KINGREAL UNIVERSAL IND., LTD

Phone

+86-13702855825| 1 | What is Double Shot Injection Molding? |

| 2 | Basic Principles of Double Shot Injection Molding |

| 3 | Advantages of Two Shot Injection Molding |

| 4 | Design Considerations for Two Shot Injection Molding |

| 5 | Common Myths and Facts About Two Shot Injection Molding |

| 6 | FAQs about Double Shot Injection Molding |

"Double Shot Injection Molding By shaping two distinct materials in the same mold, advanced injection molding technique called molding offers producers several benefits. Apart from lowering manufacturing expenses, this process enhances product quality and design flexibility.

To enable readers to fully grasp two shot injection molding, this essay will examine its definition, operation principle, benefits, design factors, and common misunderstandings."

1/ What is Double Shot Injection Molding?

Double shot injection molding, also known as two shot injection molding, is a technology that injects two different plastic raw materials into the mold simultaneously or alternately.

Unlike traditional single-material injection molding, double shot injection molding can achieve a combination of multiple materials in one production cycle.

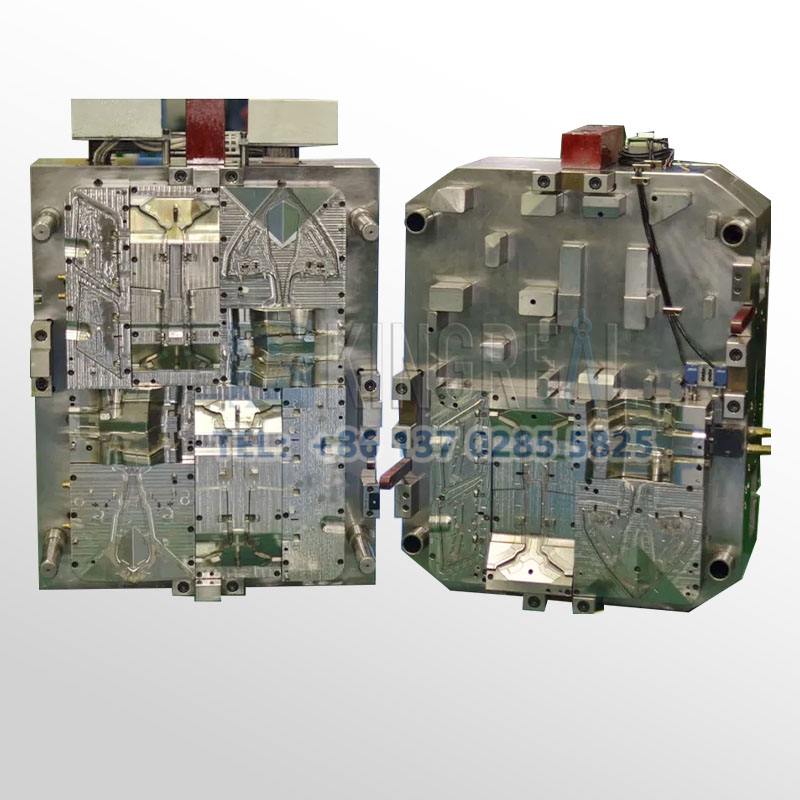

The core of this technology lies in the precise control of the injection location and time of the materials through specially designed molds.

