KINGREAL UNIVERSAL IND., LTD

Phone

+86-13702855825General Content

The Role of Automotive Rearview Mirrors

Key Elements of Auto Rearview Mirror Injection Mold Design

Quality Control for Auto Rearview Mirror Injection Mold

1.The Role of Automotive Rearview Mirrors

| Automotive rearview mirrors play an extremely important role in vehicles. They not only support the mirror lenses, ensuring they don't fall off during driving, but also enhance the vehicle's exterior design. Rearview mirrors are the driver's "third eye" for observing road conditions, affecting driving safety. As a core component, the rearview mirror housing not only needs good weather resistance and high-temperature resistance, but also needs to withstand the challenges of daily environments. As an externally visible part, its appearance design requirements are also very strict, often involving a comprehensive consideration of aesthetics and functionality. |  |

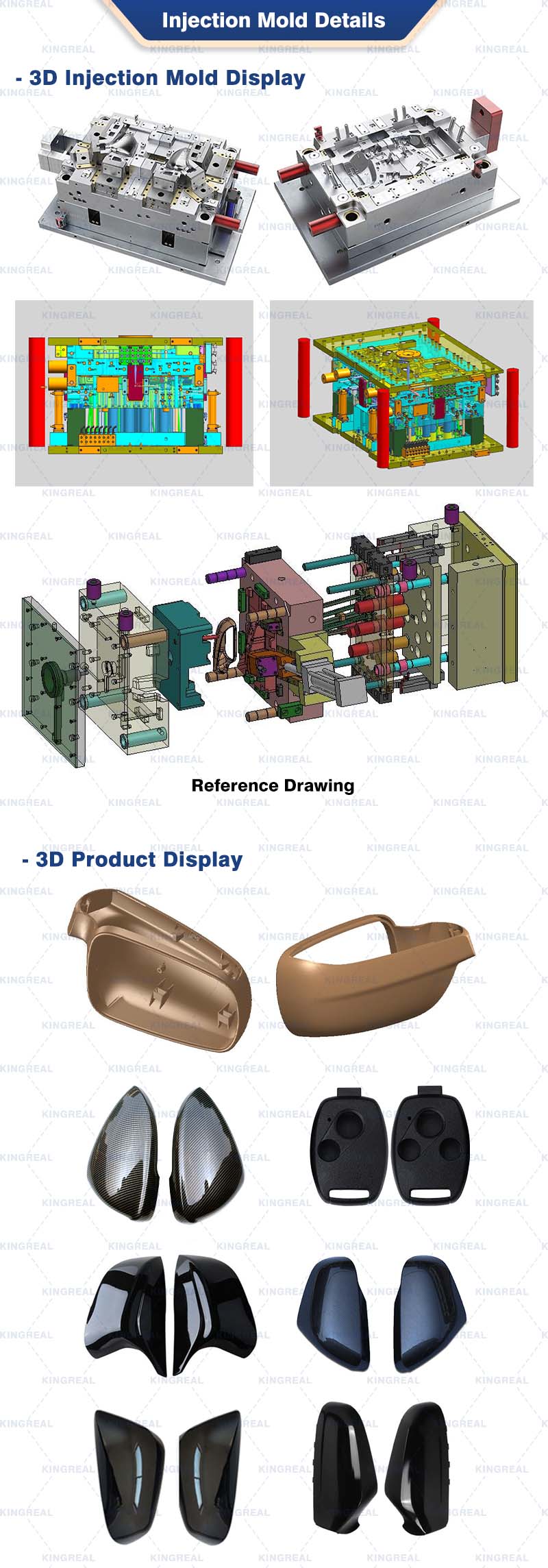

2. Key Elements of Auto Rearview Mirror Injection Mold Design

To achieve high-quality, high-precision automobile rearview mirror injection molds, multiple aspects need to be considered.

