KINGREAL UNIVERSAL IND., LTD

Phone

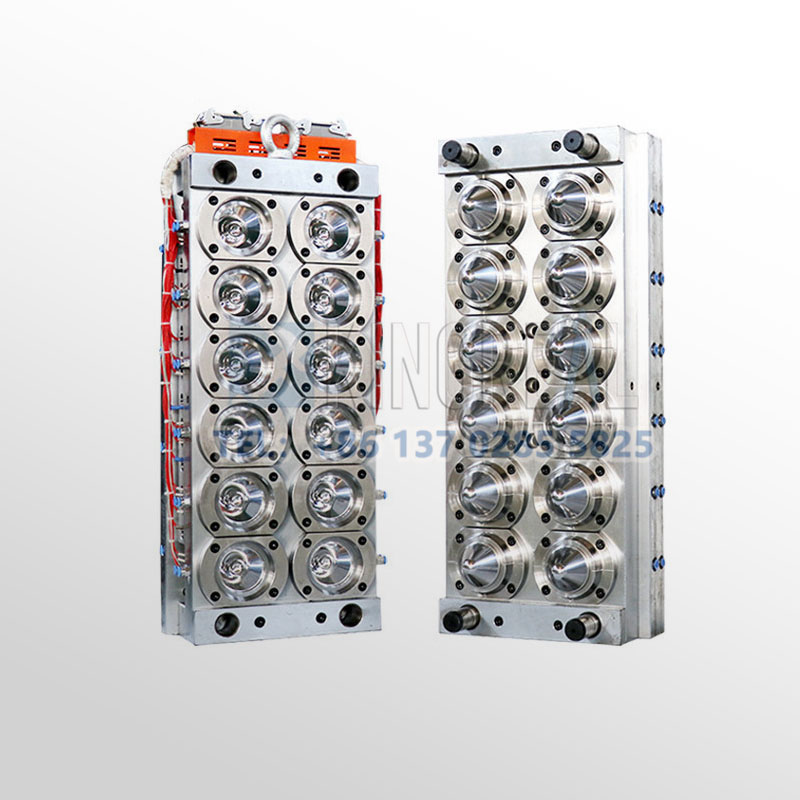

+86-13702855825In modern manufacturing, the use of multi cavity injection molds is becoming more and more common. It not only improves production efficiency, but also reduces the cost of a single product. However, multi cavity injection molds may have various defects during the multi cavity injection molding process. Many problems are caused during the mold plasticization and multi cavity injection molding stages, and are sometimes closely related to the irrationality of the design. Therefore, it is crucial to conduct a trial mold for a multi cavity injection molds to ensure the quality of the final product and the smooth progress of production. If you want to know more about multi cavity injection molding, welcome to consult KRMOLD! |  |

| 1 | Factors Affecting Defects in Multi Cavity Injection Molded Products |

| 2 | Importance of Trial Multi Cavity Injection Molds |

| 3 | Processing Defects and Solutions of Multi Cavity Injection Molds |

| 4 | Common Problems and Solutions During Mold Trial |

1/ Factors Affecting Defects in Multi Cavity Injection Molded Products

The success of multi cavity injection molds depends on multiple factors, including the type of injection port, the number, position and size of the mold cavities, the design of the cold/hot runner system, and the structure of the product itself. These factors are interrelated, and any slight difference may affect the final multi cavity injection molding effect. For example, the design of the number of cavities is directly related to production efficiency and cost. If the design is improper, it may lead to unstable product quality. Therefore, when making multi cavity injection molds, these factors must be fully analyzed to avoid product defects caused by mold design.

