KINGREAL UNIVERSAL IND., LTD

Phone

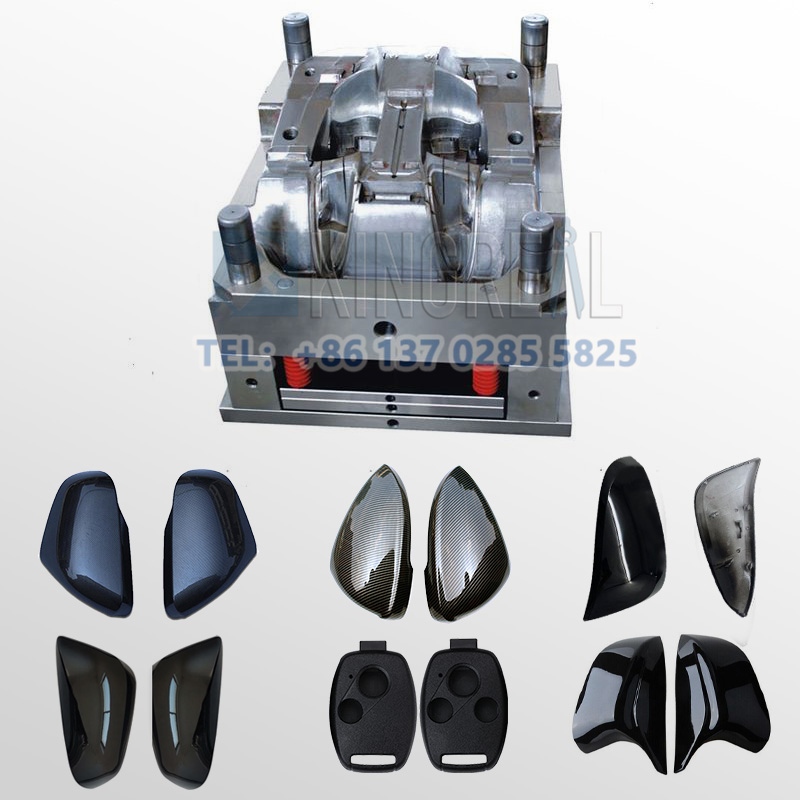

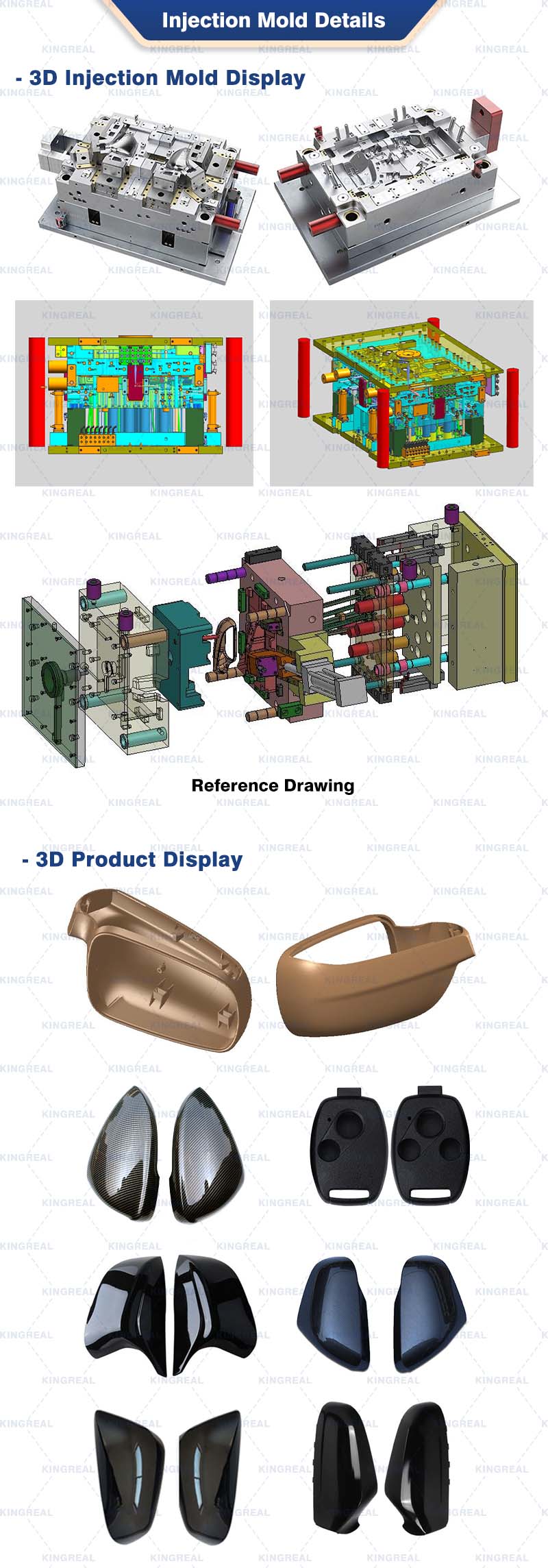

+86-13702855825| 1 | Key Components of Rearview Mirror Shell Injection Molds |

| 2 | Materials Used in Rearview Mirror Shell Injection Molds |

| 3 | Benefits of Using Rearview Mirror Shell Injection Molding to Produce Customized Plastic Parts |

