KINGREAL UNIVERSAL IND., LTD

Phone

+86-13702855825PEEK injection molding is a high-performance plastic processing technology widely used in aerospace, medical equipment, automotive and other industries.

However, during the PEEK plastic injection molding process, cracking often occurs in the product, among which cracking is one of the most common defects.

This article will explore the causes of cracking in the PEEK injection molding process and propose corresponding solutions.

Definition of Cracking Phenomenon

In PEEK injection molding, cracking refers to fine cracks on the surface or inside of the product. This defect not only affects the appearance of the product, but may also seriously affect its mechanical properties and service life.

The generation of cracks is usually caused by stress deformation, mainly including residual stress, external stress and external environmental factors.

| 1 | Cracks Caused by Residual Stress |

| 2 | Cracking Caused by External Stress |

| 3 | Cracking Caused by External Environment |

1. Cracks Caused by Residual Stress

Residual stress is an important factor causing cracking in PEEK plastic injection molding. Its generation is mainly related to the following situations:

1.1 Overfilling

In the PEEK injection molding process, overfilling will cause the material to generate excessive internal stress in the mold, resulting in cracking. To solve this problem, the following aspects can be considered:

Gate design: Using multi-point distribution point gates, side gates or handle-shaped gates can effectively reduce the pressure loss caused by the straight gate, thereby reducing stress concentration.

Increasing resin temperature: Under the premise of ensuring that the resin does not decompose, appropriately increasing the resin temperature can reduce the melt viscosity, enhance fluidity, thereby reducing the injection pressure and reducing the generation of residual stress.

Mold temperature control: Increasing the temperature of the injection mold can effectively reduce stress, especially when the injection speed is high, this temperature increase can effectively reduce the generation of stress.

1.2 Demolding and pushing out

Stress during the demolding process is also an important cause of cracking. When the demolding slope is too small and the mold type glue and the punch surface are rough, the pushing force will be too large, resulting in stress concentration. Observing the location of the crack can help determine the root cause of the problem.

1.3 Metal inlays

During the PEEK plastic injection molding process, if metal parts are embedded at the same time, cracks are likely to occur.

This is because the thermal expansion coefficients of metal and resin are quite different, resulting in stress concentration.

Over time, excessive stress will exceed the strength of the resin material and form cracks. To prevent this problem, the following measures can be considered:

Avoid using too thick walls: For products with thicker walls, minimize the use of metal inserts.

Preheating metal inserts: Preheating metal inserts before PEEK injection molding can effectively reduce stress concentration and reduce the occurrence of cracks.

2. Cracking Caused by External Stress

External stress is mainly caused by stress concentration caused by unreasonable design, especially at sharp corners. Sharp angles should be avoided as much as possible during design to reduce stress concentration.

Optimize design: Through reasonable design, increase transition curves and reduce sharp corners to disperse stress and reduce the risk of cracking.

3. Cracking Caused by External Environment

External environmental factors may also cause cracking of PEEK injection molded products. For example, chemical erosion, water degradation caused by moisture absorption, and excessive use of recycled materials will lead to deterioration of physical properties, resulting in cracking.

Control environmental conditions: During the PEEK injection molding process, the environmental humidity should be controlled as much as possible to avoid contact with chemicals to reduce the possibility of cracking.

In the process of PEEK plastic injection molding, the occurrence of cracking is a complex problem, involving multiple aspects such as residual stress, external stress and external environment.

By optimizing gate design, increasing resin temperature, reasonably controlling mold temperature, optimizing design and other measures, the occurrence of cracking can be effectively reduced.

