KINGREAL UNIVERSAL IND., LTD

Phone

+86-13702855825| Double shot injection molding is also often called two shot injection molding. It is a common method in plastic injection molding. It refers to the process of molding two plastics (or two plastics of different colors) into one piece in one injection molding process. In this article, KRMOLD will introduce the relevant information of double shot injection molding, and share with you the material selection method and double shot injection mold design tips for two shot injection molding. I hope that through this article, you will have a better understanding of two shot injection molding. |  |

| 1 | Advantages of Double Shot Injection Molding |

| 2 | Material selection for Double Shot Injection Molding |

| 3 | Design Guidelines for Two Shot Injection Molding |

| 4 | Difference between Two Shot Injection Molding & Insert Injection Molding |

1.Advantages of Double Shot Injection Molding

1) Increase product design flexibility two shot injection molding can integrate multiple functions into one plastic part, such as soft surface, ergonomic design, two-color appearance, brand logo, feature improvement, noise reduction, shock absorption, waterproof and anti-collision, etc., which can save design space and reduce the number of parts.

2) Reduce the number of projects to reduce costs. One injection molding process can complete multifunctional plastic parts and reduce secondary processing.

3) Different plastics are integrated into one through chemical links, with higher quality and better strength.

2.Material selection for Double Shot Injection Molding

Different plastics have different chemical properties, and their compatibility will directly affect the bonding strength and bonding effect of two shot injection molding.

Therefore, when designing double shot injection molding products, the most important thing is to choose the most suitable substrate material and covering material.

1) Choose substrate materials and covering materials with good compatibility. PC, PP, and TPE are plastic materials with high compatibility, and they can be used for two shot injection molding. Of course, this can only be used as a general selection guide. When choosing a specific material model, it is best to contact the plastic supplier for more professional advice.

2) The difference in melting temperature between the substrate material and the covering material should not exceed 30~60°. The melting temperatures of common plastics are shown in the figure below:

Plastic | Melting Temperature (C/F) | ||

| Min. | Rec. | Max. | |

| ABS | 200/392 | 230/446 | 280/536 |

| PA 12 | 230/446 | 255/491 | 300/572 |

| PA 6 | 230/446 | 255/491 | 300/572 |

| PA 66 | 260/500 | 280/536 | 320/608 |

| PBT | 230/446 | 250/482 | 280/536 |

| PC | 260/500 | 305/581 | 340/644 |

| PC/ABS | 230/446 | 265/509 | 300/572 |

| PC/PBT | 250/482 | 265/509 | 280/536 |

| HDPE | 180/356 | 220/428 | 280/536 |

| LDPE | 180/356 | 220/428 | 280/536 |

| PEI | 340/644 | 400/752 | 440/824 |

| PET | 265/509 | 270/518 | 290/554 |

| PETG | 220/428 | 255/491 | 290/554 |

| PMMA | 240/464 | 250/482 | 280/536 |

| POM | 180/356 | 210/410 | 235/455 |

| PP | 200/392 | 230/446 | 280/536 |

PPE/PPO | 240/464 | 280/536 | 320/608 |

| PS | 180/356 | 230/446 | 280/536 |

| PVC | 160/320 | 190/374 | 220/428 |

| SAN | 200/392 | 230/446 | 270/516 |

3) The coefficient of thermal expansion CTE of the substrate material and the covering material should be as close as possible.

4) The shrinkage of the substrate material and the covering material should be as close as possible.

5) Avoid the combination of amorphous plastics and semi-crystalline plastics.

6) The HDT of the substrate material should be higher;