| 4 | Customized Car Rearview Mirror Shell Moulding |

Rearview mirror reflective injection molding is an adaptable and widely used process for assembling plastic parts and items. It can manufacture complex, precise, and detailed components in high volumes and at low cost, making it a preferred method for many industries such as automotive, consumer goods, and medical devices.

1. Key Components of Rearview Mirror Shell Injection Molds

Rearview mirror reflective injection molds contain many major components that work together to shape and produce quality plastic parts. Understanding these components is important to optimize the rearview mirror shell injection molding process. Here are the key components:

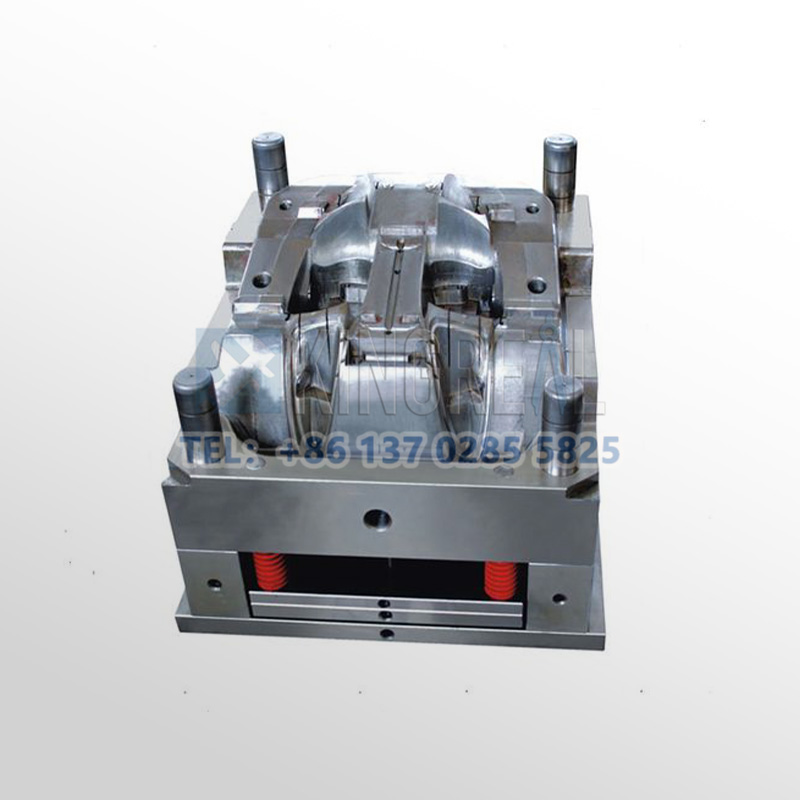

| Mold Frame: | All rearview mirror reflective injection mold components are held in place by the mold base, which acts as a frame. It consists of two major parts: the cavity plate and the core plate. These plates contain the cavity and core, respectively, which determine the shape of the molded part. |

| Cavity and Core: | These are the parts of the rearview mirror shell injection mold that come in contact with the plastic material that is made into the final product through the car rearview mirror shell moulding process. Cavity refers to the void within the rearview mirror reflective injection mold or any other object used for car rearview mirror shell moulding, while core refers to the solid part that forms the internal features of the object being produced. They are usually made using strong metals such as hardened steel to ensure durability and accuracy. |

| Ejector pins: | Ejector pins help remove the finished part from the rearview mirror reflective injection mold. The plastic cools and hardens after injection and needs to be removed, so these ejector pins force it out of the rearview mirror shell injection mold cavity. The number and arrangement of ejector pins must be chosen correctly to avoid damage during the ejection process. |

| Runner system: | This system guides the molten plastic between the nozzle and the cavity entrance during the injection phase. It includes the main gate, runners, gates, etc. The main gate is where all the material enters the system, while the runners distribute the material evenly and the gates control the entry point of the material into each cavity. |

