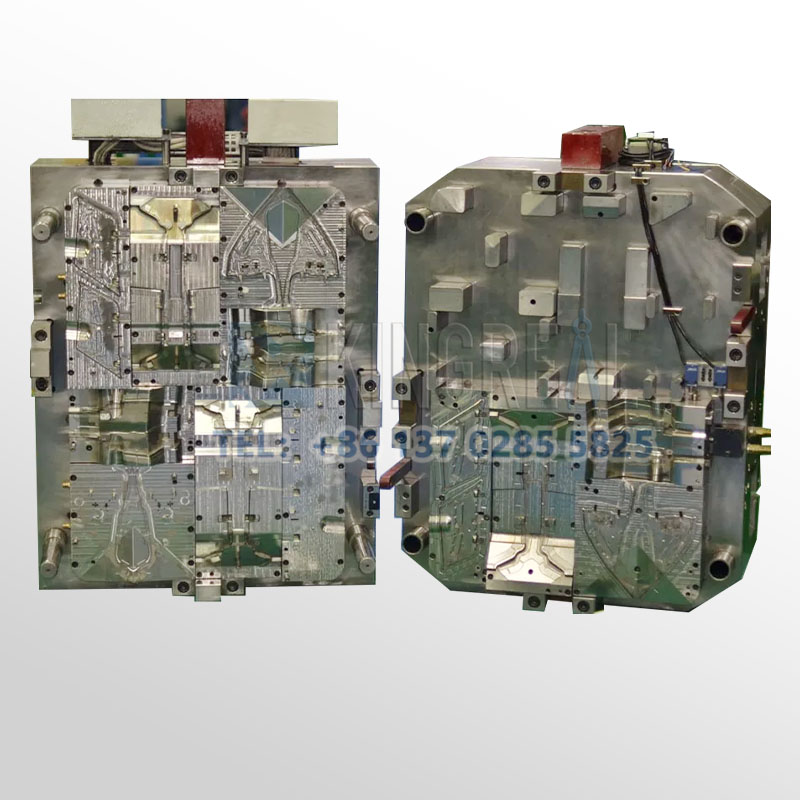

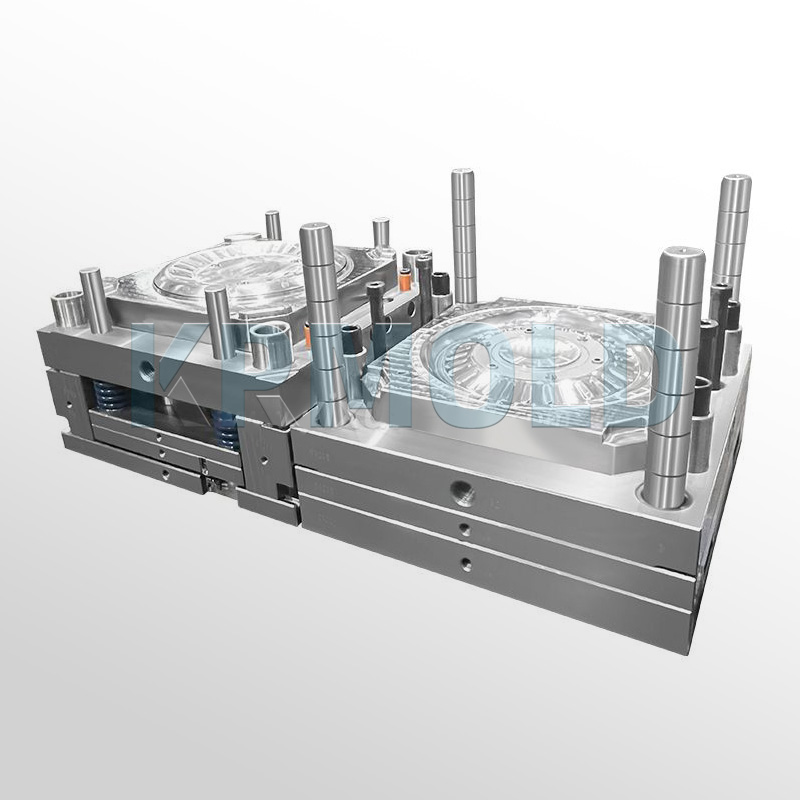

(Photos About Overmolding)

5.KRMOLD Plastic Injection Molding Solutions

Making an educated decision starts with knowing the distinctions between two-shot injection molding and overmolding. Working with a qualified manufacturing partner like KRMOLD, though, would help to streamline the process. KRMOLD experienced team of designers, engineers, and machinists can help you from design and procedure selection to final manufacturing.