KINGREAL UNIVERSAL IND., LTD

Phone

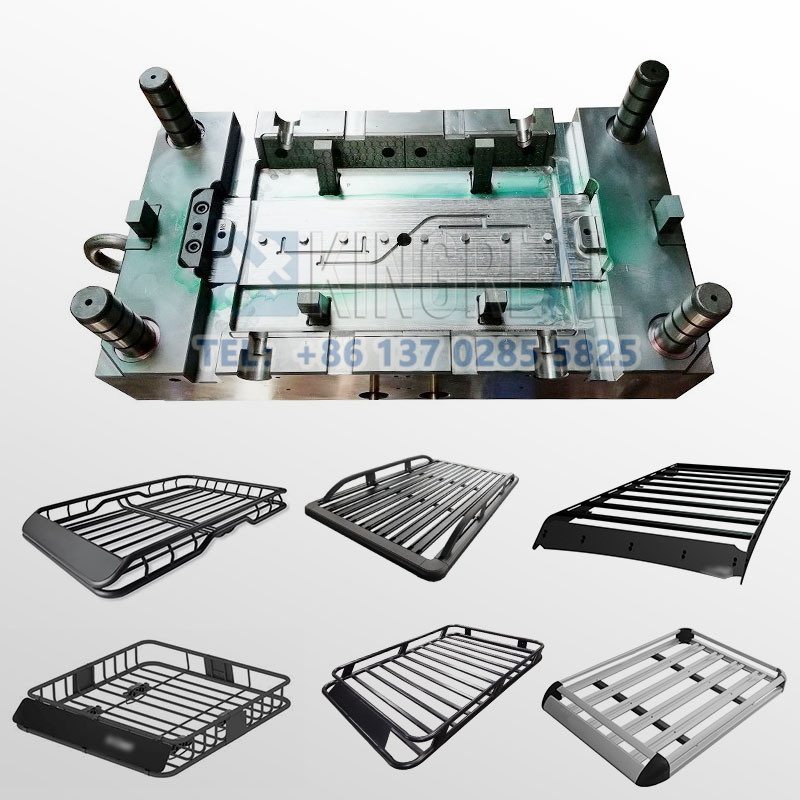

+86-13702855825In the complex system of modern manufacturing industry, car roof rack injection tooling occupies an irreplaceable key position, and its importance is reflected in many aspects, which profoundly affects the whole process of product manufacturing and the development of enterprises.

| 1 | Reasons why automotive exterior trim molds are important |

| 2 | Automotive roof rack mold design: the key link of plastic product manufacturing |

| 3 | Automotive roof rack mold technology: the core driving force of modern manufacturing industry |

1. Reasons why automotive exterior trim molds are important

Meet specific needs in all directions

Automotive exterior trim molds can be called a solid guarantee for accurate manufacturing of products. Whether facing simple daily necessities or complex industrial parts, it can strictly meet the design specifications and size requirements of products. According to the complexity of the product, material characteristics and accuracy standards, the car roof rack injection tooling can be customized. Taking children's toy mold design as an example, it is necessary to focus on material safety and interesting shape; However, the die design of automobile parts should pay close attention to material strength and dimensional accuracy. This customization ability has effectively promoted efficient and high-quality product production, ensuring that products accurately meet the diversified needs of customers or markets.

Improve production efficiency

In the design and manufacture of car roof rack injection tooling, the optimization of production process runs through. From the ingenious conception of mold structure to the reasonable layout of production technology, we are committed to reducing waste in production and shortening downtime. High-precision automotive exterior trim molds design and excellent durability not only accelerate the production speed, but also significantly reduce the defective rate. For example, some enterprises producing plastic cups, after adopting advanced car roof rack injection toolings, have greatly improved their production speed, significantly reduced the rate of defective products, enabled enterprises to produce more high-quality products in a unit time, and achieved significant growth in production efficiency.

Reduce production costs

Automotive roof rack mold has achieved remarkable results in reducing production costs. Through ingenious design, the utilization rate of materials is improved, the waste of raw materials is reduced and the cost is cut from the source. Moreover, with efficient production efficiency and stable and reliable product quality, the phenomenon of defective products and rework is greatly reduced. In the long run, this saves a lot of expenses for enterprises and enhances their price competitiveness in the market. For example, in a plastic product factory, after using the new car roof rack injection tooling, the waste of materials is reduced, the rate of defective products is reduced, the production cost is reduced, and the product price is more advantageous in the market.

