KINGREAL UNIVERSAL IND., LTD

Phone

+86-13702855825

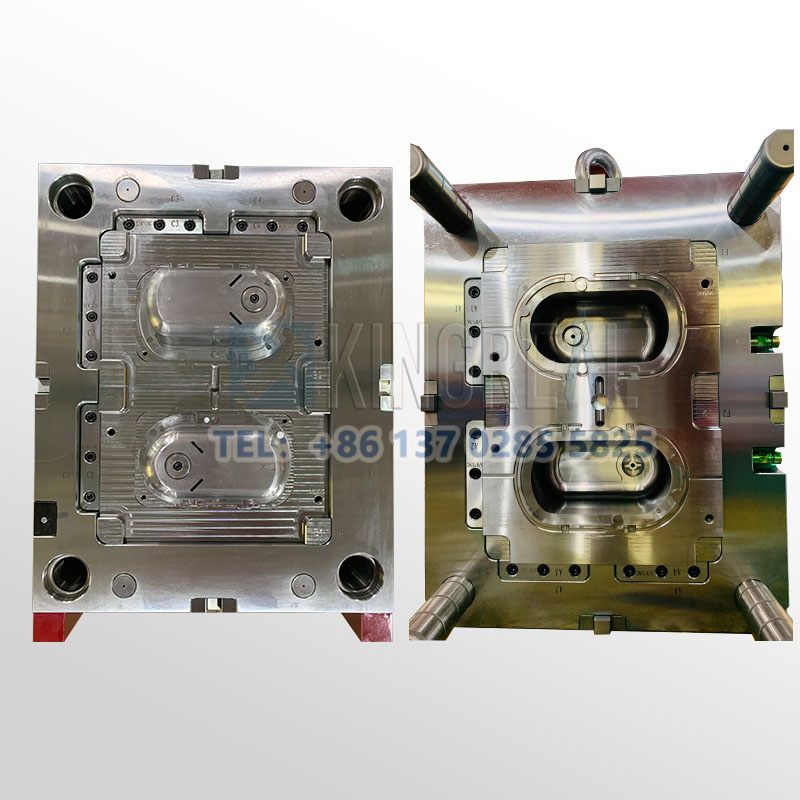

In modern manufacturing, multi cavity injection molding has gradually become a mainstream technology, which is favored for its significant improvement in production efficiency and cost reduction. The key to this technology is multi cavity injection molds, which allow multiple parts to be produced simultaneously in one injection cycle. This optimized production method makes multi cavity injection molds ideal for high-volume production, especially when consistency, speed and cost-effectiveness are required. In this article, KRMOLD will explore in detail the main advantages of multi cavity injection molding and why choosing a multi cavity injection mold is a wise decision.

| 1 | Improve Production Efficiency |

| 2 | Lowering the Cost Per Part |

| 3 | Consistency and Uniformity |

| 4 | Optimal Use of Machine Capacity |

| 5 | Reduced Material Waste |

| 6 | Scalability for High-Volume Production |

| 7 | Energy Efficiency |

| 8 | Design Flexibility |

1. Improve Production Efficiency

One of the biggest advantages of multi cavity injection molds is the ability to produce multiple parts simultaneously in one injection molding cycle. This design greatly reduces the overall production time, allowing manufacturers to achieve higher output rates in the same machine running time. This efficiency is particularly important for large-scale production, because the time saved can directly translate into cost savings.

By utilizing multi cavity injection molds, companies can significantly increase production capacity in daily operations. For example, a traditional single-cavity injection mold may only produce one part per cycle, while a multi cavity injection mold can produce multiple parts at the same time. This not only increases production, but also helps companies meet market demands faster.

2. Lowering the Cost Per Part

With multi cavity injection molding, the production of multiple parts allows the cost of materials, labor and machine operation to be spread over more products. This cost sharing directly reduces the cost per part, making multi cavity injection molds a cost-effective solution for high-volume production.

Although the initial investment in multi cavity injection molds is relatively high, the long-term production cost savings often make this investment very attractive. As production scales up, companies are able to improve overall profit margins by reducing the cost per part, which is an important competitive advantage for manufacturers.

3.Consistency and Uniformity

Multi cavity injection molds ensure that all parts produced in each injection cycle are exactly the same, which is critical for industries that pursue high quality standards. This consistency is especially important in areas such as automotive, medical and consumer electronics, where precision and repeatability are extremely important.

Using multi cavity injection molds can effectively eliminate quality fluctuations caused by mold differences during the production process, ensuring that each product meets strict specifications. This high level of consistency not only improves customer satisfaction, but also reduces additional costs caused by rework or scrap.

4.Optimal Use of Machine Capacity

Multi cavity injection molds are designed to fully utilize the capacity of the multi cavity injection molding machine. By producing multiple parts in one cycle, companies can reduce idle time and ensure that machines are running at peak efficiency. This efficient operation not only increases productivity but also reduces unit costs.

In modern manufacturing environments, equipment utilization is critical. Multi cavity injection molds can help companies achieve higher machine utilization, thereby maximizing return on investment.

5.Reduced Material Waste

Multi cavity injection molds are designed to minimize material waste by ensuring that the maximum number of usable parts are produced in each cycle. This is especially important when using expensive or exotic materials, where reduced waste can significantly save production costs.

In today's increasingly environmentally conscious world, reducing material waste is not only an economic imperative, but also a social responsibility. Companies that adopt multi cavity injection molding can reduce costs while demonstrating their commitment to sustainable development.

6.Scalability for High-Volume Production

Multi cavity injection molding are ideal for scaling production to meet high demand. Manufacturers can flexibly adjust production capacity without the need for additional machines or major changes to production processes. This scalability makes multi cavity injection molds a versatile solution for manufacturers looking to expand their business.

For companies facing rapidly changing markets, the ability to quickly adjust production scale is key to staying competitive. Multi cavity injection molding provides this flexibility, allowing manufacturers to respond quickly to market demands.

7.Energy Efficiency

The production of multiple parts in a single cycle can effectively reduce the energy consumption of each part, thus promoting more sustainable production practices. This energy efficiency meets the growing demand for environmentally friendly production methods, helping companies improve their image and comply with relevant regulations.

As the global focus on sustainable development increases, companies that adopt multi cavity injection molding can save costs while demonstrating their responsibility to environmental protection.

8.Design Flexibility

Multi cavity injection molds can be designed to produce different parts in the same mold, providing flexibility for manufacturers with different product lines. This versatility makes it more adaptable when meeting different production needs.

In a rapidly changing market, the ability to flexibly adjust production lines to meet the needs of new products is key to the success of companies. The flexibility of multi cavity injection molding allows manufacturers to gain an advantage over the competition.

In summary, multi cavity injection molding has a series of significant advantages, including increased production efficiency, lower unit cost and improved product consistency. This technology is particularly suitable for large-scale production, and can significantly save costs and improve operations by optimizing production cycles and reducing material waste. For equipment and consumables buyers, investing in multi cavity injection molds can not only increase productivity, but also reduce overall production costs, thereby gaining a competitive advantage.

In today's rapidly evolving manufacturing environment, choosing multi cavity injection molding is undoubtedly a wise decision. By utilizing these advanced technologies, manufacturers can stay invincible in the market, continue to meet customer needs and achieve long-term growth.