2.1 Auto rearview mirror injection mold components

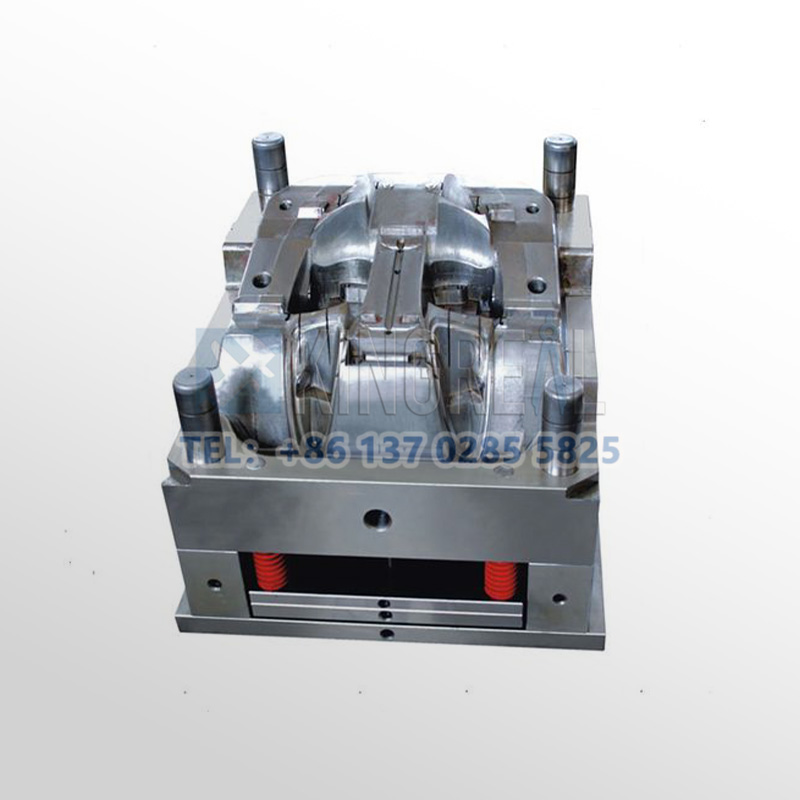

The parting surface of the automobile rearview mirror injection mold is a key factor affecting the molding quality and precision of the plastic part. Choosing a suitable parting surface during design not only ensures the molding quality of the plastic part but also simplifies the manufacturing and processing difficulty of the auto rearview mirror injection mold. Typically, placing the parting surface at the maximum cross-section of the plastic part effectively improves molding precision.

The automobile rearview mirror injection mold components mainly include the cavity and core. The auto rearview mirror injection mold adopts an embedded cavity and core structure, which has the advantages of convenient processing, high precision, and convenient subsequent maintenance. To ensure automobile rearview mirror injection mold strength and durability, P20 steel is generally selected as the material for the cavity and core. This material is not only wear-resistant but also withstands high temperatures.

2.2 Gating and cooling system design for auto rearview mirror injection mold

The gating system is another important part of automobile rearview mirror injection mold design, mainly including the main runner, branch runners, gate, and cold slug well. During design, the main runner is usually conical to facilitate material flow and slurry removal. Due to the good fluidity of ABS material, a side gate design is adopted to improve injection speed and reduce weld lines.