2/ Importance of Trial Multi Cavity Injection Molds

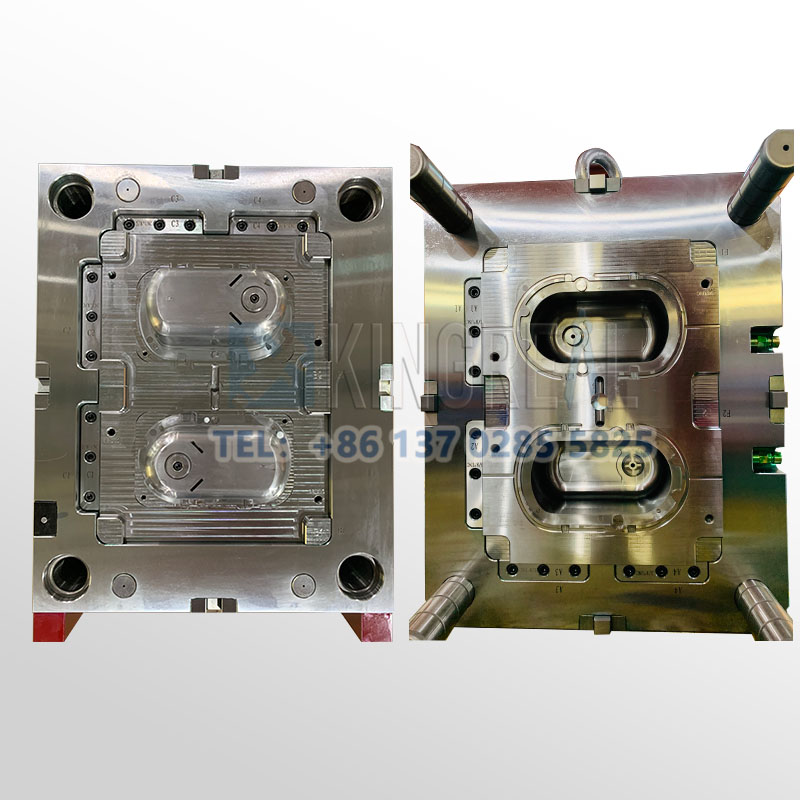

After obtaining the trial mold results of themulti cavity injection molds, the operator needs to conduct an in-depth evaluation of the specific situation of the mold. This is not only to ensure the rationality of the mold design and process parameters, but also to avoid unnecessary costs and time during the modification process. The complexity of multi cavity injection molds makes every parameter setting crucial, and the parameter setting range required to produce qualified products is very small. Once any deviation occurs in the parameter setting, the quality of the product may be far beyond the allowable error range.

The fundamental purpose of mold trial is to find out the optimized process parameters and mold design, not just to obtain a qualified sample. Even if the material, machine settings or environmental factors have changed, the data and experience obtained after the mold trial can still provide guarantee for subsequent stable and uninterrupted mass production. This is particularly important because in actual production, any small change may bring unexpected consequences. |  |

3/ Processing Defects and Solutions of Multi Cavity Injection Molds

During the processing of multi cavity injection molds, defects sometimes occur. In order to reduce these defects, the following small methods can be used:

1) Reasonable use of cooling lubricant

The use of cooling lubricant is crucial, and it can play the three major roles of cooling, washing and lubrication. During the processing of multi cavity injection molds, keeping the cooling, lubrication and clean can effectively control the grinding heat within the allowable range and prevent thermal deformation of the workpiece. Improving the cooling conditions during grinding, such as using oil-immersed grinding wheels or internal cooling grinding wheels, can effectively improve the processing quality. Introducing the cutting fluid into the center of the grinding wheel, the cutting fluid can directly enter the grinding area, play an effective cooling role, and prevent the surface of the workpiece from burning.

2) Reasonable selection of grinding amount

During the grinding process, reasonable selection of grinding amount is an important means to reduce defects. Using fine grinding methods with a small radial feed, or even fine grinding, can effectively reduce the heat generated during cutting. Appropriately reducing the radial feed and grinding wheel speed and increasing the axial feed can reduce the contact area between the grinding wheel and the workpiece, thereby improving the heat dissipation conditions and effectively controlling the increase in surface temperature.

3) Reasonable selection and dressing of grinding wheels

The selection and dressing of grinding wheels have a direct impact on the processing quality of multi cavity injection molds. It is better to use a grinding wheel made of white corundum because it is hard and brittle, easy to produce new cutting edges, with low cutting force and low grinding heat. In terms of particle size selection, it is more appropriate to use a medium particle size such as 46-60 mesh. At the same time, in terms of grinding wheel hardness, the use of medium-soft and soft grinding wheels (such as ZR1, ZR2 and R1, R2) can effectively reduce cutting heat and improve processing efficiency.

4/ Common Problems and Solutions During Mold Trial

1) Product appearance defects

During mold trial, the appearance of the product may have defects such as unevenness, bubbles, and cracks. This is usually related to the design of the mold's cooling system, injection speed and pressure. To avoid these problems, the operator needs to carefully evaluate the mold's cooling system to ensure that it can evenly cool each cavity. At the same time, adjust the injection speed and pressure parameters to achieve the best injection effect.

2) Poor injection

Poor injection means that the plastic material cannot smoothly fill the mold cavity. This may be caused by unreasonable injection port design, insufficient mold exhaust or poor material fluidity. Operators can solve this problem by optimizing the design of the injection port, increasing the number of vents, or choosing a more fluid material.

3) Dimensional deviation

Dimensional deviation is a common problem in multi cavity injection molding. Usually, this is related to the manufacturing accuracy of the mold, temperature control, and material shrinkage. Operators should strictly control the manufacturing accuracy of the mold during the mold trial stage, and monitor the temperature of the mold to ensure that it remains within a reasonable range during the multi cavity injection molding process. In addition, choosing the right material and estimating its shrinkage also have an important impact on the dimensional stability of the final product.

If you want to know more information about multi cavity injection molding, welcome to consult KRMOLD!