KINGREAL UNIVERSAL IND., LTD

Phone

+86-13702855825

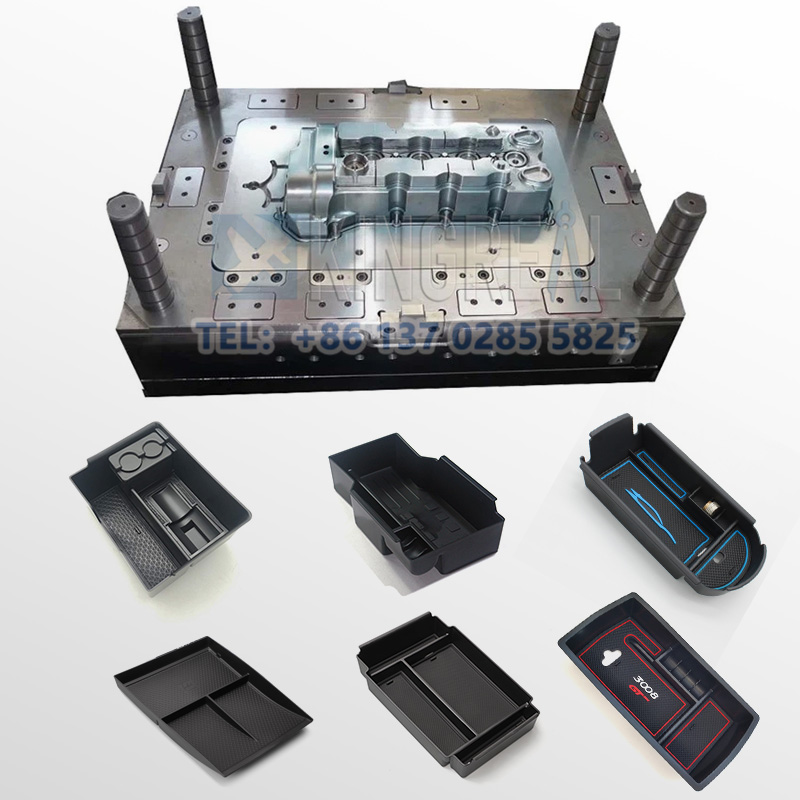

| 1 | Requirements Analysis and Design Confirmation |

| 2 | Design of Central Glove Box Injection Mold |

| 3 | Material Selection |

| 4 | Mold Processing |

| 5 | Bury in Hot Place |

| 6 | Mold Assembly |

| 7 | Mould Testing |

| 8 | Mold Optimization |

| 9 | Confirmation and Delivery |

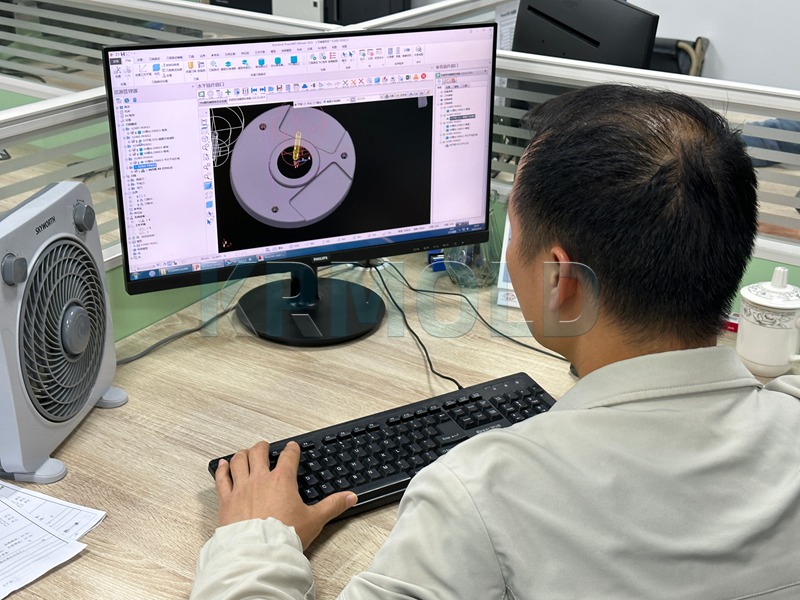

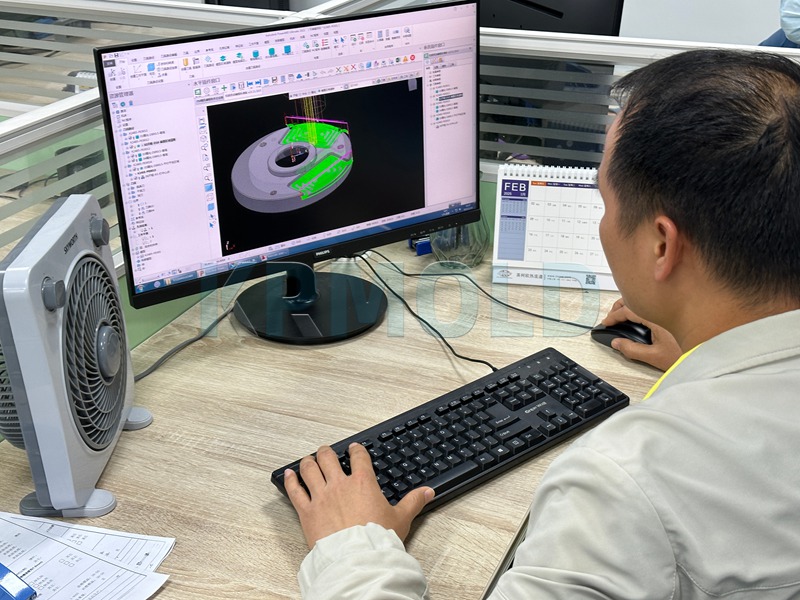

1. Requirements Analysis and Design Confirmation

Communicate with customers to confirm product requirements, and analyze the requirements of product shape, size and material in detail. KEMOLD designers will draw 3D models of automotive glove box injection moulds through computer-aided design (CAD) software to ensure that the design meets the technical specifications of customers.

2. Design of Central Glove Box Injection Mold

According to the product demand and production technology, the automotive interior glove box injection mold structure is designed, including parting surface, gating system, cooling system, exhaust system and ejection system. Consider the durability and production efficiency of the central glove box injection mold to ensure the feasibility and cost-effectiveness of the mold design.

3. Material Selection

According to the service life requirements of the automotive glove box injection mould and the specific process conditions of the product, the suitable mold material is selected. For example, copper plating, stainless steel and other materials have different wear resistance, corrosion resistance and thermal conductivity.

Ordinary steel: this kind of material is mainly composed of ordinary carbon steel and alloy steel, with low cost and easy processing. They are usually used in occasions where the production requirements of injection molded products are not high and the performance requirements are relatively low.

Tool steel (die steel): it has the characteristics of high strength, wear resistance, corrosion resistance and high temperature resistance, and is especially suitable for manufacturing key parts such as core and cavity in automotive interior glove box injection mold.

Aluminum alloy material: Because of its light weight, excellent thermal conductivity and good machinability, aluminum alloy is widely used in the manufacture of automotive glove box injection mould with complex shapes and small sizes.

Copper alloy material: Copper alloy has high thermal conductivity and electrical conductivity, and is not easy to deform, so it is often used to manufacture parts that need rapid cooling in automotive glove box injection mould.

Cemented carbide material: Cemented carbide is made by powder metallurgy process, which shows the characteristics of high hardness, high strength, wear resistance, high temperature resistance and difficult deformation, and is suitable for manufacturing key components such as the core and cavity of automotive interior glove box injection mold.