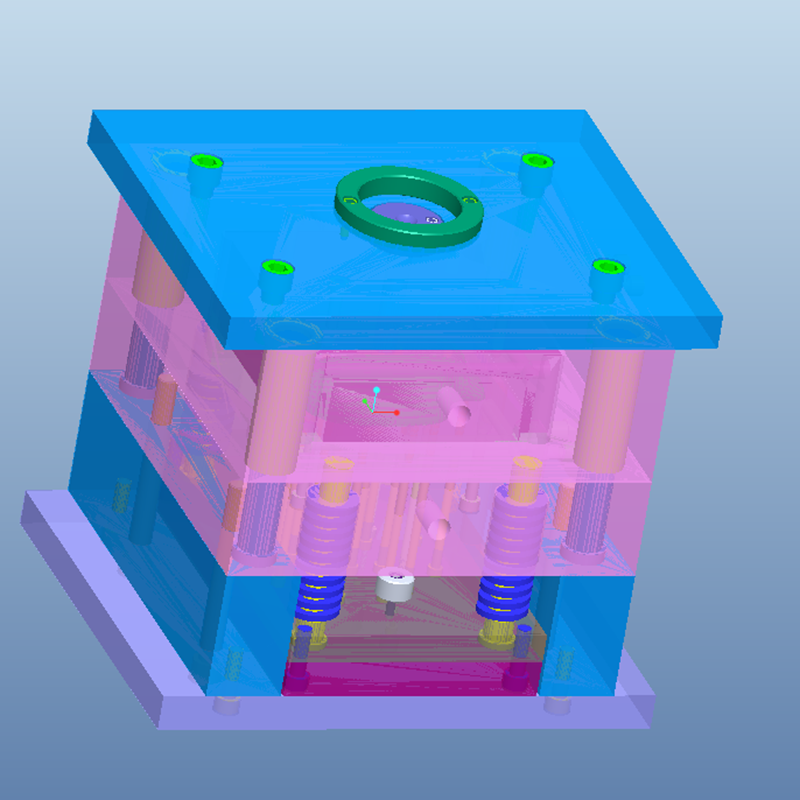

The cooling system is also crucial to the molding quality. During injection molding, the auto rearview mirror injection mold temperature directly affects the shrinkage, deformation, molding cycle, and surface quality of the plastic part. Therefore, four sets of straight-through cooling channels are designed in the fixed mold platen, while one set of circulating cooling channels is configured in the moving mold platen to ensure that the mold temperature can be reduced rapidly and evenly.

2.3 Angled ejector and demolding system design for auto rearview mirror injection mold

When designing an automobile rearview mirror injection mold, the ease of demolding must also be considered. Since the plastic part has 16 reinforcing ribs and clips in the vertical direction, simple ejection methods often cannot demold smoothly. Therefore, an angled ejector mechanism is designed. This mechanism consists of multiple angled ejectors, ejector pins, and angled ejector bases, which can effectively help the plastic part to be smoothly ejected from the auto rearview mirror injection mold.

During the demolding process, the ejector pin ejection mechanism must ensure uniform pushing force to avoid deformation or damage to the plastic part due to uneven forces during ejection. The reset structure uses a reset rod and spring for reset. The spring's rebound force ensures the structure returns to its original position after ejection, guaranteeing the automobile rearview mirror injection mold can quickly return to its ready state for the next injection molding.

2.4. Working principle of auto rearview mirror injection mold

The working process of an automobile rearview mirror injection mold can be summarized as follows: First, molten plastic enters the auto rearview mirror injection mold through the injection molding machine nozzle, passing through the main runner, branch runners, and gate, finally flowing into the cavity. Inside the cavity, the plastic material undergoes filling, pressure holding, and cooling to form the final automotive rearview mirror housing.

Subsequently, when the plastic part cools to a certain temperature, the automobile rearview mirror injection mold is opened. During auto rearview mirror injection mold opening, the injection molding machine's push rod fixing plate pushes the fixing plate, further pushing the ejector pin, while simultaneously pulling the core to push the plastic part out of the automobile rearview mirror injection mold. After the plastic part is removed, the ejection mechanism resets under the action of the reset rod and spring, and the guide sleeve, guide pillar, and push rod fixing plate return to their original positions, ready for the next injection molding.

3. Quality Control for Auto Rearview Mirror Injection Mold

In the design and manufacturing process of automobile rearview mirror injection molds, quality control is a crucial and indispensable aspect. To ensure that every part of the auto rearview mirror injection mold meets design requirements, strict control is typically exercised in the following areas:

3.1 Material selection for auto rearview mirror injection mold

The choice of materials for automobile rearview mirror injection molds is crucial. High-quality materials enhance the auto rearview mirror injection mold's durability and stability. Generally, high-quality steels such as P20 or H13 are preferred, as these materials perform excellently during high-temperature and high-pressure injection molding.

3.2 Precision machining for auto rearview mirror injection mold

Every component of the automobile rearview mirror injection mold must undergo precision machining to ensure a perfect fit and prevent gaps or looseness. Modern machining technologies such as CNC machine tools achieve high machining accuracy, making the overall mold structure more stable.

3.3 Functional testing for auto rearview mirror injection mold

After production, the mold undergoes functional testing to ensure that its various indicators meet design requirements. By simulating the injection and demolding processes, potential problems can be detected and adjustments made promptly.