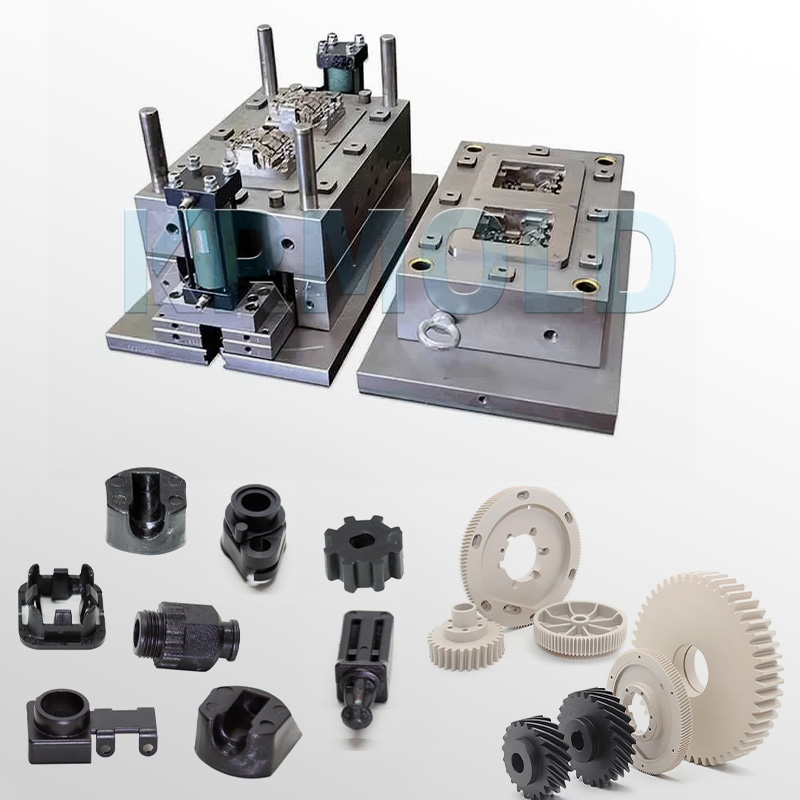

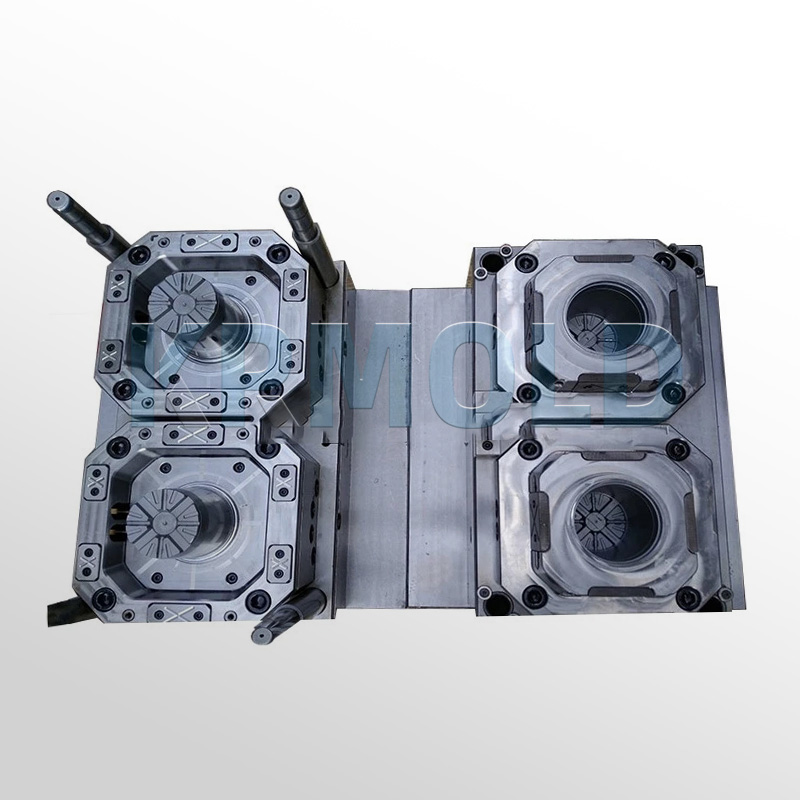

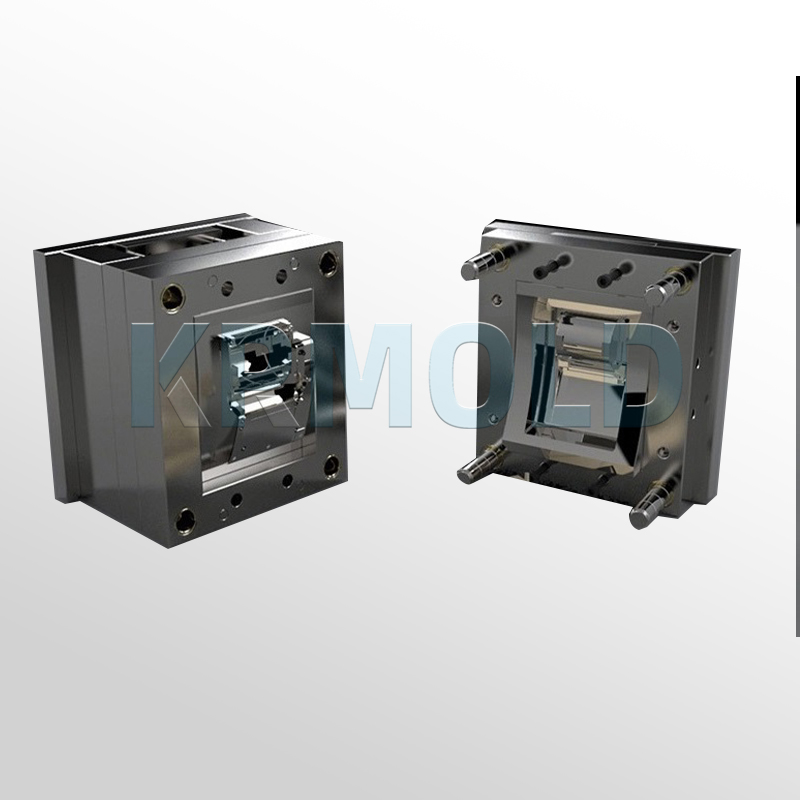

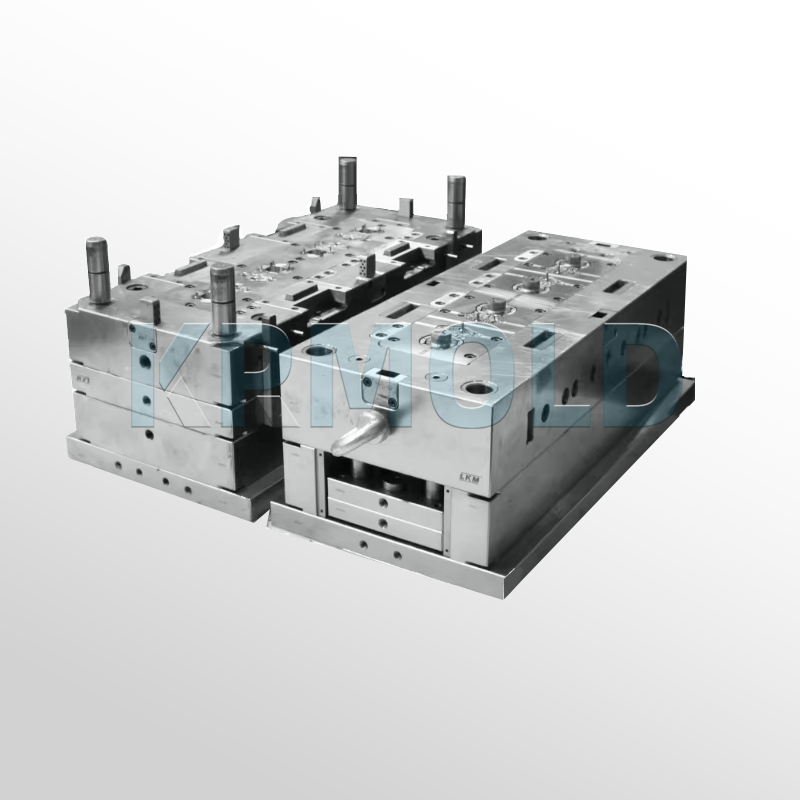

In addition, as a professional mold development, design and manufacturing company, KEMOLD has advanced equipment and a professional team, which can provide customers with high-quality PEEK plastic injection molding services and help customers solve various problems such as cracking.

Through the above analysis, we can see that the success of PEEK injection molding depends not only on the performance of the material itself, but also on the design and control of the entire PEEK plastic injection molding process.

Only by comprehensively considering various influencing factors can the quality of PEEK injection molded products be ensured and its application value in various fields be improved.