Enhance the competitiveness of products

With the help of automotive exterior trim molds, enterprises can create products with unique appearance, excellent functions and reliable performance. Taking the mobile phone case as an example, various beautiful shapes can be created by car roof rack injection tooling, which can improve the hand feel and better protect the mobile phone. High-quality, high-precision products help to enhance the brand image of enterprises, win the trust of customers, and then open up more business opportunities for enterprises and promote their sustainable development and growth.

Adapt to market changes

Automotive roof rack mold has keen market adaptability. Be able to adjust and optimize quickly according to the dynamic changes of market demand to meet the needs of new product development. Enterprises can quickly switch to produce car roof rack injection toolings with different specifications and models according to the diversified needs of different customers. For example, clothing enterprises introduce new styles every quarter, and the automotive exterior trim molds can be adjusted in time to produce automotive roof rack molds that adapt to new styles of clothing accessories, helping enterprises keep up with the market trend.

Promote technological innovation

In the process of car roof rack injection tooling manufacturing, enterprises actively introduce advanced manufacturing technology and new materials. For example, the use of new materials can improve the durability of the car roof rack injection tooling, and the use of advanced manufacturing technology can optimize the performance of the automotive exterior trim molds. At the same time, enterprises and car roof rack injection tooling manufacturers work closely together to carry out joint innovation in Industry-University-Research. Some enterprises have joined hands with universities and scientific research institutions to jointly develop new automotive roof rack mold technologies and solutions, so as to push the automotive exterior trim molds industry towards high-end and intelligent direction.

Guarantee the stability of production

Once the car roof rack injection tooling is successfully put into use, its high precision and high repeatability ensure that the products that meet the standards can be produced stably in each production cycle. This greatly reduces the interference of human factors on product quality control, makes the production process more stable and reliable, and the product quality is always maintained at a high level. Taking the factory that produces electronic components as an example, the automotive exterior trim molds ensures that the size and performance of each electronic component are consistent, which provides a solid guarantee for the continuous and stable production of enterprises.

Practice environmental responsibility

With the increasing awareness of environmental protection, the concept of environmental protection is fully integrated into the design and manufacture of car roof rack injection toolings. By optimizing the use of materials, reducing waste and reducing the negative impact on the environment. Mold manufacturers actively adopt environmentally friendly materials and green manufacturing processes, such as using degradable materials and reducing energy consumption in the manufacturing process. This not only meets the requirements of environmental laws and regulations, but also reflects the positive actions of the car roof rack injection tooling industry in sustainable development and contributes to environmental protection.

Protect the intellectual property rights of enterprises

The design, structure and manufacturing technology of car roof rack injection tooling constitute the core intellectual property rights of enterprises and have high commercial value. These intellectual property rights effectively protect the technical and commercial secrets of enterprises and prevent competitors from imitating and copying. For example, the unique automotive exterior trim molds manufacturing technology developed by an enterprise has become a technical barrier in the market competition, maintaining the unique market position of the enterprise and providing a solid legal guarantee for its long-term development.