3.Design Guidelines for Two Shot Injection Molding

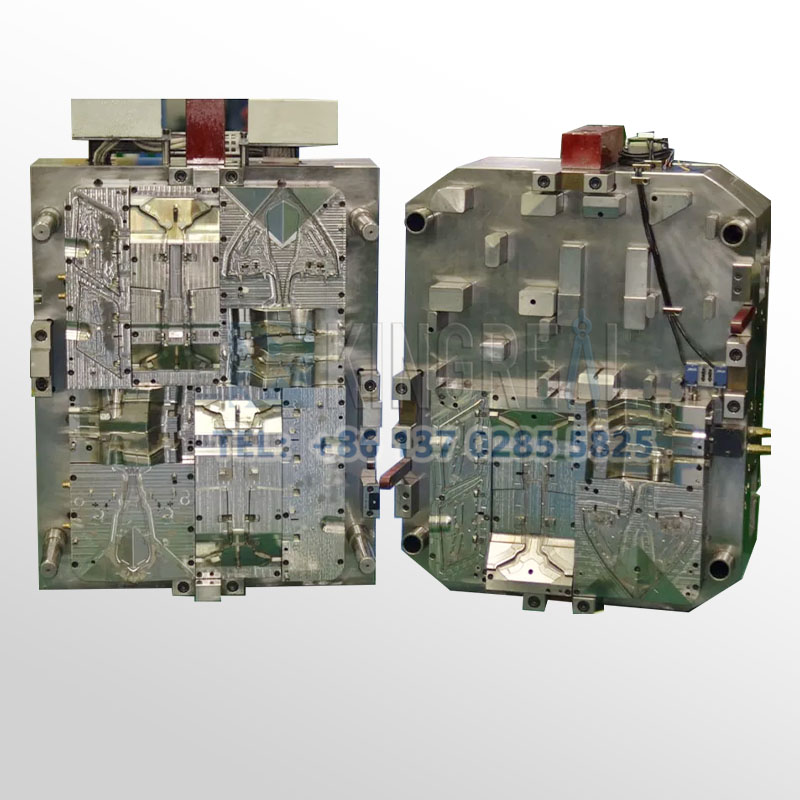

| The product design of double shot injection moldingneeds to follow the following design guidelines:

1) Design of internal bonding surface The bonding strength between the substrate material and the covering material depends on the compatibility between the materials, the process temperature, the bonding surface, the molding sequence and the design of the mechanical interlocking structure of the internal bonding surface. First, the area ofthe bonding surface should be increased as much as possible to increase the bonding strength. When the internal joint surface is too small, on the one hand, the roughness can be increased by biting on the joint surface, and on the other hand, a mechanical interlocking structure can be designed. 2) Design of the appearance mating surface The design of the appearance mating surface during the first and second injections is very challenging. Sufficient bonding strength must be provided, otherwise it is easy to produce flash, burrs, curling and peeling, especially for two shot injection molding of soft and hard plastics. Common appearance mating surface designs include step type and groove type. 3) Uniform wall thickness and avoid sharp corners, etc. Double shot injection molding is a type of injection molding, so the DFM design guidelines for injection molding, such as uniform wall thickness, avoid sharp corners and uniform transition, must also be followed for two shot injection molding. 4) Demolding angle The demolding angle is important for double shot injection molding because the demolding angle determines which mold the part is attached to during the rotation process. During the first injection, the part should be attached to the movable mold; during the second injection, the part should be attached to the ejection side of the mold. After the first injection, if the surface of the part directly matches another fixed mold, the plane should have a sufficiently large demolding slope to avoid scratches during mold closing.

5) Weight difference The weight difference between the substrate material and the covering material should not be too large, otherwise it will affect the molding cycle and injection pressure, etc. |

