KINGREAL UNIVERSAL IND., LTD

Phone

+86-13702855825As the terminal interface for electrical power transmission, sockets not only affect electrical safety but also directly impact user experience. Plastic plug socket injection mold, an efficient production method, can significantly improve the production efficiency and quality of sockets. This article will delve into the "plastics used in switch socket plastic injection molds," analyzing the importance of plastic plug socket injection molds and the necessity of the materials used.

Introduction to Switch Socket Plastic Injection Molds

-------------------------------------------------------------

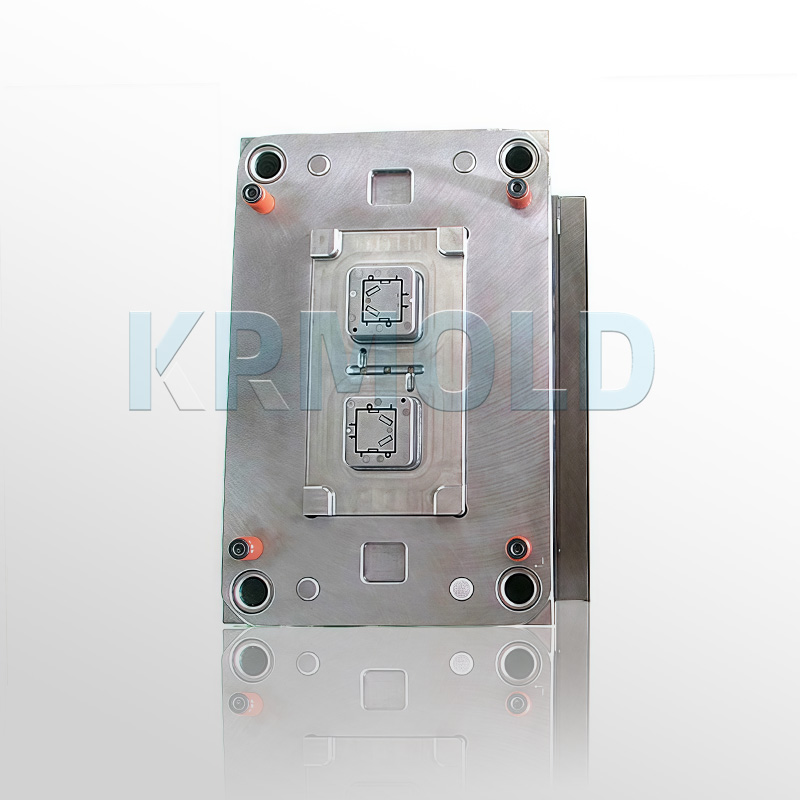

Plastic plug socket injection molds are crucial equipment for the mass production of plastic sockets. By injecting molten plastic into the switch socket plastic injection mold, which then cools and solidifies, the socket shell is formed. Plastic plug socket injection mold offers advantages such as high efficiency, low cost, and adaptability to complex shapes.

According to statistics, over 300 million plastic plug sockets are consumed globally each year, with nearly 80% produced using switch socket plastic injection molds. These plastic plug socket injection molds are painstakingly created to guarantee a perfect fit between the plug and socket by limiting socket hole spacing tolerances within ±0.02mm. Moreover, the switch socket plastic injection molds have a lifespan of 800,000 to 1,000,000 cycles; the molding cycle is usually shortened to under 20 seconds.

In terms of safety, plastic plug socket injection molds must meet the shockproof standards of each region to ensure user electrical safety. Meanwhile, the surface treatment standards of the switch socket plastic injection mold are also crucial. Between 0.8 and 1.6 μm, the Ra value of the matte texture should be regulated to enhance aesthetics and tactile feel. In essence, the plastic plug socket should strike design and manufacturing efficiency, safety, and utility as a critical electrical interface in modern homes and industrial equipment during switch socket plastic injection mold.

Plastic Plug Socket Injection Mold Materials and Surface Treatment Technology

-------------------------------------------------------------------------------------------

The choice of switch socket plastic injection mold material directly affects its service life and the quality of the final product. Commonly used mold materials and their treatment methods include:

| Component | Preferred Material | Heat Treatment | Surface Treatment |

| Cavity/Core | S136 Mirror Steel | Vacuum Quenching HRC48-52 | Nano PVD Coating |

| Slide Rail | 8407 Hot Work Steel | Nitriding (0.1mm layer) | TD Treatment |

| Ejector Pin | SKD61 | Cryogenic Treatment | DLC Coating |

This meticulous material selection and treatment technology ensures that the plastic plug socket injection mold is not only wear-resistant but also guarantees a smooth and uniform plastic plug socket, meeting the product's appearance requirements.

Importance of Plastic Selection for Switch Socket Plastic Injection Molds

-----------------------------------------------------------------------------------

The plastic material used in plastic plug socket injection molds is a core factor determining the quality of the socket shell. Here are some commonly used plastic materials and their characteristics:

1

Polycarbonate (PC)

This material has high transparency and excellent impact resistance and heat resistance. It is often used in high-end socket products to ensure that it is not easily broken under high temperatures and severe impacts. Apart from great electrical insulation qualities and mechanical strength, this material resists certain temperature variations, hence appropriate for extended use. For instance, household outlets' design calls for prioritizing personal safety and electrical performance; hence using polycarbonate material will really improve the general quality of the outlet. Furthermore meeting the aesthetic and use needs of several consumer segments is the range of PC material in terms of color, texture, and other surface treatments.

2

Nylon (PA)

Nylon is a material with high strength and abrasion resistance, making it particularly suitable for manufacturing durable sockets. It can maintain good mechanical properties during long-term use.

3

Polypropylene (PP)

PP material has excellent chemical resistance and electrical insulation properties, and is widely used in economical sockets. Its lightweight and low cost make the production process more economical.

Factors to Consider When Choosing Plastics

---------------------------------------------------

Several key factors need to be considered when selecting plastics for switch socket plastic injection mold:

1. Functional Requirements

Different kinds of sockets have varying material and production process functional requirements. For instance, plastics with great heat resistance are usually chosen by those for sockets needing high temperature resistance and flame retardancy. These sockets usually demand accurate manufacturing using plastic plug socket injection molds to guarantee elaborate forms and structures.

2. Cost Considerations

The cost of materials and manufacturing processes directly affect the pricing of the final product. When selecting plastic materials, it is necessary to comprehensively consider the price of different materials, processing costs, and market demand. For example, for some high-end products, although the materials chosen may be more expensive, their superior performance and market acceptance make the investment worthwhile.

3. Environmental Requirements

The application environment of the socket significantly influences material selection. In harsh industrial environments, corrosion-resistant and wear-resistant materials should be prioritized, and appropriate manufacturing processes should be adopted to enhance the durability of the socket. In this case, materials that can withstand moisture and high temperatures are particularly important.

Careful material selection, reasonable design, and excellent manufacturing processes are key to ensuring the quality of sockets. For more information about switch socket plastic injection molds, or if you have any questions about material selection, please feel free to contact KRMOLD. KRMOLD is dedicated to providing you with professional advice and services.