| Cooling channels: | To ensure uniform cooling throughout the rearview mirror reflective injection mold, cooling channels should be incorporated into every part of the car rearview mirror shell mould design, depending on the size and complexity. Coolant (usually water) flows through these channels to reduce the heat within the plastic, thereby promoting rapid solidification. Well-designed cooling channels save time required for each cycle while improving part quality. |

| Venting: | This is an important stage in the rearview mirror reflective injection molding process, allowing air and other gases to escape from the cavity when the plastic is filled. Without proper venting at specific locations on the mold parting line or ejector pin area, problems such as burns and incomplete filling may occur due to air entrapment. |

| Temperature Control System: | Temperature control systems include devices such as heaters and thermocouples that are used to regulate the heat levels in different parts of the rearview mirror shell injection mold. Maintaining the required operating temperature within the mold during production greatly affects the quality of the final product, so precise control should always be ensured. |

2.Materials Used in Rearview Mirror Shell Injection Molds

(1) Car rearview mirror shell mould manufacturers recommend choosing tool steel with moderate quenching. Otherwise, the microstructure of the material and the dimensions of the rearview mirror shell injection mold will change. Most car rearview mirror shell mould parts that are easy to process are made of metal materials, some of which have complex structures and shapes.

(2) Acrylic resin has high tensile strength, can withstand loads, does not absorb odors, and can maintain tight tolerances during the rearview mirror reflective injection molding process. The material can also resist sunlight and weather, making it suitable for outdoor use.

(3) The following are some plastic materials used in rearview mirror shell injection molding: Acrylic (PMMA) Acrylic, also known as plexiglass, is a hard, transparent plastic material commonly used in electronic products and automotive parts.

(4) Traditional rearview mirror reflective injection mold materials Steel: The most widely used in car rearview mirror shell moulds are high-quality cold-working die steel, hot-working die steel and alloy tool steel, which have the characteristics of high hardness, good processability, wear resistance and impact resistance, and are suitable for making rearview mirror shell injection molds for mass-produced products.

(5) Generally speaking, the materials of car rearview mirror shell moulds can be divided into three categories: ordinary steel, alloy steel and special steel. Ordinary steel refers to steel with a low carbon content in carbon steel and alloy steel. Its main characteristics are low price and easy processing, but low hardness and strength, and insufficient wear resistance and corrosion resistance.

(6) Rearview mirror reflective injection molds are generally mainly made of steels such as CrCrWMn, Cr12MoV, and TT1S-136.

3.Benefits of Using Rearview Mirror Shell Injection Molding to Produce Customized Plastic Parts

High efficiency and high productivity: This process can produce many detailed parts quickly and with high precision, thereby improving quality consistency and shortening manufacturing time.

High cost performance: As the production quantity increases, the cost per unit will decrease, making it suitable for mass production.

Design flexibility: This method allows for complex shapes, enabling people to create items of varying sizes or forms.

Material variety: Rearview mirror reflective injection molding is suitable for a wide range of different thermoplastics, so manufacturers can choose materials based on the specific mechanical or chemical properties required.

Repeatability: This ensures dimensional consistency across large batches of similar parts, which is important for maintaining quality control during mass production.

Waste reduction: With rearview mirror shell injection molding, only the material required for each part is used, resulting in less material waste and the ability to recycle the remaining resources.

4. Customized Car Rearview Mirror Shell Moulding

To meet the needs of a variety of industries, custom rearview mirror reflective injection molding provides a one-of-a-kind solution for unique applications. This operation is based on specific design and functional requirements, requiring the creation of custom rearview mirror shell injection molds, which can produce parts with precise dimensions and material properties. Some of the advantages are:

To meet the needs of a variety of industries, custom rearview mirror reflective injection molding provides a one-of-a-kind solution for unique applications. This operation is based on specific design and functional requirements, requiring the creation of custom rearview mirror shell injection molds, which can produce parts with precise dimensions and material properties. Some of the advantages are:

Design Flexibility: Custom rearview mirror reflective injection molding can achieve complex shapes or intricate patterns that are not possible through ordinary methods.

Material Selection: A wide range of options allows a variety of materials, such as high-performance engineering plastics, to meet different mechanical strength, thermal conductivity, and chemical resistance.

Prototyping and Production: Advanced prototyping technology allows designers to test their ideas more thoroughly before full production, saving costs because only the best designs can be produced in large quantities.

Specific Application Solutions : Whether it is automotive parts, medical devices, consumer electronics, or aerospace components, these industries require customized solutions that meet their individual needs and standards, making them effective through this process called custom rearview mirror shell injection molding.

Manufacturers can use expertise in rearview mirror reflective injection mold design and engineering technology to produce precision engineered products. This increases opportunities for innovation while ensuring that each part accurately meets its intended purpose.