2/ Basic Principles of Double Shot Injection Molding

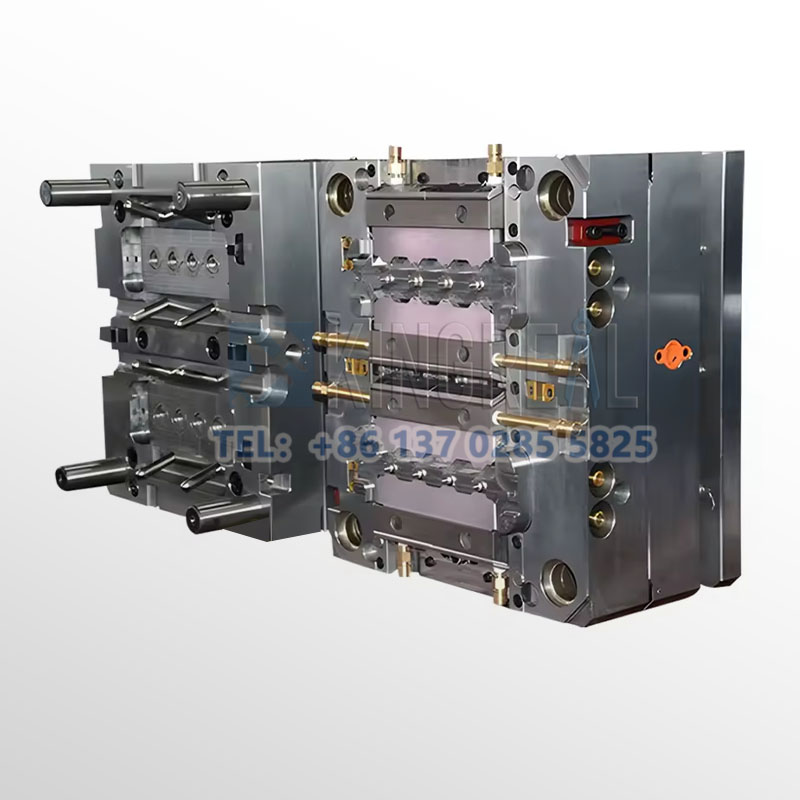

To fit two materials, the mold has to have a rotating core or several cavities. This design guarantees that the materials can be injected at the where and when they are required.

The injection molding machine injects the first substance into the mold. To guarantee the stuff entirely fills the mold, this stage calls for rigorous regulation of the injection speed and pressure.

Injection temperature, pressure, and speed among other factors have to be carefully observed and changed as necessary during the injection process to guarantee proper molding of the primary material.

Injection of the second material: After the first material is molded, the second material is injected onto the first material. At this point, the two substances will establish a close connection.

After the injection is finished, the substance needs to cool and solidify before releasing the last product.

Eject the completed product: After the mold is opened, the finished product is ejected, finishing the whole double shot injection molding process.

3/ Advantages of Two Shot Injection Molding

1. Cost savings

Double shot injection molding helps to greatly cut production costs, therefore one of its primary benefits.

Traditional injection molding processes often involve several assembly stages, but two shot injection molding can accomplish the injection of two materials in one production cycle thereby removing the extra assembly process. Manufacturers can properly shorten production time after using double shot injection molding, hence lowering labor and material expenses.

2. Stronger, more durable parts

By mixing rigid materials with flexible ones, two shot injection molding can create stronger components. Particularly for parts used in hostile surroundings, this material mix makes the product less prone to standard damage.

Parts in cars and industrial equipment, for instance, frequently need both strength and hardness, and double shot injection molding solves this requirement.

3. Design flexibility

Two shot injection molding provides designers with great design flexibility. By combining materials with different properties in the same mold, designers can create products that are both functional and aesthetically pleasing.

For example, in medical devices and consumer electronics, designers can use hard materials for support structures and soft materials for user comfort. This flexibility makes the product not only functionally optimized, but also more visually appealing.

4. Faster production speed

The production steps are lessened and the total production time is much reduced as two-shot molding finishes the injection of many materials in one production cycle. For time-sensitive production methods, double shot injection molding is a great option because of its effectiveness.

In addition, the fast production cycle can also help manufacturers better respond to changes in market demand.

4/ Design Considerations for Two Shot Injection Molding

1. Draft angle

The draft angle plays a vital role in double shot injection molding. Proper draft angles ensure that the substrate moves easily between molds and prevents jamming.

If the draft angle is not designed properly, it will increase the risk of the production process, which may lead to interruptions in production schedules and reduced product quality.

2. Rotation and mechanical design

When designing production machinery, special attention should be paid to the necessity of rotation. The second gate usually needs to be close to the location of the ejection system to ensure smooth production operations and high-quality output. At the same time, the accuracy of mechanical design is also crucial to the efficiency of production.

3. Sealing effect

Good sealing effect depends on precise fit, material shrinkage and overall design. Since more material is used in the initial shot, the strength of the product is enhanced by the tightness of the substrate. Designers need to ensure the sealing between the various parts to improve the quality of the final product.

5/ Common Myths and Facts About Two Shot Injection Molding

Myth: Overmolding and double shot injection molding are the same operation

Fact: Overmolding is done in two separate molding steps, usually requiring different machines. Two shot injection molding, on the other hand, combines the two steps into one continuous cycle with a single machine, which improves production efficiency.

6/ FAQs about Double Shot Injection Molding

1. What is two shot injection molding?

Double shot injection molding is a process that injects two different plastic materials into the same mold to form a product with multiple properties in one production cycle.

2. What is the compatibility of two shot injection molding materials?

The compounds employed must mix well in order to guarantee the effectiveness of double shot injection molding. Materials chosen should have comparable melting points and fluidity normally recommended to guarantee a flawless injection molding operation.

3. Which materials are best for two shot injection molding?

Many thermoplastics, including ABS, polycarbonate, and nylon, find great use of 2K injection molding. Combining these materials with silicone or thermoplastic elastomers (TPE) results in goods that are both aesthetically pleasing and practical.

4. What does co-molding involve?

Co-molding is a process that combines two different materials into a single part, typically combining a hard material such as ABS plastic with a soft material such as TPE to achieve specific functions and effects.