4. Mold Processing

Use high-precision processing equipment (such as CNC machine tools, wire cutting, EDM, etc.) to finely process the automotive glove box injection mould. Key parts (such as cavities, cores, etc.) usually need high-precision machining to ensure central glove box injection mold accuracy and product quality.

5. Bury in Hot Place

Heat treatment is carried out on the main parts of the automotive glove box injection mould to improve the hardness, wear resistance and impact resistance of the material and prolong the life of the central glove box injection mold. Common heat treatment processes include quenching and tempering.

○ Quenching: A heat treatment process in which steel is heated to a certain temperature above Ac3 or Ac1, kept for a certain time, and then cooled at a proper speed to obtain martensite or bainite structure.

Purpose: To obtain martensite and improve the strength and hardness of steel.

○ Tempering: a heat treatment process in which the quenched steel is heated to a certain temperature below the Ac1 point, kept for a certain time, and then cooled to room temperature.

Purpose:

A, eliminating internal stress;

B, obtain the required mechanical properties (improve the toughness of steel, properly adjust the strength and hardness of steel);

C, stable structure and size

6. Mold Assembly

Assemble the processed automotive glove box injection mould parts, including the die frame, core, cavity, guiding system, etc. Ensure the precise fit between all parts to avoid dislocation or looseness.

7. Mould Testing

After the assembly, the automotive interior glove box injection mold is tested, installed on the central glove box injection molding machine for small batch trial production, and the runner system, cooling effect and product molding effect of the automotive interior glove box injection mold are tested. By measuring the product size and detecting the surface quality of the product, it is confirmed whether the automotive glove box injection mould meets the requirements.

8. Mold Optimization

According to the problems in the process of automotive glove box injection mould trial, optimization is carried out, including adjusting the cooling water channel, exhaust design and ejection system of the central glove box injection mold. Through continuous adjustment, the product quality and mold efficiency are improved, and the stability and service life of the central glove box injection mold during mass production are ensured.

9. Confirmation and Delivery

After the automotive glove box injection mould optimization is completed, KEMOLD staff will try the automotive interior glove box injection mold again and prepare for delivery after confirming that the central glove box injection mold can stably produce qualified products.