4.Difference between Two Shot Injection Molding & Insert Injection Molding

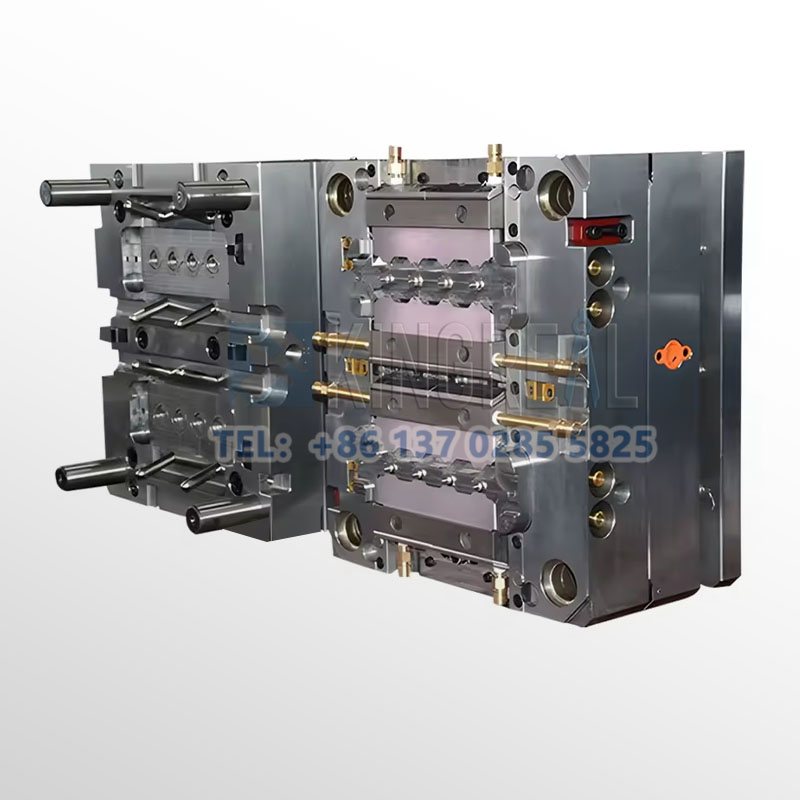

(1) Insert injection molding uses an ordinary injection molding machine. After the product is removed from one set of molds, it is placed in another set of molds for a second injection molding.

Therefore, insert injection molding is usually completed by 2 sets of molds, and no special double shot injection molding machine is required.

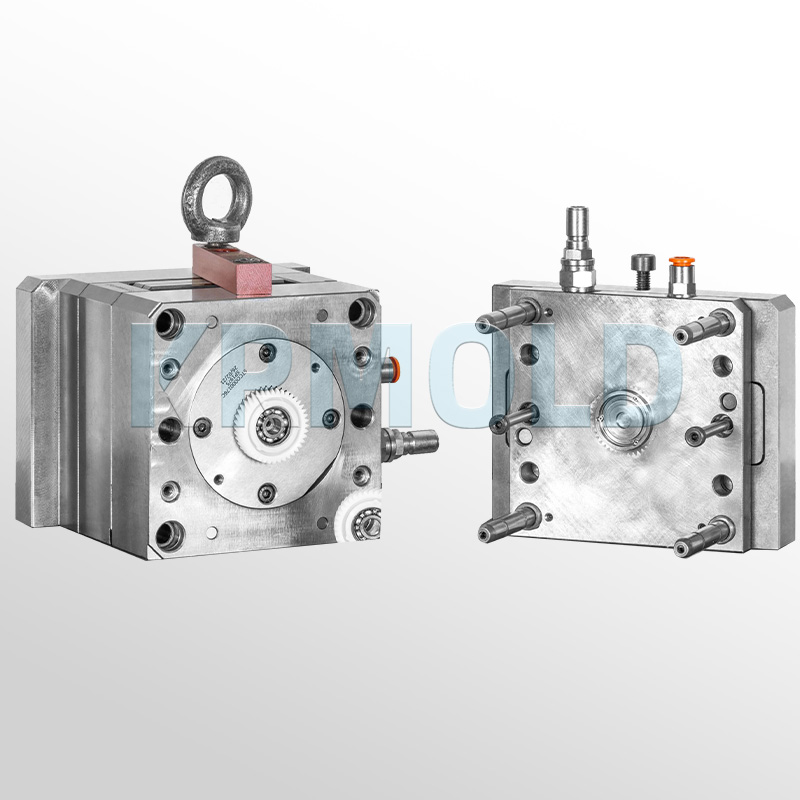

Two shot injection molding is to simultaneously inject and mold two plastics at one time on a special two shot injection molding machine.

Two plastics are injected on the same injection molding machine and molded in two times, but the product is only ejected from the mold once. Therefore, double shot injection molding is usually completed by one set of molds and requires a special double shot injection molding machine.

2) During the entire process of two shot injection molding, the plastic is in a molten state without cooling shrinkage, which means that there is an opportunity to form a strong chemical link between the substrate material and the covering material, with high strength and reduced risk of burrs.

3) Compared with insert injection molding, two shot injection molding does not require the insertion process of the insert, and the molding cycle is shorter, more efficient, and of higher quality.