2. Automotive roof rack mold design: the key link of plastic product manufacturing

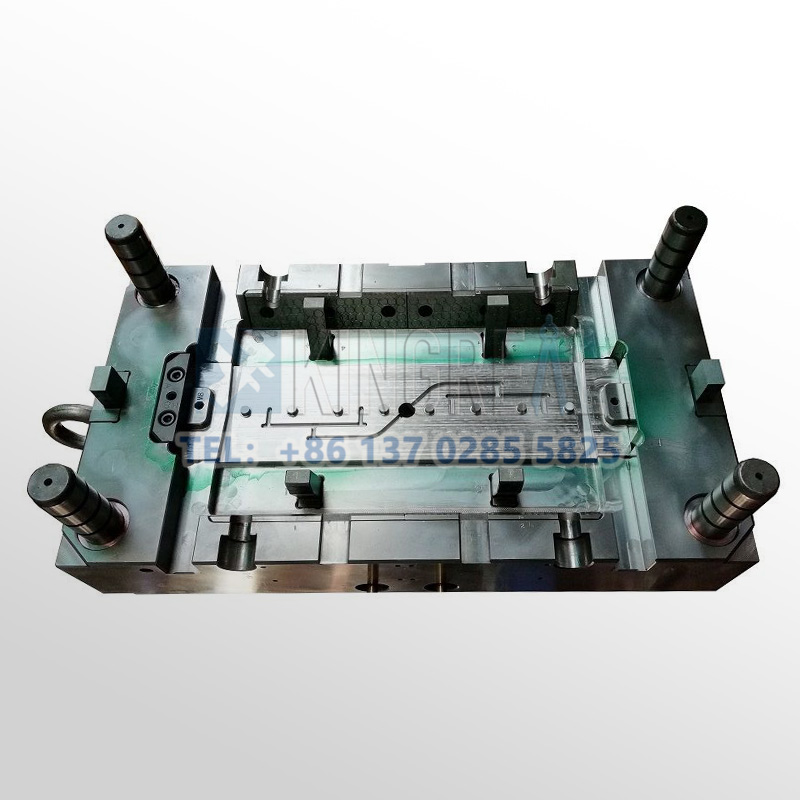

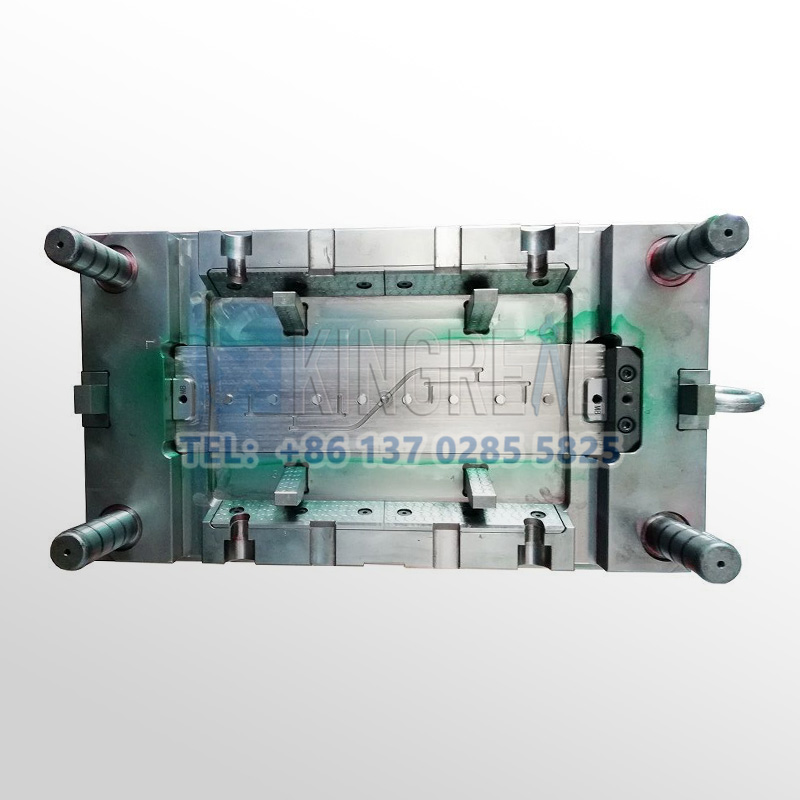

Car roof rack injection tooling design plays an extremely important role in the manufacture of plastic products. It can accurately determine the shape and size of products, just like drawing an accurate blueprint for products. Reasonable automotive exterior trim molds design can ensure the uniform filling of products in the injection process, reduce defects and deformation, and effectively improve product quality. Excellent automotive roof rack mold design can also shorten injection cycle, reduce production pause and improve overall production efficiency. In the plastic processing industry, an excellent automotive exterior trim molds design can not only improve the appearance and quality of products, but also save materials and reduce costs. With the intensification of market competition and the growth of consumers' demand for personalized and customized products, the design of car roof rack injection tooling needs constant innovation and greater flexibility. This is a highly professional and demanding job, which requires comprehensive consideration of many factors, such as material selection, structural strength, thermal conductivity, injection pressure and so on. Designers need to rely on deep professional knowledge and rich practical experience to create an automotive exterior trim molds that meets product requirements and has efficient production performance.

3. Automotive roof rack mold technology: the core driving force of modern manufacturing industry

Automotive exterior trim molds technology plays a core role in modern manufacturing industry. In terms of production efficiency, a large number of products with the same specifications can be produced quickly and accurately through accurately designed car roof rack injection toolings, which saves time and cost and helps enterprises seize the opportunities in market competition. In terms of product quality assurance, high-quality automotive exterior trim molds ensure that the size, shape and performance of each product meet the design requirements, and maintains the consistency and reliability of products, which is of great significance to corporate image, customer satisfaction and brand reputation. With the progress of science and technology, automotive roof rack molding technology continues to innovate, and new materials and design concepts are constantly emerging, which promotes product performance improvement and appearance optimization, and promotes the upgrading and development of the whole industry.