KINGREAL UNIVERSAL IND., LTD

Phone

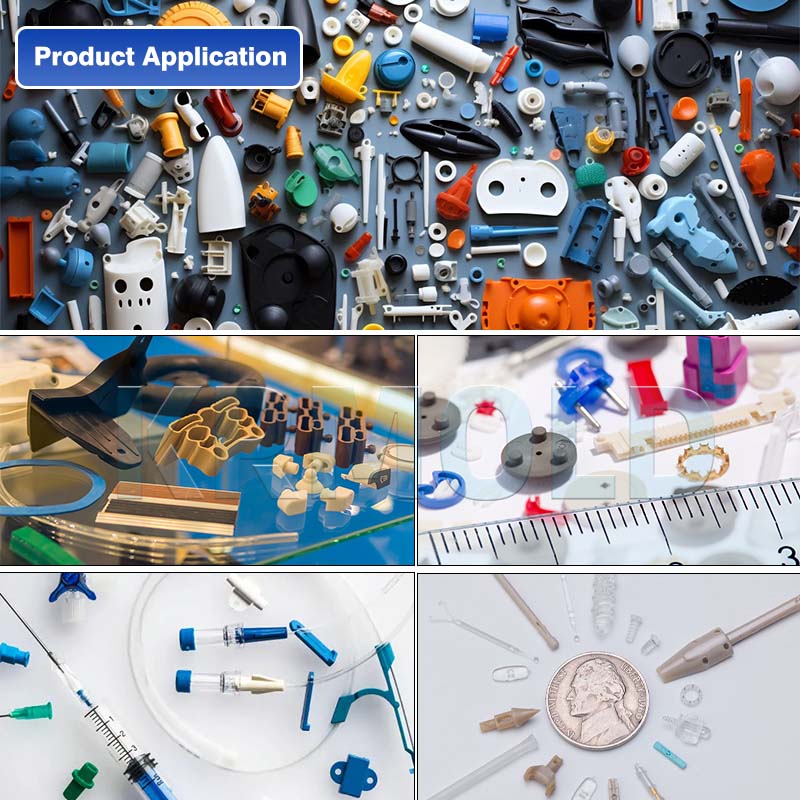

+86-13702855825In modern manufacturing, micro injection molding technology has attracted widespread attention due to its high precision and high efficiency. However, when choosing micro injection molds, many companies tend to focus only on product design and ignore the importance of mold manufacturing. In this article, KRMOLD will explore in depth the key factors that should be considered when choosing micro injection molds to help companies make wise decisions in a complex market environment. If you want to know more about micro injection molding,welcome to consult KRMOLD! |  |

| 1 | Ensure Coordination of Micro Injection Molds Design and Manufacturing |

| 2 | Comprehensive Consideration of Price, Quality and Service |

| 3 | Avoid Multi-head Collaboration and Promote One-stop Service |

| 4 | Continue to Pay Attention to Industry Trends and Technological Progress |

1. Ensure Coordination of Micro Injection Molds Design and Manufacturing

1.1 The importance of early communication In the early stages of product development, many companies tend to focus only on product design and research and development, and ignore communication with micro injection molds manufacturers. This practice may result in the final design not meeting actual production requirements, and even require substantial modifications in the later stage. By contacting micro injection molds manufacturers as soon as possible after the product design plan is initially determined, the following benefits can be achieved: Reasonableness of the forming process: Early communication can ensure that the designed product meets the requirements of the forming process and avoid design modifications caused by difficult parts processing. Advance design preparation: The micro injection molds manufacturer can make adequate preparations in the design stage to reduce mistakes caused by haste, which is crucial to shortening the production cycle. Reduce costs: High-quality micro injection molds require close cooperation between supply and demand parties. Only in this way can production costs be reduced and production efficiency be improved.

1.2 Coordination of design and manufacturing Micro injection molding has extremely high requirements for mold design and manufacturing accuracy. The design of the micro injection molds should not only consider the appearance and function of the product, but also many factors such as material properties and micro injection molding process. Close cooperation with micro injection molds manufacturers can ensure the rationality and manufacturability of the design and avoid many problems in the later stage. |  |

2. Comprehensive Consideration of Price, Quality and Service

2.1 Comprehensive evaluation of micro injection molds

When choosing micro injection molds, price is not the only consideration. Enterprises should conduct comprehensive evaluations from multiple aspects such as quality, cycle, and service:

Mold type: Select the appropriate mold type according to the material, physical and chemical properties, mechanical strength, dimensional accuracy and other requirements of the parts.

Processing accuracy: High-precision micro injection molds need to be processed using precision CNC machine tools, and mold materials and forming processes must also be strictly controlled.

Special processes: Some parts require advanced processes such as hot runners and gas-assisted injection molding when molding, which need to be considered when choosing micro injection molds.

2.2 Evaluation of the manufacturer's capabilities

It is crucial to choose the right manufacturer. The company should ensure that it has the necessary equipment and technology:

Hardware facilities: The manufacturer should have CNC, EDM, wire cutting machine tools and other equipment.

Technical strength: Not only the number and type of hardware equipment should be considered, but also its management level and processing experience should be evaluated.

As a professional plastic injection mold manufacturer, KRMOLD has rich equipment and technical strength and can provide customers with high-quality micro injection molds solutions.

3. Avoid Multi-head Collaboration and Promote One-stop Service

3.1 Advantages of integrated service In the micro injection molding process, having a qualified micro injection molds does not mean that a batch of qualified products can be produced smoothly. The selection of machine tools for parts processing, micro injection molding process, and the technical quality of the operator will have an impact on the quality of the final product. Therefore, try to choose a partner who can provide integrated services, which can significantly improve production efficiency and product quality. Reduce communication costs: One-stop service can reduce the communication costs between different links and avoid errors in information transmission. Improve efficiency: The connection between each link is smoother, which helps to solve problems in the production process in a timely manner. 3.2 Make a clear cooperation agreement If the conditions do not provide one-stop service, the company should clearly stipulate the responsibilities of each party when choosing a partner. Clearly stating the respective responsibilities in the contract can effectively reduce disputes caused by unclear responsibilities. |  |

4. Continue to Pay Attention to Industry Trends and Technological Progress

In the field of micro injection molding, technology is rapidly updated. Companies should keep an eye on industry trends and understand the latest technological trends and market demands. This will not only help companies maintain their advantages in competition, but also make more scientific decisions when choosing micro injection molds. 4.1 Participate in industry exhibitions and seminars By participating in industry exhibitions and seminars, companies can communicate with experts and peers in the industry and obtain the latest information and technological trends. This provides a valuable reference for companies when choosing micro injection molds.

4.2 Strengthen R&D investment Companies should increase investment in the research and development of micro injection molding technology and continuously improve their own technical level. Cooperation with universities and research institutions can bring more innovation opportunities to companies, thereby improving the competitiveness of their products. |  |